You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 3 by Amina Yu and Version 2 by Amina Yu.

Coffee is a worldwide used product and of the most valued commodities in trade, being one of the most important agricultural exports in Costa Rica.

- coffee pulp

- coffee by-products

- composting

- methane

1. Introduction

Agriculture is responsible for an essential portion of global emissions, contributing to 45% of their methane (CH4) emissions globally, impacting climate change [1]. In addition, gas concentrations act as indicators that show biological degradation, and this guides optimization possibilities of developing new strategies for emissions reduction [2]. Therefore, it is required to estimate greenhouse gas (GHG) emission rates as they are the flow of a pollutant expressed in weight per unit of time [3]. Emissions rates are necessary to calculate an emission factor, a representative value that attempts to relate the amount of a pollutant released into the atmosphere with an activity associated with the release of that pollutant [4]. The detection of gaseous emissions during composting coffee by-products is one of the most critical tools to meet the challenge of reducing CH4 emissions from the waste residues generated in the coffee processing industry [5][6]. Coffee is a worldwide used product and of the most valued commodities in trade, being one of the most important agricultural exports in Costa Rica [7]. In coffee processing, the production chain comprehends several steps. Firstly, the berries from the coffee plants are transported to be washed and peeled (de-pulping), separating the green beans from the pulp or husk [8]. The outer membrane that envelops the coffee bean is called the pulp (CP) (mesocarp), which contains 43% w/w of the morphology of the coffee fruit [9][10][11]. CP is one of the main by-products generated during the process [11]. It contributes to pollution, environmental and health problems of the surrounding waters, soil, and atmosphere when the coffee berries are ripe and processed during the wet method and mishandled [12][13]. Some researchers and the Costa Rican Coffee Institute (ICAFE) indicate CP management has been one of the challenged coffee by-products with the most significant volume of waste [9][14]. In addition, it accumulates for long periods, and it leads to the generation of foul odors, being a favorable environment for reproducing flies and other pests responsible for multiple diseases [15][16]. Currently, the country has a top priority: reducing GHG emissions in the coffee industry, together with a National Decarbonization Plan 2050 [17]. Hence, studying methane emissions during the composting of the coffee by-products and finding new approaches will be crucial to achieving future goals and mitigating the current challenges with coffee by-products each harvest.

Composting has been a promising technique for waste treatment in converting organic matter and agricultural residues into compost, even using minor technologies and operational expenses [18][19]. Aerobic composting involves the changes in the properties and degradation of the substrates [20]. In addition, the existence of aeration in the system gives biological products from the metabolism of the process, such as carbon dioxide, water, and [21][22] heat. During the composting process, three phases are observed in the aerobic decomposition: initial and degradation, conversion, and maturation. In addition, possess two types of microbial activity during this decomposition: thermophilic stage (45–70 °C) and mesophilic stage (15–45 °C) [21][23][24][25][26] The first stage is linked with the microbial activity of the material and is followed by a second stage, where the conversion of the organic material occurs [27]. The final stage is the maturation process, which occurs at ambient temperature and mesophilic micro-organisms play a role in finishing the product (mainly bacteria and fungi) [28]. Even if a composting technique is beneficial to the environment, GHG is present during the process, enhancing global warming [29]. The emissions will depend on the waste type and composition, key composting parameters such as C/N, temperature, moisture, pH [27][30], and the final use of the compost [31].

2. Methane Gas Emissions

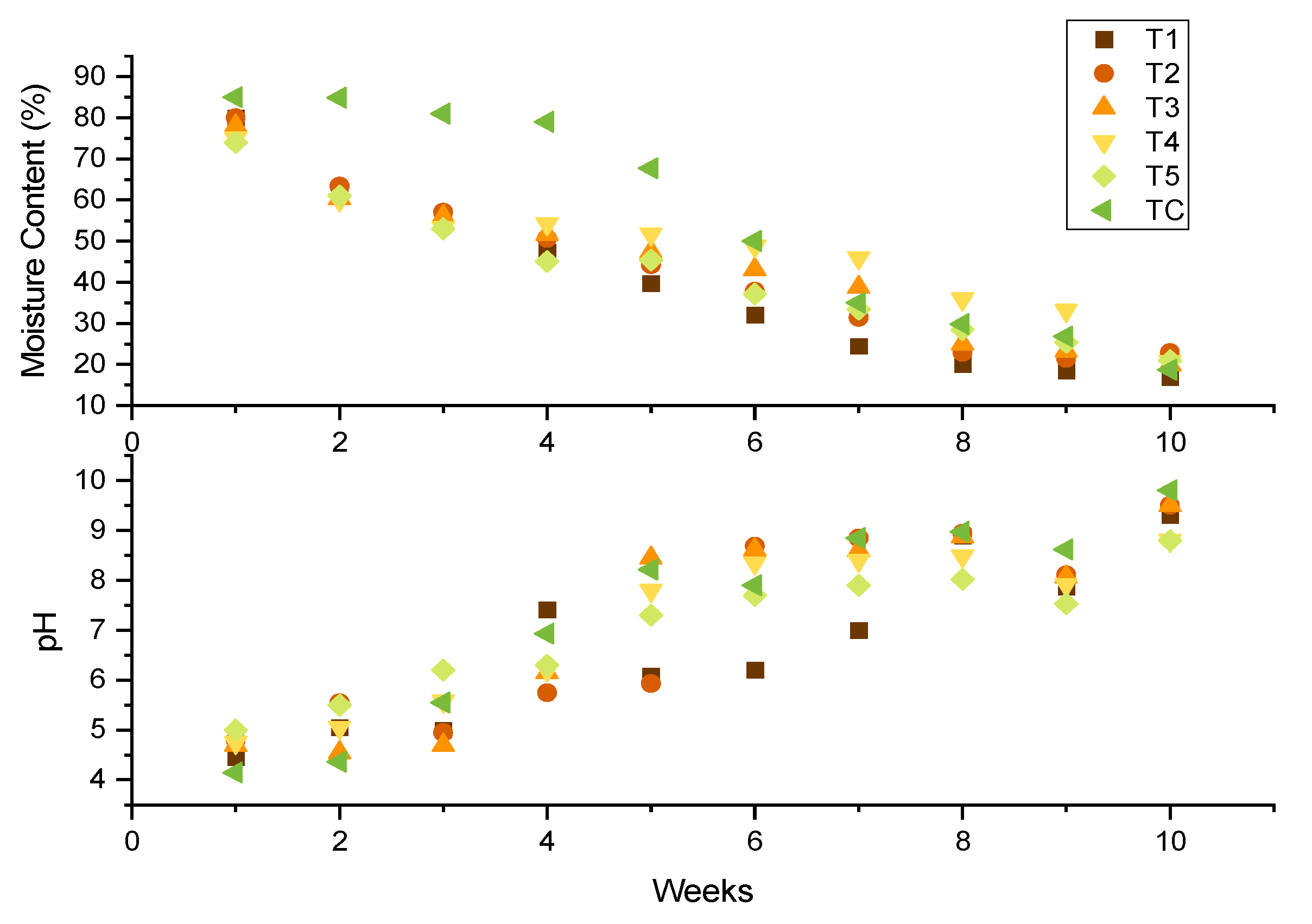

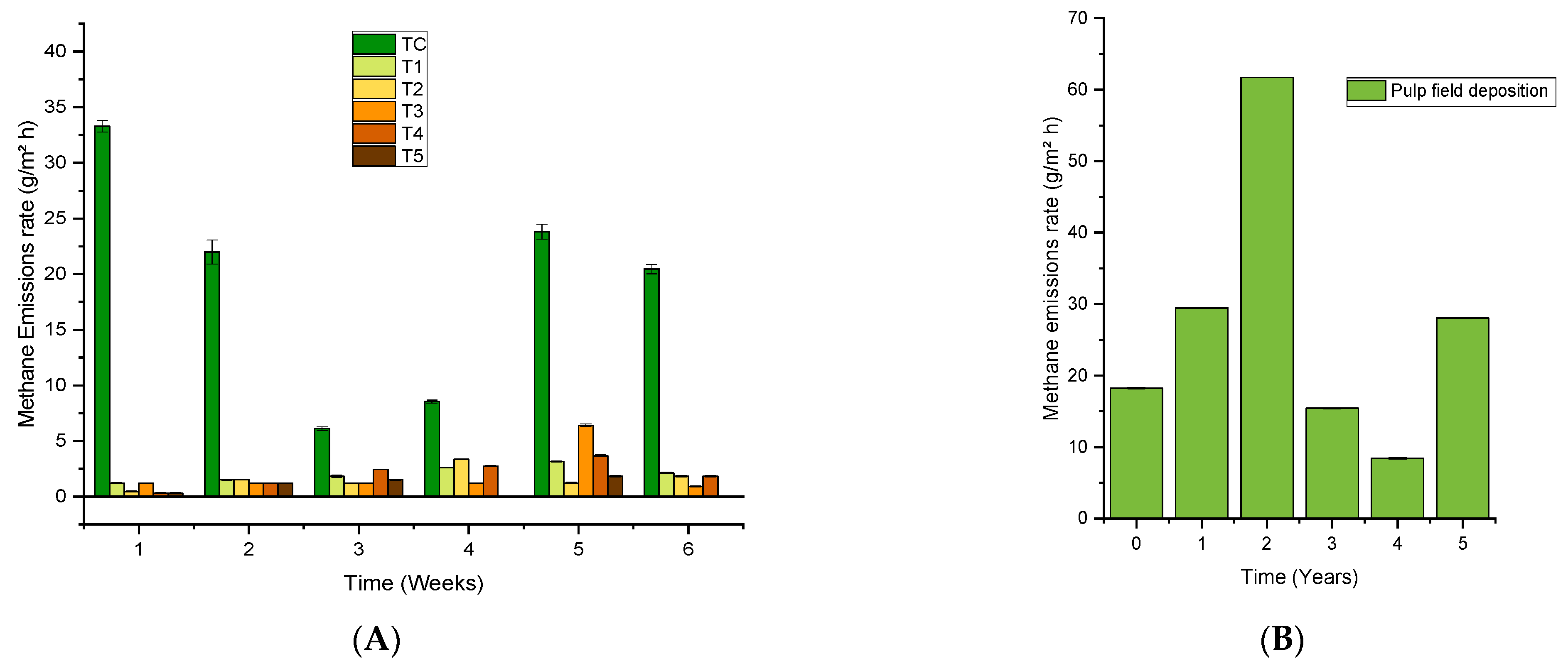

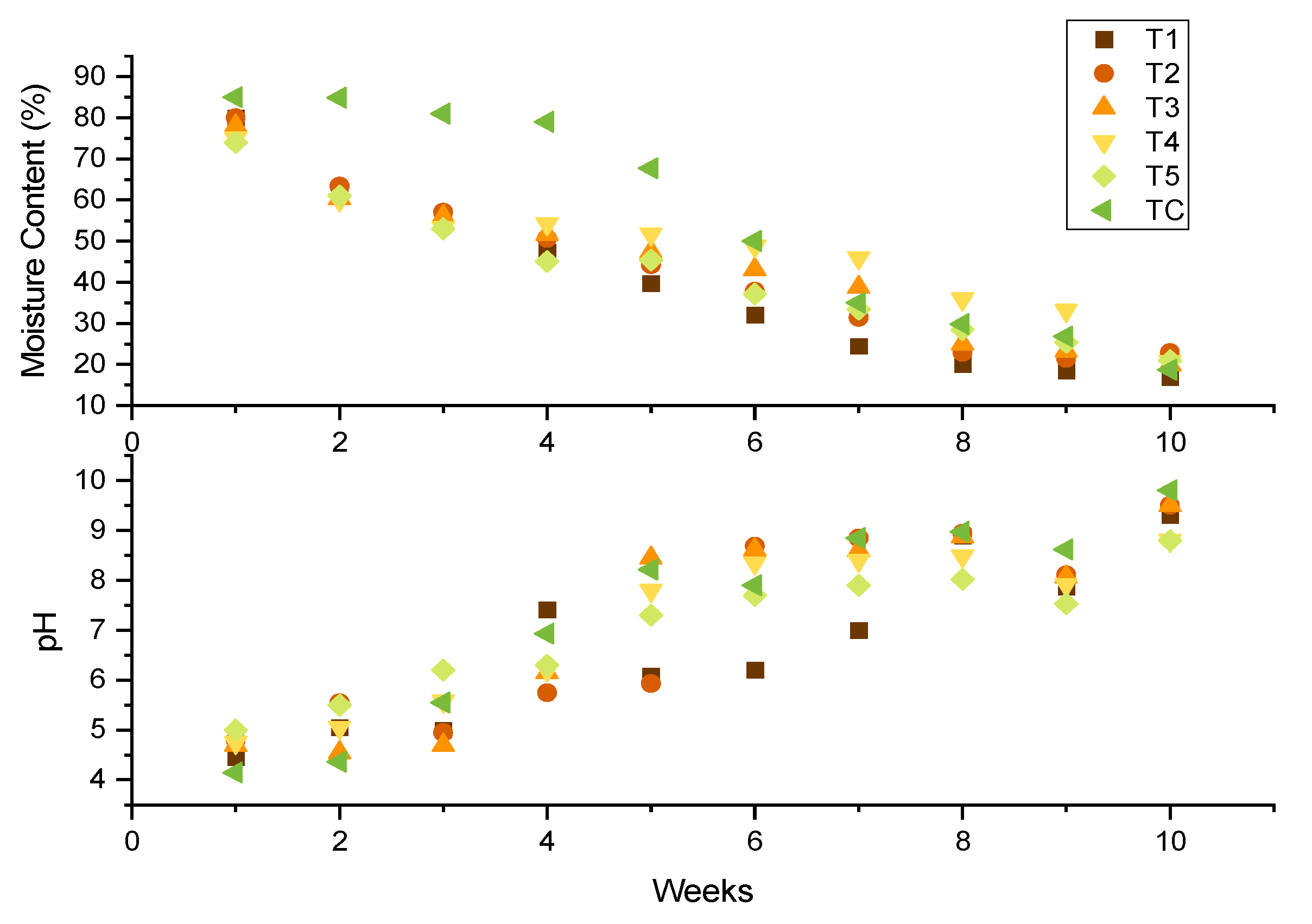

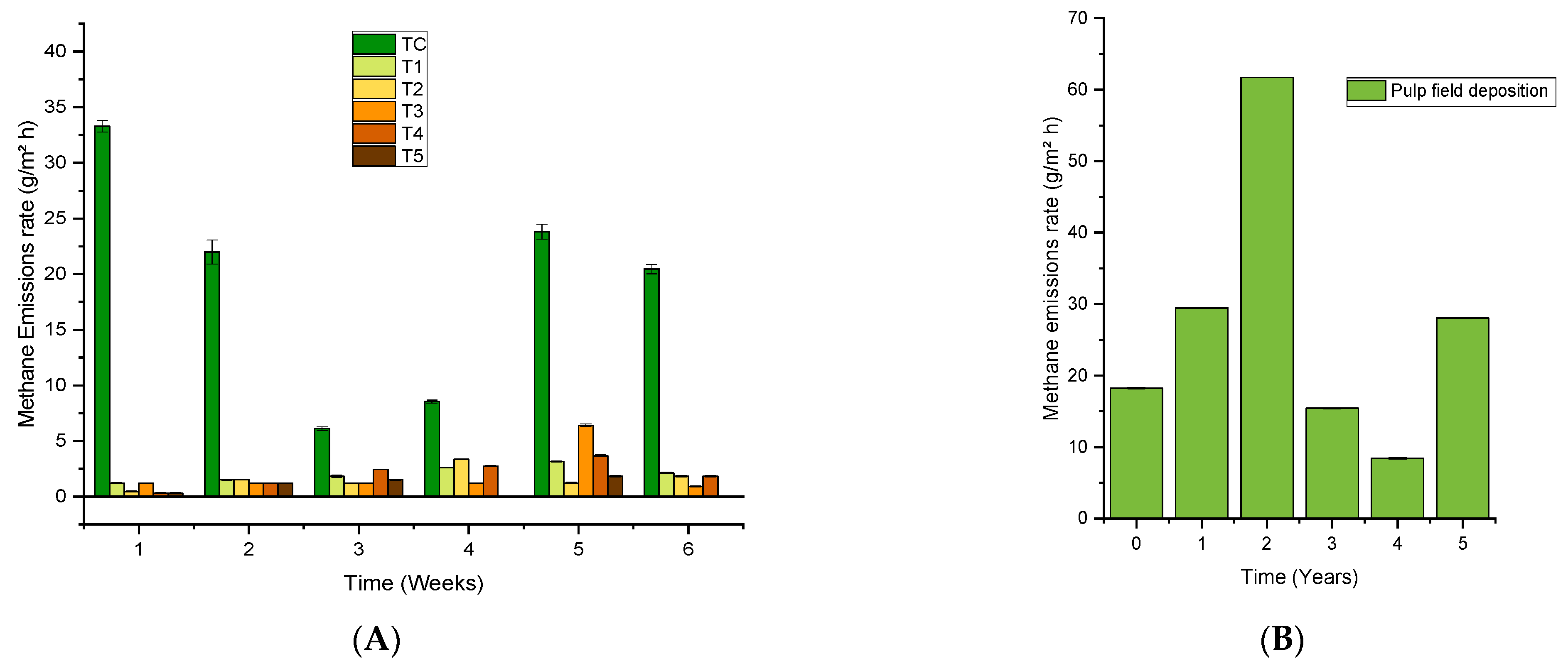

The CH4 is influenced by different factors such as temperature, moisture, and pH directly [32]. When the aeration is not proper and the moisture content increases in the windrow, this can result in high CH4 emissions affecting the oxygen restrictions in the microbiological metabolism in the windrow [5][33][34]. Methane emissions rates shown in Figure 2A were measured during the first six weeks of the composting process and compared if the addition of green waste (GW) influences their emissions in the windrows. The highest value is TC with 38 g × m−2 × h−1 in the first week of composting. Comparing Figure 1 of moisture content (MC) and Figure 2, the first week of composting process possesses the highest value for moisture content among the study. Thus, the production of CH4 is also increased exponentially with the moisture level, allowing the formation of undesirables anaerobic zones enhancing the methanogenesis and anaerobic metabolism in the windrow [30][35]. Even if the composting treatment is under aerobic conditions, the diversity of the input materials, moisture content, temperature, biological microbial activity, and redox requirements could be developed in the window [2].

Figure 1. Moisture content and pH profiles in all the types of windrows throughout CP composting. Values are the means (n = 3).

Figure 2. (A) Methane emissions rate for all the treatments using coffee pulp for composting and (B) methane emissions rate in field deposition. Bars represent the standard error of the mean (n = 4).

The reduction of CH4 during composting is accomplished if additional material is used, such as GW. The weekly highest values among the treatments were found for T1 and T2 with 3.1 g × m−2 × h−1 and 3.3 g × m−2 × h−1, respectively. Each value was found during the fourth week and for T3, T4, T5 with 6.4 g × m−2 × h−1, 3.6 g × m−2 × h−1, and 1.8 g × m−2 × h−1, respectively in the fifth week. Emissions formation increases faster when temperatures are over 65 °C [3]. Furthermore, a correlation between the temperature profiles and the emissions peaks is shown since the highest peaks of temperatures and emissions were found for the windrows during the same weeks of the composting process.

The presence of low pH, which illustrates the presence latency of organic acids, and the present of also CH4 emissions, indicates that anaerobic conditions have been since the initial formation of the windrow pile [33]. The reduction of total emissions CH4 was between 89–95% compared to the control treatment, which shows the difference of aeration and proper management within the treatments compared to the control. Researchers recommend that increasing the oxygen level available in the system is necessary during the first week [3]. In the fifth week, methane emissions were higher than in the first week for T1–T5. This could be attributed to the moisture suppressing the airflow since the material at that week is more compact. The pores in the feedstock are filled with water, favoring the formation of anaerobic conditions and methane emissions [31]. The emissions in the fifth week were the highest among the treatment compared to the control (TC). The reduction of emissions with GW is added in the window is seen. In other studies, it has been found that CH4 emissions are present during the initial stage of the thermophilic phase since there is an oxygen solubility reduction, enhancing anaerobic zones in the windrow [36]. During CH4 emission exists other microbial factors affecting the gas transport and gas diffusion, including the presence of methanotrophic bacteria (these bacteria are colonizing the area nearby anaerobic zones being able to oxidize up to 98% of the CH4 formed in the windrow) [37].

A previous study [10] shows the magnitude of the CH4 emissions in open field depositions when the CP is not composted or pre-treated before field deposition, generating serious environmental concerns. Figure 6B shows the behavior of the methane emissions over the years when the CP is buried for a lifetime. The highest emission was in the second year with 53.7 g × m−2 × h−1. Equivalent emissions are seen in the first and the fifth year of field deposition with 25.6 and 24.4 g × m−2 × h−1. These results imply that the material is not degraded over time, producing continuous emissions of great magnitude when not treated correctly. This behavior of high CH4 emissions over this period is due to the properties of the CP. When it is buried with high moisture content, high material density, and a lack of aeration, anaerobic zones are created, enhancing the methane emissions.

Given this problem and its emissions, the mill aims for successive harvests to avoid this practice. For example, during the 2019–2020 harvest, open field depositions were made with about 630 Mg (6000 fanegas). In previous years, a minimum of 1500 Mg of CP was transported in the fields. It is clear that the depositions are a risk and a focus of emissions since they are large spaces of at least 925 m2 of surface area; therefore, the high levels of emissions over the years can be attributed to the surface area, amount of material, and the management in that area.

For the estimation of EF among all the treatments, it is shown in two different options. Firstly, a calculation of EF regarding the amount of CP added in each treatment. It is crucial to establish since there is no EF associated directly with CP in the literature, where the results show that the more CP added into the system, the higher EF is obtained. After this, an EF calculation was input to represent the treatments better and was compared with literature regarding green waste from some regulations in composting plants.

The government is currently developing a new national composting plan accomplishing the strategic guidelines of the National Decarbonization Plan 2050. The inventories of GHGs in Costa Rica regarding waste management are made by the National Meteorological Institute (IMN for its abbreviation in Spanish). Therefore, the results are compared with the National Inventory’s values; nevertheless, it is necessary to be analyzed. These inventories are for municipal solid waste; therefore, these results cannot be thoroughly compared since the country does not explicitly relate to agricultural waste. On the other hand, there is no emission factor directly linked to CP; a comparison in the literature shows 4 g CH4/kg solid waste [38], 4 g CH4/kg waste treated [39], 2.2 g CH4/Mg GW FM [5], 4.7 and 7.6 g CH4/kg GW [40].

The emissions factors shown in Table 1 show the decrease of emissions comparing TC with the rest of the treatments. The utmost emission values found were in T3 and T4 with 14 g CH4/kg CP. The closest value compared to the literature is T5. One of the reasons could be the amount of GW added since it had the most significant amount of material in a pile. Compared with the literature values of biological treatments, these results present elevated values. However, with the proposed methodology for all the five treatments, these values are approaching the values recommended by the literature for composting. For the open field depositions, even if there is no management involved, the emissions factors represented the highest values among all the treatments, including the current treatment of the mill.

Table 1. Emissions factors from all the treatments proposed.

| Treatment | EF (g CH4/kg CP) | EF (g CH4/kg Input) | SD * |

|---|---|---|---|

| T1 | 43.9 | 35.1 | 0.23 |

| T2 | 14.4 | 10.8 | 0.17 |

| T3 | 20 | 14 | 0.23 |

| T4 | 23.4 | 14 | 0.24 |

| T5 | 11.6 | 5.8 | 0.14 |

| TC | 129 | 129 | 2.96 |

3. Conclusions

The study achieved the development of an experimental methodology using coffee by-products and GW. An improvement in the key parameters of composting was observed, such as temperature, pH, and WC profiles, when coffee by-products were mixed with GW for composting treatment. Therefore, waste valorization within the process is concluded together with the reduction of methane emissions. The proposed treatments experienced fewer methane emissions rates than the control; hence, implementing this technique suggests a good practice in the future for the coffee sector and the mill in Costa Rica. Results show that T2–T5 are strongly recommended treatments involving methane emissions, physical parameters during the process, plant nutrient content, and finished compost classified (Grade IV and V) following the German Quality Assurance Organization standards for Compost (BKG) standards. Overall, it promotes a better understanding of the performance of CP when the material is composted and their methane emissions during the process. This approach might be necessary for the future to guide a national mitigation plan in the agricultural and coffee sector of the country. In addition, it will be a helpful tool for the future calculations of the global emissions using a technology already studied in another place or another treatment plant. Suppose it is considered the agronomic and environmental aspects in an integrated manner. It is recommended to investigate further the benefits of using the compost and the relationship between GHG emitted during the process. The compost utilization can also compensate for this reduction in the long term in the coffee plantations. Continuous but robust research is suggested to develop emissions and factors that adequately cover national conditions to establish new inventories, especially for the coffee sector, including coffee by-products and management.

References

- Smith, P.; Bustamante, M.; Ahammad, H.; Clark, H.; Dong, H.; Elsiddig, E.A.; Haberl, H.; Harper, R.; House, J.; Jafari, M.; et al. Agriculture, Forestry and Other Land Use (AFOLU). In Climate Change 2014 Mitigation of Climate Change Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovern-Mental Panel on Climate Change; Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Farahani, E., Kadner, S., Seyboth, K., Adler, A., Baum, I., Brunner, S., Eickemeier, P., Eds.; Cambridge University Press: Cambridge, UK, 2014; pp. 811–922.

- Bridgham, S.D.; Richardson, C.J. Mechanisms controlling soil respiration (CO2 and CH4) in southern peatlands. Soil Biol. Biochem. 1992, 24, 1089–1099.

- Vergara, S.E.; Silver, W.L. Greenhouse gas emissions from windrow composting of organic wastes: Patterns and emissions factors. Environ. Res. Lett. 2019, 14, 124027.

- US EPA. AP 42, Fifth Edition Compilation of Air Pollutant Emission Factors, Volume 1: Stationary and Point Sources; US EPA: Research Triangle Park, NC, USA, 1995; pp. 1–10.

- Amlinger, F.; Peyr, S.; Cuhls, C. Green house gas emissions from composting and mechanical biological treatment. Waste Manag. Res. 2008, 26, 47–60.

- Sánchez, A.; Gabarrell, X.; Artola, A.; Barrena, R.; Colón, J.; Font, X.; Komilis, D.; Taherzadeh, M.J.; Richards, T. Composting of Wastes. Resource Recovery to Approach Zero Municipal Waste, 1st. ed.; Taherzadeh, M.J., Richards, T., Eds.; Green Chemistry and Chemical Engineering: Boca Raton, FL, USA, 2015; pp. 77–106.

- Blinová, L.; Sirotiak, M.; Bartošová, A.; Soldán, M. Review: Utilization of Waste from Coffee Production. Res. Pap. Fac. Mater. Sci. Technol. Slovak Univ. Technol. 2017, 25, 91–101.

- Chong, J.A.; Dumas, J.A. Coffee pulp compost: Chemical properties and distribution of humic substances. J. Agric. Univ. Puerto Rico 2012, 96, 77–87.

- Braham, J.; Bressani, R. Coffee Pulp: Composition, Technology, and Utilization; IDRC: Ottawa, ON, Canada, 1979.

- San Martin Ruiz, M.; Reiser, M.; Hafner, G.; Kranert, M. A Study about Methane Emissions from Different Composting Systems for Coffee By-products on Costa Rica. Environ. Ecol. Res. 2018, 6, 461–470.

- Chala, B.; Oechsner, H.; Latif, S.; Müller, J. Biogas Potential of Coffee Processing Waste in Ethiopia. Sustainability 2018, 10, 2678.

- Beyene, A.; Kassahun, Y.; Addis, T.; Assefa, F.; Amsalu, A.; Legesse, W.; Kloos, H.; Triest, L. The impact of traditional coffee processing on river water quality in Ethiopia and the urgency of adopting sound environmental practices. Environ. Monit. Assess. 2011, 184, 7053–7063.

- Desai, N.M.; Varun, E.; Patil, S.; Pimpley, V.; Murthy, P.S. Environment Pollutants During Coffee Processing and Its Valorization BT. In Handbook of Environmental Materials Management; Hussain, C.M., Ed.; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–13.

- Misra, R.V.; Roy, R.N.; Hiraoka, H.; Food and Agriculture Organisation of the United Nations. FAO On-farm com-posting methods, Composting Methods and Techniques, Rome. 2003. Available online: http://www.fao.org/docrep/007/y5104e/y5104e05.htm (accessed on 17 February 2021).

- Sánchez, A.; Artola, A.; Font, X.; Gea, T.; Barrena, R.; Gabriel, D.; Sánchez-Monedero, M.Á.; Roig, A.; Cayuela, M.L.; Mondini, C. Greenhouse Gas from Organic Waste Composting: Emissions and Measurement. In CO2 Sequestration, Biofuels and Depollution. Environmental Chemistry for a Sustainable World; Lichtfouse, E., Schwarzbauer, J., Robert, D., Eds.; Springer: Cham, Switzerland, 2015; Volume 5.

- Diaz, L.F.; De Bertoldi, M.; Bidlingmaier, W. Compost Science and Technology; Elsevier: Amsterdam, The Netherlands, 2007.

- Haug, R.T. The Practical Handbook of Compost Engineering, 1st ed.; Lewis Publishers: Atascadero, CA, USA, 1993.

- Shemekite, F.; Gómez-Brandón, M.; Franke-Whittle, I.H.; Praehauser, B.; Insam, H.; Assefa, F. Coffee husk composting: An investigation of the process using molecular and non-molecular tools. Waste Manag. 2014, 34, 642–652.

- VDI Guideline: Emission Control Mechnical-Biological Treatment Facilities for Municipal Solid Waste; VDI 3475 Part 3; Beuth Verlag GmbH: Berlin, Germany, 2006.

- Kranert, M. Einführung in die Kreislaufwirtschaft: Planung-Recht-Verfahren; Springer: Vieweg, Wiesbaden, 2017.

- Shilev, S.; Naydenov, M.; Vancheva, V.; Aladjadjiyan, A. Composting of Food and Agricultural Wastes. In Utilization of By-Products and Treatment of Waste in the Food Industry; Springer: Berlin, Germany, 2006; pp. 283–301.

- Ghazifard, A.; Kasra-Kermanshahi, R.; Far, Z.E. Identification of thermophilic and mesophilic bacteria and fungi in Esfahan (Iran) municipal solid waste compost. Waste Manag. Res. 2001, 19, 257–261.

- Azim, K.; Soudi, B.; Boukhari, S.; Perissol, C.; Roussos, S.; Alami, I.T. Composting parameters and compost quality: A literature review. Org. Agric. 2018, 8, 141–158.

- IVillar, I.; Alves, D.; Garrido, J.; Mato, S. Evolution of microbial dynamics during the maturation phase of the composting of different types of waste. Waste Manag. 2016, 54, 83–92.

- Zhu-Barker, X.; Bailey, S.K.; Paw, U.K.T.; Burger, M.; Horwath, W.R. Greenhouse gas emissions from green waste composting windrow. Waste Manag. 2017, 59, 70–79.

- VDI Guideline: Emission Control Biological Waste Treatment Facilities Composting and Anaerobic Digestion Plant Capacities More Than Approx. 6; VDI 3575 Part 1; Beuth Verlag GmbH: Berlin, Germany, 2003.

- Sánchez, A.; Artola, A.; Font, X.; Gea, T.; Barrena, R.; Gabriel, D.; Sanchez-Monedero, M.A.; Roig, A.; Cayuela, M.L.; Mondini, C. Greenhouse gas emissions from organic waste composting. Environ. Chem. Lett. 2015, 13, 223–238.

- Díaz, M.V.; Prada, P.; Mondragon, M. Optimización del proceso de compostaje de productos post-cosecha (cereza) del café con la aplicación de microorganismos nativos. Nova 2010, 8, 214.

- Muzaifa, M.; Rahmi, F.; Syarifudin. Utilization of Coffee By-Products as Profitable Foods—A Mini Review. IOP Conf. Ser. Earth Environ. Sci. 2021, 672, 012077.

- Ijanu, E.M.; Kamaruddin, M.A.; Norashiddin, F.A. Coffee processing wastewater treatment: A critical review on current treatment technologies with a proposed alternative. Appl. Water Sci. 2019, 10, 11.

- Duong, B.; Marraccini, P.; Maeght, J.-L.; Vaast, P.; Lebrun, M.; Duponnois, R. Coffee Microbiota and Its Potential Use in Sustainable Crop Management. A Review. Front. Sustain. Food Syst. 2020, 4, 237.

- Hao, X.; Benke, M.B. Nitrogen Transformation and Losses during Composting and Mitigation Strategies; Global Science Books: Isleworth, UK, 2008.

- Taconi, K.A.; Zappi, M.E.; French, W.T.; Brown, L.R. Methanogenesis under acidic pH conditions in a semi-continuous reactor system. Bioresour. Technol. 2008, 99, 8075–8081.

- Ermolaev, E.; Sundberg, C.; Pell, M.; Smårs, S.; Jönsson, H. Effects of moisture on emissions of methane, nitrous oxide and carbon dioxide from food and garden waste composting. J. Clean. Prod. 2019, 240, 118165.

- Moldvaer, A. Coffee Obsession, 1st ed.; Dorling Kindersley Limited: London, UK, 2014.

- Jiang, T.; Schuchardt, F.; Li, G.; Guo, R.; Zhao, Y. Effect of C/N ratio, aeration rate and moisture content on ammonia and greenhouse gas emission during the composting. J. Environ. Sci. 2011, 23, 1754–1760.

- Jäckel, U.; Thummes, K.; Kämpfer, P. Thermophilic methane production and oxidation in compost. FEMS Microbiol. Ecol. 2005, 52, 175–184.

- IMN. Factores de Emisión Gases Efecto Invernadero, San José, Costa Rica. 2020. Available online: http://cglobal.imn.ac.cr/index.php/publications/factores-de-emision-gei-decima-edicion-2020/ (accessed on 10 February 2021).

- IPCC. Volume 5 Waste-Chapter 4 Biological Treatment of Solid Waste, 2006 IPPC Guidel. National Greenhouse Gas Inventories. 2006, pp. 4.1–4.8. Available online: http://www.ipcc-nggip.iges.or.jp/public/2006gl/vol5.html (accessed on 5 February 2021).

- ARB. Air Resources Board (ARB): Method for Estimating Greenhouse Gas Emission Reduction from Diversion of Organic Waste from Landfills to Compost Facilities. 2017. Available online: https://ww2.arb.ca.gov/sites/default/files/classic/cc/waste/cerffinal.pdf (accessed on 18 February 2021).

More