A nature-inspired musculoskeletal-actuator system is developed using 3d printing for robotic applications. The actuator resembles the rigid segments and the soft-rigid interaction architecture found in limbless vertebrates such as snakes. The rigid segments provide an increase in the range of motion while maintaining structural durability and stability. The soft-rigid interactions provided a remarkable increase in energy transmission and storage, which enhanced the reliability of the musculoskeletal-actuator. Additionally, passive structural stiffness and damping control are achieved. Similar to a muscular system, our musculoskeletal-actuator is capable of increasing its stiffness and damping up to 100% and 60%, respectively, upon load lifting.

- Nature-inspired

- Nonlinear

- Actuators

- Soft Robots

- Artificial Spine

- 3D Printing

1. Introduction

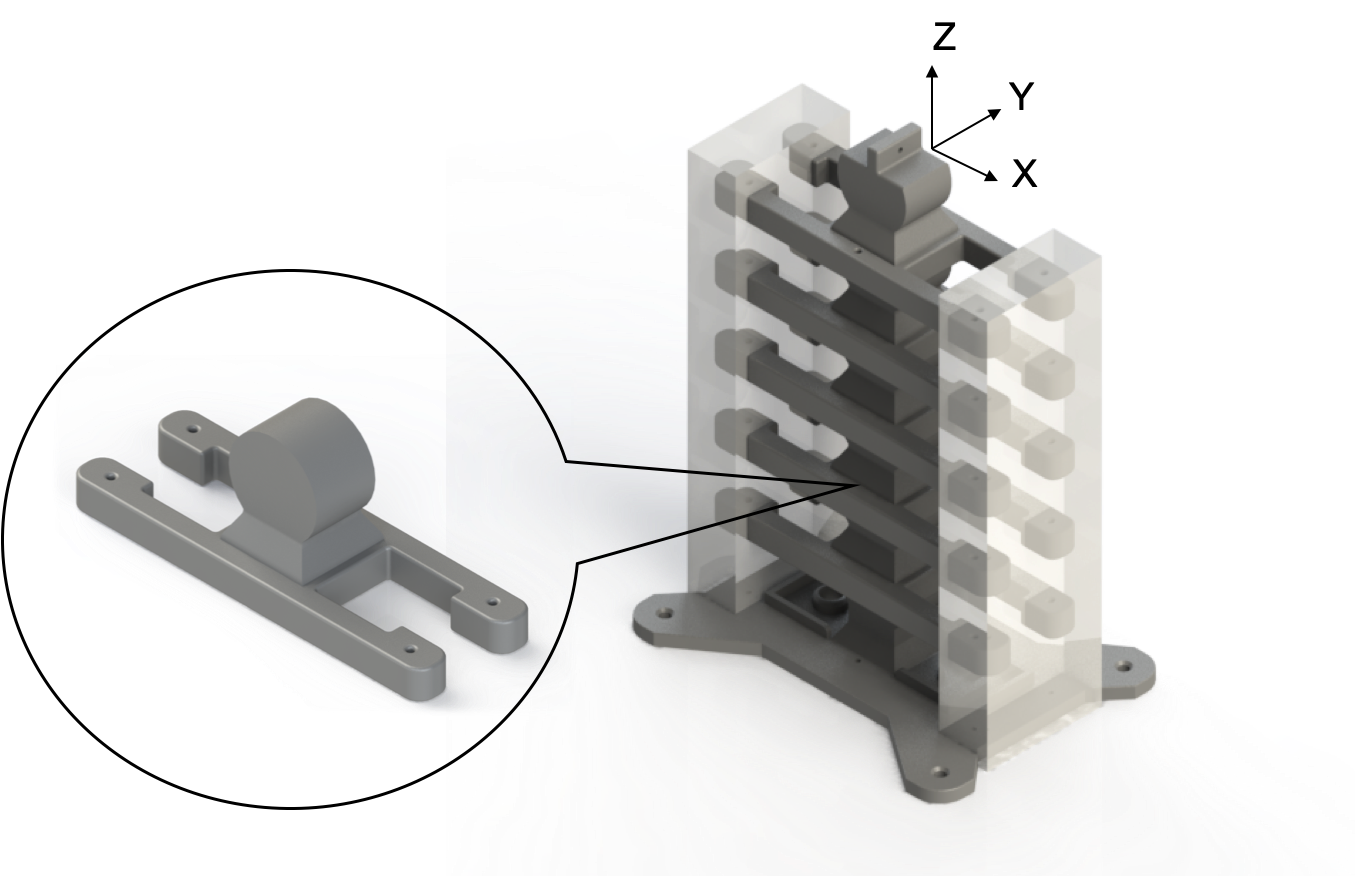

Musculoskeletal-actuators are vertebrate-like actuation systems, see Figure 1. They are comprised of rigid segments connected with soft silicon materials. Musculoskeletal-actuators hold promise in overcoming the current limitations of soft actuators for robotic applications. Often those limitations include poor structural integrity, susceptibility to fatigue, high power input requirements, and tethering to provide instrumentation and control. Unlike current 3d printed soft actuators for robots, the musculoskeletal-actuator understudy achieved a high range of motion and load-carrying capacity while maintaining adequate structural stability. The musculoskeletal-actuators provide adaptive stiffness tuning, a desirable feature for most robots to bear loads reliably, store and release the elastic energy efficiently, and change motion rapidly.

In general, soft actuators are fabricated using highly deformable materials. There are a variety of material systems that can be utilized to create 3d printed soft actuators, such as but not limited to, hydrogels, conductive polylactic acid, shape memory alloys, phase changing matters, and liquid metal. Depending on the intended applications, soft actuator designs can be complex and may require integrating auxiliary systems, examples may include variable gearing mechanisms, Electrothermal circuits, fluidic networks, pneumatic systems, magnetic controllers, and electrical tethering units. On the other hand, rigid mechanical actuators have limited maneuverability envelop and require complex components such as electrical motors, mechanical joints, and moving parts.

It is well known that musculoskeletal systems seen in nature strive to achieve the most energy-efficient actuation for performing complex motions. As part of their evolution process, their actuation tasks are typically executed with minimal energy losses. Achieving such a remarkable efficiency stems from mainly two architectural features: (i) segmented rigid structural elements to increase the range of motion and energy transmission; and (ii) soft-rigid interactions to maximize energy storage and release while maintaining structural stability.

2. Features

These architectural features allow vertebrates to increase their motion degrees of freedom by increasing the number of their rigid segments, for example, the spinal system. The soft matters, such as muscles, ligaments, and cartilages, enable the assembly of rigid segments (bones). The experimental results showed amplification in the nonlinear soft-rigid interactions, which simultaneously increased the damping and stiffness on demand. The dominating nonlinearities were the high compliance of the soft materials and the geometric displacement of the rigid segments--- both augment the range of motion. The advantageous features mentioned above suggest that musculoskeletal-actuators are prime candidates for 3d printing. In this study, 3d printing allowed us to fabricate rigid segments (similar to vertebral bones) and assemble them. The soft (hyperelastic) material provided the connections between the rigid segments. The contraction of the hyperelastic material provided us with autonomous modulation of the actuator's structural stiffness and damping.

Recent studies have shown that both structural segmentation and soft-rigid material coupling will improve the range of motion when compared to soft actuators \cite{nassour2021soft}. Combining structural segmentation and soft-rigid interaction have been gaining attention in designing surgical robotics, medical prostheses, swimming robots, snake-inspired robots, and structural health monitoring of infrastructures. However, limited studies have observed or explained the effect of geometric and material nonlinear coupling.