The civil construction sector is under pressure to make construction processes more sustainable, that is, aligned with economic, social, and environmental sustainability. Civil construction faces the challenge of reducing the consumption of natural resources, ensuring safe work, and optimizing processes, especially handwork. However, the insertion of Industry 4.0 Technologies into civil construction has allowed sensors, robots, modelling and simulation systems, artificial intelligence, and drones to have their productivity, efficiency, safety, strategic and environmental management enhanced. Furthermore, Industry 4.0 Technologies can contribute to civil construction through innovative, sustainable, and technological solutions focused on the flow of work, which can provide growth through the balance of costs/benefits in the management of projects and works.

1. Introduction

According to Lezoche et al.

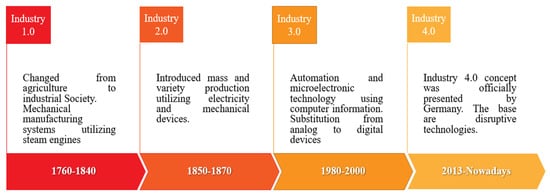

[1], the historical evolution of industry is marked by four phases, the first of which is referred to as the First Industrial Revolution, with the advent of steam machines and the use of coal as fuel. The Second Industrial Revolution stood out for the emergence of electric power and serial production lines. The Third Industrial Revolution provided automation of machines, computers, and the Internet. Currently, the Fourth Industrial Revolution highlights the most abrupt change, where the concept of digitalization and the virtual world are responsible for technologically innovating the production processes.

Figure 1 shows the evolutionary phases of the industry, from 1.0 to 4.0.

Figure 1. The Evolution from Industry 1.0 to 4.0. Source: Adapted from [2,3].

Industry 4.0 appeared for the first time in 2011 in Germany and is referred to as the fourth industrial revolution

[2][4]. This concept aims to integrate technologies such as the Internet of Things (IoT), Industrial Internet of Things (IoT), Intelligent Objects, Big Data, Cloud Computing, Artificial Intelligence, 3D printing, Sensors, Actuators, Virtual and Augmented Reality

[3][4][2,5] to create an environment of digital and intelligent manufacturing. Thus, the goal is to use these technologies to generate efficiency and optimize production processes continuously and upwardly by generating greater productivity, quality, and customization. The rapid advance in technological innovations in sensors, devices, information networks, and machine learning has helped robotics and automation progress rapidly, bringing improvements in several productive sectors

[4][5]. In early 2020, during the COVID-19 pandemic

[5][6] in Brazil, according to Zhou et al.

[6][7] the use of technologies has shown its importance using Big Data in Geographic Information Systems (G.I.S.). Mainly regarding rapid visualization of information on epidemics, tracking of confirmed cases, transmission forecast, balance and management of supply and demand of material resources

[7][8] and the use of artificial intelligence (A.I.) to identify the transmissibility of the virus, populations at risk, and thus the ability to establish the infection cycle and suggest effective and preventative control measures

[8][9].

All productive sectors are under pressure to develop their activities sustainably, based on environmental, social, and economic pillars, to promote the future of current and new generations. The continuous growth of cities and society elicits various concerns for improved development and management of the multifaceted urban systems, including resilience and sustainability

[9][10]. Thus, considering these new scenarios and paradigms, the civil construction sector stands out, which is still regarded as unsustainable when employing archaic processes and activities, collection procedures, data recording, less automated and incomplete monitoring that results in waste of materials and exacerbated use of natural resources, beyond the unavailability of qualified labor

[10][11].

However, sustainability was defined in the World Commission on Environment and Development’s 1987 Brundtland report ‘Our Common Future’ as ‘development that meets the needs of the present without compromising the ability of future generations to meet their own needs’

[11][12]. Since then, industries and business have also become part of the search for the sustainability of operations so that they can remain profitable and positively impact society and with concern about the environment’s ability to regenerate, thus, the American businessman Elkington, defines the Triple Bottom Line (TBL) concept determining three pillars: economic, social and environmental with a focus on the business perspective

[12][13]. The implementation of the Sustainable Development Goals (S.D.G.s) since 2016, is strengthened through the S.D.G. 9—Industry, Innovation and Infrastructure, civil construction to actively participate in this universal call, in search of sustainable development, which contributes to a change in business and construction models supported by people and technologies

[13][14]. This new model supported by construction, society and environment contributes to the attainment of the seventeen goals proposed by the U.N., since it affects the entire supply chain and brings improvements in resource efficiency, error elimination, reduction in waste of materials, energy and transportation (S.D.G. 7; S.D.G. 14; S.D.G. 15), as well as help achieve poverty eradication (S.D.G. 1) and zero hunger (S.D.G. 2), good health and well-being (S.D.G. 3), gender equality (S.D.G. 5), clean water and sanitation (S.D.G. 6), decent work and economic growth (S.D.G. 8), reduction inequalities (S.D.G. 10), sustainable cities and communities (S.D.G. 11), responsible consumption and production (S.D.G. 12) and direct actions against global climate change (S.D.G. 13)

[10][11].

Some review articles related to the Civil Construction and Industry 4.0 Technologies were published. However, the review scopes are concentrated in just one industry technology 4.0, such as patterns and trends IoT by Ghosh et al.

[14][15], extrusion-based additive manufacturing with 3D printing analyzed by Valente et al.

[15][16], Sepasgozar

[16][17] studied the Digital Twin application to expedite a smart and sustainable built environment, Darko et al.

[17][18] explored Building information modelling (BIM) and appointed the survey and future needs, and Zhang et al.

[18][19] identified Virtual reality applications for the built environment. Furthermore, the implications for the sustainability pillars are not the main research focus, thus there is a gap regarding the Industry 4.0 Technologies main contributions to the Triple Bottom Line.

Although these studies contributed to the state of the art in Civil Construction and Industry 4.0 Technologies, this paper adds to these previous reviews the systematization of the Industry 4.0 Technologies set that can help us to face current civil construction challenges and contribute to the identification of opportunities through practical examples in order to permit the sector to achieve sustainability.

2. Background

Construction 4.0 is the application of the concepts of Industry 4.0 in the construction sector, that is, the application of digital technologies and processes adapted to the construction environment

[19][20]. Construction represents one of the largest industries in the world, which contributes to around 13 percent of the global gross domestic product (GDP)

[15][16]. In Brazil, the forecast of the civil construction sector’s gross domestic product (GDP) is expected to increase by over 22 percent until 2025

[20][21]. However, this sector is responsible for the use of scarce natural resources

[14][15], exacerbation of fossil energy source use even considering its limitation and delivery capacity

[21][22]; increasing greenhouse gas emissions and global warming at large

[22][23], energy consumption

[16][17] generation of big quantities of solid wastes which are difficult to apply to waste management

[23][24], and low use of technologies

[24][25].

An abundance of research activity has been conducted to optimize civil construction utilizing Industry 4.0 Technologies, but review studies available on the topics are limited in terms of examples of using technologies and their final applications, and, mainly, in terms of the implications for the sustainability of the construction industry. Relevant studies review the use of only one technology in construction, such as IoT

[14][15], 3D printing

[25][26][27][26,27,28] and Virtual and Augmented Reality

[18][26][19,27]. Others have reviewed a joint application of technologies such as BIM and IoT

[16][17], Blockchain and BIM together in disaster recovery of buildings

[28][29], or application of BIM to applications under construction in forum sites

[29][30]. None of these studies present detailed discussions on the environmental, social and economic impacts of adopting new technologies in operations.

Nevertheless, some studies have comprehensively revealed the application of Industry 4.0 Technologies in construction

[30][31][32][31,32,33]. However, these studies also have a limited scope in terms of Triple Bottom Line contemplate

[32][33] which reviews the implications of adopting smart technologies for sustainable construction and the positive consequences for health, safety, and the environment. These analyses are restricted to operations carried out on site, that is, while the construction project is being carried out.

Thus, it is noted that the implications for sustainability are not the main target of the reviews conducted so far. Despite the growing interest in the application of Industry 4.0 Technologies in construction, there is a knowledge gap regarding contributions to the sustainability dimensions of the adoption of such technologies in the construction production chain

[33][34]. The researchers are more focused on the technical aspects of

[30][31]. Environmental, social, socio-cultural and ethical issues are yet under explored in research relating to the adoption of Industry 4.0 Technologies in civil construction

[31][32].

3. Current Studies

The construction industry plays an essential role in a country’s economic growth, mainly in developing countries such as Brazil, where the construction sector represents one of the largest sectors of the global economy, employing about 7% of the population every year

[34][48]. However, civil construction has been criticized for activities and processes that generate a loss of materials, overuse of natural resources, high volumes of waste whilst obstructing achievement of the sustainable development goals (S.D.G.s) goals

[35][67].

In highlighting the civil construction sector, it is necessary to understand that it is an area facing many challenges in maintaining its activities and consequently in achieving sustainable development goals, given that the construction production chain significantly impacts the three pillars of sustainability. Furthermore, construction remains one of the least digitalized and innovative sectors in using Industry 4.0 Technologies. It is only ahead of agriculture, which occupies last place in the McKinsey Global Institute Industry Digitization Index

[36][68]. Although construction is moving towards automation, it still has no links to promising topics such as sustainability

[37][69].

The construction sector bears the highest rates of work accidents worldwide, improving the implementation of technologies can be seen as a social solution to the health and safety of workers

[32][33]. Technologies for information management and visualization are instrumental in enhancing human perceptions and interpretations of complicated project information

[38][70]. Furthermore, an essential contribution of the industry 4.0 technologies use in construction lies in the possibility of automated data collection for environmental impact assessments in a life cycle approach, called Life Cycle Assessment (LCA). In LCA studies, the availability of specific data, inputs and outputs associated with the production of materials, products and processes is a challenge for the execution of reliable studies. The lack of data compromises the quality of the study and the validity of the results found. Thus,

[39][61] propose a framework in which BIM can automate data collection and LCA studies in the context of construction, allowing recognition of the environmental load of materials, processes and operations and direct design improvements to reduce such impacts. Data collection for the LCA is operationalized through the integration of sensors and IoT enabled devices to BIM

[40][57]. Green BIM for environmental sustainability can be used for monitoring and management over a building’s full life cycle, and should then be considered in future research

[41][71].

The adoption of Industry 4.0 Technologies can support the construction industry to implement Circular Economy standards and consequently achievement of the S.D.G.s, promoting resource efficiency from project inception to end-of-life. By incorporating circular design requirements into the technologies, such as design for disassembly, deconstruction, and recycling, it is possible to reduce the use of non-renewable natural resources, properly manage the waste stream, and close the materials loop

[42][43][43,72].