Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Beatrix Zheng and Version 1 by Soussi Soussi.

The climate control inside the greenhouse constitutes an efficient methodology for maintaining a satisfactory environment that fulfills the requirements of high-yield crops and reduced energy and water resource consumption. In hot climates, the cooling systems, which are assisted by an effective control technique, constitute a suitable path for maintaining an appropriate climate inside the greenhouse, where the required temperature and humidity distribution is maintained.

- greenhouse

- control methods

- cooling

- dehumidification

- energy consumption

- water recovery

- arid areas

1. Water Recovery in Greenhouses

Agriculture is the largest water-consuming sector, with a rate of 70% of the global fresh water [1]. Furthermore, given the relevant decreases in the groundwater reserves because of high consumption rates and the warranty of water availability in the face of climate change, the development and improvement of irrigation water management techniques has become a major priority in agriculture development, particularly in arid areas. Protected cultivation has contributed significantly to the enhancement of water efficiency, as it produces higher yields with reduced water consumption, as well as the efficient use of other resources, such as fertilizers, pesticides, and labor, compared to open-field cultivation [2][3][4]. Water management, which is correlated with issues such as the limitation of freshwater resources, efficient water use, and water desalination, consists of water recovery monitoring techniques that apply closed, or semiclosed, air cycles in the greenhouse design. Another source of the water supply consists of recovering the wastewater that is treated and recycled. Wastewater can be collected from any water-consuming process, such as industrial processes or those of households. Hence, converting wastewater or the loss of water by evapotranspiration into irrigation water could be an ideal strategy for transforming crop agriculture from its status as the greatest water consumer, to the status of water producer.

1.1. Condensation on a Cold Surface

This technology is based mainly on collecting the condensate of humid air. The existing systems of water recovery are based on the following two conditions: taking advantage of the high values of the air humidity that are achieved in greenhouses, especially in closed ones; and decreasing the greenhouse temperature by cooling processes. Actually, condensation occurs when the humid air of the greenhouse comes into contact with a surface that is at a temperature that is lower than its dew point. The water content of the air is thus removed by means of condensation. The relative humidity of the air in a closed greenhouse is mainly affected by the ventilation and the evapotranspiration of the plants. Hence, it remains a great challenge to apply humidification with the aim of collecting more droplets, without causing crop damage. Indeed, water recovery could be achieved by coupling a condensation process to the natural convection or mechanical cooling systems, or even to air-to-air heat exchangers. On the basis of the developed dynamic model for predicting the energy and mass exchanges in a greenhouse as a function of the dynamic environmental factor, Yildiz and Stombaugh [5] prove that condensation, in the case of a closed heat pump system that was used for greenhouse cooling in the United States, could ensure a water recovery reaching 1.17 kg of water day−1 m−2 during the summer season, which is the same amount as the daily water transpiration. They found that the closed loop system was the most water-conserving system, since all the transpired water could be recovered on the coils, making the overall water consumption in this system null. Moreover, the cooling process maintained the greenhouse temperature at 20 °C during the day, and at 18 °C during the night, with an energy consumption of 0.69 kWh day−1 m−2. In the arid region of Oman [6], the performance of an evaporative cooling system for the recovery of freshwater was investigated by utilizing two condensers placed after the second pad of the system. Perret et al. [6] found that the relative humidity often reached 100%, and that the water temperature was reduced by 3 °C through the two cooling pads. The dew point temperature was higher than the temperature of the condensers, by about 4 °C, and condensation was therefore observed on the dehumidifier, but the amount of condensate was negligible, and was not measurable. This was justified by the high air flowrate through the condensers, and improvements in the condenser design were, thus, highly recommended.

1.2. Advanced Desalination Processes

Several studies have focused on desalination in greenhouses as a key process of water management, and they have investigated several techniques to improve its efficiency and sustainability, particularly in the water-scarce countries [7]. Desalination processes are generally coupled to solar processes in order to guarantee low costs and zero-energy integrated systems. Buchholz et al. [8] and Zaragoza et al. [9] performed an experimental study in Spain under the Watergy project, which achieved a controlled indoor climate and water recovery. The solar-assisted system is based on water and air cycles, with the additional usage of a heat exchanger that harnesses the temperature difference between the night cooling and the indoor air to condensate the water vapor on the envelope surface. The 200 m2 closed greenhouse ensured thermal energy capture, water recycling, water desalination, and advanced horticultural use. The greenhouse control climate allowed for a 75% savings in the water consumption. El-Awady et al. [10] performed an experimental investigation of an integrated solar greenhouse that combined the methods of desalination and wastewater treatment, along with water condensation harvesting, in the arid area of Giza in Egypt. The proposed prototype showed satisfying results for the zones suffering from water shortages, given that the greenhouse that was studied provided a low-cost solution, on the one hand, for indoor climate control, and, on the other hand, for the production of freshwater that was suitable either for drinking or irrigation purposes. In Muscat, Oman, the seawater greenhouse studied by Al-Ismaili and Jayasuriya [11] combined humidification–dehumidification and solar desalination processes. The freshwater production is about half of the irrigation demands: 300–600 L day−1 of a salinity lower than 0.020 dS·m−1. Furthermore, multiple studies have aimed to integrate the desalination system into the roof of the greenhouse. Chaibi and Jilar [12] demonstrated that this technique aims to maximize the grower economic return, and they proved that a roof-integrated desalination system in Tunisia guaranteed the plant water supply, with a rate that ranged from 1 to 1.6 kg day−1 m−2, and a system efficiency of about 40% [13]. Davies and Paton [14] studied the temperature variation trends in a seawater greenhouse in Dubai, where the cooling was achieved by an evaporative system that was equipped with fans and two cooling pads. An array of plastic pipes, which were used for the greenhouse shading, provided the back evaporative pad with hot seawater to boost the freshwater production, and the condenser was fed with cooled seawater from the front pad. The greenhouse mean temperature and the radiant temperature were decreased, respectively, by 1 °C and 7 °C. Moreover, the freshwater production was enhanced by 63% [14]. In conclusion, water production is a necessary design objective, especially in hot and arid countries, where water scarcity is increasing.

2. Advanced Cooling Systems

2.1. Renewable-Energy-Powered Cooling Systems

- (i)Solar Thermal systems

Solar thermal applications in agriculture have the advantage of the heat being generated by solar radiation. They include desalination processes, crop drying, greenhouse heating, as well as solar cooling, which is the most promising technology, given that the peaks of the cooling requirements in greenhouses match the solar radiation peaks. Solar cooling thermal systems use the thermal energy of the sun as an energy source to generate coolness. They have been widespread in protected cropping agriculture for years since they offer a zero-impact technology. Their performance has been consistently investigated and improved by coupling solar collectors to different cooling processes [2][15][16]. As was detailed in the previous sections, several experimental and numerical studies were performed on solar systems that were based on the evaporative or desiccation cooling processes [17][18][19][20][10][21]. The results show that solar cooling systems that are adapted for greenhouse units are showing satisfactory results in terms of the efficiency and the economic income. Furthermore, the reviews of the research that focus on the solar cooling processes in greenhouses [22][23][24][25][26][27] point out that these systems enhance the greenhouse energy efficiency and reduce their dependence on the grid electricity supply. High-performance solar thermal plants, which reach up to 40% [28], consist of integrating concentrating solar collectors (CSCs) into greenhouse cooling systems. The main CSCs that are integrated into protected faming fields are linear Fresnel collectors and parabolic trough solar collectors, which are usually coupled to an absorption chiller. Sonneveld et al. [29] performed an experiment on linear Fresnel collectors combined with PV cells to provide the greenhouse with hot water and electric power to be used for cooling and lighting purposes. The linear Fresnel lenses were integrated between the double glass of the southerly oriented roof cover. The Fresnel system splits direct radiation from diffuse radiation, and it concentrates it on the PV modules that are mounted within the focal line of the Fresnel lenses. As a result, the amount of solar energy that is blocked reaches 77%, which leads to a reduction in the greenhouse cooling requirements by about a factor of 4. The Fresnel system also generated 143.89 kWh m−2 of thermal energy, and 29 kWh m−2 of electrical energy, which can be exploited for further cooling by means of an evaporative system.

CSCs are usually mounted with solar tracking systems to collect the maximum radiation, and they are coupled to solar cooling processes, particularly in hot desert locations or rural areas, where electrification is difficult and expensive, and where solar resources are abundant [28]. CSCs remain particularly expensive, compared to conventional thermal power generation, and further research and development is needed on this emerging technology for power cooling systems. Alternative ways of improving the operations could be considered and applied, either for the component materials, or for the whole design, in order to enhance the system effectiveness.

- (ii)PV Solar systems

Contrary to solar thermal energy, photovoltaics enable sunlight to be directly converted into electrical power for use in cooling systems, or any other electric equipment, such as pumps, heat pumps, dryers, and artificial lighting. Ghoulem et al. [30] demonstrated that a solar cooling system, which was based on a heat pump coupled with PV panels, covered 33.2 to 67.2% of the greenhouse demand in the summer periods. Carlini et al. [31] affirm that the efficiency of PV cooling systems ranges between 30% in the summer and 11% in the winter. Actually, the capacity generated by PV cooling systems is dependent on different factors, namely, the location of the panels and their areas, as well as the greenhouse requirements.

The selection of the appropriate panel area and characteristics should accord with the energy demand and the load profile [32]. Moreover, the structure and the covering of the greenhouse with large PV panels causes extensive shading, which may contribute to a reduction in the greenhouse temperature and to plant stress in hot climates. This affects the plant growth and productivity [33][34], as light is considered to be one of the most important sources for photosynthesis.

PV panels, when installed properly and when coupled with cooling systems, show satisfying results, as was demonstrated by Al-Ibrahim et al. [35], who experimented with the use of PV panels of 14.72 kW to cover the electrical needs of a 9 × 39 m greenhouse, which was, namely, an evaporative cooling system. The PV cooling system performance was satisfactorily established since it met the required load of the greenhouse under the hot and arid conditions of Saudi Arabia. As for Ganguly et al. [36], they proved that the cooling solar plant that was tested in India, which combined a fan and pad evaporative system and PV panels, provided the coolness required for a 90 m2 greenhouse. According to them, the PV cooling system constitutes a viable option for powering stand-alone greenhouses in a self-sustained manner. The use of PV systems has expanded in recent years thanks to the decrease in the photovoltaic equipment costs [36]. The satisfactory performances of the PV cooling systems will allow this sustainable technology to be promptly implemented worldwide, and specifically in hot and rural locations.

- (iii)Geothermal cooling systems

Geothermal cooling systems, which are often referred to as “shallow geothermal systems”, consist of a ground pipe that is implanted at a depth that is inferior to 100 m, and that exploits the relatively stable low-temperature earth surface to exchange heat and deliver cooling in warm and hot climates [37]. Ground heat exchangers are mainly classified into three types: vertical, horizontal, and basket.

The earth–air heat exchanger systems have been studied and tested in several countries, and usually with satisfactory results, such as in Thailand [38], where the cooling performance and condensation impact of a horizontal earth tube system, at a depth of 1 m, was investigated. During the summer season, the generated cooling capacity of the system was about 74.84%, and the COP, which is defined as the ratio of the cooling power to the electrical input power, reached 3.56 [38]. In Kuwait [39], the greenhouse temperature reduction was about 2.8 °C for a 1.7 m ground-buried heat exchanger. Several studies also focus on geothermal heat pumps, which are vapor compression systems that use the relatively stable earth surface temperature as the heat exchange medium, instead of the outside air temperature, in order to produce either cooling or heating power. Rabbi et al. [40] show that geothermal heat pumps outperformed all the other heating methods, except for natural gas. Sanaye and Niroomand [41] performed an optimization study of a ground heat pump in Iran, which reached a capacity of 8 to 32 kW, and a coefficient of performance (COP) that varied from 3.9 to 5.4. Boughanmi et al. [42] studied the thermal performance of a conic basket heat exchanger, which was implanted at a 3 m depth and coupled to a geothermal heat pump for greenhouse cooling in the Tunisian climate.

The heat pump COP is defined as the ratio of the amount of heat extracted from the greenhouse by the compressor input power. The overall process COP is defined as the ratio between the amount of heat absorbed from the greenhouse and the total electric input power (to the compressor and the pumps). An evaluation of the thermal performance of the system shows that the heat pump COP varied from 3.9 to 4.7, and that the overall process COP ranged between 2.82 and 3.25. The maximum average temperature difference between the inlet and outlet of the geothermal process system was approximately 30 °C. Hence, the greenhouse temperature was decreased by about 12 °C.

2.2. Future Trends in Cooling Systems

- (i)Day-to-night thermal storage

During the last few years, several types of thermal storage have been exploited in greenhouses, which aim to take advantage of the available heat sources (solar gain, ground heat, exhaust heat, etc.). The thermal storage achieved by means of storage mediums, namely, water, rock bed, soil, and phase change materials (PCMs), enhanced the overall thermal performance of the greenhouse [28].

Day-to-night thermal storage is an innovative recovery process that extracts heat during the day for the purpose of using it at night. It consists of a passive system that stores the rising water that is to be served for cooling the air flow that falls through a heat exchanger during the day. The stored heat is released back inside the greenhouse during the night by the buffered water that flows in the opposite direction of the water loop (back to cold storage). As a result, the thermal storage is cooled, and the cooling capacity for the next day is recharged. As for diurnal cooling, this is achieved by naturally low air temperatures inside the closed greenhouse, as well as by plant evaporation. A first prototype of the day-to-night storage concept was reported by Buchholz et al. [8] and Zaragoza et al. [9] in Almeria, Spain, and it showed satisfactory results. Under the hot climate conditions of the region, the day-to-night storage system succeeded, without any extra energy to maintain the temperature during the day between 20 and 35 °C, which is a suitable range for crop growth. The water consumption was also reduced by 75%. Accordingly, day-to-night thermal storage constitutes a basic innovative device that can be mounted in any cooling system and that can generate important energy savings.

- (ii)Closed Desiccant Greenhouses

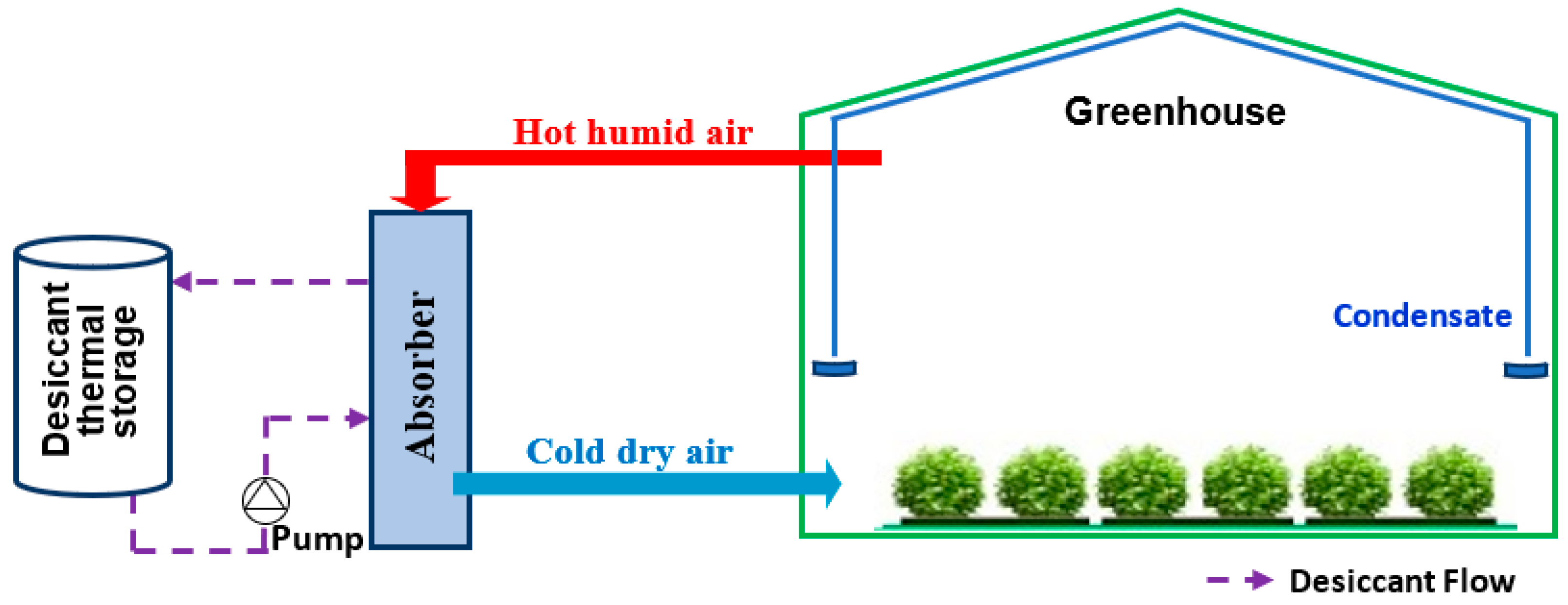

In a closed desiccant greenhouse (Figure 13), the humidity is consistently withdrawn from the hot air by a fluid desiccant that allows for the regulation of the humidity and the temperature, and for the recovery of the heat. A particular surface covering material and design can also be applied in closed desiccant greenhouses in order to guarantee condensation and the recovery of the water vapor that is evaporated by the plants.

Figure 13.

Closed desiccant greenhouse (daytime operation).

During the day, the hot humid air in the greenhouse drops in the counterflow with the cold dry fluid desiccant. Then, it reaches the crop zone as cold dry air, while the hot diluted desiccant solution is buffered in the thermal storage. Air cooling is also achieved by means of the evapotranspiration of plants. During the night, the amount of heat stored is used for the desiccant regeneration, as well as for greenhouse heating, and, hence, the evaporation process drags the humid air up into the covering surface, where it condensates and can be recovered. The main advantage of this technology is that it is independent of the air humidity [44][45][46]. Hence, its implementation is suitable either for hot arid or humid climates. In fact, the first prototype of a desiccant greenhouse, which is mounted in Cairo, Egypt, is under experimentation [21]. This emerging technology offers the substitution of energy-intensive mechanical cooling units by a low-cost and economical heat-driven solution.

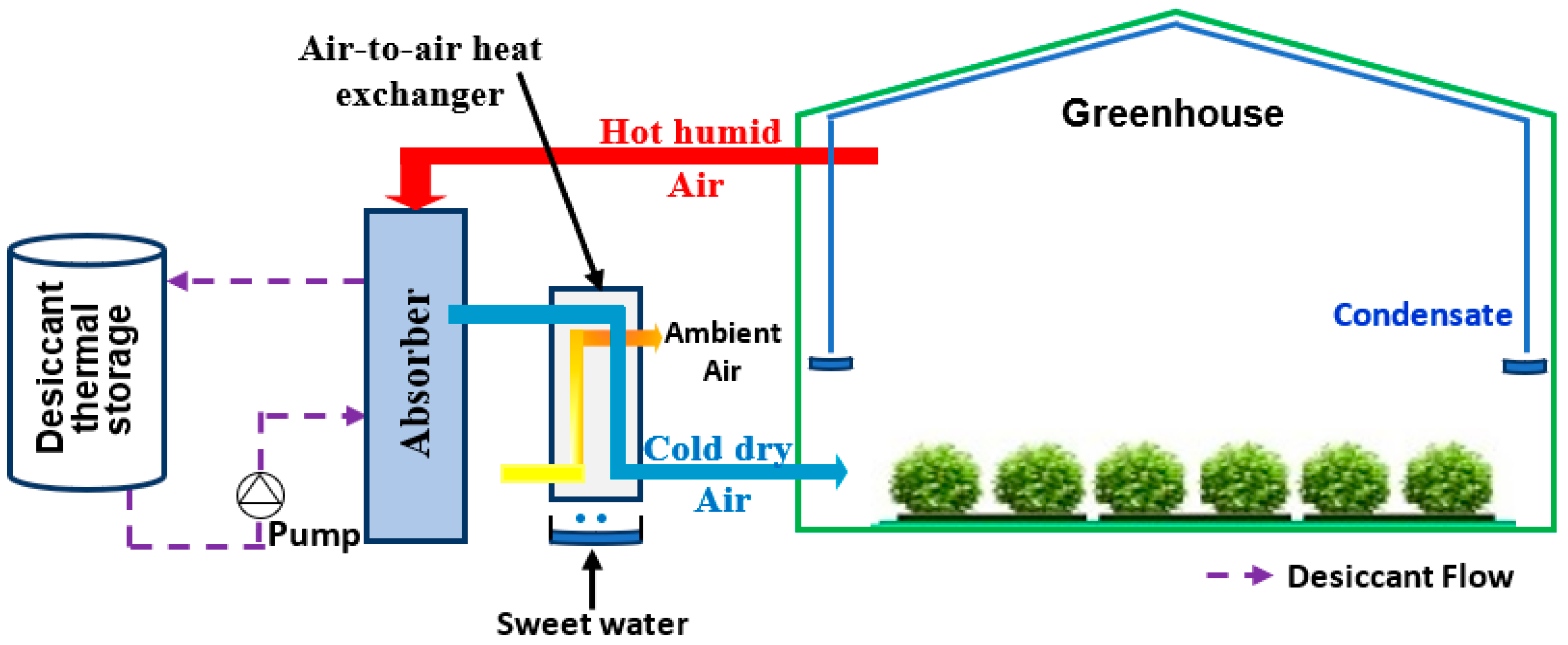

The thermal energy required for a closed desiccant greenhouse is provided either by the solar thermal energy or the residual heat. The source of the residual heat can be either the return air of the heating loop, or the unexploited heat of an industrial process, or an air-to-air heat exchanger or ground heat exchanger (Figure 142). A desiccant greenhouse that is coupled to an air-to-air heat exchanger requires less mechanical ventilation, and important heat transfer occurs without resorting to water use. In addition, this system guarantees lower temperature and humidity levels than desiccant greenhouses [47]. Actually, this system is being installed at the National Research Institute for Rural Engineering, Water, and Forestry (INRGREF) in Tunisia in order to test its performance and operational capabilities.

Figure 142.

Desiccant greenhouse with use of additional residual heat (daytime operation).

Closed desiccant greenhouses can also be coupled to a solar thermal source, such as solar ponds or solar thermal collectors, namely, concentrating solar collector systems that generate high temperatures, such as parabolic trough collectors (PTC) or Fresnel collectors [28]. Closed desiccant greenhouses also offer the opportunity of being mounted onto several existing and emerging systems, for instance, CSP plants. The waste heat of the CSP plant is harnessed into the desiccant regeneration, and the cooling energy is transferred to the CSP plant; hence, the coupling of these two technologies could be very effective if the ventilation electricity consumption is lowered. Nonetheless, it is worth developing closed desiccant greenhouse technology in a cost-effective way. For instance, coupling desiccant greenhouses to simple plastic solar absorbers, which are two magnitudes lower in cost than concentrating solar collectors, makes this technology more profitable and convenient for growers. Consequently, this technology is considered to be among the most promising future trends in greenhouses, particularly in hot and arid climates. To this end, the INRGREF has planned to continue future work on testing desiccant systems in a prototype closed greenhouse in Tunisia, using calcium chloride and magnesium chloride desiccants, with relatively low solution concentrations that do not require high temperatures for regeneration.

References

- FAO. The State of the World’s Land and Water Resources: Managing Systems at Risk; FAO: Rome, Italy; Earthscan: London, UK, 2011.

- Baudoin, W.; Baeza, E.; Teitel, M.; Kacira, M. Good Agricultural Practices for Greenhouse Vegetable Crops; FAO: Rome, Italy, 2013.

- Pardossi, A.; Tognoni, F.; Incrocci, L. Mediterranean Greenhouse Technology. Chron. Hortic. 2004, 44, 28–34.

- Abou-Hadid, A.; El-Beltagy, A. Water balance under plastic house conditions in Egypt. In Proceedings of the Protected Cultivation, XXIII IHC, Firenze, Italy, 1 February 1992; pp. 61–72.

- Yildiz, I.; Stombaugh, D.P. Heat pump cooling and greenhouse microclimates in open and confined greenhouse systems. In Proceedings of the ISHS Acta Horticulturae 719: International Symposium on Greenhouse Cooling, Almería, Spain, 24–27 April 2006; pp. 255–262.

- Perret, J.S.; Al-Ismaili, A.; Sablani, S.S. Development of a Humidification–Dehumidification System in a Quonset Greenhouse for Sustainable Crop Production in Arid Regions. Biosyst. Eng. 2005, 91, 349–359.

- Shekarchi, N.; Shahnia, F. A comprehensive review of solar-driven desalination technologies for off-grid greenhouses. Int. J. Energy Res. 2018, 43, 1357–1386.

- Buchholz, M.; Buchholz, R.; Jochum, P.; Zaragoza, G.; Pérez-Parra, J. Temperature and Humidity Control in the Watergy Greenhouse. Acta Hortic. 2006, 719, 401–408.

- Zaragoza, G.; Buchholz, M.; Jochum, P.; Pérez-Parra, J. Watergy project: Towards a rational use of water in greenhouse agriculture and sustainable architecture. Desalination 2007, 211, 296–303.

- El-Awady, M.; El-Ghetany, H.; Latif, M.A. Experimental Investigation of an Integrated Solar Green House for Water Desalination, Plantation and Wastewater Treatment in Remote Arid Egyptian Communities. Energy Procedia 2014, 50, 520–527.

- Al-Ismaili, A.M.; Jayasuriya, H. Seawater greenhouse in Oman: A sustainable technique for freshwater conservation and production. Renew. Sustain. Energy Rev. 2016, 54, 653–664.

- Chaïbi, M.; Jilar, T. Effects of a Solar Desalination Module integrated in a Greenhouse Roof on Light Transmission and Crop Growth. Biosyst. Eng. 2005, 90, 319–330.

- Chaibi, M.T. Analysis by simulation of a solar still integrated in a greenhouse roof. Desalination 2000, 128, 123–138.

- Davies, P.A.; Paton, C. The seawater greenhouse in the United Arab Emirates: Thermal modelling and evaluation of design options. Desalination 2005, 173, 103–111.

- Chen, X.; Riffat, S.; Bai, H.; Zheng, X.; Reay, D. Recent progress in liquid desiccant dehumidification and air-conditioning: A review. Energy Built Environ. 2019, 1, 106–130.

- Fekadu, G.; Subudhi, S. Renewable energy for liquid desiccants air conditioning system: A review. Renew. Sustain. Energy Rev. 2018, 93, 364–379.

- Davies, P.A. A solar cooling system for greenhouse food production in hot climates. Sol. Energy 2005, 79, 661–668.

- Abu-Hamdeh, N.H.; Almitani, K.H. Solar liquid desiccant regeneration and nanofluids in evaporative cooling for greenhouse food production in Saudi Arabia. Sol. Energy 2016, 134, 202–210.

- Alizadeh, S.; Saman, W. An experimental study of a forced flow solar collector/regenerator using liquid desiccant. Sol. Energy 2002, 73, 345–362.

- Lychnos, G.; Davies, P. Modelling and experimental verification of a solar-powered liquid desiccant cooling system for greenhouse food production in hot climates. Energy 2012, 40, 116–130.

- Nour, M.H.; Ghanem, A.; Buchholz, M.; Nassar, A. Greenhouse based desalination for brackish water management using bittern evaporative cooling technique. Water Sci. Technol. Water Supply 2015, 15, 709–717.

- Amani, M.; Foroushani, S.; Sultan, M.; Bahrami, M. Comprehensive review on dehumidification strategies for agricultural greenhouse applications. Appl. Therm. Eng. 2020, 181, 115979.

- Ghani, S.; Bakochristou, F.; ElBialy, E.M.A.A.; Gamaledin, S.M.A.; Rashwan, M.M.; Abdelhalim, A.M.; Ismail, S.M. Design challenges of agricultural greenhouses in hot and arid environments—A review. Eng. Agric. Environ. Food 2018, 12, 48–70.

- Hassanien, R.H.E.; Li, M.; Lin, W.D. Advanced applications of solar energy in agricultural greenhouses. Renew. Sustain. Energy Rev. 2016, 54, 989–1001.

- Baldwin, C.; Cruickshank, C.A. A review of solar cooling technologies for residential applications in Canada. Energy Procedia 2012, 30, 495–504.

- Daou, K.; Wang, R.; Xia, Z. Desiccant cooling air conditioning: A review. Renew. Sustain. Energy Rev. 2006, 10, 55–77.

- Alazazmeh, A.J.; Mokheimer, E.M. Review of Solar Cooling Technologies. J. Appl. Mech. Eng. 2015, 4, 15p.

- Gorjian, S.; Calise, F.; Kant, K.; Ahamed, M.S.; Copertaro, B.; Najafi, G.; Zhang, X.; Aghaei, M.; Shamshiri, R.R. A review on opportunities for implementation of solar energy technologies in agricultural greenhouses. J. Clean. Prod. 2021, 285, 124807.

- Sonneveld, P.; Swinkels, G.; van Tuijl, B.; Janssen, H.; Campen, J.; Bot, G. Performance of a concentrated photovoltaic energy system with static linear Fresnel lenses. Sol. Energy 2011, 85, 432–442.

- Ghoulem, M.; El Moueddeb, K.; Nehdi, E.; Boukhanouf, R.; Calautit, J.K. Greenhouse design and cooling technologies for sustainable food cultivation in hot climates: Review of current practice and future status. Biosyst. Eng. 2019, 183, 121–150.

- Carlini, M.; Honorati, T.; Castellucci, S. Photovoltaic Greenhouses: Comparison of Optical and Thermal Behaviour for Energy Savings. Math. Probl. Eng. 2012, 2012, 743764.

- Nakoul, Z.; Bibi-Triki, N.; Kherrous, A.; Bessenouci, M.; Khelladi, S. Optimization of a Solar Photovoltaic Applied to Greenhouses. Phys. Procedia 2014, 55, 383–389.

- Cossu, M.; Murgia, L.; Ledda, L.; Deligios, P.A.; Sirigu, A.; Chessa, F.; Pazzona, A. Solar radiation distribution inside a greenhouse with south-oriented photovoltaic roofs and effects on crop productivity. Appl. Energy 2014, 133, 89–100.

- Fatnassi, H.; Poncet, C.; Bazzano, M.M.; Brun, R.; Bertin, N. A numerical simulation of the photovoltaic greenhouse microclimate. Sol. Energy 2015, 120, 575–584.

- Al-Ibrahim, A.; Al-Abbadi, N.; Al-Helal, I. PV Greenhouse system—System description, performance and lesson Learned. Acta Hortic. 2006, 710, 251–264.

- Ganguly, A.; Misra, D.; Ghosh, S. Modeling and analysis of solar photovoltaic-electrolyzer-fuel cell hybrid power system integrated with a floriculture greenhouse. Energy Build. 2010, 42, 2036–2043.

- Ghosal, M.K.; Tiwari, G.N.; Srivastava, N.S.L.; Sodha, M.S. Thermal modelling and experimental validation of ground temperature distribution in greenhouse. Int. J. Energy Res. 2003, 28, 45–63.

- Mongkon, S.; Thepa, S.; Namprakai, P.; Pratinthong, N. Cooling performance and condensation evaluation of horizontal earth tube system for the tropical greenhouse. Energy Build. 2013, 66, 104–111.

- Al-Ajmi, F.; Loveday, D.; Hanby, V. The cooling potential of earth–air heat exchangers for domestic buildings in a desert climate. Build. Environ. 2006, 41, 235–244.

- Rabbi, B.; Chen, Z.-H.; Sethuvenkatraman, S. Protected Cropping in Warm Climates: A Review of Humidity Control and Cooling Methods. Energies 2019, 12, 2737.

- Sanaye, S.; Niroomand, B. Horizontal ground coupled heat pump: Thermal-economic modeling and optimization. Energy Convers. Manag. 2010, 51, 2600–2612.

- Boughanmi, H.; Lazaar, M.; Bouadila, S.; Farhat, A. Thermal performance of a conic basket heat exchanger coupled to a geothermal heat pump for greenhouse cooling under Tunisian climate. Energy Build. 2015, 104, 87–96.

- Gourdo, L.; Fatnassi, H.; Tiskatine, R.; Wifaya, A.; Demrati, H.; Aharoune, A.; Bouirden, L. Solar energy storing rock-bed to heat an agricultural greenhouse. Energy 2018, 169, 206–212.

- Buchholz, M. The new generation of greenhouses. In Unlocking the Potential of Protected Agriculture in the Countries of the Gulf Cooperation Council—Saving Water and Improving Nutrition; FAO: Cairo, Egypt, 2021; pp. 97–132.

- Karasu, A.; Buchholz, M.; Steffan, C. Climate Envelopes; Technical University of Berlin: Berlin, Germany, 2013.

- ElSoudani, M. Cooling Techniques for Building-Greenhouse Interconnections in Hot-Arid Climates: The Case of Red Sea, Egypt. Ph.D. Thesis, Technical University of Berlin, Berlin, Germany, 2016.

- Campen, J.B.; Bot, G.P.A. SE—Structures and Environment: Design of a Low-Energy Dehumidifying System for Greenhouses. J. Agric. Eng. Res. 2001, 78, 65–73.

More