Here, we aim to assess the current modelling and experimental achievements in the design for additive manufacturing of bonded joints, providing a summary of the current state of the art. To limit its scope, the document is focused only on polymeric additive manufacturing processes. As a result, this work contains a structured collection of the tailoring methods adopted for additively manufactured adherends and adhesives with the aim of maximizing bonded joint performance.

- additive manufacturing (AM)

- adhesively bonded joint

- polymer

- fused filament fabrication (FFF)

- selective laser sintering (SLS)

- polijet

- photo-polymerization

- design for AM

- review

1. Introduction

The industrial interest in additive manufacturing (AM) has been a driving factor behind the development of modern 3D printer machines [1] and their novel features, such as multi material AM (MMAM) simultaneous processing [2]. This interest has led to increased process standardization [3] besides the adoption of new design approaches for additive manufacturing (DfAM) [4], and new materials. DfAM urges us to rethink component design by taking in account both the specific constraints and new opportunities created by the AM processes. Many studies have analyzed these constraints, demonstrating how positioning for printability, printing parameters and printing set ups can affect the surface finishing, geometrical accuracy and the mechanical properties of the resultant components [4][5][6][7].

As the knowledge in DfAM increases, so too does the potential of additive manufacturing (AM). Although still limited by a relatively modest production rate, if compared to traditional manufacturing processes, AM finds practical use in the production of highly optimized components of limited size to be assembled in larger structures [8]. Moreover, this approach addresses the exponential relationship between building volume and printer cost and allows us to improve productivity using several 3D printers working in parallel, avoiding complete stoppages of production during maintenance [9]. However, the design approach that focuses on splitting the components in order to overcome current AM processes limitations introduced above, requires the use of an effective joining procedure to create a larger final product from the smaller subassemblies.

One of the earliest works on joining AM components was carried out by Espalin et al. [10], in which the authors identified the techniques suitable for assembling polymeric AM components, which include ultrasonic spot welding, hot air welding, solvent joining and adhesive joining, and another was carried out by Arenas et al. [11], in which a method was proposed to select structural adhesives for AM.

Subsequent studies explored joint performance improvements using AM as a joining tool, the AddJoining process [12][13] with or without co-curing, and a voxel-oriented design [14] approach. A hybrid approach combining the first two solutions was also considered. The AddJoining process consists in 3D printing the substrates and the joint simultaneously, using the structure as the build plate. The voxel-oriented design approach consists in exploring the local material control conferred by AM with previously acquired know-how on adhesive bonding [15] to develop new joint design solutions.

2. Joint Design Strategies for Additive Manufacturing

The process of optimizing the design of bonded joints can be briefly described as maximizing the load carrying capacity of assembled components in order to withstand higher service loads. Initially, joint design strategies were based on selecting materials with better material properties and on maximizing the bonding area. Later, with the growing need for developing lightweight structures, the investigations on the physics of the adhesion and the advances in modelling techniques enabled the development of alternative joint design strategies [16]. These design strategies are based on a better understanding of stresses acting on the adhesive layer, on the adhesive and of the effect of adherends material properties. This knowledge is implemented in novel geometrical configurations in order to lower peel and cleavage stresses [17]. Even if the overall joint design is a compromise between an optimal geometrical configuration and constraints on components sizes, more localized solutions can be implemented in order to change the stress distribution in the bondline. Adhesive stiffness is a major factor that affects the stress distribution along the overlap [18], thus a locally modified adhesive [19] can improve the strain tolerance of the joint and delay failure. Another option to improve the stress distribution in the adhesive can be to locally modify the adherend geometry [20] achieved; for example, by tapering the adherends at the overlap ends to lower the stiffness, and thus stress in these critical locations. Another approach that can be used to improve the level of adhesion [21] is the use of chemical or mechanical treatments, to modify the bonding surfaces. All of these design concepts can be taken to an extreme by exploiting the material properties and geometrical AM controlled at the voxel resolution [14]. In this section, the use of AM to improve joint design is discussed in detail, sorting the works as detailed in Figure 1.

Figure 1. Macro sorting of the design strategies for additive manufacturing (AM) bonded joints.

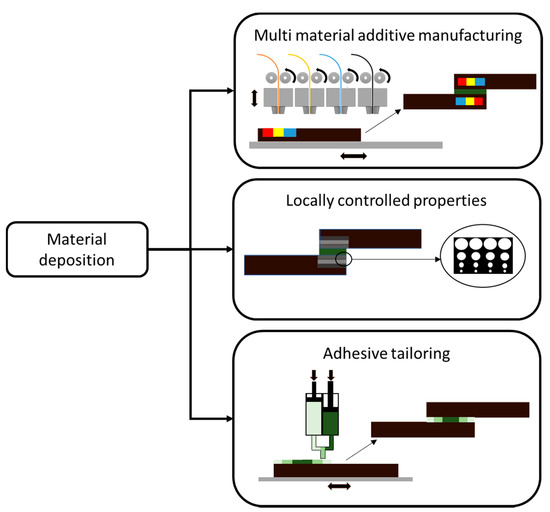

2.1. Material Tailoring

Material tailoring as design strategy is the use of AM to locally change the material properties in the joint. This approach can be implemented by simultaneous deposition of different materials, for example with MMAM [2] in order to obtain functionally graded adherends and adhesives. This is a design concept that has already been investigated for other manufacturing processes [19][22]. Another option can be using AM to create complex structures in the thickness direction, such as a lattice, cellular or auxetic structures, which will guide the deformation under load of the joint and affect the modulus by introducing controlled porosity ( Figure 2 ).

Figure 2. Voxel oriented material deposition design strategies for AM bonded joints.

2.2. Overlap Geometry Tailoring

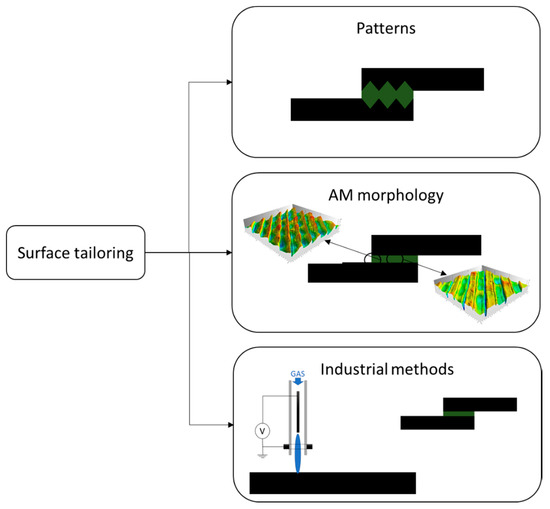

The aim of the overlap tailoring is to improve the performance of adhesive bonded joints performance with an optimized geometrical design of the adherend in the overlap area. The approaches presented here were often originally proposed for laminate materials [20][23], which have many similarities to AM processed components, such as a layering effect and an anisotropic behavior under load [24].

The AM design strategies to increase the bonding area or to modify surface properties are shown in Figure 3. At macro-scale, adherend modifications can be achieved by including features such as pins or wavy interfaces. At micro-scale, AM process parameters, such as layer height or nozzle temperatures, can be used to finely modify surface properties, leading to changes in the morphology. Some surface modifications suitable for industrial contexts were also investigated.

Figure 3. AM design strategies for tailoring the adherend at surface overlap.

3. ConclusOvervionsew

Different design strategies have been investigated to take advantage of the beneficial effect of voxel size control provided by additive manufacturing on the geometry and material properties.q

Most of the works focused on additively manufactured adherend tailoring. Kumar et al. [25][26] and Khan et al. [27][28][29] in their works modelled the stress distributions of joints using functionally graded materials achieved with digital materials and Ubaid et al. [30] experimentally assessed load carrying and toughness improvements due to a modified strain field distribution in the bondline using single lap joints and digital image correlation.

Other authors focused on the so-called geometrical-complexity-for-free provided by additive manufacturing processes and used tailoring of adherends at the bonding interface and in the thickness. The first approach is used to create the desired pattern able to provide mechanical interlocking and increase the area at the interface between adherend and adhesive. Several authors [31][32][33][34] used geometrical patterns indented in the adherend thickness to maximize the overlap area, while others [25][35] used patterns protruded in the bondline to seek mechanical interlocking and to alter the strain distribution in the adhesive.

The second approach draws inspiration from organisms that show high adhesion and toughness. Using a fracture mechanics-based approach, several authors [36][37][38][39] developed through the thickness structures able to delay crack propagation and the failure of the joints.

The results of these works provided the first quantification of the effects of tailored additively manufactured adherends and highlighted the advantages and disadvantages of this design approach. Major limitations are due to the minimum size of the printable features, inherent to a given additive manufacturing process specifications, and the effect of the tailoring on the adherend stiffness. Indeed, an unsuccessful tailoring procedure can increase the susceptibility to bending, leading to increased peel stress in the bondline and causing failure at loads lower than that of a non-tailored joint configuration.

New developments in additive manufacturing processes, such as the multi material additive manufacturing and the use of new materials, are enabling different design solutions, such as the creation of functionally graded adherends or embedded sensors, although they urgently require the development of new testing methods and standards to address the resultant complex material response. Available results indicate that this approach can improve joints' performance, although it is still common for joints manufactured using additive manufacturing technology to fail predominantly by adhesive failure, pointing out that further performance improvements can be achieved by improving the quality of surface treatments and material compatibility.

A possible solution for these limitations could be the combination of several different design approaches for the manufacture of the adherends or the use of surface modifications. Some of the studies applied surface modifications which are already in industrial use [40][41][42][43], while others [9][32][34][44][45][46] explored how the printing parameters affect the physical and the mechanical properties of the polymeric adherends. Plasma treatment was assessed as the most effective surface modification for this purpose as it is suitable for use in hollow structures and has the potential of being process integrated. For example, an FFF printer can include a plasma torch on the nozzle. On the other hand, while tailoring the printing parameters does not require any additional equipment or post processing, it can be a highly complex process, as the interaction between different parameters can lead to unexpected and undesirable results.

Some authors explored the feasibility of using additive manufacturing to tailor the bondline by controlling the adhesive composition or shape [47][48][49][50][51]. The main benefits of this approach are the compatibility with non-additively manufactured adherends and the improved joint quality, as the adhesive layer is relatively free from porosities and possesses high geometrical accuracy and reproducibility. Such local control has the potential to enable the manufacturing of true functionally graded adhesives by controlling adhesives' composition, adhesives' mixing, or the dispersion of reinforcements in the adhesives. This concept has been successfully demonstrated in laboratorial settings, but no commercial solution is available at the time of writing this document.

Finally, tailoring additively manufactured adherends and adhesives, following a design for additive manufacturing approach, has proven to be an extremely useful, yet relatively unexplored, solution to improve the performance of adhesively bonded joints. While many researchers have laid the foundations for more extensive use of additive manufacturing in conjunction with adhesive bonding, additional research is still required to enhance manufacturing reliability and repeatability. Another important conclusion of this work is that aspects related to the degradation and long-term durability of polymeric additively manufactured bonded joints are relatively unstudied. This represents a topic of great interest for industrial applications and must certainly be an important subject of research in the coming years.

References

- Ali, M.H.; Batai, S.; Sarbassov, D. 3D printing: a critical review of current development and future prospects. Rapid Prototyp. J. 2019, 25, 1108–1126, doi:10.1108/RPJ-11-2018-0293.

- Rafiee, M.; Farahani, R.D.; Therriault, D. Multi-Material 3D and 4D Printing : A Survey. 2020, 1902307, 1–26, doi:10.1002/advs.201902307.

- Monzón, M.D.; Ortega, Z.; Martínez, A.; Ortega, F. Standardization in additive manufacturing: activities carried out by international organizations and projects. Int. J. Adv. Manuf. Technol. 2014, 76, 1111–1121, doi:10.1007/s00170-014-6334-1.

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. - Manuf. Technol. 2016, 65, 737–760, doi:10.1016/j.cirp.2016.05.004.

- Huang, J.; Chen, Q.; Jiang, H.; Zou, B.; Li, L.; Liu, J.; Yu, H. A survey of design methods for material extrusion polymer 3D printing. Virtual Phys. Prototyp. 2020, 0, 1–15, doi:10.1080/17452759.2019.1708027.

- Ulu, E.; Gecer Ulu, N.; Hsiao, W.; Nelaturi, S. Manufacturability Oriented Model Correction and Build Direction Optimization for Additive Manufacturing. J. Mech. Des. 2020, 142, doi:10.1115/1.4045107.

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166, doi:10.1016/j.polymertesting.2018.05.020.

- Polenz, S.; Oettel, M.; López, E.; Leyens, C. Hybrid Process Chain from Die Casting and Additive Manufacturing. Light. Des. Worldw. 2019, 12, 44–49, doi:10.1007/s41777-019-0021-8.

- Bürenhaus, F.; Moritzer, E.; Hirsch, A. Adhesive bonding of FDM-manufactured parts made of ULTEM 9085 considering surface treatment, surface structure, and joint design. Weld. World 2019, 63, 1819–1832, doi:10.1007/s40194-019-00810-4.

- Espalin, D.; Arcaute, K.; Anchondo, E.; Adame, A.; Medina, F.; Winker, R.; Hoppe, T.; Wicker, R. Analysis of bonding methods for FDM-manufactured parts. 21st Annu. Int. Solid Free. Fabr. Symp. - An Addit. Manuf. Conf. SFF 2010 2010, 37–47.

- Arenas, J.M.; Alía, C.; Blaya, F.; Sanz, A. Multi-criteria selection of structural adhesives to bond ABS parts obtained by rapid prototyping. Int. J. Adhes. Adhes. 2012, 33, 67–74, doi:10.1016/j.ijadhadh.2011.11.005.

- Falck, R.; Goushegir, S.M.; dos Santos, J.F.; Amancio-Filho, S.T. AddJoining: A novel additive manufacturing approach for layered metal-polymer hybrid structures. Mater. Lett. 2018, 217, 211–214, doi:10.1016/j.matlet.2018.01.021.

- Richter, A.; Kessing, D.; Fischer, F.; Pelzer, L.; Dilger, K. Print-on strategies to bond injection molded parts with structures produced by fused-deposition-modeling. Proc. Int. Conf. Eng. Des. ICED 2019, 2019-Augus, 819–828, doi:10.1017/dsi.2019.86.

- Pei, E.; Loh, G.H. Technological considerations for 4D printing: an overview. Prog. Addit. Manuf. 2018, 3, 95–107, doi:10.1007/s40964-018-0047-1.

- Handbook of Adhesion Technology; da Silva, L.F.M., Öchsner, A., Adams, R.D., Eds.; Springer International Publishing: Cham, 2018; ISBN 978-3-319-55410-5.

- da Silva, L.F.M.; Marques, E.A.S.; Campilho, R.D.S.G. Design Rules and Methods to Improve Joint Strength. In Handbook of Adhesion Technology; da Silva, L.F.M., Öchsner, A., Adams, R.D., Eds.; Springer International Publishing: Cham, 2018; pp. 773–810 ISBN 978-3-319-55411-2.

- Tong, L.; Luo, Q. Analytical Approach to Joint Design. In Handbook of Adhesion Technology; da Silva, L.F.M., Öchsner, A., Adams, R.D., Eds.; Springer Berlin Heidelberg: Berlin, Heidelberg, 2011; pp. 597–627 ISBN 978-3-642-01169-6.

- da Silva, L.F.M.; Rodrigues, T.N.S.S.; Figueiredo, M.A. V; de Moura, M.F.S.F.; Chousal, J.A.G. Effect of Adhesive Type and Thickness on the Lap Shear Strength. J. Adhes. 2006, 82, 1091–1115, doi:10.1080/00218460600948511.

- Marques, J.B.; Barbosa, A.Q.; da Silva, C.I.; Carbas, R.J.C.; da Silva, L.F.M. An overview of manufacturing functionally graded adhesives–Challenges and prospects. J. Adhes. 2019, 0, 1–35, doi:10.1080/00218464.2019.1646647.

- Shang, X.; Marques, E.A.S.; Machado, J.J.M.; Carbas, R.J.C.; Jiang, D.; da Silva, L.F.M. Review on techniques to improve the strength of adhesive joints with composite adherends. Compos. Part B Eng. 2019, 177, 107363, doi:10.1016/j.compositesb.2019.107363.

- Packham, D.E. Theories of fundamental adhesion. In Handbook of Adhesion Technology: Second Edition; 2018; Vol. 1–2, pp. 11–41 ISBN 9783319554112.

- Boss, J.N.; Ganesh, V.K.; Lim, C.T. Modulus grading versus geometrical grading of composite adherends in single-lap bonded joints. Compos. Struct. 2003, 62, 113–121, doi:10.1016/S0263-8223(03)00097-7.

- Sarantinos, N.; Tsantzalis, S.; Ucsnik, S.; Kostopoulos, V. Review of through-the-thickness reinforced composites in joints. Compos. Struct. 2019, 229, 111404, doi:10.1016/j.compstruct.2019.111404.

- Casavola, C.; Cazzato, A.; Moramarco, V.; Pappalettere, C. Orthotropic mechanical properties of fused deposition modelling parts described by classical laminate theory. Mater. Des. 2016, 90, 453–458, doi:10.1016/j.matdes.2015.11.009.

- Kumar, S.; Wardle, B.L.; Arif, M.F. Strength and performance enhancement of bonded joints by spatial tailoring of adhesive compliance via 3D printing. ACS Appl. Mater. Interfaces 2017, 9, 884–891, doi:10.1021/acsami.6b13038.

- Kumar, S.; Wardle, B.L.; Arif, M.F.; Ubaid, J. Stress Reduction of 3D Printed Compliance-Tailored Multilayers. Adv. Eng. Mater. 2018, 20, 1–8, doi:10.1002/adem.201700883.

- Khan, M.A.; Kumar, S. Performance enhancement of tubular multilayers via compliance-tailoring: 3D printing, testing and modeling. Int. J. Mech. Sci. 2018, 140, 93–108, doi:10.1016/j.ijmecsci.2018.02.038.

- Khan, M.A.; Kumar, S.; Cantwell, W.J. Additively manufactured cylindrical systems with stiffness-tailored interface: Modeling and experiments. Int. J. Solids Struct. 2018, 152–153, 71–84, doi:10.1016/j.ijsolstr.2018.06.002.

- Khan, M.A.; Kumar, S.; Reddy, J.N. Material-tailored adhesively bonded multilayers: A theoretical analysis. Int. J. Mech. Sci. 2018, 148, 246–262, doi:10.1016/j.ijmecsci.2018.08.017.

- Ubaid, J.; Wardle, B.L.; Kumar, S. Strength and Performance Enhancement of Multilayers by Spatial Tailoring of Adherend Compliance and Morphology via Multimaterial Jetting Additive Manufacturing. Sci. Rep. 2018, 8, 1–10, doi:10.1038/s41598-018-31819-2.

- Spaggiari, A.; Denti, F. Mechanical strength of adhesively bonded joints using polymeric additive manufacturing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 0, 1–9, doi:10.1177/0954406219850221.

- Cavalcanti, D.K.K.; Banea, M.D.; de Queiroz, H.F.M. Mechanical characterization of bonded joints made of additive manufactured adherends. Ann. “Dunarea Jos” Univ. Galati, Fascicle XII, Weld. Equip. Technol. 2019, 30, 27–33, doi:10.35219/awet.2019.04.

- García-Guzmán, L.; Távara, L.; Reinoso, J.; Justo, J.; París, F. Fracture resistance of 3D printed adhesively bonded DCB composite specimens using structured interfaces: Experimental and theoretical study. Compos. Struct. 2018, 188, 173–184, doi:10.1016/j.compstruct.2017.12.055.

- Dugbenoo, E.; Arif, M.F.; Wardle, B.L.; Kumar, S. Enhanced Bonding via Additive Manufacturing-Enabled Surface Tailoring of 3D Printed Continuous-Fiber Composites. Adv. Eng. Mater. 2018, 20, 1800691, doi:10.1002/adem.201800691.

- Garcia, R.; Prabhakar, P. Bond interface design for single lap joints using polymeric additive manufacturing. Compos. Struct. 2017, 176, 547–555, doi:10.1016/j.compstruct.2017.05.060.

- Alfano, M.; Morano, C.; Bruno, L.; Muzzupappa, M.; Pagnotta, L. Analysis of debonding in bio-inspired interfaces obtained by additive manufacturing. Procedia Struct. Integr. 2018, 8, 604–609, doi:10.1016/j.prostr.2017.12.059.

- Morano, C.; Bruno, L.; Pagnotta, L.; Alfano, M. Analysis of crack trapping in 3D printed bio-inspired structural interfaces. Procedia Struct. Integr. 2018, 12, 561–566, doi:10.1016/j.prostr.2018.11.063.

- Morano, C.; Zavattieri, P.; Alfano, M. Tuning energy dissipation in damage tolerant bio-inspired interfaces. J. Mech. Phys. Solids 2020, 141, 103965, doi:10.1016/j.jmps.2020.103965.

- Kolednik, O.; Predan, J.; Fischer, F.D.; Fratzl, P. Bioinspired design criteria for damage-resistant materials with periodically varying microstructure. Adv. Funct. Mater. 2011, 21, 3634–3641, doi:10.1002/adfm.201100443.

- Fieger, T.; Nugara, D.; Huebner, J.; Witt, G. Optimization of adhesively joined laser-sintered parts. Solid Free. Fabr. 2017 Proc. 28th Annu. Int. Solid Free. Fabr. Symp. - An Addit. Manuf. Conf. SFF 2017 2017, 567–577.

- Leicht, H.; Orf, L.; Hesselbach, J.; Vudugula, H.; Kraus, E.; Baudrit, B.; Hochrein, T.; Bastian, M. Adhesive bonding of 3D-printed plastic components. J. Adhes. 2020, 96, 48–63, doi:10.1080/00218464.2019.1682561.

- Li, W.; Sang, L.; Jian, X.; Wang, J. Influence of sanding and plasma treatment on shear bond strength of 3D-printed PEI, PEEK and PEEK/CF. Int. J. Adhes. Adhes. 2020, 100, 102614, doi:10.1016/j.ijadhadh.2020.102614.

- Yap, Y.L.; Toh, W.; Koneru, R.; Lin, R.; Chan, K.I.; Guang, H.; Chan, W.Y.B.; Teong, S.S.; Zheng, G.; Ng, T.Y. Evaluation of structural epoxy and cyanoacrylate adhesives on jointed 3D printed polymeric materials. Int. J. Adhes. Adhes. 2020, 100, 102602, doi:10.1016/j.ijadhadh.2020.102602.

- Kovan, V.; Altan, G.; Topal, E.S.; Camurlu, H.E. Surface roughness effect on the 3D printed butt joints strength. Dedic. to 50th Anniv. Year Tribol. - Proc. 8th Int. Sci. Conf. BALTTRIB 2015 2016, 117–121, doi:10.15544/balttrib.2015.21.

- Kovan, V.; Altan, G.; Topal, E.S. Effect of layer thickness and print orientation on strength of 3D printed and adhesively bonded single lap joints. J. Mech. Sci. Technol. 2017, 31, 2197–2201, doi:10.1007/s12206-017-0415-7.

- Kariz, M.; Kuzman, M.K.; Sernek, M. Adhesive bonding of 3D-printed ABS parts and wood. J. Adhes. Sci. Technol. 2017, 31, 1683–1690, doi:10.1080/01694243.2016.1268414.

- Redmann, A.J.; Setter, R.N.; Dahmen, V.; Austermann, J.; Quintanilla, A.L.; Mecham, S.J.; Osswald, T.A. Additively manufactured B-stage epoxy for adhesive bonding in composite structures. In Proceedings of the CAMX 2018 - Composites and Advanced Materials Expo; 2018.

- Dahmen, V.; Redmann, A.J.; Austermann, J.; Quintanilla, A.L.; Mecham, S.J.; Osswald, T.A. Fabrication of hybrid composite T-joints by co-curing with 3D printed dual cure epoxy. Compos. Part B Eng. 2020, 183, 107728, doi:10.1016/j.compositesb.2019.107728.

- Niese, B.; Stichel, T.; Amend, P.; Urmoneit, U.; Roth, S.; Schmidt, M. Manufacturing of conductive circuits for embedding stereolithography by means of conductive adhesive and laser sintering. Phys. Procedia 2014, 56, 336–344, doi:10.1016/j.phpro.2014.08.179.

- Schmidt, K.; Zimmermann, A. Evaluation of process and anisotropy of thermosetting adhesives with ultraviolet-assisted 3D dispensing. Addit. Manuf. 2020, 34, 101262, doi:10.1016/j.addma.2020.101262.

- Sekiguchi, Y.; Nakanouchi, M.; Haraga, K.; Takasaki, I.; Sato, C. Experimental investigation on strength of stepwise tailored single lap adhesive joint using second-generation acrylic adhesive via shear and low-cycle shear tests. Int. J. Adhes. Adhes. 2019, 95, 102438, doi:10.1016/j.ijadhadh.2019.102438.