Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Jason Zhu and Version 3 by Jason Zhu.

As a promising candidate in the construction industry, iron-based shape memory alloy (Fe-SMA) has attracted lots of attention in the engineering and metallography communities because of its foreseeable benefits including corrosion resistance, shape recovery capability, excellent plastic deformability, and outstanding fatigue resistance. Pilot applications have proved the feasibility of Fe-SMA as a highly efficient functional material in the construction sector.

- iron-based shape memory alloy (Fe-SMA)

- martensitic transformation

- shape memory effect

- Seismic Dampers

- Strengthening

- Novel Strengthening Solution

1. Introduction

Iron-based shape memory alloy (Fe-SMA, especially referring to Fe-Mn-Si class shape memory alloy) possesses shape memory effect (SME) [1][2], outstanding low-cycle fatigue (LCF) resistance [3], and some other desirable characteristics by which the material has proven its potential in the field of the construction industry. Fe-SMA was traditionally regarded as an ideal material used in fasteners and tie systems, e.g., pipe joints, rail couplings, and crane rail joint plates, where constrained stress is required [4]. The main purpose of using such materials is to simplify the construction process by its SME property which induces prestress conveniently. The so-called SME-induced prestress, also known as ‘recovery stress’, is associated with its unique deformation-induced martensitic transformation and subsequent heating–cooling process, where an approximate stress of 200–400 MPa can be generated.

Apart from its desirable prestressing capability, Fe-SMA also has excellent low-cycle fatigue resistance, which was first recognized by Sawaguchi in 2006 [3]. A series of studies have been carried out on this front and considerable achievements have been made. The engineering community has gained particular confidence with the completion of the 196-m skyscraper ‘JP Tower Nagoya’, where Fe-SMA seismic dampers were first employed in an actual project in seismic-prone cities. These works further expand the application boundary of Fe-SMA and inspire the interests of seismic engineers.

Fe-SMA has some extra benefits. It is reported that the corrosion-resistance of Fe-SMA is close to that of stainless steel due to the addition of Nickel and Chromium elements [5]. This makes Fe-SMA well suited to chloride environments, e.g., coastal/offshore engineering construction. In addition, in contrast to Nitinol (another popular class of SMA) which is less easily produced in large scale because of the demanding metallurgical process [6][7][8], Fe-SMA can be mass produced with conventional metallurgical equipment [9], and, more encouragingly, the cost of the raw materials is inherently low [10]. This facilitates practical use of Fe-SMA in the civil engineering sector, where the necessary size of elements/members is often large and the budget is often controlled.

2. Novel Strengthening Solution Based on SME of Fe-SMA

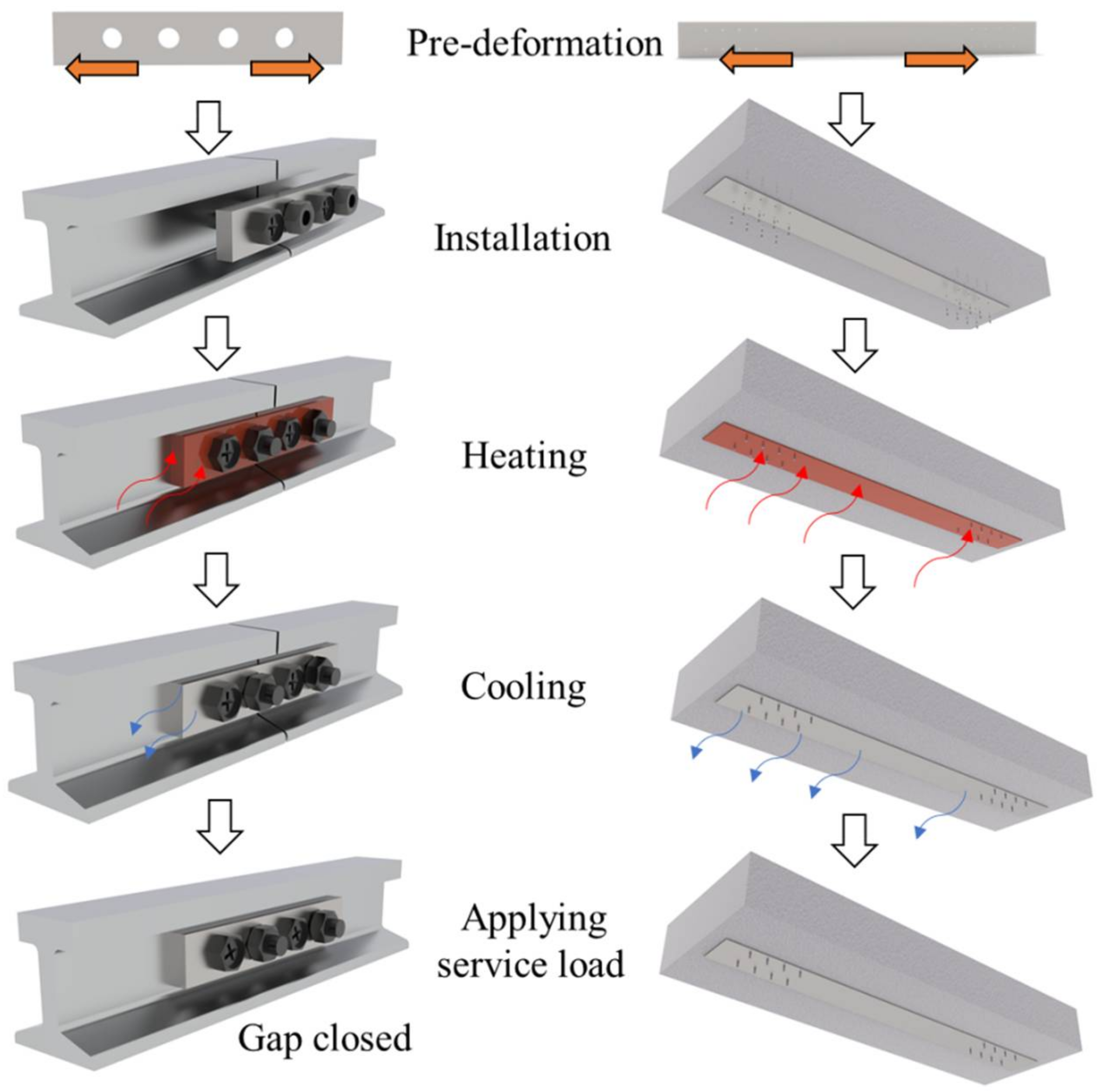

High-cycle fatigue causes crack propagation in structural components, a case which in turn leads to the deterioration of stiffness/strength and shortens the service life of the structure. Practice has proven that through strengthening the cracked or damaged components, the service life can be effectively prolonged. Existing strengthening strategies include using external bonding reinforcing materials or applying prestressing. Overcoming some possible shortcomings such as the difficulty in construction for the traditional reinforcing strategies, a new method utilizing Fe-SMA has received great attention. The main procedure of the Fe-SMA-based strengthening solution is similar to that of the aforementioned SME-triggered tightening method and can be summarized as follows:

- (1) Pre-deform (for most cases, pre-tension) the Fe-SMA elements to a preset strain value or the expected shape;

- (2) Connect the pre-deformed Fe-SMA elements to the base components (i.e., those ready for strengthening or connecting);

- (3) Apply electric heating (or infrared heating) to the pre-deformed Fe-SMA elements to a preset temperature and keep it for a short period of time to guarantee fully activated SME;

- (4) Wait until the Fe-SMA elements cool down to room temperature, and recovery stress is generated;

- (5) The structures then return to normal service state.

2.1. Strengthening for Reinforced Concrete (RC) Structures

The earliest practical application of Fe-SMA in the field of prestressing can be traced back to 2001 where a bridge in Michigan, United States, experienced fatigue-induced cracking [11]. In this case, Fe-SMA tendons were installed perpendicularly to the shear cracks. After electric heating, a recovery stress of approximately 225 MPa was induced in the Fe-SMA tendons. Field measurements indicated that the generated recovery stress closed the width of the shear cracks to a large extent and the load-carrying capacity of this bridge was effectively recovered.

Since the initial success, laboratory research works have been conducted on concrete structures strengthened by Fe-SMA reinforcement, and suitable anchorage systems have been developed. For example, EMPA (Swiss Federal Laboratories for Materials Science and Technology) proposed an anchorage system for Fe-SMA tendons employed as near-surface mounted reinforcement (NSMR) in RC structures [12][13][14]. As shown in Figure 1a, Fe-SMA prestressing elements are embedded in pre-made grooves and covered with adhesive material such as cement-based mortar herein. Lap-shear experiments have been carried out to clarify the bonding behavior between the Fe-SMA strips and cement-based mortar [13]. Deeper embedment depth and ribbed surface for Fe-SMA strips are recommended for practical application [15]. It is also found that the current design guidelines would underestimate the necessary anchorage length for Fe-SMA bars [16]. The corresponding calculation methods are yet to be available.

Figure 1. Schematic illustration of different anchoring methods for Fe-SMA tendon/strip strengthening RC components: (a) NSMR method; (b) shotcrete method; (c) NSMR-expansion anchor method; and (d) nail-based method.

With the aim of further simplifying the anchoring process and satisfying the objective of rapid recovery on site, a new anchoring method employing shotcrete is proposed (see Figure 1b) [17]. The previously tensioned Fe-SMA tendons are installed beneath the beam with an additional cementitious layer (shotcrete) sprayed on, covering the Fe-SMA tendons. After sufficient curing, current resistance heating is applied for activation and prestress is induced. Feasibility studies on flexural strengthening [17] and shear strengthening [18] of RC beams with this anchoring method have been conducted. Both the test results revealed that this strengthening system can efficiently increase the flexural/shear-resistant performance of RC beams. At the same time, beam deflections, number of cracks, and the widths of cracks were all reduced.

The flexural behavior of RC beams strengthened by the Fe-SMA NSMR system was investigated in [19], where ribbed Fe-SMA strips were longitudinally embedded at the bottom of the beam. Copper clamps were used to transmit the electric current. After current resistance heating to a target temperature of 160 °C, a permanent prestress of about 200 MPa was created in the Fe-SMA strips. Rojob et al. [20] conducted a comparative experimental study on the effect of strengthening through CFRP strips and Fe-SMA strips, and confirmed that the Fe-SMA strips lead to better ductility of the beam. Rojob et al. [21] further added expansion anchor to this system (see Figure 1c) and found that the ductility of the RC beam was further improved. This is because the additional expansion anchor provides an extra force transmission path, which maintains beam function after the Fe-SMA tendons are stripped from the adhesive material.

Nail-based mechanical anchorage system is an alternative method for the Fe-SMA NSMR system. As shown in Figure 1d, Fe-SMA strips can be easily fixed to the surface of the base concrete layer by the aid of direct-fasteners (e.g., nails) and nail-setting devices [22]. The total duration for installing and activating a 5-m Fe-SMA strip is within 20 min [23]. This method has been applied to some retrofitting cases in Switzerland [23]. However, nail-based anchorage systems may not be the best solution for bridges since the nails tend to loosen under HCF-loading conditions.

It should be noted that for RC structures, the target temperature during electric heating should be carefully controlled, since high temperatures may cause concrete cracking/damage and could be detrimental to the bond strength between Fe-SMA and concrete [24]. As reported in [16], a longitudinal splitting crack with a width of about 0.05 mm appeared in the mortar surface when the Fe-SMA was heated up to 190 °C. Most existing studies adopt a maximum activation temperature of around 160 °C, which can be regarded as a feasible target temperature.

2.2. Strengthening for Steel Structures

The friction-based mechanical anchorage system, which is feasible for strengthening steel structures with Fe-SMA prestressing strips, was first developed by EMPA[25]. Glass-fiber-reinforced plastic (GFRP) laminates and friction foils are also involved in this anchorage system, along with clamping plates and bolts which are necessary for anchoring. The GFRP laminates electrically insulate the Fe-SMA strips from the steel plate during the activation procedure, thus avoiding energy waste and reduction of heating efficiency. Extra friction foils are often used to increase the static friction coefficient for this joint. The experiment was first conducted on simple steel plates, and it was shown that a 2% pre-strain of the Fe-SMA strips can produce a recovery stress of about 330–410 MPa after heating to 260 °C, resulting in a compressive stress of about 35–74 MPa in the base steel plates. A fatigue test was further conducted and the results proved that the fatigue life of these strengthened steel plates was evidently increased and the propagation of initial cracks was postponed and even arrested in some cases [26]. Appropriate modifications were subsequently made and the applications were extended to fatigue strengthening of metallic girders[27][28] and connections[29]. Similar conclusions were drawn from these works.

Recently, a novel fatigue strengthening solution for steel structures using adhesively bonded Fe-SMA strips was investigated by EMPA. The adhesive Sika1277 was used to bond the Fe-SMA strips to the steel plates [30]. It is reported that the bonding force is approximately twice the prestress achieved in the Fe-SMA strips. No softening behavior was observed during the activation process, which means that the adhesive can securely anchor the Fe-SMA strip throughout the whole strengthening process [31]. Due to the bridging mechanism of the adhesive anchorage, crack opening in the base structure was suppressed and stress singularity at the crack tip was also significantly reduced [31]. However, future studies are still needed to investigate the time-varying behavior of this bonding-based anchorage system during the entire service life.

3. Seismic Dampers

Conventional metal dampers are usually made of steel with a reasonably low yield strength, which encourages early participation in energy dissipation. Ductility and durability are also important characteristics, since many strong ground motions followed by a series of aftershocks have been recorded in the past decades [32]. A Japanese industry–academic–government joint research group had developed Fe-SMA-based (Fe-15Mn-4Si-10Cr-8Ni) buckling restrained shear dampers and buckling-restrained braces, and used them in the JP Tower Nagoya and The Aichi International Convention & Exhibition Center, Tokoname, respectively [33]. Related experiments have been conducted [34][33][35] and the results confirmed that the Fe-SMA seismic dampers exhibit considerably longer fatigue life (around ten times) than conventional steel dampers. Loading tests with random seismic wave inputs were also performed and the results showed that the seismic dampers exhibit stable energy absorption behavior under a wide range of deformation angles, reflecting a reliable performance during earthquake sequences [33].

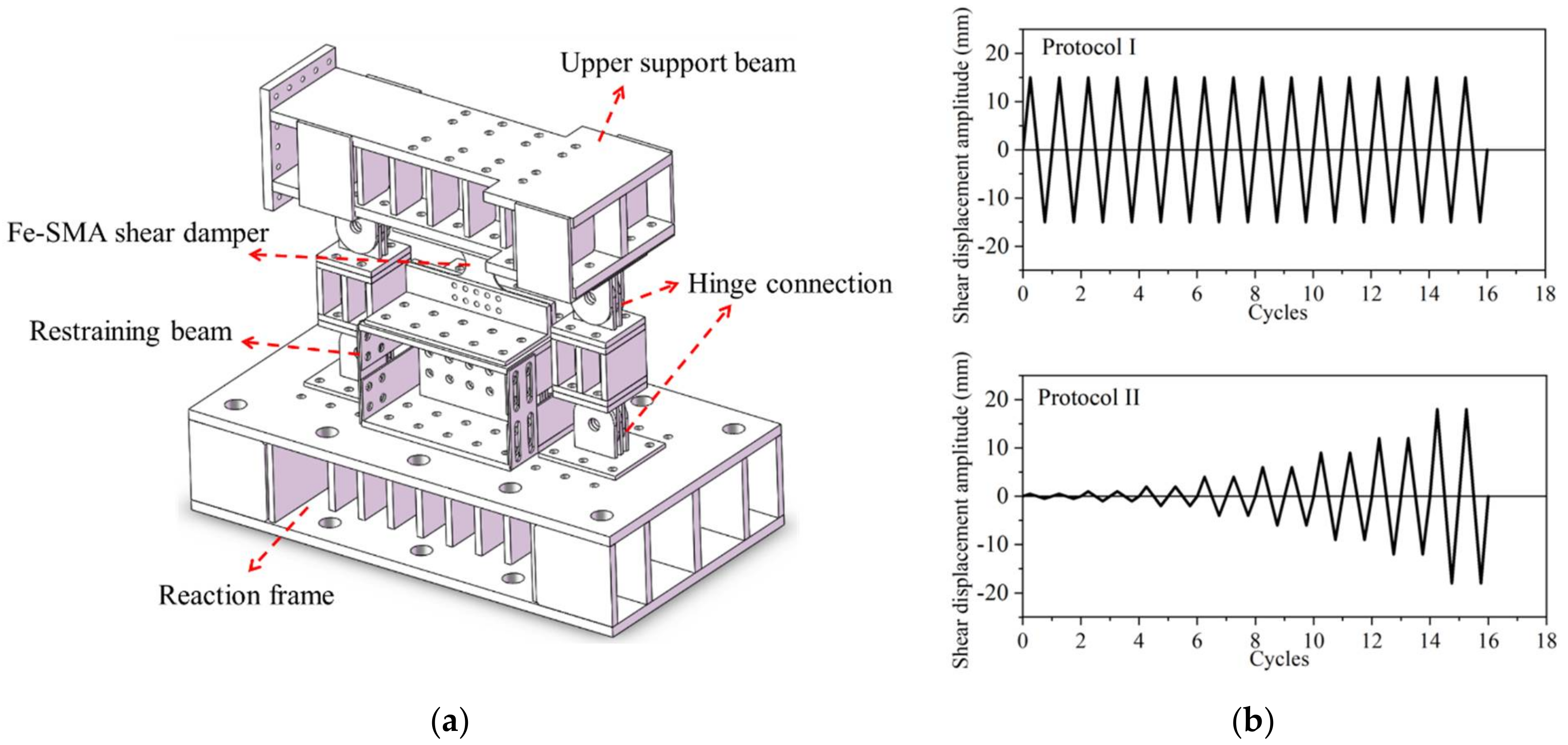

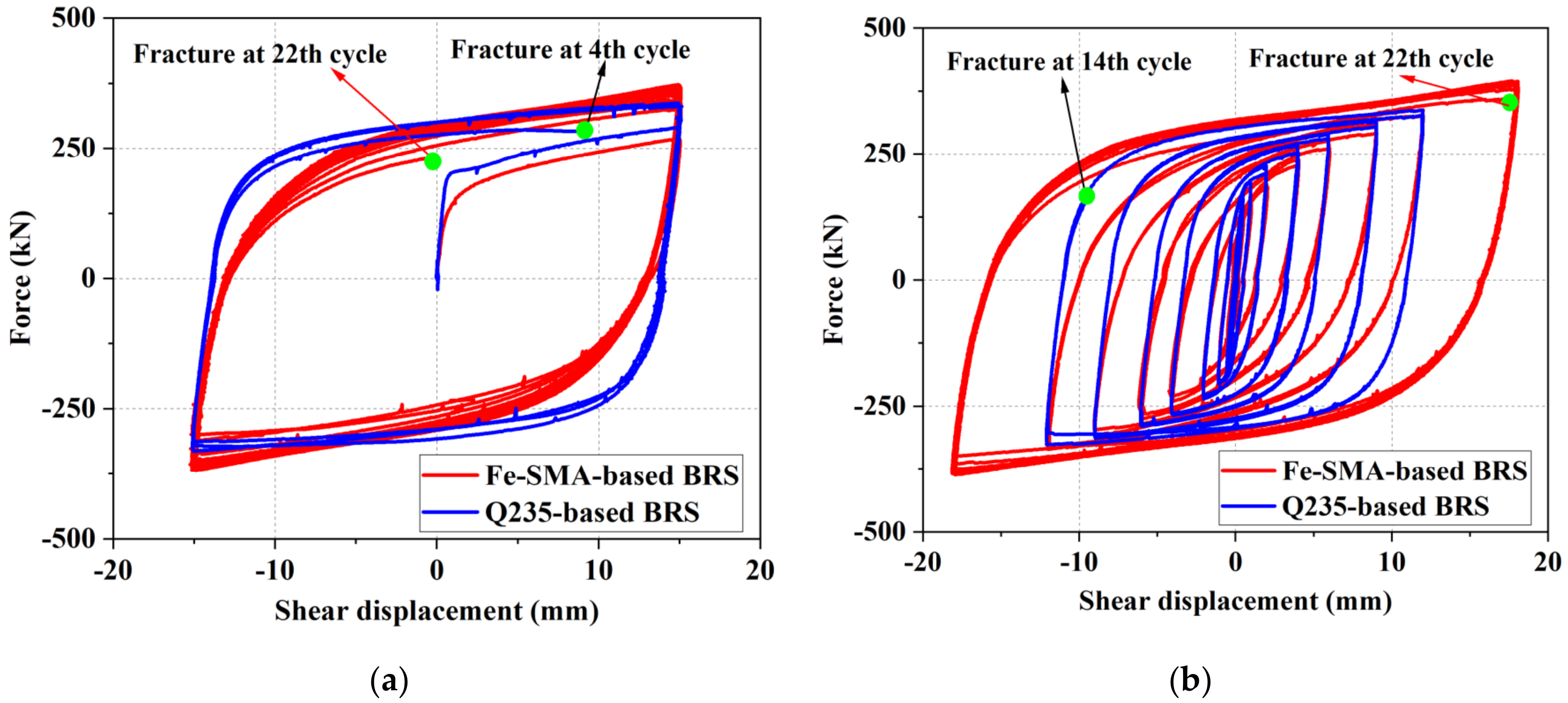

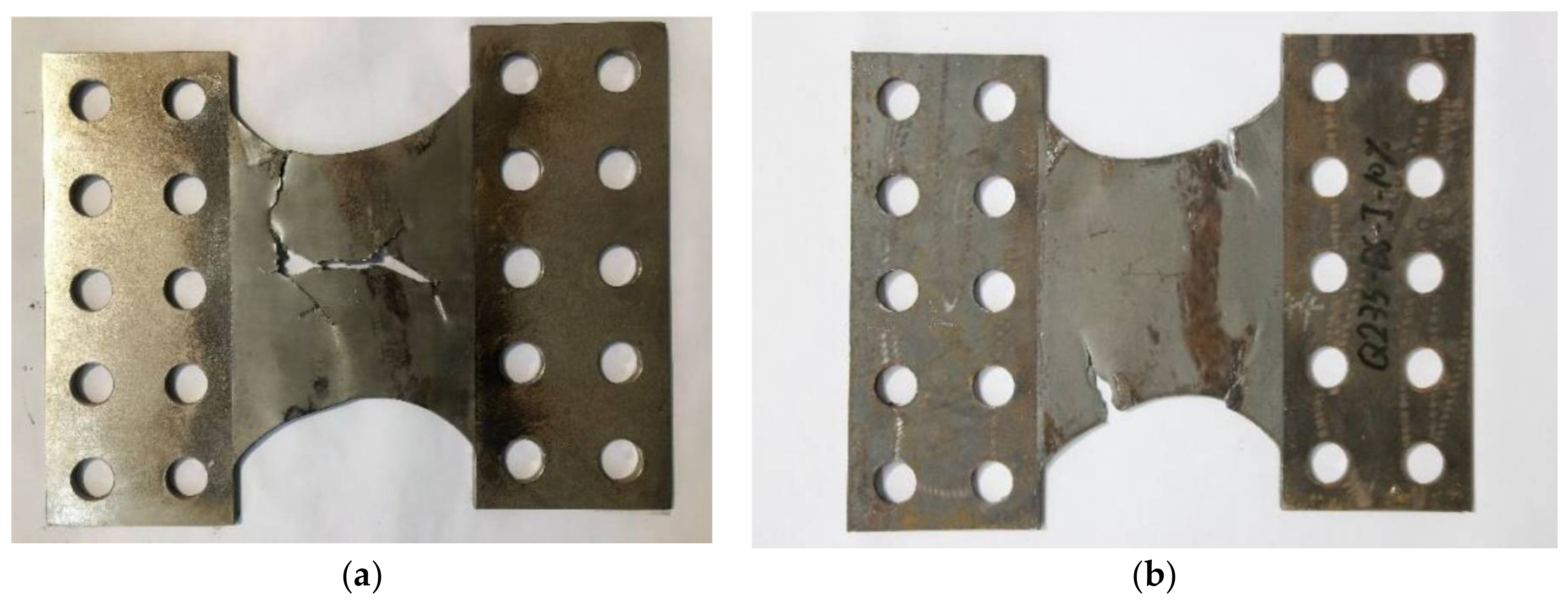

A more comprehensive experimental study on Fe-SMA (Fe-17Mn-5Si-10Cr-5Ni) BRS was conducted by the researchers and co-workers recently [34] (Figure 2a). Loading protocols with constant and incremental symmetrical shear displacement amplitudes, marked as ‘protocol I’ and ‘protocol II’ in Figure 2b, respectively, were employed to investigate the hysteresis response of the Fe-SMA-based BRSs. Such loading protocols were also conducted on steel (Q235) BRSs with the same geometry, and the test results are compared in Figure 3. The hysteretic loops of Fe-SMA-based BRSs are slightly narrower than those of steel BRSs (half-life cycle EVD = 0.42 vs. 0.52 under constant displacement amplitude), which is consistent with the material-level observation described previously. Importantly, significantly enhanced fatigue resistance was achieved in the Fe-SMA-based BRSs, leading to a considerable increase in the total accumulated energy dissipation (ET). Figure 4 shows the final crack patterns of Fe-SMA- and Q235-based BRSs in this experiment. The cracks of the Fe-SMA-based BRSs tended to be initiated in the center region of the core plates, with a subsequent crack propagation to the arc-shaped edge, whereas the cracks of the Q235-based ones were initiated from the arc-shaped edge region. Research opportunities exist in further investigating the reasons behind the difference in the fracture mechanism between Fe-SMA and steel shear dampers.

Figure 2. Laboratory experiment of Fe-SMA-based BRS: (a) illustration of test setup; and (b) loading protocols.

Figure 3 Hysteretic behavior for Fe-SMA- and Q235-based BRS under: (a) Protocol ‘I’; and (b) Protocol ‘II’.

Figure 4.

Macroscopic fracture behavior of (

a

) Fe-SMA-based BRS; and (

b

) Q235-based BRS under loading protocol ‘I’.

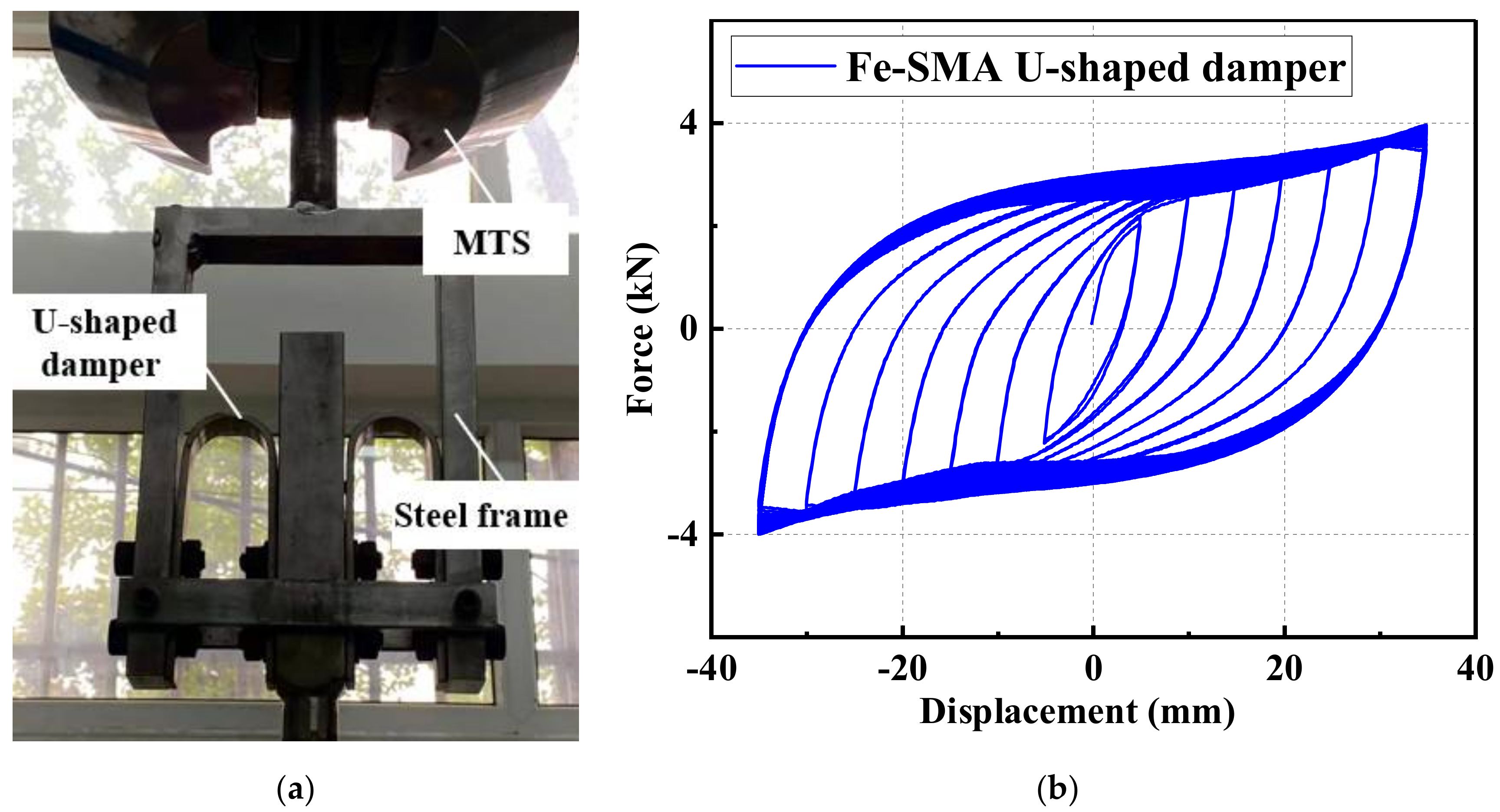

More recently, the researchers and co-workers have completed a series of tests on Fe-SMA U-shaped dampers, as shown in Figure 5a. It was found that the LCF life of the Fe-SMA dampers is 5–7 times that of their steel counterparts. A representative Fe-SMA damper hysteretic curve is shown in Figure 5b, where full and stable hysteresis curves are observed.

Figure 5. Fe-SMA U-shaped damper tests: (a) test setup; and (b) hysteretic response under incremental loading protocol.

4. Advantages Compared with Alternative Solutions

Summarizing the above studies and applications, the main advantages of the Fe-SMA solutions are further elaborated here. In the field of retrofitting, the prestressing process of Fe-SMA strips is easier than that of the CFRP tendon-based reinforcement which currently prevails [25][28][31][36]. This is mainly because the former can be activated through electrical heating without any heavy hydraulic jacks or dedicated mechanical clamps. Moreover, the required fire protection for Fe-SMA strips can be less demanding than that required for CFRP strips. Studies have found that Fe-SMA strips have a positive effect in countering the relaxation behavior of structures at elevated temperatures [37]. Furthermore, corrosion, creep, and relaxation behavior under extreme environments (e.g., high-temperature and chlorine environments) have been investigated which confirmed the suitability and reliability of Fe-SMA [11][38][39][40][41][42][43][44][45]. Another attractive advantage of Fe-SMA-based strengthening strategy is its re-prestressing property, i.e., HCF-induced relaxation in recovery stress can be restored through repeated rounds of thermal activation [46][26][47]. This process is simple and can be implemented without the necessity for the time and labor-intensive disassembling procedure.

As for the Fe-SMA-based seismic dampers which have attracted great attention in the community of seismic designers, the fatigue-free and maintenance-free seismic design ambition may become possible. These significantly benefit society since the maintenance costs including those related to hazards have become an important part of governments’ expenditure over the years (for example, about 400 billion Euros are paid for maintenance of buildings in Europe [48]).

Despite the fact that the price of Fe-SMA is currently higher than conventional structural steel, the whole-life costing of Fe-SMA-based applications may be comparable with the conventional technologies. It is noted that Fe-SMA is much cheaper than NiTi SMA which is often criticized for its high cost [49][50][51][52][53]. Existing studies also found that the total costs of Fe-SMA- and CFRP-based strengthening solutions are comparable when the cost of dedicated mechanical clamps for prestressing CFRP strips as well as the cost of labor were considered [36]. Moreover, long term costs can be saved to some degree due to the low maintenance requirements and the corrosion-resistance property of Fe-SMA. Importantly, since Fe-SMA shares similar production process to stainless steel [9], it is optimistic to predict that the price of Fe-SMA has the potential to approach that of stainless steel as long as the demand matches with production quantities.

References

- Sato, A.; Chishima, E.; Soma, K.; Mori, T. Shape memory effect in gamma-ebsel transformation in Fe-30Mn-1Si alloy single crystals. Acta Metall. 1982, 30, 1177–1183.

- Sato, A.; Mori, T. Development of a shape memory alloy Fe-Mn-Si. Mater. Sci. Eng. A 1991, 146, 197–204.

- Sawaguchi, T.; Kikuchi, T.; Ogawa, K.; Yin, F.X.; Kajiwara, S.; Kushibe, A.; Ogawa, T. Internal Friction of Fe-Mn-Si-Based Shape Memory Alloys Containing Nb and C and Their Application as a Seismic Damping Material. Key Eng. Mater. 2006, 319, 53–58.

- Lee, W.J.; Weber, B.; Leinenbach, C. Recovery stress formation in a restrained Fe–Mn–Si-based shape memory alloy used for prestressing or mechanical joining. Constr. Build. Mater. 2015, 95, 600–610.

- Cladera, A.; Weber, B.; Leinenbach, C.; Czaderski, C.; Shahverdi, M.; Motavalli, M. Iron-based shape memory alloys for civil engineering structures: An overview. Constr. Build. Mater. 2014, 63, 281–293.

- Fang, C.; Yam, M.C.H.; Ma, H.; Chung, K.F. Tests on superelastic Ni–Ti SMA bars under cyclic tension and direct-shear: Towards practical recentring connections. Mater. Struct. 2013, 48, 1013–1030.

- Fang, C.; Zhou, X.; Osofero, A.; Shu, Z.; Corradi, M. Superelastic SMA Belleville washers for seismic resisting applications: Experimental study and modelling strategy. Smart Mater. Struct. 2016, 25, 105013.

- Wang, W.; Fang, C.; Liu, J. Large size superelastic SMA bars: Heat treatment strategy, mechanical property and seismic application. Smart Mater. Struct. 2016, 25, 075001.

- Sawaguchi, T.; Maruyama, T.; Otsuka, H.; Kushibe, A.; Inoue, Y.; Tsuzaki, K. Design Concept and Applications of Fe–Mn–Si-Based Alloys—from Shape-Memory to Seismic Response Control. Mater. Trans. 2016, 57, 283–293.

- Janke, L. Applications of shape memory alloys in civil engineering structures—Overview, limits and new ideas. Mater. Struct. 2005, 38, 578–592.

- Soroushian, P.; Ostowari, K.; Nossoni, A.; Chowdhury, H. Repair and Strengthening of Concrete Structures Through Application of Corrective Posttensioning Forces with Shape Memory Alloys. Transp. Res. Rec. J. Transp. Res. Board 2001, 1770, 20–26.

- El-Hacha, R.; Soudki, K. Prestressed near-surface mounted fibre reinforced polymer reinforcement for concrete structures—A review. Can. J. Civ. Eng. 2013, 40, 1127–1139.

- Czaderski, C.; Shahverdi, M.; Brönnimann, R.; Leinenbach, C.; Motavalli, M. Feasibility of iron-based shape memory alloy strips for prestressed strengthening of concrete structures. Constr. Build. Mater. 2014, 56, 94–105.

- Abouali, S.; Shahverdi, M.; Ghassemieh, M.; Motavalli, M. Nonlinear simulation of reinforced concrete beams retrofitted by near-surface mounted iron-based shape memory alloys. Eng. Struct. 2019, 187, 133–148.

- Schranz, B.; Czaderski, C.; Vogel, T.; Shahverdi, M. Bond behaviour of ribbed near-surface-mounted iron-based shape memory alloy bars with short bond lengths. Mater. Des. 2020, 191, 108647.

- Schranz, B.; Czaderski, C.; Vogel, T.; Shahverdi, M. Bond investigations of prestressed, near-surface-mounted, ribbed memory-steel bars with full bond length. Mater. Des. 2020, 196, 109145.

- Shahverdi, M.; Czaderski, C.; Annen, P.; Motavalli, M. Strengthening of RC beams by iron-based shape memory alloy bars embedded in a shotcrete layer. Eng. Struct. 2016, 117, 263–273.

- Czaderski, C.; Shahverdi, M.; Michels, J. Iron based shape memory alloys as shear reinforcement for bridge girders. Constr. Build. Mater. 2021, 274, 121793.

- Shahverdi, M.; Czaderski, C.; Motavalli, M. Iron-based shape memory alloys for prestressed near-surface mounted strengthening of reinforced concrete beams. Constr. Build. Mater. 2016, 112, 28–38.

- Rojob, H.; El-Hacha, R. Ductility behavior of RC beams strengthened in flexure with NSM Iron-based Shape Memory Alloy bars. In Proceedings of the Third Conference on Smart Monitoring, Assessment and Rehabilitation of Civil Structures, Antalya, Turkey, 7–9 September 2015.

- Rojob, H.; El-Hacha, R. Self-Prestressing Using Fe-SMA for Flexural Strengthening of Reinforced Concrete Beams. ACI Struct. J. 2017, 114, 523–532.

- Cladera, A.; Montoya-Coronado, L.A.; Ruiz-Pinilla, J.G.; Ribas, C. Shear strengthening of slender reinforced concrete T-shaped beams using iron-based shape memory alloy strips. Eng. Struct. 2020, 221, 111018.

- Rojob, H.; El-Hacha, R. Strengthening of concrete structures with iron-based shape memory alloy elements: Case studies. In Proceedings of the SMAR 2019—Fifth Conference on Smart Monitoring, Assessment and Rehabilitation of Civil Structures, Potsdam, Germany, 27–29 August 2019.

- Gu, X.-L.; Chen, Z.-Y.; Yu, Q.-Q.; Ghafoori, E. Stress recovery behavior of an Fe-Mn-Si shape memory alloy. Eng. Struct. 2021, 243, 112710.

- Izadi, M.; Ghafoori, E.; Shahverdi, M.; Motavalli, M.; Maalek, S. Development of an iron-based shape memory alloy (Fe-SMA) strengthening system for steel plates. Eng. Struct. 2018, 174, 433–446.

- Izadi, M.; Ghafoori, E.; Motavalli, M.; Maalek, S. Iron-based shape memory alloy for the fatigue strengthening of cracked steel plates: Effects of re-activations and loading frequencies. Eng. Struct. 2018, 176, 953–967.

- Izadi, M.; Hosseini, A.; Michels, J.; Motavalli, M.; Ghafoori, E. Thermally activated iron-based shape memory alloy for strengthening metallic girders. Thin-Walled Struct. 2019, 141, 389–401.

- Hosseini, A.; Ghafoori, E.; Motavalli, M.; Nussbaumer, A.; Zhao, X.-L.; Al-Mahaidi, R. Flat prestressed unbonded retrofit system for strengthening of existing metallic I-Girders. Compos. Part B Eng. 2018, 155, 156–172.

- Izadi, M.; Motavalli, M.; Ghafoori, E. Iron-based shape memory alloy (Fe-SMA) for fatigue strengthening of cracked steel bridge connections. Constr. Build. Mater. 2019, 227, 116800.

- Wang, W.; Hosseini, A.; Ghafoori, E. Experimental study on Fe-SMA-to-steel adhesively bonded interfaces using DIC. Eng. Fract. Mech. 2021, 244, 107553.

- Wang, W.; Li, L.; Hosseini, A.; Ghafoori, E. Novel fatigue strengthening solution for metallic structures using adhesively bonded Fe-SMA strips: A proof of concept study. Int. J. Fatigue 2021, 148, 106237.

- Hou, H.; Qu, B. Duraion effect of spectrally matched fround motions on seismic demands of elasric perfectly plastic SDOFS. Eng. Struct. 2015, 90, 48–60.

- Inoue, Y.; Kushibe, A.; Umemura, K.; Mizushima, Y.; Sawaguchi, T.; Nakamura, T.; Otsuka, H.; Chiba, Y. Fatigue-resistant Fe-Mn-Si-based alloy seismic dampers to counteract long-period ground motion. Jpn. Archit. Rev. 2020, 4, 76–87.

- Fang, C.; Wang, W.; Ji, Y.; Yam, M.C. Superior low-cycle fatigue performance of iron-based SMA for seismic damping application. J. Constr. Steel Res. 2021, 184, 106817.

- Wang, B.; Zhu, S. Cyclic behavior of iron-based shape memory alloy bars for high-performance seismic devices. Eng. Struct. 2021, 252, 113588.

- Hosseini, A.; Michels, J.; Izadi, M.; Ghafoori, E. A comparative study between Fe-SMA and CFRP reinforcements for prestressed strengthening of metallic structures. Constr. Build. Mater. 2019, 226, 976–992.

- Ghafoori, E.; Neuenschwander, M.; Shahverdi, M.; Czaderski, C.; Fontana, M. Elevated temperature behavior of an iron-based shape memory alloy used for prestressed strengthening of civil structures. Constr. Build. Mater. 2019, 211, 437–452.

- Bu, D.; Peng, H.; Wen, Y.; Li, N. Influence of ageing on wear resistance of an Fe–Mn–Si–Cr–Ni–Ti–C shape memory alloy. Mater. Des. 2011, 32, 2969–2973.

- Della Rovere, C.; Alano, J.; Otubo, J.; Kuri, S. Corrosion behavior of shape memory stainless steel in acid media. J. Alloys Compd. 2011, 509, 5376–5380.

- Della Rovere, C.; Alano, J.; Silva, R.; Nascente, P.; Otubo, J.; Kuri, S. Influence of alloying elements on the corrosion properties of shape memory stainless steels. Mater. Chem. Phys. 2012, 133, 668–673.

- Ma, R.; Peng, H.; Wen, Y.; Zhang, L.; Zhao, K. Oxidation behavior of an austenitic stainless FeMnSiCrNi shape memory alloy. Corros. Sci. 2013, 66, 269–277.

- Leinenbach, C.; Lee, W.J.; Lis, A.; Arabi-Hashemi, A.; Cayron, C.; Weber, B. Creep and stress relaxation of a FeMnSi-based shape memory alloy at low temperatures. Mater. Sci. Eng. A 2016, 677, 106–115.

- Lee, W.J.; Partovi-Nia, R.; Suter, T.; Leinenbach, C. Electrochemical characterization and corrosion behavior of an Fe-Mn-Si shape memory alloy in simulated concrete pore solutions. Mater. Corros. 2016, 67, 839–846.

- Silva, R.; Arana, C.; Malafaia, A.D.S.; Filho, A.M.; Pascal, C.; Otubo, J.; Sordi, V.; Rovere, C. Microstructure and surface oxidation behavior of an austenitic Fe-Mn-Si-Cr-Ni-Co shape memory stainless steel at 800 °C in air. Corros. Sci. 2019, 158, 158.

- Silva, R.; Vacchi, G.; Santos, Í.; Malafaia, A.; Kugelmeier, C.; Filho, A.M.; Pascal, C.; Sordi, V.; Rovere, C. Insights into high-temperature oxidation of Fe-Mn-Si-Cr-Ni shape memory stainless steels and its relationship to alloy chemical composition. Corros. Sci. 2020, 163, 163.

- Ghafoori, E.; Hosseini, E.; Leinenbach, C.; Michels, J.; Motavalli, M. Fatigue behavior of a Fe-Mn-Si shape memory alloy used for prestressed strengthening. Mater. Des. 2017, 133, 349–362.

- Hosseini, E.; Ghafoori, E.; Leinenbach, C.; Motavalli, M.; Holdsworth, S.R. Stress recovery and cyclic behaviour of an Fe–Mn–Si shape memory alloy after multiple thermal activation. Smart Mater. Struct. 2018, 27, 025009.

- Baddoo, N.R. Stainless steel in construction: A review of research, applications, challenges and opportunities. J. Constr. Steel Res. 2008, 64, 1199–1206.

- Fang, C.; Ping, Y.; Zheng, Y.; Chen, Y. Probabilistic economic seismic loss estimation of steel braced frames incorporating emerging self-centering technologies. Eng. Struct. 2021, 241, 112486.

- Zheng, Y.; Fang, C.; Liang, D.; Sun, R. An innovative seismic-resilient bridge with shape memory alloy-washer-based footing rocking RC piers. J. Intell. Mater. Syst. Struct. 2021, 32, 549–567.

- Chen, J.; Fang, C.; Wang, W.; Liu, Y. Variable-friction self-centering energy-dissipation braces (VF-SCEDBs) with NiTi SMA cables for seismic resilience. J. Constr. Steel Res. 2020, 175, 106318.

- Wang, W.; Fang, C.; Zhang, A.; Liu, X. Manufacturing and performance of a novel self-centring damper with shape memory alloy ring springs for seismic resilience. Struct. Control Health Monit. 2019, 26, e2337.

- Fang, C.; Yam, M.C.H.; Lam, A.C.C.; Zhang, Y. Feasibility study of shape memory alloy ring spring systems for self-centring seismic resisting devices. Smart Mater. Struct. 2015, 24, 75024.

More