Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 3 by Lindsay Dong and Version 2 by Lindsay Dong.

Biopolymers are the organic substances present in natural sources. The term biopolymer originates from the Greek words bio and polymer, representing nature and living organisms. Large macromolecules made up of numerous repeating units are known as biopolymers. As per the IUPAC definition, a macromolecule defines a single molecule. The biopolymers are found to be biocompatible and biodegradable, making them useful in different applications, such as edible films, emulsions, packaging materials in the food industry, and as drug transport materials, medical implants like medical implants organs, wound healing, tissue scaffolds, and dressing materials in pharmaceutical industries.

- biopolymers

- medical applications

1. Sources of Biopolymers

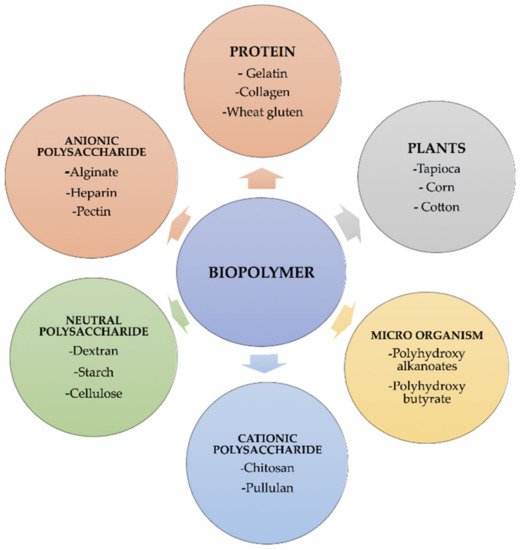

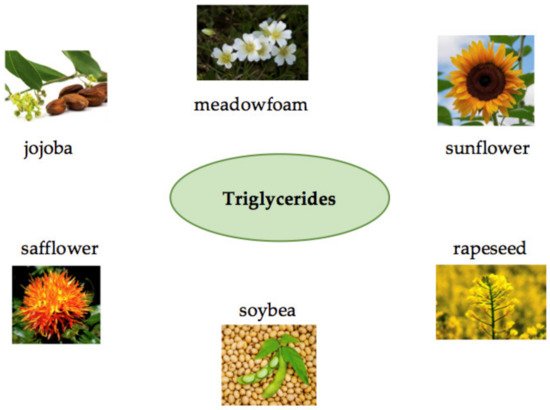

Plants, animals, microorganisms, and agricultural wastes are examples of natural biological sources of biopolymers. Plant sources, such as rice, maize [1], wheat [2], sorghum [3], yams [4], cassava [5], potatoes [6], banana [7], tapioca [8], corn [9], cotton [10], and barley [11] biopolymers can be produced chemically from monomeric components, such as oils, sugars, and amino acids. Cattles are the most common animal sources, while corals, sponges, fish, lobster, and shrimp are the most common marine sources. Algae, fungus, and yeasts are the most common microbiological sources (Figure 1). The origins and chemical structures of the main biopolymers are shown in Table 1. Agro leftovers, paper wastes, crops, green wastes, and wood wastes are carbohydrate-rich biomass-based sources. Triglycerides are found in vegetable oils, such as sunflower, soybean, safflower, jojoba, rapeseed, castor, and meadowfoam oil (Figure 2) [12]. Vegetable oils obtained from food producers, in particular, are excellent alternatives for natural polymer synthesis [13]. PHAs are a kind of biopolymer, secondary metabolites generated by microbes and plants. PHAs are stored as inclusion bodies in bacteria and are generated and aggregated intracellularly as transparent granules [14]. These biopolymers are produced naturally and degraded by microbial metabolisms, even though these biopolymers can be melted and shaped in the same way as the chemical and synthetic thermoplastics [15].

Figure 1. A pictorial depiction of several natural renewable biopolymers categorised according to their source.

Figure 2. Tryglycerides in vegetable oils are an important source of biopolymers.

Table 1. Main biopolymers with their origins and chemical structures [16].

| Biopolymers | Sources | Structure | Reference (Ref.) |

|---|---|---|---|

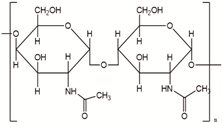

| Chitin | Corals, horseshoe worms, lamp shells, sponges, squid, cuttlefish, and clams are examples of aquatic species |  |

[17][18] |

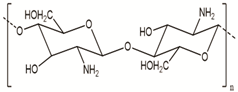

| Chitosan | Fungi, mollusks, algae, crustaceans, and insects |  |

[17][19] |

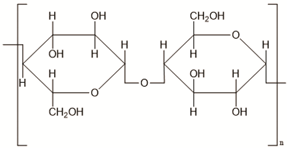

| Cellulose | Agricultural trashes, such as Seaweed, rice husk, and sugarcane bagasse. Plant sources like wood, bamboo, sugarbeet, banana rachis, potato tubers, cotton, fique, kapok, agave, jute, kenaf, flax, hemp, vine, sisal, coconut, grass, wheat, rice, and barley |

|

[20] |

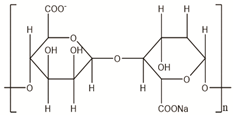

| Alginate | Seawood |  |

[21] |

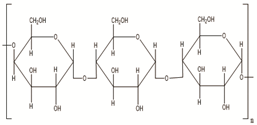

| Starch | Potatoes, maize, cassava, rice, sorghum, banana wheat, yams |  |

[22] |

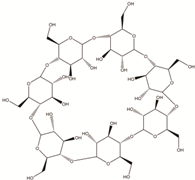

| Cyclodextrin | Starch sources like tapioca, potato, wheat, rice, and corn |  |

[23] |

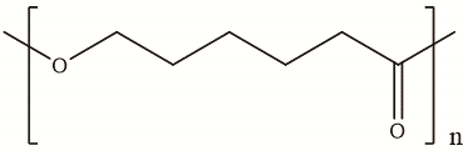

| Polycaprolactone | Polycondensation of ε -caprolactone |

|

[24] |

2. Biopolymers for Medical Applications

Science and technology are essential factors in extending life expectancy. In this regard, various creative approaches and new equipment have been created, resulting in lower morbidity and death rates. The utilisation of drug delivery methods to increase the effectiveness of bioactive molecules is an essential technique for treating illnesses, and development in this area has been substantial. Synthetic, semi-synthetic, and natural polymers are commonly employed in the development of drug delivery systems in this context [25]. Suturing, fixing, adhesion, covering, occlusion, isolation, contact inhibition, cell proliferation, tissue guiding, and controlled drug administration [26][27][28][29] are just some of the medicinal applications that biopolymers could be used for. Several biomaterial production techniques and processes have been developed in recent decades to address and examine natural tissues’ important functional architectural and compositional characteristics [30]. The hunt for better and more tissue-oriented implantable units has increased the understanding of biomaterials’ potential and heightened interest in multimodal scaffolds with unique shapes and physical-chemical properties [31]. These scaffolds have multifunctional or multimodal qualities due to the integration of diverse topographies not generally present in each material, which boosts their potential relevance in regenerative medical techniques [32]. Polymers have a critical role in developing three-dimensional templates and the creation of synthetic extracellular matrix (ECM) habitats for tissue regeneration [33]. Biopolymers could be synthesised synthetically or from natural assets [34]. A range of composite materials and interpenetrating networks have been used to attain the required objectives since each group has specific benefits and limits. Due to the adaptability of synthetic polymers, which enables them to be adjusted to a broad range of degradation efficiency, structural traits, and mechanical characteristics, they are a reliable source of innovative materials. The synthetic polymer composition may be tailored to reduce immune response and combine the most significant features. Owing to its superior biodegradability and lack of cytotoxicity, natural polymers have been proposed as a viable alternative to commonly utilised synthetic materials. They are derived from natural sources, resemble soft tissues, and are formed through enzyme-catalysed chain-growth polymerisation processes of activated monomers, often created within cells during metabolic activities. Collagen, gelatine, dextran, agarose/alginate, hyaluronic acid, cellulose, and fibrin gels are all included in this category (Table 2). Despite being cleansed to prevent a foreign body reaction after implantation, natural polymers are commonly employed in regenerative medicine. Biodegradable polymers were chosen for the drug delivery system because they do not need surgery to remove once the medications have been released and may be excreted by the body. Some of the famous examples of biomedical applications that use biopolymers include soft-tissue replacement vascular grafts, breast implants, intraocular lenses, artificial hearts, components of extracorporeal oxygenators, contact lenses, plasmapheresis units, sutures, adhesives, and blood substitutes, dialyzers, liver, pancreas, bladder, kidney, bone cement, catheters, external and internal ear repairs, coatings for pharmaceutical tablets and capsules, cardiac assist devices, implantable pumps, pacemaker, encapsulations, heart valves, artificial blood vessels, joint replacements artificial skin, dentistry, drug delivery, and targeting sites of tumors or inflammation [35][36][37][38]. Since PHAs are biodegradable, they can be used as a substitute for petrochemical plastics in biomedical applications. The adaptability of poly (3-hydroxyoctanoate) in particular makes it a potentially appropriate choice as a biopolymer for drug delivery formulation as well as features of prospective tissue engineering [39].

Table 2. Examples of some biopolymers with their medical application.

| Biopolymer | Medical Application | Ref. |

|---|---|---|

| Collagen | Surface coating for tissue culture plates | [40] |

| Simple gels for cell culture | ||

| Alginate | Regenerative medicine | [41] |

| Tissue engineering | ||

| Hyaluronic acid | Treatment and lubrication of damaged joints | [42] |

| Cutaneous and corneal wound healing | ||

| Fibrin | Blood clotting, wound healing, and tumor growth | [43] |

| Hemostatic agent, sealant, and surgical glue | ||

| Silk fibroin | Regenerative medicine Treatment of wounds, bioengineering of tissues |

[44] |

| Agarose | Skeletal tissues regeneration, kidney and fibroblast encapsulation |

[45] |

| Carrageenan | Skeletal tissues regeneration, cell delivery system |

[46] |

| Fibronectin | Wound healing, cardiac repair, bone regeneration |

[47] |

| PHAs | Drug delivery systems, one tissue regeneration, |

[48] |

| Elastin | soft-tissue reconstruction, orthopedics and cell encapsulation |

[49] |

| Keratin | Cornea tissue engineering, skin regeneration |

[50] |

| Starch | Bone and cartilage regeneration, spinal cord injury treatment |

[51] |

Many natural biomaterials based on biopolymers have been studied for hard and soft-tissue repair. They can be utilised independently or with other synthetic or inorganic components. The specific dressing, nursing care, and decreased grafting time are the key features of these tissue-engineered materials. Many recent in vivo studies contributed to the FDA clearance of innovative biomaterials for clinical use based on natural biopolymers as matrices for cell distribution and scaffolds for cell-free support of native tissues, despite their mechanical fragility and high cost. For cell encapsulation, a variety of naturally occurring and manufactured biopolymers that might be synthesised into diverse physical forms and geometries are used. The biomaterial component of these therapies must offer suitable mass transport characteristics, membranes, or scaffold stability, and acceptable cellular interactions depending on the site and intended function of the implant. Intelligent biopolymer hydrogels that vary their swelling behaviour and other features in response to chemical and physical stimuli, including pH, metabolites or/and ionic variables, temperature, and electric fields, have piqued curiosity. These “smart” hydrogels exhibit single or multiple stimuli-responsive properties. They may be used in a variety of biomedical applications, varying from cell adhesion mediators and controlled drug delivery systems to controllers of gene expression and enzyme function in bioengineering or tissue engineering, in addition to their biocompatibility, biodegradability, and biological processes. Biopolymers may be readily functionalized to improve cell interactions and provide an appropriate platform for cellular and tissue functions. There are two types of peptide-based biopolymers in tissue engineering: self-assembling polypeptides that form gels in response to environmental cues, and polypeptides that create gels by chemical cross-linking. The biopolymer block’s unique bioactivity, biocompatibility, and biodegradability properties enable it to be used in various biomedical applications [52]. Polymer–biopolymer interactions are becoming more and more capable of being planned and selected, allowing for their intervention in cellular dysfunctions and developing more effective, targeted, and efficacious therapeutics. Due to the degree of control possible via live polymerisation techniques, previously available structure-function connections for bio-macromolecules may now be inferred for fully synthetic materials. Simultaneously, the production and activity of biopolymers may be controlled using molecular biology techniques. Because the ability to control the structure of polymers results in the power to modify their functioning, this synthesis of natural and synthetic macromolecular chemistry inevitably results in biomedical applications. A few examples of the medical application of biopolymers have been presented in Table 2. Bio-printers can automate the assembly process and allow for complex biopolymer manipulation—from the macromolecular to the living cell level—to achieve architectural and biochemical complexity never before possible, resulting in tissue and organ substitutes that closely resemble their natural counterparts. These many regenerative medicine approaches are likely to transition from ‘bench to bedside’ in the future.

The potential of biodegradable nanoparticles has been explored by various researchers for a wide range of biomedical applications due to their properties, such as biocompatibility and bio-safety. Depending on their size, nature, and design, various nanoparticles have distinct therapeutic efficacy, bioavailability, and delivery components. Nanotechnology-assisted imaging is advantageous not only in the field of cancer but also in the field of cardiovascular disease [53][54]. Micelles are helpful in cancer treatment by focusing on malignant cells using tumor molecular probes [55].

2.1. Biomedical Applications of Protein-Based Biopolymers

Protein-based biopolymers play a vital role in medical applications. Biopolymers have biocompatible, non-toxic, and biodegradable properties. Their application to implantable devices is expanding rapidly and has great potential [56]. As the molecular sizes of proteins are governed by their secondary structures, the production of nanoparticles proteins permits the formation of precisely constructed nanoparticles [57]. Regenerative tissue engineering aims to use the body’s inherent healing potential to improve injured or damaged tissue function. Synthetic polymers and biopolymers are used as scaffolding to establish a favorable environment for cell proliferation and tissue repair. Collagen, keratin, gelatine, sericin, and fibroin are used to make films, pickering emulsions, hydrogels, nanogels, nanofibers, linked porous scaffolds, and 3D-printed scaffolds [29][58][59][60][61][62][63]. Tissue engineering and therapeutics molecules (gene delivery, drug delivery, protein delivery) are delivered via collagen-based nanospheres, nanoparticles, sponges, electrospun fiber, and hydrogel [64]. Gelatine is a non-toxic, biodegradable, and FDA-approved substance. Acid (type A gelatine) or essential (type B gelatine) hydrolysis is used to extract from bovine or porcine sources. Gelatine has been extracted from a variety of sources, including jellyfish, fins, bones, and sea urchins [65]. Gel formation, thickening, emulsification, and foaming are characteristics of gelatine [66].2.2. Chitosan in Medical Applications

Chitosan is also widely used in medical uses because of its biodegradable and biocompatible properties. It has a variety of uses (gels, films, particles, membranes, or scaffolding, etc.) from biomedical to industrial fields. In addition, due to its properties, chitosan plays an essential role in cell attachment and growth. It is widely used as a tissue engineering matrix when manufactured in a porous structure. The main uses of chitosan in implants are bone, ligament, cartilage, tendon, liver, nerve, stent, and skin regeneration. Several examples of chitosan-based matrices for bone applications have been reported. However, due to its mechanical weakness [67], there is a need to combine chitosan with other materials in applications for bone tissue engineering [68]. Nanoparticles formed using chitosan display interesting properties, such as low toxicity; good absorbability, permeability, and moisture retention; and is easily degradable. However, they suffer from poor long-term stability and are very sensitive to environmental temperature and pH, which affects the degradation rate [69].

References

- Awad, Y.M.; Blagodatskaya, E.; Ok, Y.S.; Kuzyakov, Y. Effects of polyacrylamide, biopolymer and biochar on the decomposition of14C-labelled maize residues and on their stabilization in soil aggregates. Eur. J. Soil Sci. 2013, 64, 488–499.

- Karmanov, A.P.; Kanarsky, A.V.; Kocheva, L.S.; Belyy, V.A.; Semenov, E.I.; Rachkova, N.G.; Bogdanovich, N.I.; Pokryshkin, S.A. Chemical structure and polymer properties of wheat and cabbage lignins–Valuable biopolymers for biomedical applications. Polymer 2021, 220, 123571.

- Tanamool, V.; Imai, T.; Danvirutai, P.; Kaewkannetra, P. An alternative approach to the fermentation of sweet sorghum juice into biopolymer of poly-β-hydroxyalkanoates (PHAs) by newly isolated, Bacillus aryabhattai PKV01. Biotechnol. Bioprocess Eng. 2013, 18, 65–74.

- Gutiérrez, T.J.; Pérez, E.; Guzmán, R.; Tapia, M.S.; Famá, L. Physicochemical and Functional Properties of Native and Modified by Crosslinking, Dark-Cush-Cush Yam (Dioscorea trifida) and Cassava (Manihot esculenta) Starch. J. Polym. Biopolym. Phys. Chem. 2014, 2, 1–5.

- Perotti, G.F.; Tronto, J.; Bizeto, M.A.; Izumi, C.M.S.; Temperini, M.L.A.; Lugão, A.B.; Parra, D.F.; Constantino, V.R.L. Biopolymer-Clay Nanocomposites: Cassava Starch and Synthetic Clay Cast Films. J. Braz. Chem. Soc. 2013, 25, 320–330.

- Borah, P.P.; Das, P.; Badwaik, L.S. Ultrasound treated potato peel and sweet lime pomace based biopolymer film development. Ultrason. Sonochem. 2017, 36, 11–19.

- Redondo-Gómez, C.; Rodríguez Quesada, M.; Vallejo Astúa, S.; Murillo Zamora, J.P.; Lopretti, M.; Vega-Baudrit, J.R. Biorefinery of Biomass of Agro-Industrial Banana Waste to Obtain High-Value Biopolymers. Molecules 2020, 25, 3829.

- Abral, H.; Dalimunthe, M.H.; Hartono, J.; Efendi, R.P.; Asrofi, M.; Sugiarti, E.; Sapuan, S.M.; Park, J.-W.; Kim, H.-J. Characterization of Tapioca Starch Biopolymer Composites Reinforced with Micro Scale Water Hyacinth Fibers. Starch-Stärke 2018, 70, 1700287.

- Lauer, M.K.; Tennyson, A.G.; Smith, R.C. Inverse vulcanization of octenyl succinate-modified corn starch as a route to biopolymer–sulfur composites. Mater. Adv. 2021, 2, 2391–2397.

- Aguilar, N.M.; Arteaga-Cardona, F.; de Anda Reyes, M.E.; Gervacio-Arciniega, J.J.; Salazar-Kuri, U. Magnetic bioplastics based on isolated cellulose from cotton and sugarcane bagasse. Mater. Chem. Phys. 2019, 238.

- Yu, P. Molecular chemical structure of barley proteins revealed by ultra-spatially resolved synchrotron light sourced FTIR microspectroscopy: Comparison of barley varieties. Biopolymers 2007, 85, 308–317.

- Flaris, V.; Singh, G. Recent developments in biopolymers. J. Vinyl Addit. Technol. 2009, 15, 1–11.

- Sharma, V.; Kundu, P.P. Addition polymers from natural oils—A review. Prog. Polym. Sci. 2006, 31, 983–1008.

- Muhamad, I.I.; Sabbagh, F.; Abdul Karim, N. Polyhydroxyalkanoates: A Valuable Secondary Metabolite Produced in Microorganisms and Plants. In Plant Secondary Metabolites, 1st ed.; Apple Academic Press: Oakville, MO, USA, 2017; Volume 3, pp. 205–234.

- Mojaveryazdi, F.S.; Muhamad, I.I.; Rezania, S.; Benham, H. Importance of Glucose and Pseudomonas in Producing Degradable Plastics. J. Teknol. 2014, 69, 7–10.

- Udayakumar, G.P.; Muthusamy, S.; Selvaganesh, B.; Sivarajasekar, N.; Rambabu, K.; Sivamani, S.; Sivakumar, N.; Maran, J.P.; Hosseini-Bandegharaei, A. Ecofriendly biopolymers and composites: Preparation and their applications in water-treatment. Biotechnol. Adv. 2021, 52, 107815.

- Elieh-Ali-Komi, D.; Hamblin, M.R. Chitin and Chitosan: Production and Application of Versatile Biomedical Nanomaterials. Int. J. Adv. Res. 2016, 4, 411–427.

- Satitsri, S.; Muanprasat, C. Chitin and Chitosan Derivatives as Biomaterial Resources for Biological and Biomedical Applications. Molecules 2020, 25, 5961.

- Aranaz, I.; Alcántara, A.R.; Civera, M.C.; Arias, C.; Elorza, B.; Heras Caballero, A.; Acosta, N. Chitosan: An Overview of Its Properties and Applications. Polymers 2021, 13, 3256.

- Farooq, A.; Patoary, M.K.; Zhang, M.; Mussana, H.; Li, M.; Naeem, M.A.; Mushtaq, M.; Farooq, A.; Liu, L. Cellulose from sources to nanocellulose and an overview of synthesis and properties of nanocellulose/zinc oxide nanocomposite materials. Int. J. Biol. Macromol. 2020, 154, 1050–1073.

- Lee, K.Y.; Mooney, D.J. Alginate: Properties and biomedical applications. Prog. Polym. Sci. 2012, 37, 106–126.

- Carvalho, A.J.F. Starch: Major Sources, Properties and Applications as Thermoplastic Materials. In Monomers, Polymers and Composites from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2008; pp. 321–342.

- Li, Z.; Wang, M.; Wang, F.; Gu, Z.; Du, G.; Wu, J.; Chen, J. γ-Cyclodextrin: A review on enzymatic production and applications. Appl. Microbiol. Biotechnol. 2007, 77, 245–255.

- Espinoza, S.M.; Patil, H.I.; San Martin Martinez, E.; Casañas Pimentel, R.; Ige, P.P. Poly-ε-caprolactone (PCL), a promising polymer for pharmaceutical and biomedical applications: Focus on nanomedicine in cancer. Int. J. Polym. Mater. Polym. Biomater. 2019, 69, 85–126.

- Gutierrez Cisneros, C.; Bloemen, V.; Mignon, A. Synthetic, Natural, and Semisynthetic Polymer Carriers for Controlled Nitric Oxide Release in Dermal Applications: A Review. Polymers 2021, 13, 760.

- Neuendorf, R.E.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Adhesion between biodegradable polymers and hydroxyapatite: Relevance to synthetic bone-like materials and tissue engineering scaffolds. Acta Biomater. 2008, 4, 1288–1296.

- Chen, Y.; Hung, S.-T.; Chou, E.; Wu, H.-S. Review of Polyhydroxyalkanoates Materials and other Biopolymers for Medical Applications. Mini Rev. Org. Chem. 2018, 15, 105–121.

- Tsai, C.-H.; Wang, P.-Y.; Lin, I.C.; Huang, H.; Liu, G.-S.; Tseng, C.-L. Ocular Drug Delivery: Role of Degradable Polymeric Nanocarriers for Ophthalmic Application. Int. J. Mol. Sci. 2018, 19, 2830.

- Park, S.-B.; Lih, E.; Park, K.-S.; Joung, Y.K.; Han, D.K. Biopolymer-based functional composites for medical applications. Prog. Polym. Sci. 2017, 68, 77–105.

- Yahya, E.B.; Amirul, A.A.; Khalil, H.P.S.A.; Olaiya, N.G.; Iqbal, M.O.; Jummaat, F.; Atty Sofea, A.K.; Adnan, A.S. Insights into the Role of Biopolymer Aerogel Scaffolds in Tissue Engineering and Regenerative Medicine. Polymers 2021, 13, 1612.

- Chaikof, E.L.; Matthew, H.; Kohn, J.; Mikos, A.G.; Prestwich, G.D.; Yip, C.M. Biomaterials and Scaffolds in Reparative Medicine. Ann. N. Y. Acad. Sci. 2002, 961, 96–105.

- Song, W.; Lima, A.C.; Mano, J.F. Bioinspired methodology to fabricate hydrogel spheres for multi-applications using superhydrophobic substrates. Soft Matter 2010, 6, 5868–5871.

- Hook, A.L.; Anderson, D.G.; Langer, R.; Williams, P.; Davies, M.C.; Alexander, M.R. High throughput methods applied in biomaterial development and discovery. Biomaterials 2010, 31, 187–198.

- Hassan, N.; Verdinelli, V.; Ruso, J.M.; Messina, P.V. Assessing structure and dynamics of fibrinogen films on silicon nanofibers: Towards hemocompatibility devices. Soft Matter 2012, 8, 6582–6592.

- Pattanashetti, N.A.; Heggannavar, G.B.; Kariduraganavar, M.Y. Smart Biopolymers and their Biomedical Applications. Procedia Manuf. 2017, 12, 263–279.

- Reddy, N.; Reddy, R.; Jiang, Q. Crosslinking biopolymers for biomedical applications. Trends Biotechnol. 2015, 33, 362–369.

- Wróblewska-Krepsztul, J.; Rydzkowski, T.; Michalska-Pożoga, I.; Thakur, V.K. Biopolymers for Biomedical and Pharmaceutical Applications: Recent Advances and Overview of Alginate Electrospinning. Nanomaterials 2019, 9, 404.

- Gagliardi, A.; Giuliano, E.; Venkateswararao, E.; Fresta, M.; Bulotta, S.; Awasthi, V.; Cosco, D. Biodegradable Polymeric Nanoparticles for Drug Delivery to Solid Tumors. Front. Pharmacol. 2021, 12, 17.

- Sabbagh, F.; Muhamad, I.I. Production of poly-hydroxyalkanoate as secondary metabolite with main focus on sustainable energy. Renew. Sustain. Energy Rev. 2017, 72, 95–104.

- Tripathi, D.; Rastogi, K.; Tyagi, P.; Rawat, H.; Mittal, G.; Jamini, A.; Singh, H.; Tyagi, A. Comparative Analysis of Collagen and Chitosan-based Dressing for Haemostatic and Wound Healing Application. AAPS PharmSciTech 2021, 22, 76.

- Álvarez-Castillo, E.; Aguilar, J.M.; Bengoechea, C.; López-Castejón, M.L.; Guerrero, A. Rheology and Water Absorption Properties of Alginate–Soy Protein Composites. Polymers 2021, 13, 1807.

- Dulińska-Litewka, J.; Dykas, K.; Felkle, D.; Karnas, K.; Khachatryan, G.; Karewicz, A. Hyaluronic Acid-Silver Nanocomposites and Their Biomedical Applications: A Review. Materials 2021, 15, 234.

- Nelson, D.W.; Gilbert, R.J. Extracellular Matrix-Mimetic Hydrogels for Treating Neural Tissue Injury: A Focus on Fibrin, Hyaluronic Acid, and Elastin-Like Polypeptide Hydrogels. Adv. Healthc. Mater. 2021, 10, 2101329.

- Grabska-Zielińska, S.; Sionkowska, A. How to Improve Physico-Chemical Properties of Silk Fibroin Materials for Biomedical Applications?—Blending and Cross-Linking of Silk Fibroin—A Review. Materials 2021, 14, 1510.

- Mahmood, A.; Patel, D.; Hickson, B.; DesRochers, J.; Hu, X. Recent Progress in Biopolymer-Based Hydrogel Materials for Biomedical Applications. Int. J. Mol. Sci. 2022, 23, 1415.

- Khaliq, T.; Sohail, M.; Minhas, M.U.; Ahmed Shah, S.; Jabeen, N.; Khan, S.; Hussain, Z.; Mahmood, A.; Kousar, M.; Rashid, H. Self-crosslinked chitosan/κ-carrageenan-based biomimetic membranes to combat diabetic burn wound infections. Int. J. Biol. Macromol. 2022, 197, 157–168.

- Klavert, J.; van der Eerden, B.C.J. Fibronectin in Fracture Healing: Biological Mechanisms and Regenerative Avenues. Front. Bioeng. Biotechnol. 2021, 9, 274.

- Goswami, M.; Rekhi, P.; Debnath, M.; Ramakrishna, S. Microbial Polyhydroxyalkanoates Granules: An Approach Targeting Biopolymer for Medical Applications and Developing Bone Scaffolds. Molecules 2021, 26, 860.

- Sarangthem, V.; Singh, T.D.; Dinda, A.K. Emerging Role of Elastin-Like Polypeptides in Regenerative Medicine. Adv. Wound Care 2021, 10, 257–269.

- Sellappan, L.K.; Anandhavelu, S.; Doble, M.; Perumal, G.; Jeon, J.-H.; Vikraman, D.; Kim, H.-S. Biopolymer film fabrication for skin mimetic tissue regenerative wound dressing applications. Int. J. Polym. Mater. Polym. Biomater. 2020, 71, 196–207.

- Varma, K.; Gopi, S. Biopolymers and their role in medicinal and pharmaceutical applications. In Biopolymers and Their Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 175–191.

- Yadav, P. Biomedical Biopolymers, their Origin and Evolution in Biomedical Sciences: A Systematic Review. J. Clin. Diagn. Res. 2015, 9, ZE21.

- Bhatia, M.; Girdhar, A.; Tiwari, A.; Nayarisseri, A. Implications of a novel Pseudomonas species on low density polyethylene biodegradation: An in vitro to in silico approach. SpringerPlus 2014, 3, 497.

- Liu, C.; Li, Z.; Du, B.; Han, C.; Hou, Z. Effect of Fullerene Nanoparticle on Tuning Trap Level Distribution of Fullerene/Polyethylene Nanocomposites. In Proceedings of the 2019 2nd International Conference on Electrical Materials and Power Equipment (ICEMPE), Guangzhou, China, 7–10 April 2019; pp. 333–336.

- Peters, D.; Kastantin, M.; Kotamraju, V.R.; Karmali, P.P.; Gujraty, K.; Tirrell, M.; Ruoslahti, E. Targeting atherosclerosis by using modular, multifunctional micelles. Proc. Natl. Acad. Sci. USA 2009, 106, 9815–9819.

- Rebelo, R.; Fernandes, M.; Fangueiro, R. Biopolymers in Medical Implants: A Brief Review. Procedia Eng. 2017, 200, 236–243.

- Nitta, S.; Numata, K. Biopolymer-Based Nanoparticles for Drug/Gene Delivery and Tissue Engineering. Int. J. Mol. Sci. 2013, 14, 1629–1654.

- Nagarajan, S.; Abessolo Ondo, D.; Gassara, S.; Bechelany, M.; Balme, S.; Miele, P.; Kalkura, N.; Pochat-Bohatier, C. Porous Gelatin Membrane Obtained from Pickering Emulsions Stabilized by Graphene Oxide. Langmuir 2018, 34, 1542–1549.

- Biscarat, J.; Bechelany, M.; Pochat-Bohatier, C.; Miele, P. Graphene-like BN/gelatin nanobiocomposites for gas barrier applications. Nanoscale 2015, 7, 613–618.

- Li, Y.; Rodrigues, J.; Tomás, H. Injectable and biodegradable hydrogels: Gelation, biodegradation and biomedical applications. Chem. Soc. Rev. 2012, 41, 2193–2221.

- Kharkar, P.M.; Kiick, K.L.; Kloxin, A.M. Designing degradable hydrogels for orthogonal control of cell microenvironments. Chem. Soc. Rev. 2013, 42, 7335–7372.

- Sridhar, R.; Lakshminarayanan, R.; Madhaiyan, K.; Amutha Barathi, V.; Lim, K.H.C.; Ramakrishna, S. Electrosprayed nanoparticles and electrospun nanofibers based on natural materials: Applications in tissue regeneration, drug delivery and pharmaceuticals. Chem. Soc. Rev. 2015, 44, 790–814.

- Jammalamadaka, U.; Tappa, K. Recent Advances in Biomaterials for 3D Printing and Tissue Engineering. J. Funct. Biomater. 2018, 9, 22.

- Lee, C.H.; Singla, A.; Lee, Y. Biomedical applications of collagen. Int. J. Pharm. 2001, 221, 1–22.

- Gómez-Guillén, M.C.; Giménez, B.; López-Caballero, M.E.; Montero, M.P. Functional and bioactive properties of collagen and gelatin from alternative sources: A review. Food Hydrocoll. 2011, 25, 1813–1827.

- Gaspar-Pintiliescu, A.; Stefan, L.M.; Anton, E.D.; Berger, D.; Matei, C.; Negreanu-Pirjol, T.; Moldovan, L. Physicochemical and Biological Properties of Gelatin Extracted from Marine Snail Rapana venosa. Mar. Drugs 2019, 17, 589.

- Ak, H.P.S.; Saurabh, C.K.; Nurul Fazita, M.R.; Syakir, M.I.; Davoudpour, Y.; Rafatullah, M.; Abdullah, C.K.; Haafiz, M.M.K.; Dungani, R. A review on chitosan-cellulose blends and nanocellulose reinforced chitosan biocomposites: Properties and their applications. Carbohydr. Polym. 2016, 150, 216–226.

- Sharifianjazi, F.; Khaksar, S.; Esmaeilkhanian, A.; Bazli, L.; Eskandarinezhad, S.; Salahshour, P.; Sadeghi, F.; Rostamnia, S.; Vahdat, S.M. Advancements in Fabrication and Application of Chitosan Composites in Implants and Dentistry: A Review. Biomolecules 2022, 12, 155.

- Su, S.; Kang, P.M. Systemic Review of Biodegradable Nanomaterials in Nanomedicine. Nanomaterials 2020, 10, 656.

More