Spilled mineral oils in the marine environment pose a number of challenges to sampling and analysis. Mineral oils are complex assemblages of hydrocarbons and additives, the composition of which can vary considerably depending on the source oil and product specifications. Further, the marine microbial and chemical environment can be harsh and variable over short times and distances, producing a rigorous source of hydrocarbon degradation of a mineral oil assemblage. Researchers must ensure that any measurements used to determine the nature and extent of the oil release, the fate and transport of the mineral oil constituents, and any resultant toxicological effects are derived using representative data that adhere to the study’s data quality objectives (DQOs).

- mineral oils

- marine oil spills

- data quality

- data usability

- sampling and analysis

1. Introduction

Mineral oils are complex assemblages of hydrocarbons manufactured from crude petroleum [1]. Mineral oil production involves first distilling crude oils at atmospheric pressure and then, under high vacuum, generating distillates and residuals that can be further refined into mineral oils [2][3]. Mineral oils refined from crude oils consist of a mixture of straight and branched-chained paraffinic, naphthenic, and aromatic hydrocarbons within a boiling point range of 300–600 °C [4], with resulting carbon ranges from C15 to C50 [2]. Mineral oil composition and physical characteristics can vary widely depending on the source of the oil and product specifications. Further, base stock mineral oils can be chemically modified into “synthetic” mineral oils [5]. The expansive composition of mineral oils allows for a wide variety of uses [6], which include non-lubricating products (e.g., agricultural spray oils, insulating oils, coatings, and printing inks), lubricating products (e.g., crank case oils and transmission fluids), and highly refined medicinal white oils and “paraffinum perliquidum” [3][7]. Further enhancing the complex composition of mineral oils is the liberal use of additives (“additive packages”), often organo-metallic compounds, including corrosion inhibitors, antioxidants, antifoaming agents, detergents, dispersants, and emulsifiers, which are blended into the mineral oils [8][9].

Petroleum releases into the ocean are significant, resulting from natural seeps as well as spills during oil extraction, processing, transportation, and use [10]. Oil spills can either be accidental or intentional. Accidental spills are most often from tankers transporting crude oil or petroleum products such as mineral oils or, to a lesser extent, are the result of pipeline leaks, coastal facility spills, and offshore oil production facilities [11]. The largest sources of intentional operational discharges include discharges from vessels (e.g., bilge releases, which may include mineral oils) and water discharges from offshore platforms [10]. The presence of petroleum lubricants, i.e., mineral oils, in today’s ships have varied purposes, including engine lubrication, hydraulics control, and the “oiling” of motors and cranes that may find their way accidentally, or intentionally, into the waterways [12]. Over the past two decades, oil spill occurrences have lessened due, in part, to improved prevention programs, technological advances such as the use of double-hulled tankers [13][14], and the enactment of legislation such as the Oil Pollution Act of 1990 (33 U.S.C.&2701 et seq. (1990)) [15]. In addition, there have been recent efforts to promote more environmentally friendly mineral oils for marine applications [16]. Nonetheless, significant mineral oil spill risks still exist and cannot be ignored.

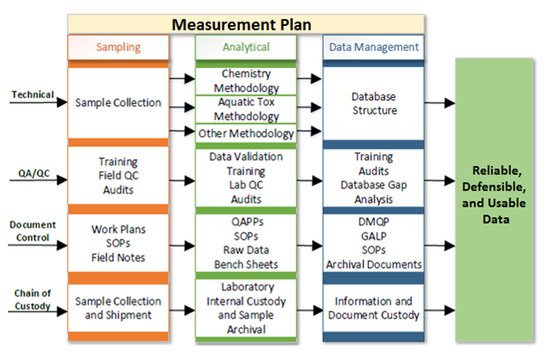

The objective of any sampling and analysis program is to determine the representative physical and chemical characteristics of a sample and, in the case of a mineral oil spill, to reliably understand the nature, extent, and impact of the spill [17]. The need for measurements that are reliable, and of known quality is key to any relevant oil spill study and can be an especially challenging undertaking considering the complex and sometimes unknown composition of mineral oils and the rigorous degradative forces encountered in the marine environment [18].

2. Data Quality Primer

-

Blanks, which provide information on possible contamination during sample and analysis activities. Elevated blank levels can lead to higher detection limits and false positives.

-

Replicates, which provide information on precision. Data sets with poor replicate precision may not be able to provide confidence in diagnostic forensic evaluations where the data must be evaluated against identification criteria.

-

Spikes, which evaluate bias. Samples with out-of-range spike recoveries may be biased low or high relative to the true concentration.

| Objectives | Project Details | Sampling | Analytical | Validation and Assessment |

|---|---|---|---|---|

| Need for program | History | Representativeness | Subsampling | Data quality objectives |

| Regulations | Waste generation | Health and safety | Analytes | Documentation of quality |

3. Marine Mineral Oil Spill Sampling

The objective of a marine mineral oil spill sampling program is to address questions about the marine environment being sampled, for which these questions should be clearly established prior to sample collection. Alternatively, a researcher may attempt to define the concentration of the mineral oil or mineral oil constituent within a decision unit to determine the total mass of material discharged or to locate a source by evaluating concentration gradients [18]. To meet these objectives, investigators should consider sampling strategies and sample handling requirements as part of their effort to satisfy the study’s DQOs. Trying to achieve DQOs for studies conducted in the harsh marine environment (in which mineral oils are subject to, e.g., photolytic reactions, volatilization, biodegradation) can be particularly daunting [27]. Confoundingly, the frequent need for an immediate response to a spill can hamper the planning process. Sampling programs should be crafted to consider, in part, marine background conditions, potential contaminant sources, and inadvertent sample contamination. Background conditions are key to understanding original conditions and can be established using previous long-term monitoring programs, provided they are available in the region and are of adequate data quality. Determining background conditions usually results in additional sampling from unimpacted areas with similar characteristics as the impacted areas or, if the trajectory of an oil spill can be predicted, from pre-impacted areas. In establishing background conditions, anthropogenic and natural sources of the investigation’s contaminants need to be determined. Rigorous methods of sample handling may be needed to eliminate as much cross-contamination and sampling-derived contamination as possible, particularly if the contaminant levels are expected to be low. Contamination introduced during sample collection and processing is cumulative and can be substantially greater than contamination introduced elsewhere in the sample handling and analysis process [18]. Methods for contamination control [28] can include:-

Sample collection techniques, for example:

-

○ proceeding toward a sample location from down current

○ progressing from least contaminated areas to most contaminated areas

○ circumventing boat exhaust and discharges, which may include mineral oils

○ wearing appropriate gloves

-

-

Equipment selection

-

Pre-cleaning sampling equipment

-

Using contaminant-free and appropriate sample containers

-

Decontamination methods for sampling equipment

| Thresholds or standards | ||||

| Waste handling | ||||

| Logistics | Preparatory method | Documentation of activities | ||

| Protection of human health | Contaminants | Sampling approach | Analytical method | Completeness/representativeness |

| Environment protection | Fate and transport | Sampling locations and depths | Aquatic toxicity testing | Bias and precision |

| Liability | Sources of contamination | Number of samples | Matrix/interferences | Audits |

| Data quality objectives | Areas to study | QA samples | Detection limits | Performance evaluation samples |

| Company/agency directives | Exposure pathways | Sample volume | Holding/turnaround times | Chain of custody |

| Public relations | Use of dispersants | Compositing | Contamination | Usability assessment |

| End-of-use data | Containers/equipment | QC samples | ||

| Decontamination | Reagents/supplies | |||

| Reporting requirements |

To ensure that the analytical samples are representative of site conditions, QA measures must be associated with each sampling and analysis event. The sampling plan must specify these QA measures, which include, but not limited to, sample collection, laboratory standard operating procedures (SOPs), sample container preparation, equipment decontamination, field blanks, replicate samples, performance evaluation samples, sample preservation and handling, and chain of custody requirements [30].As such, the study design will define the specific number and types of QC samples needed to meet the DQOs, which should be detailed in the QAPP [31]. QC samples typically collected as part of a well-conceived sampling program include [18]:Unlike standard sampling methods that are often available for chemical analysis, standard methods for collecting samples in marine matrices do not exist. When using non-standard sampling methods for marine mineral oil spill research, understanding and applying methodologies used and accepted by other researchers can be key to implementing a reliable sampling program [27]. Accepted practices for sampling mineral oils [32], sediments [33], water column [34], and ecological samples [35][36] have been discussed elsewhere.

4. Mineral Oil Analytical Chemistry

The characterization of mineral oils is hindered by its complex assemblage of hydrocarbons and unique additives, of which composition can vary widely depending on the source oil and product specifications. Additives may comprise 10–20% of the mineral oil product [37], which is typically not a consideration when devising a sampling and analysis program for crude oil and refined petroleum spills. As such, additives may prove to be useful as a forensic tool in differentiating mineral oil sources. The testing approach and target analytes will be driven by the DQOs. Broadly, mineral oil spill investigations fall into three categories: (i) the initial spill incident investigation, to better understand the direction of the spill and the amount of material spilled; (ii) the fate and transport of the mineral oil constituents, with forensic implications as to the who, what, how, when, and where of the mineral oil spill; (iii) a toxicological assessment focused on possible human and ecological damages. Fate, source, and transport forensic investigations require rigorous QA/QC programs based on well-crafted DQOs. For example, many forensic studies focus on unique ratios of specific analytes. Known precision and accuracy with tight tolerances are key to producing reliable diagnostic ratios [38]. The minimum laboratory QC measures needed include:The collection of background samples and source oil samples are key to any successful marine mineral oil spill investigation, particularly for a forensic sampling and analysis program, and should be integral to the development of DQOs for the investigation. Obtaining and analyzing mineral source oils can be fruitful for providing useful fingerprint information for forensic identification [39].

5. Conclusions

Understanding the ramifications of a marine mineral oil spill can be complex. Representative data of known quality and integrity is key to making scientifically sound decisions that can be defended when scrutinized by others. Marine mineral oil investigators should proactively design sampling and analysis studies with clearly defined DQOs and ensure that the study is performed according to the plan and that its implementation is properly recorded.

References

- Mang, T. Base oils. In Lubricants and Lubrications; Mang, T., Dresel, W., Eds.; Wiley-VCH: New York, NY, USA, 2001; pp. 32–60.

- Hedelin, A. Mineral Oil—Origin, Production and Composition; Nynas AB for CONCAWE; Mocrinis Work-Shop: Bologna, Italy, 2013.

- CONCAWE. Mineral oils, untreated or mildly treated. In Hazard Classification and Labeling of Petroleum Substances in the European Economic Area; Report 22/20; International Agency for Research on Cancer: Lyon, France, 2020; pp. 179–196.

- IARC. Polynuclear Aromatic Hydrocarbons, Part 2, Carbon Blacks, Mineral Oils (Lubricant Base Oils and Derived Products) and Some Nitroarenes. In IARC Monographs on the Evaluation of Carcinogenic Risk of Chemicals to Humans; IARC: Lyon, France, 1984; Volume 33, pp. 1–222.

- Henderson, H.E. Chemically modified mineral oils. In Synthetics, Mineral Oils, and Bio-Based Lubricants—Chemistry and Technology; Rudnick, L.R., Ed.; CRC Press: Boca Raton, FL, USA, 2006; pp. 287–315.

- Guthrie, V.B. Petroleum Products Handbook; McGraw-Hill Book Company: New York, NY, USA, 1960; pp. 24–25.

- Lauer, D.A. Industrial gear lubricants. In Synthetics, Mineral Oils, and Bio-Based Lubricants—Chemistry and Technology; CRC Press: Boca Raton, FL, USA, 2006; pp. 1–928.

- ASTM. Standard Test Method for Multielement Determination of Used and Unused Lubricating Oils and Base Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES); ASTM D5185-18; ASTM International: West Conshohocken, PA, USA, 2018; pp. 1–18.

- ASTM. Standard Test Method for Determination of Additive Elements in Lubricating Oils by EDXRF Analysis; ASTM D7751-16; ASTM International: West Conshohocken, PA, USA, 2021; pp. 1–7.

- National Research Council. Oil in the Sea III; The National Academies Press: Washington, DC, USA, 2003; pp. 7–18.

- Stout, S.A.; Wang, Z. Chemical fingerprinting methods and factors affecting petroleum fingerprints in the environment. In Standard Handbook Oil Spill Environmental Forensics; Stout, S.A., Wang, Z., Eds.; Academic Press: Cambridge, MA, USA, 2016; pp. 61–62.

- Uhler, A.D.; Stout, S.A.; Douglas, G.D.; Healey, E.D.; Emsbo-Mattingly, S.D. Chemical character of marine heavy fuel oils and lubricants. In Standard Handbook Oil Spill Environmental Forensics; Stout, S.A., Wang, Z., Eds.; Academic Press: Cambridge, MA, USA, 2016; pp. 665–666.

- Etkin, D.S. Analysis of U.S. Oil Spillage, API Publication 356; American Petroleum Institute: Washington, DC, USA, 2009; pp. 1–71.

- Etkin, D.S. Risk analysis and prevention. In Handbook of Oil Spill Science and Technology, 1st ed.; Fingas, M., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2015; pp. 3–35.

- Ketkar, K.W. The Oil Pollution Act of 1990: A decade later. Spill Sci. Technol. Bull. 2002, 7, 45–52.

- ASTM. Standard Guide for Selection of Environmentally Acceptable Lubricants for the U.S. Environmental Protection Agency (EPA) Vessel General Permit; ASTM D8324-21; ASTM International: West Conshohocken, PA, USA, 2021; pp. 1–14.

- Tuit, C.B.; Wait, A.D. Sampling and analysis. In Environmental Science Deskbook: Environmental Law Series; Conrad, J.W., Ed.; Thomson Reuters: Eagan, MN, USA, 2021; Chapter 3.

- Wait, A.D.; Ramsey, C.; Maney, J. The measurement process. In Introduction to Environmental Forensics, 3rd ed.; Murphy, B.L., Morrison, R.D., Eds.; Elsevier: Oxford, UK, 2015; pp. 65–97.

- US Congress. Habitability of the Love Canal Area: An Analysis of the Technical Basis for the Decision on the Habitability of the Emergency Declaration Area—A Technical Memorandum; OTA-TM-M-I3, DOJ 127, NTIS PB84-114917; Office of Technical Assessment: Washington, DC, USA, 1983.

- Wait, A.D. Evolution of organic analytical methods in environmental forensic chemistry. Environ. Forensics 2000, 1, 37–46.

- US EPA. Policy and Program Requirements for the Mandatory Agency-Wide Quality System; EPA Order No. 5360.1 A2; US EPA: Washington, DC, USA, 2000.

- Maney, J.; Wait, D. The role of representativeness in the project lifecycle. Environ. Forensics 2005, 6, 17–19.

- US EPA. Guidance on Systematic Planning Using the Data Quality Objectives Process; EPA QA/G-4; Report No. EPA/240/B-06/001; Office of Environmental Information: Washington, DC, USA, 2006.

- ASTM. Standard Practice for Generation of Environmental Data Related to Waste Management Activities: Development of Data Quality Objectives; ASTM D5792-10(2015); ASTM International: West Conshohocken, PA, USA, 2015; pp. 1–17.

- Bayne, C.K.; Dindal, A.B.; Jenkins, R.A.; Crumbling, D.M.; Koglin, E.N. Meeting data quality objectives with interval information. Environ. Sci. Technol. 2001, 35, 3350–3355.

- Crumbling, D.M.; Groenjes, C.; Lesnik, B.; Lynch, K.; Shockley, J.; van EE, J.; Howe, R.; Keith, L.; McKenna, J. Managing uncertainty in environmental decisions. Environ. Sci. Technol. 2001, 35, 404A–409A.

- Wait, A.D.; Tuit, C.B.; Maney, J.P. Forensic sampling practices for oil spills in the marine environment. Environ. Forensics 2020, 21, 310–318.

- Daling, P.V.; Buxhoeveden, A.; Hellstrom, K.C. Sampling procedures for securing evidence for water-borne oil spill identifications. In Standard Handbook Oil Spill Environmental Forensics; Stout, S.A., Wang, Z., Eds.; Academic Press: Cambridge, MA, USA, 2016; pp. 25–29.

- USGS. National Field Manual for the Collection of Water-Quality Data: Techniques of Water-Resources Investigations (Book 9); U.S. Geological Survey: Reston, VA, USA, 2015; p. 1539.

- US EPA. Superfund Program Representative Sampling Guidance. Volume 5. Water and Sediment. Part I—Surface Water and Sediments (Interim Final); OSWER Directive 9360(4–16); Office of Solid Waste and Emergency Response (OSWER): Washington, DC, USA, 1995; p. 117.

- Kulkarni, S.V.; Bertoni, M.J. Environmental sampling quality assurance. In Principles of Environmental Sampling, 2nd ed.; Keith, L.H., Ed.; American Chemical Society: Washington, DC, USA, 1996; pp. 111–137.

- Kneeland, J.M.; Tcaciuc, A.P.; Tuit, C.B.; Wait, A.D. A review of marine oil sampling methods. Environ. Forensics 2021, 21.

- Tuit, C.B.; Wait, A.D. A review of marine sediment sampling methods. Environ. Forensics 2020, 21, 291–309.

- Noble, A.E.; Tuit, C.B.; Maney, J.P.; Wait, A.D. A review of marine water sampling methods for trace metals. Environ. Forensics 2020, 21, 267–290.

- Verslycke, T.A.; Wait, A.D. Data quality in natural resource and environmental damage litigation. Nat. Resour. Environ. 2017, 31, 15–19.

- Wait, A.D.; Verslycke, T.A. Uniform data quality ecotoxicity assessment. In Natural Resource Damages—A Guide to Litigating and Resolving NRD Cases; Israel, B.D., Marston, B., Daniel, L., Eds.; American Bar Association: Washington, DC, USA, 2019; pp. 213–215.

- Ghosh, P.; Upadhyay, M.; Das, T. Multifunctional biodegradable lube oil additives: Synthesis, characterization, and performance evaluation. Pet. Sci. Technol. 2017, 35, 66–71.

- Douglas, G.S.; Emsbo-Mattingly, S.D.; Stout, S.A.; Uhler, A.D.; McCarthy, K.J. Hydrocarbon fingerprinting methods. In Introduction to Environmental Forensics, 3rd ed.; Murphy, B.L., Morrison, R.D., Eds.; Elsevier: Oxford, UK, 2015; pp. 201–309.

- Shang, D.; Park, G.; Brunswick, P.; van Aggelen, G.; Yang, C.; Kim, M. Combined gas and liquid chromatography tandem mass spectrometry applications for forensic lubricant and vegetable oil spill identification. In Oil Spill Environmental Forensics Case Studies; Stout, S.A., Wang, Z., Eds.; Elsevier: Oxford, UK, 2018; pp. 117–130.