Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 4 by Beatrix Zheng and Version 3 by Beatrix Zheng.

Rare earth elements (REEs) are key chemical raw materials in the development of low-carbon industrial processes and especially in green energy technologies. The REEs include 17 elements that can be found in nature (15 lanthanides La-Lu, Sc, and Y). They are ironically quite well represented in the Earth’s crust, except for the radioactive promethium, which is very rare. However, they are rarely found alone and at economically attractive concentrations, which make them expensive and complicated to extract and separate in high purity with conventional separation techniques.

- circular economy

- separations

- rare earths

- energy systems

- recycling

- e-waste

- critical raw materials

1. Introduction

The elemental form of Rare earth elements (REEs) can be iron-gray to metal-silvery that are reactive at high temperatures, most commonly ductile and soft. Reserves of these elements are thought to be large, but some ores involve complications in mining because of the co-presence of radioactive components. This makes the valorization of secondary resources such as e-waste or end-of-life energy systems very attractive. REEs are especially used in the production of magnets, catalysts, alloys, electronics, glasses, and ceramics. They make electric and hybrid vehicles work [2][1]. Even though their name suggests that REEs are very rare and difficult to find, most of them are quite abundant in the Earth’s overall crust. They are nevertheless hard to extract from ores because they are often linked to other minerals and occur at low concentrations. They barely exist in pure form on earth. In addition, the processes required for their extraction and mutual separation use high amounts of energy and demand complex drilling technologies. Finally, the extractive separations of REEs have inevitable problems with radioactive compounds as by-products. The demand for these elements has been importantly increasing in past years.Green energy, technology, and e-mobility strategy, now adopted by many countries are being strongly linked to the availability of REEs, and therefore the recycling of these elements is becoming increasingly important [2][1]. It is essential for the transition to a green and circular economy. Despite that, commercial recycling of REEs is still very low, mainly because of inefficient collection, technological separation challenges, and lack of incentives even though it has great potential [3,4][2][3].

Recycling could be an effective strategy to overcome the impact due to mining REEs. Targeting, the most sought metals such as neodymium (Nd) can help avoid the overproduction of low-value metals such as lanthanum (La) and cerium (Ce). In a way, it can also help to tackle the balance problem of surplus amounts of unwanted/less sought for REEs and their uneven pricing dynamics [3][2]. It is also important to determine what energy input is needed to develop this separation and recycling cycle and to see how difficult it will be to isolate the different materials products and by-products because they could also be recovered as mixed materials with less valuable purities. Finally, it is important to assess the economic feasibility of these recycling processes and rigorous separations required, as well as the availability of the feed if such processes are in place.

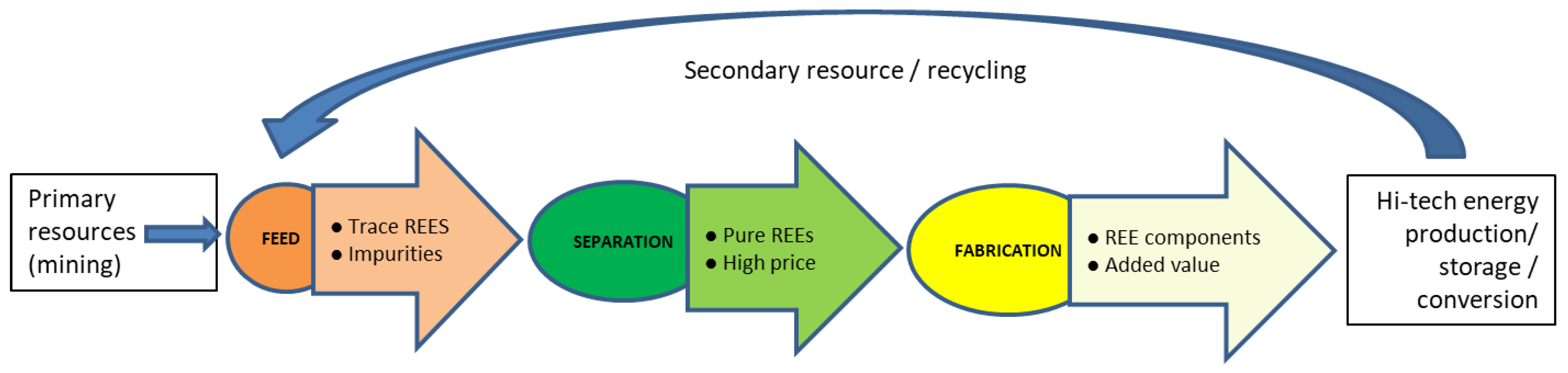

The focus area of the present research is shown in Figure 1. It is aiming to map the lifecycle of REEs in energy systems and the availability of the feedstock for the separation and recycling of rare earths and their economic viability. This is much needed as the techno-economic perspective of earlier reports and reviews has focused on the uses and the front-end material properties of the REEs [5][4]. Therefore, there remained the need to focus on back-end value chains, amount of feedstock availability, economic viability of available feedstock, and separation and recycling approaches. This can also serve as a concise summary of scattered details about the REE feed availability in different back-end energy systems.

Figure 1. Lifecycle of REE resources in energy production/storage/conversion systems and scope of the present research.

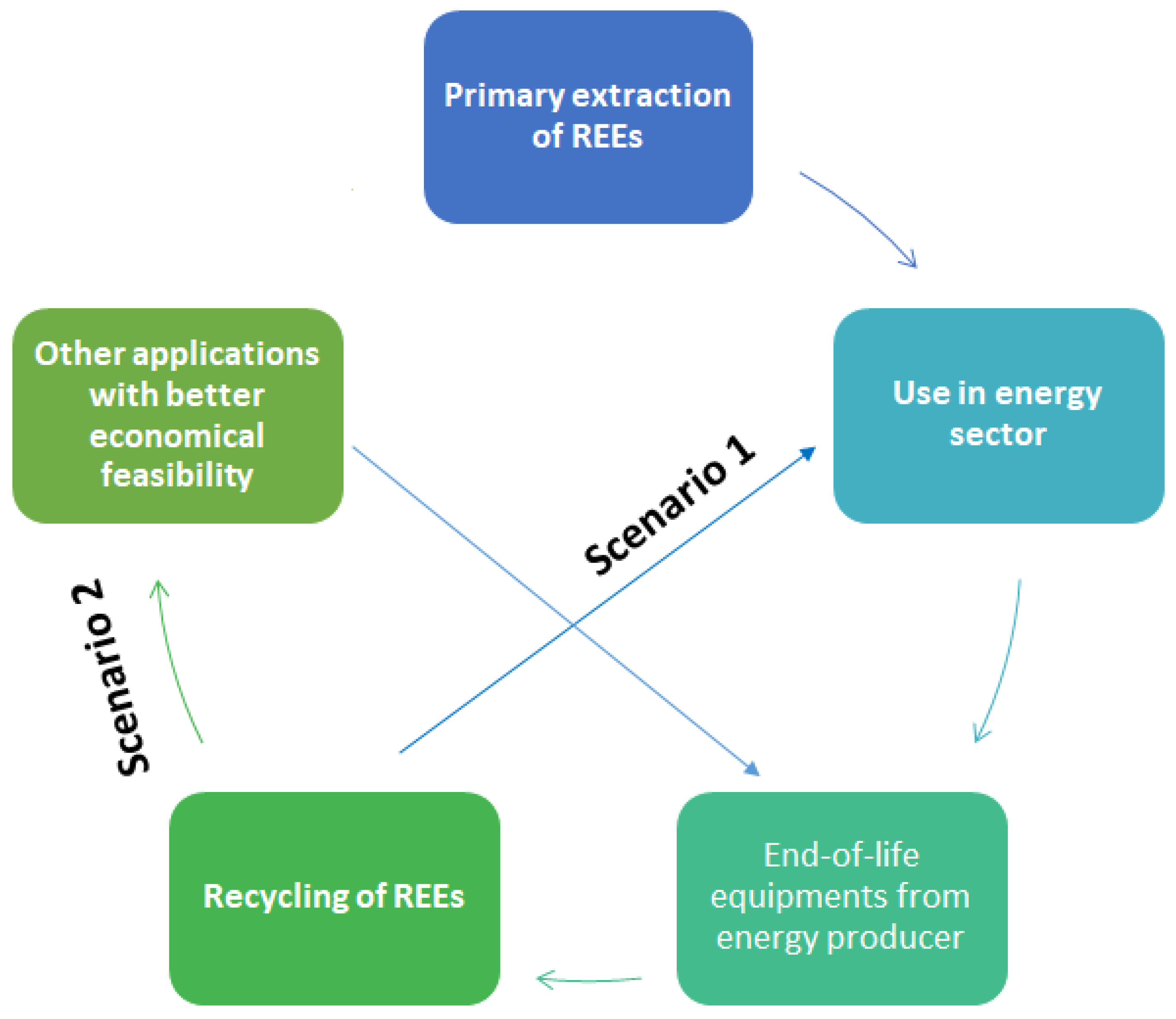

The resulting closed-loop economy of REEs could be defined as shown in Figure 2 below, by which recycled materials go back into the same energy system from which they came from (Scenario 1). A second possibility is to use recycled materials is to find other applications that require lower quality of the recovered materials. If there is an existing market with higher demand than the energy systems (Scenario 2). Therefore, there are two recycling streams of REEs possible from waste of a single energy sector [6][5].

Figure 2. Process cycle of the current research.

There is also material recovery potential with the primary production of REE-containing products at the initial manufacturing stage. They are usually referred as “recycling of production scrap”. It means that the waste is generated during the production phase. It can be directly collected and recovered at the production plants, for example, the waste from turbine magnets production or energy-saving lamps fabrication. The second step is conventionally understood as recycling and occurs at the end-of-life phase of a product as secondary production.

2. Current Insights

Most studies dealing with the recycling of REEs state the same global situation for supply, demand, and end-of-life treatment issues in energy sectors (energy generation, use, and conversion). The current recycling of REEs is extremely low (only 2% of REEs are recovered by recycling processes against 90% for iron and steel). The lower prices of the elements today harm the development of recycling technologies as well as their economic feasibility. Moreover, there is a real challenge for recycling REEs because they are found at very low concentrations in end-of-life feedstocks, and they are located very deep in the energy-relevant equipment/gadgets and therefore their access is complex. Despite the low recycling rates, REEs are not expected to be used less in the upcoming years. On the contrary, their demand is growing rapidly, and the supply will have to adapt. Recycling of REEs is thus a real topic that will develop more and more rapidly with encouraging projects from large recycling companies located in Asia in the fields of NiMH batteries and lamp phosphors, for example. Such growth is often driven by the availability of appropriate and economically viable separation technologies for different metals. Europe has a few projects as well that are being developed that are quite promising but are not yet as large as the Asian projects. It would be beneficial to enhance the cooperation between the different REE recycling companies to gain more knowledge and accelerate the learning and implementation process.

Waste from energy technologies such as batteries, lamps, and magnets represent a powerful and futuristic opportunity for REE supply chain. Recycling will add up to mining to satisfy the future REE demand. It is found that about 7% of REEs in magnet use stocks, 10% in batteries, and 17% in phosphor lighting could be recovered through recycling processes. The biggest potential seems thus to come from lamp recycling, but this depends on viable separation process developments and its economic implementation and future demands of REEs present therein. Moreover, in Europe, 10 tons of terbium and 230 tons of neodymium are estimated to be recoverable from waste streams every year. Recycling of REEs should be prioritized for elements that are short in supply (dysprosium, neodymium, europium, yttrium, and terbium). Recycling should also be focused on the most valuable elements. Therefore, high-purity REE separation processes have to be developed from the complex energy system wastes.

However, it is inevitable and necessary for rare earths from energy-relevant appliances or end-of-life feedstocks to be recycled in order to implement green technologies hereby needed for the energy transition in a circular economy. Finally, it must also be noted that there are also theoretical, technical, economical, and environmental potentials to be elaborated on in more detail in future studies.

References

- Rare Earth Element Metals Recycling: Is There Hope After All? (Part 1). (13 September 2016) and Rare Earth Element Metals Recycling: Is There Hope After All? (Part 2) (20 September 2016). Available online: https://www.thermofisher.com/blog/metals/rare-earth-element-metals-recycling-is-there-hope-after-all-part-1/; https://www.thermofisher.com/blog/metals/rare-earth-element-metals-recycling-is-there-hope-after-all-part-2/ (accessed on 16 October 2018).

- Binnemans, K.; Jones, P.T.; Blanpain, B.; Van Gerven, T.; Yang, Y.; Walton, A.; Buchert, M. Recycling of rare earths: A critical review. J. Clean. Prod. 2013, 51, 1–22.

- Binnemans, K.; McGuiness, P.; Jones, P.T. Rare-earth recycling needs market intervention. Nat. Rev. Mater. 2021, 6, 459–461.

- Zepf, V.; Reller, A.; Rennie, C.; Ashfiled, M.; Simmons, B.P. Materials Critical to the Energy Industry. An Introduction. 2nd Edition. 2014. Available online: https://dokumen.tips/documents/materials-critical-to-the-energy-industry-an-introduction-a-materials-critical.html (accessed on 17 February 2022).

- FOEN, Federal Office for the Environment. Electrical and Electronic Equipment. Available online: https://www.bafu.admin.ch/bafu/en/home/themen/thema-abfall/abfallwegweiser--stichworte-a--z/elektrische-und-elektronische-geraete.html (accessed on 23 December 2021).

More