Timber buildings can now stand very tall using new products. As timber materials are expected to be easily ignitable, the fire hazard of timber is a concern. Charring of the timber surface would maintain structural stability, but would also be accompanied by smoke. Although treating timber products with fire retardants would delay the ignition time under low radiative heat flux, toxic combustion products and unburnt fuel would be emitted immediately upon burning. More smoke and higher toxic gas concentrations such as carbon monoxide would be given off upon burning some fire retardants under high flashover heat fluxes. Due to the fast upward movement of smoke under stack effect, spreading of toxic smoke in tall timber buildings would lead to a hazardous environment. Engineered timber consists of derivative timber products. New engineered timber products are manufactured with advanced technology and design, including cross-laminated-timber (CLT), laminated veneer lumber (LVL) and glue-laminated timber (Glulam). The fire behaviour of timber products has been studied for several decades. However, the smoke hazards of using new timber products in building construction should be monitored. The objective of this study is to inspire stakeholders in fire safety of timber buildings, inter alia smoke hazards, to use new timber products to build tall buildings.

- tall timber buildings

- fire hazards

- smoke hazards

- public concerns

- new timber products

1. Introduction

2. Fire-Resisting Construction Requirements

3. Fire Studies of Timber

4. Smoke Hazards of Wood and Wood-Based Products

5. Use of Timbers in Multi-Storey Building Construction over the World

| Building Name | Stories | City, Country | Year of Completion |

|---|---|---|---|

| Mjøstårnet | 18 | Brumunddal, Norway | 2018 |

| HAUT | 21 | Amsterdam, The Netherlands | 2019 |

| Brock Commons | 18 | Vancouver, Canada | 2017 |

| Treet | 14 | Bergen, Norway | 2015 |

| Origine | 13 | Quebec, Canada | 2017 |

| Framework | 12 | Portland, Oregon, United States | 2018 |

| Leader’s Building | 12 | Wellington, New Zealand | 2018 |

| 25 King | 10 | Brisbane, Australia | 2018 |

| Trafalgar Place | 10 | London, United Kingdom | 2015 |

| Forte | 10 | Melbourne, Australia | 2012 |

| Dalston Lane | 10 | London, United Kingdom | 2008 |

| Moholt 50/50 | 9 | Trondheim, Norway | 2016 |

| Cenni di Cambiamento | 9 | Milan, Italy | 2013 |

| Stadthaus | 9 | London, United Kingdom | 2009 |

| Murray Grove | 9 | Hackney, Finland | 2009 |

6. Fire Safety Concerns on Timber Buildings and the Way Forward

- (i)

-

Public perception. The fire safety of timber buildings, even up to very recently, has been a major concern [2][12]. This forms an obstacle to the development of timber buildings according to surveys in Australia and China [40][41]. Compared with conventional concrete buildings, the knowledge of fire safety of timber buildings may not be adequately digested by professionals even in developed countries [42][43].

- (ii)

-

Training for professionals. Besides the perception of the fire safety of timber buildings, another obstacle is the lack of provision of training for professionals in this area. As multi-storey timber buildings are becoming more popular, the training of professionals in the fire safety of timber buildings is an important area in the development of the building industry. There are articles on wood and evolving codes for timber buildings [44]. A presentation on knowledge related to the fire safety of tall wood buildings was delivered by the Wood Products Council [45]. In response to the higher occurrence rate of fire incidents during the construction phase of timber buildings, the Structural Timber Association has published a design guide with particular guidance on separating distances during construction [46]. Others reported [47][48] fire safety issues of timber buildings, or provided educational and information resources on the fire safety of timber buildings.

- (iii)

-

Research. More research should be carried out to identify the difference in fire characteristics, related safety issues, and rescue strategy between concrete buildings and timber buildings. Without extensive research work to identify the difference, it is very difficult and also unreliable to translate current knowledge on fire safety for conventional buildings to timber buildings. Specifically, smoke spread in tall timber buildings, as discussed in this paper, has not yet been handled thoroughly. While the behaviour and performance of timber products such as CLT and glulam have been quite extensively studied, the structural integrity of a timber building has not been adequately investigated [49]. In fire hazard assessment, thermal effects under an agreed design fire described by heat release rate such as 10 MW was studied. Smoke hazards were neglected in many projects [50] assessing fire hazards, thus erroneously and dangerously giving longer Available Safe Egress Time [51][52].

- (iv)

-

Codes and regulations. Regulations, codes and guidelines specifically for the fire safety of timber buildings have to be formulated. Recently, Kincelova et al. [53] proposed a building–information–modelling (BIM) approach to improve fire protection aspects in compliance with fire safety regulations in timber buildings. As reported by Nomura et al. [54], the Japanese government has been promoting wider use of wood buildings. Construction of larger-scale timber building is allowed recently in many other countries. Requirements of external fire spread between buildings and impact on fire safety codes were studied. As reported by Hagiwara [55], Building Standard Law in Japan was reviewed in 2014 to include large buildings constructed with timber, and in 2018, for the promotion of wood utilization. Future directions will be on further relaxation and promotion of timber construction and members. Fire spread and evacuation requirements are imposed. Assessing smoke toxicity is not yet observed, apart from enhancing evacuation strategy.

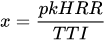

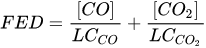

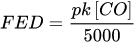

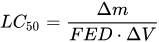

7. Recommendation on Assessing Smoke Hazard

8. Conclusions

References

- Vlosky, R.P. Louisiana Forest Products Development Center, Tall timber: A Global Audit. CTBUH J. 2017, 2, 47–49.

- Chow, W.K.; Ng, Y.W.; Yue, T.K. Case study for a high-rise residential building using cross-laminated timber. SFPE Fire Prot. Eng. Mag. 2018, 79, 37–42.

- Stora Enso. CLT Documentation on Fire Protection. 2013. Available online: http://www.clt.info/clt-documentation-on-fire-protection/ (accessed on 22 November 2021).

- Yadav, R.; Kumar, J. Engineered Wood Products as a Sustainable Construction Material: A Review. 2021. Available online: https://www.intechopen.com/online-first/78315 (accessed on 22 November 2021).

- Connolly, T.; Loss, C.; Iqbal, A.; Tannert, T. Feasibility study of mass-timber cores for the UBC tall building. Buildings 2018, 8, 98.

- Salminen, M.; Hietaniemi, J. Performance-based fire design of a 14-storey residential mass timber building. In Proceedings of the International Conference of Applications of Structural Fire Engineering, (ASFE 2017), Manchester, UK, 7–8 September 2017.

- Brandon, D. Engineering Methods for Structural Fire Design of Wood Buildings–Structural Integrity during a Full Natural Fire. 2018. Available online: https://www.brandforsk.se/en/research-projects/2018/engineering-methods-for-structural-fire-design-of-wood-buildings-structural-integrity-during-a-full-natural-fire/ (accessed on 22 November 2021).

- Wiesner, F.; Bisby, L.A.; Bartlett, A.I.; Hidalgo, J.P.; Santemaria, S.; Deeny, S.; Hadden, R.M. Structural capacity in fire of laminated timber elements in compartments with exposed timber surfaces. Eng. Struct. 2019, 179, 284–295.

- Chow, W.K.; Fang, M.X.; Luo, Z.Y.; Cen, K.F. Fire safety concern for timber partition in the Far East. Int. J. Eng. Perform.-Based Fire Codes 2005, 7, 148–154.

- Shen, D.K.; Fang, M.X.; Chow, W.K. A review on ignition of cellulose materials under external heat flux. Int. J. Eng. Perform. Based Fire Codes 2006, 8, 28–42.

- Kodur, V.R.; Benichou, N.; Sultan, M.A. Behaviour of load-bearing wood-stud shear walls exposed to fire. In Proceedings of the Interflam 2001, 9th International Fire Science & Engineering Conference, Scotland, UK, 17–19 September 2001; Volume 2, pp. 1369–1374.

- Chow, W.K.; Ng, Y.W.; Yue, T.K. Case study on high-rise residential building using CLT in Hong Kong. In Proceedings of the 12th International Conference on Performance-Based Codes and Fire Safety Design Methods, Honolulu, HI, USA, 23–27 April 2018.

- Gerard, R.; Barber, D.; Wolski, A. Fire Safety Challenges of Tall Wood Buildings—Phase 1: Final Report 2013; Fire Protection Research Foundation, NFPA: Quincy, MA, USA, 2013.

- Janssens, M.L. Modeling of the Thermal Degradation of Structural Wood Members Exposed to Fire. In Proceedings of the Second International Workshop «Structures in Fire», Christchurch, New Zealand, 18–19 March 2002.

- Atreya, A.; Olszewski, P.; Chen, Y.; Baum, H.R. The effect of size, shape and pyrolysis conditions on the thermal decomposition of wood particles and firebrands. Int. J. Heat Mass. Transf. 2017, 107, 319–328.

- Richter, F.; Atreya, A.; Kotsovinos, P.; Rein, G. The effect of chemical composition on the charring of wood across scales. Proc. Combust Inst. 2019, 37, 4053–4061.

- Chow, W.K. Moisture content of timber species in Hong Kong. Constr. Build. Mater. 1990, 4, 68–72.

- Koo, J.H.; Wootan, W.; Chow, W.K.; Au Yeung, H.W.; Venumbaka, S. Flammability studies of fire retardant coatings of wood. In Proceedings of the Fire and Polymer Symposium, American Chemical Society National Meeting, Washington, DC, USA, 20–25 August 2000; Volume 83, pp. 51–52.

- Chow, W.K.; Han, S.S.; Chow, C.L. Fire behaviour of timber products with and without fire retardant. J. Appl. Fire Sci. 2002, 3, 209–227.

- Brandon, D.; Sjöström, J.; Hallberg, E.; Temple, A.; Kahl, F. Fire Safe Implementation of Visible Mass Timber in Tall Buildings—Compartment fire Testing (Summary Report); RISE Report 2020:94; Research Institute of Sweden: Gothenburg, Sweden, 2021.

- Schmid, J.; Voulpiotis, K.; Klippel, M.; Jockwer, R.; Frangi, A. Robustness in fire—possibilities for tall timber buildings. In Proceedings of the WCTE 20, World Conference on Timber Engineering, Santiago, Chile, 24–27 August 2020.

- Brandon, D.; Östman, B. Fire Safety Challenges of Tall Wood Buildings—Phase 2: Task 1—Literature Review; Report FRFP-2016-22; Fire Protection Research Foundation: Quincy, MA, USA, 2016.

- Östman, B.; Brandon, D.; Frantzich, H. Fire safety engineering in timber buildings. Fire Saf. J. 2017, 91, 11–20.

- Hoehler, M.S.; Su, J.; Lafrance, P.S.; Bundy, M.F.; Kimball, A.; Brandon, D.; Östman, B. Fire safety challenges of tall wood buildings: Large-scale cross laminated timber compartments fire tests. In Proceedings of the SiF 2018-The 10th International Conference on Structures in Fire, FireSERT, Belfast, UK, 6–8 June 2018.

- Su, J.Z.; Lougheed, G.D. Report to Research Consortium for Wood and Wood Hybrid Mid-Rise Buildings—Fire Safety Summary; Report: A1-004377.1; Nation Research Council: Ottawa, ON, Canada, 2014.

- Li, X.; McGregor, C.; Medina, A.; Sun, X.; Barber, D.; Hadjisophocleous, G. Real-scale fire tests on timber constructions. In Proceedings of the World Conference on Timber Engineering, Vienna University of Technology, Vienna, Austria, 22–25 August 2016.

- Lindsay, R.; Dagenais, C.; Benichou, N. Solutions for Upper Mid-Rise and High-Rise Mass Timber Construction; FPInnovations: Vancouver, BC, Canada, 2019.

- Chow, W.K. Use of Computational Fluid Dynamics for simulating enclosure fires. J. Fire Sci. 1995, 13, 300–334.

- Chow, W.K. Use of zone models on simulating compartmental fires with forced ventilation. Fire Mater. 1995, 19, 101–108.

- Chow, W.K. Application of Computational Fluid Dynamics in building services engineering. Build. Environ. 1996, 31, 425–436.

- Dembsey, N.A.; Meacham, B.J.; Wang, H.G.; Kamath, P. Fire Modeling Results for Sprinkler Trade-Offs Related to Building Size/Egress, Unprotected Opening Areas and Fire Resistance Ratings for Selected R-2 Occupancies; Fire Protection Engineering, Worcester Polytechnic Institute: Worcester, MA, USA, 2018.

- Kmiecik, K. The influence of the fire source location on the load-bearing capacity of timber beam exposed to fire. In Fire and Environmental Safety Engineering 2018, Proceedings of the MATEC Web of Conferences, Lviv, Ukraine, 7–8 November 2018; EDP Sciences: Les Ulis, France, 2018; Volume 247, p. 247.

- Tian, D.H.; Wu, X.S.; Song, Z.G.; Wang, H.Y. Reverse analysis for fire pyrolysis parameters of timber buildings based on response surface method. Proc. Eng. 2016, 135, 19–24.

- Dârmon, R.; Suciu, M. Smoke ventilation strategy for a timber structure building. Proc. Manuf. 2018, 22, 249–255.

- Cholin, J.H. Wood and Wood-Based Products. In Fire Protection Handbook, 20th ed.; Cote, A.E., Ed.; National Fire Protection Association: Quincy, MA, USA, 2008; pp. 6–73.

- Department of Health. Exposure to Smoke from Fires. 2019. Available online: https://health.ny.gov/environmental/outdoors/air/smoke_from_fire.htm (accessed on 22 November 2021).

- Milke, J.A.; Klote, J.H. Smoke Movement in Buildings. In Fire Protection Handbook, 20th ed.; Cote, A.E., Ed.; National Fire Protection: Quincy, MA, USA, 2008; pp. 18–46.

- Hirst, R. Underdown’s Practical Fire Precautions, 3rd ed.; Gower Technical: Aldershot, UK, 1989.

- Vlosky, R.P. Louisiana Forest Products Development Center, Tall timber: A Global Audit. CTBUH J. 2017, 2, 47–49.

- Hu, Q.N.; Dewancker, B.; Zhang, T.; Wongbumru, T. Consumer attitudes towards timber frame houses in China. Proc. Soc. Behav. Sci. 2016, 216, 841–849.

- Xia, B.; O’Neill, T.; Zuo, J.; Skitmore, M.; Chen, Q. Perceived obstacles to multi-storey timber-frame construction: An Australian study. Archit. Sci. Rev. 2014, 57, 169–176.

- Barber, D. Fire Safety of CLT and Mass Timber Buildings. Construction Executive. 2018. Available online: https://constructionexec.com/article/fire-safety-of-clt-and-mass-timber-buildings (accessed on 14 December 2021).

- Barber, D. Tall Timber Buildings: What’s Next in Fire Safety? Fire Tech. 2015, 51, 1279–1284.

- Hunt, A.A. Wood and Evolving Codes: The 2018 IBC and Emerging Wood Technologies. Available online: https://www.thinkwood.com/education/modern-building-codes-keeping-pace-wood-revolution (accessed on 22 November 2021).

- Gerard, R. Fire Safety of Tall Wood Buildings: A Research Review; The Wood Products Council: San Francisco, CA, USA, 2014.

- Structural Timber Association. Design Guide to the Separating Distances during Construction; Version 3.3; Structural Timber Association: Alloa, UK, 2017.

- Francis, S.; Smart, J. Fire Tests in Support of Tall Mass Timber Buildings, American Wood Council Course DES603, The Wood Institute, American Wood Council. 2018. Available online: https://www.woodinstitute.org/enrol/index.php?id=104 (accessed on 1 December 2021).

- PRISM Media. Think Wood: Think Wood Research Library Answers Industry Call for More Research. 2018. Available online: https://prismpub.com/think-wood-research-library-answers-industry-call-for-more-research/ (accessed on 1 December 2021).

- Brandon, D.; Just, A.; Andersson, P.; Östman, B. Mitigation of Fire Damages in Multi-Storey Timber Buildings—Statistical Analysis and Guidelines for Design. Report:43 2018. Available online: https://www.brandforsk.se/wp-content/uploads/2020/03/brandforsk_302_151_rapport_2.pdf (accessed on 14 December 2021).

- Huang, L.; Ma, J.; Li, A.; Wu, Y. Scale modeling experiments of fire-induced smoke and extraction via mechanical ventilation in an underground hydropower plant. Sustain. Cities Soc. 2019, 44, 536–549.

- Babrauska, V.; Fleming, J.M.; Russell, B.D. RSET/ASET, a flawed concept for fire safety assessment. Fire Mater. 2010, 34, 341–355.

- Chow, W.K. Letter to the Editor: Comment on “RSET/ASET, a flawed concept for fire safety assessment” by Babrauskas, V., Fleming, J.M., Russell, B.D., Fire Mater 2010, 34, 341–355. Fire Mater. 2013, 37, 257–258.

- Kincelova, K.; Boton, C.; Blanchet, P.; Dagenais, C. Fire safety in tall timber building: A BIM-based automated code-checking approach. Buildings 2020, 10, 121.

- Nomura, E.; Hagiwara, I.; Ohmiya, Y. International comparison of fire safety code on prevention of fire spread between buildings: Target at opening and façade. AIJ J. Technol. Des. 2015, 21, 163–166.

- Hagiwara, I. “Recent revisions of the Building Standard Law and research topics related to safe evacuation”. In Proceedings of the Seminar of the 8th Forum for Advanced Fire Education/Research in Asia, Tokyo University of Science, Tokyo, Japan, 28 October 2021.

- Lui, G.C.H.; Chow, W.K. A demonstration on working out fire safety management schemes for existing karaoke establishments in Hong Kong. Int. J. Eng Perform.-Based Fire Codes 2000, 2, 104–123.

- Hagen, R.; Heijmen, D.; Siaens, I. European Fire Safety Plan; European Fire Safety Alliance: Beverwijk, The Netherlands, 2020.

- International Fire Safety Standards. Global Plan for a Decade of Action for Fire Safety. 2021. Available online: https://www.rics.org/globalassets/rics-website/media/knowledge/decade-of-action-for-fire-safety_oct2021.pdf (accessed on 22 November 2021).

- Dekui, S.; Rui, X.; Mengxiang, F.; Wanki, C. Thermal-balanced integral model for pyrolysis and ignition of wood. Korean J. Chem. Eng. 2013, 30, 228–234.

- Chow, C.L.; Han, S.S.; Chow, W.K. (VCDBox1) Smoke toxicity assessment of burning video compact disc boxes by a cone calorimeter. J. Appl. Fire Sci. 2002, 11, 349–366.

- Chow, W.K.; Han, S.S. (ConeVCD2A1) Studies on fire behaviour of video compact disc (VCD) materials with a cone calorimeter. Polym. Test 2004, 23, 685–694.

- Han, S.S.; Chow, W.K. (SNFED) Calculating FED and LC50 for testing toxicity of materials in bench-scale tests with a cone calorimeter. Polym. Test 2005, 24, 920–924.

- Han, S.S.; Chow, W.K. (ConePC1) Cone calorimeter studies on fire behaviour of polycarbonate glazing sheets. J. Appl. Fire Sci. 2003, 12, 245–261.

- Corbett, G.P. Effect of Building Construction and Fire Protection Systems on Fire Fighter Safety. In Fire Protection Handbook, 6th ed.; Cote, A.E., Ed.; National Fire Protection: Quincy, MA, USA, 2008; pp. 12–137.

- Chow, W.K.; Zhao, J.H. (JFS_BriefStackSM11B) Scale modeling studies on stack effect in tall vertical shafts. J. Fire Sci. 2011, 29, 531–542.

- Leung, C.W.; Chow, W.K.; Zou, G.; Dong, H.; Gao, Y. (ATPMwRC1) Preliminary experimental results on fire behaviour of timber partition materials with a room calorimeter. Int. J. Eng Perform.-Based Fire Codes 2005, 7, 107–127.

- Ivanov, M.L.; Chow, W.K.; Yue, T.K.; Tsang, H.L.; Peng, W. Upgrading of fire safety requirement for tall buildings in Bulgaria and proposal of implementing fire safety management under facility management. Facilities 2022, 40, 380–393.