Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 5 by Jason Zhu and Version 6 by Jason Zhu.

A considerable number of fatalities and injuries are reported in construction projects annually, and the adoption of digital technologies could provide safer construction sites. The adoption of IoT-based technologies in construction projects has offered myriad benefits, especially in the field of construction safety management. Barriers to the adoption of IoT-based technologies in construction site safety management (CSSM) have been studied. Then, the most significant barriers were determined using a comprehensive fuzzy Delphi method. Once the external validity of the findings had been checked through semi-structured interviews, 18 barriers were found to hamper the adoption of IoT-based technologies in CSSM.

- digital technology

- fuzzy sets

- Delphi

1. Current Studies

In recent times, the dynamic evolution of the construction industry has been witnessed for meeting modern-day infrastructure development challenges. To tackle these challenges, not only construction site safety, but also other critical aspects such as time, cost, and quality need to be well managed. Safety is of the utmost importance in many sectors, and the construction sector is no different. Moreover, the application of innovative concepts, tools, and theories is key to the solution of the current safety challenges.

Zhou et al. [1] used IoT technologies (i.e., radio frequency identification (RFID), ultrasonic detection, and infrared access technologies) through a three-tier network architecture to develop a safety barrier warning system for underground construction sites. The proposed system was implemented in the underground construction of the Yangtze River crossing project to generate early warnings and alarms for the hazards at the site. It showed improvements in the safety performance by reducing the number of accidents.

Antwi-Afari et al. [2] examined the application of IoT to ergonomic risk assessment by identifying the awkward working postures of construction workers using a wearable insole pressure system. Awkward working postures lead to non-fatal occupational injuries to workers, which, in turn, result in poor construction productivity, hence affecting the overall project performance in a negative manner. The researchers believed that there is great potential for the application of their proposed wearable insole pressure system, as it has both practical uses and economic benefits due to the usage of IoT technologies including sensors, vision-based technologies, and wireless communication. Sigcha et al. [3] believed that wearable technology, such as microelectronic mechanical systems (MEMS), accelerometers, and smartwatches had witnessed tremendous evolution in the domain of safety research. Among these, smartwatches are easy to use and have broad applicability, e.g., integrating an accelerometer with a smartwatch for precise motion detection, and considering any uncertainty effects in the occupational risk assessment.

Soltanmohammadlou et al. [4] addressed the construction site safety issue by providing an in-depth review on the real-time locating systems (RTLS) used for better site safety. It was observed that RTLS could facilitate the safety management process in various pertinent research directions, such as accident prevention, safety monitoring, safety alerts and warnings, behavior-based safety, physiological status monitoring, communication-based safety, ergonomics analysis, and on-site safety trainings. Moreover, the following IoT technologies were identified in their review: locating sensors, vision-based technologies, ultra-wide band technologies, Bluetooth, Zigbee, ultrasound, and infrared technologies. Costin et al. [5] identified real-time feedback, global positioning systems (GPSs), lasers, geographic information systems (GIS), accelerometers, gyroscope sensors, RFID technology, Bluetooth systems, and wearable sensors as being considered IoT technologies. Based on that, they proposed a conceptual IoT-based framework to generate active leading indicators (ALIs) that had the potential to identify safety hazards and prompt immediate actions to prevent incidents. The use of IoT assists the collection of quantifiable data and triggers an actionable response in real-time based on defined thresholds. In addition, the interactive physical–virtual feedback loop is a vital component of the proposed IoT system. The case study findings validated the IoT-based ALI framework and demonstrated the feasibility of the system.

In another study, Zhang et al. [6] used smart phones and sensors such as accelerometers and gyroscopes as tools to find and realize construction workers’ near miss falls based on the artificial neural network. A loss of balance situation was created using a balance board to simulate the near miss fall event in the training and evaluation phases of the experimentations. The smartphones are used for data acquisition purposes on sites with an average error-detection rate of 16.26%; thus, if adopted on a large scale, these devices can be useful in improving site safety. Zhou et al. [7] utilized RFID-based location and tracking technology, ultrasonic detection technology, and infrared access technology to propose a cyber–physical system-based safety monitoring system for blind hoisting in metro and underground construction projects. The proposed IoT-based system, through simulating and monitoring, helps to prevent accidents that occur in the dynamic hoisting process. Moreover, the results of a case study showed that the proposed system could be effectively applied to several cases, for example, dams, high-rise buildings, and large infrastructure projects.

Chung et al. [8] presented an IoT-based application for monitoring construction site safety in the Hong Kong construction sector. The study first investigated the effectiveness of mandatory basic safety training delivered to construction workers. Afterwards, an IoT-based innovative safety model was designed to provide real-time monitoring of the construction site personnel and environment. In the end, a cost comparison was provided, which suggested significant cost savings with respect to the traditional manual systems. Okpala et al. [9] assessed the feasibility of integrating IoT into safety management systems (SMS), with specific focus on wearable sensing devices (WSDs) and location tracking biosensors. A structured questionnaire was used to assess the usefulness of WSDs in the SMS context. In addition to the increased utility of WSDs, the analysis revealed that the use of WSDs provides useful information on the safety and health of workers, offers value for money, has the potential to prevent accidents and its associated costs, and provides compatible and seamless solutions to the concerned stakeholders. Furthermore, interoperability and standardization were found to be key challenges. Asadzadeh et al. [10] presented a comprehensive systematic review of the existing literature on the use of IoT sensors in the safety management context for the construction industry. The findings reflected a strong inclination of the researchers working in this field to adopt IoT technology, such as sensor-based technologies, accelerometers, and gyroscopes, to solve safety issues due to the unsafe and hazardous nature of the construction industry.

Furthermore, the integration of different sensor-driven systems with information modeling technologies such as BIM for the improvement of construction safety has also been addressed in the recent literature. Yang et al. [11] utilized IoT technologies including Wi-Fi modules, photoresistors, optical sensors, force stretchable resistors, and touch sensors for productivity improvement by developing an automated personal protection equipment (PPE)-tool pair checking system using IoT with Wi-Fi modules attached to the PPE. The developed automated system simultaneously warns the user and the safety officer about the improper usage of PPE. The researchers’ belief about the system being efficient and effective in relation to the productivity and site safety improvement was well supported by the detailed lab experiments as well. With the rise in the usage of IoT and its accompanying technologies, Häikiö et al. [12] investigated construction workers’ attitudes using an online survey towards the acceptability of IoT-based wearable technologies. Based on the analysis of over 4000 survey forms, it was found out that privacy and security related to the wearables in the workplace were the main concerns of the workers. User acceptance and trust building are known to be crucial aspects for better adoption.

Regarding the implementation of IoT into the construction safety domain, Rey-Merchán et al. [13] proposed a virtual fence system based on Bluetooth Low Energy (BLE) beacon technology to avoid the intrusion of workers into hazardous areas. The designed system was then evaluated by a structured questionnaire distributed to the industry experts. The findings indicated that the system was not only inexpensive, but also convenient to integrate and configure; some other factors, such as top management support, social acceptance, alignment with organizational culture, and legislations, will also boost its applicability. Ghosh et al. [14] are of the opinion that sensor-based integrated virtual IoT technologies provide exciting opportunities for the construction sector to solve a range of problems, and with the use of a scientific mapping tool, different patterns and trends of IoT research in the construction sector have been explored as well. Having reviewed the corpus of literature, it was found that there is still a limited number of studies undertaken in this field. Huang et al. [15] considered augmented hearing protection technology in addition to the explored critical drivers of IoT adoption, which includes interoperability, data privacy and security, flexible governance structures, and proper business planning and models.

From a review of the potentials of IoT technology adoption in the construction site safety domain (as shown in Table 1), it was well observed that most of the studies were quite recent (i.e., undertaken in the last 2–3 years) and did not focus much on the documentation and detailed evaluation of the barriers to the extensive adoption of IoT-based technologies, such as RFID, ultrasonic detection and infrared access technologies, sensors, vision-based technologies, wireless communication, wearable technologies, MEMS, accelerometers, smart devices and watches, location sensors, ultra-wide band (UWB) technologies, Bluetooth, Zigbee, real-time feedback, GPS, lasers, GIS, gyroscope sensors, location tracking, biosensors, Wi-Fi modules, photoresistors, optical sensors, force stretchable resistors, touch sensors, BLE beacons, integrated physical and virtual technology, and augmented hearing protection technology.

2. Methodology

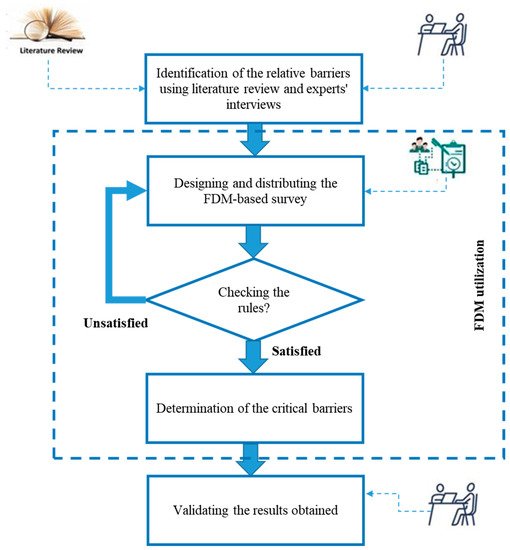

The methodology adopted for identifying and analyzing the barriers to the implementation of IoT-based technologies in CSSM is explained in detail. Figure 1 illustrates the different steps undertaken towards achieving the objectives specified. First, a comprehensive literature review for the identification of the relative barriers was carried out, after which the list of identified barriers was presented to nine experts who were asked to add any missing items from their viewpoints. Then, to investigate the importance and prioritize the identified barriers, the fuzzy Delphi method (FDM) was employed. Finally, to validate the results, several interviews were held with the experts. The steps involved in the methodology are illustrated in Figure 1.

Figure 1. Research methodology taken for determination and ranking of barriers to IoT-based technologies implementation in CSSM.

2.1. Data Collection

In order to obtain practical results, the researchers attempted to select qualified experts with relevant experience (in the context of Hong Kong) and knowledge in this domain. To this end, various criteria (as suggested in [16][17]) were considered in the selection of qualified panels. The criteria used were: (1) to have at least an undergraduate degree relevant to the area, such as in construction engineering, construction management, architecture, or building (this criterion was taken into account to ensure that the respondents were aware of the technical aspects of building projects); and (2) to have at least five years of relevant experience with construction safety; they should be involved in checking and investigating the safety operations being undertaken on site (as managers, engineers, supervisors, or operators in the daily construction activities). Notably, to select the qualified experts for satisfying the second criterion, only those who had five years of experience together with the experience of working in a reflective project (where any IoT-based technologies were adopted) were considered. The second criterion was defined in order to make sure that the respondents had first-hand experience of the technical aspects targeted. The two above-mentioned criteria led to the selection of nine experts for FDM, and five for the validation stage.

2.2. Identification of Barriers

To obtain an exhaustive list of barriers to the adoption of IoT-based technologies in CSSM, a two-step approach was undertaken. First, a comprehensive literature review on the publications published on the topic was conducted, which led to the identification of 18 barriers. Then, an online interview with the senior experts (described in the previous section) was carried out. The list of identified barriers was sent to the selected senior experts and, accordingly, they were asked to add any items missing from the list. Notably, in the interviews undertaken to add more barriers to the list presented to the experts, all of them unanimously stated that the prepared list was quite exhaustive; thus, no more barriers were added.

2.3. Prioritization of the Identified Barriers Using the Fuzzy Delphi Method

The literature consists of many studies that have adopted the Delphi method in order to elicit, refine, and draw upon the collective opinions of a number of experts about a specific subject [18]. Many scholars use this method with the aim of alleviating the adverse impacts of group interactions and providing equal opportunities to all people participating in a study to share their viewpoints and take part in decision making processes [19]. The Delphi method collects all participating experts’ opinions using anonymous questionnaires; afterwards, when the answers are exposed to statistical analyses, the final results are fed back to the experts to be modified again if required. Finally, researchers who make use of this method expect to obtain convergence in the experts’ opinions [20]. On the other hand, several studies have mentioned that the drawback of the traditional Delphi method is the low convergence of the experts’ opinions, as well as the inefficient process of the method when it is taken into action. This is because iterative inquiries are needed to achieve consensus in the experts’ opinions [16]. Furthermore, in the Delphi approach, the participants express their opinions in a verbal manner. This is a challenge, given the fact that verbal expression cannot fully reflect an individual’s real thinking styles and it often fails to show their mental latencies. Therefore, a fuzzy set theory (FST) was proposed with the aim of effectively addressing the issues in relation to the subjectivity, ambiguity, and fuzziness of people’s judgments. FST was able to quantify the linguistic facets of the available data and the preferences for group or individual decision-making sessions [21]. FST is, in fact, a developed version of the traditional set theory, where the elements of a set possess the membership grades ranging between 0 (non-membership) to 1 (full membership) [22]. With this in mind, the following steps were involved in the execution of the FDM for ranking the identified barriers and determining those considered most critical.

Step 1. Designing the FDM-based questionnaire survey. After determining the obstacles to the implementation of IoT in CSSM, a structured questionnaire was provided on the basis of the identified barriers, using the linguistic variables presented in Table 1 (starting from very low importance to very high importance), as suggested in [23]. Afterwards, nine experts were invited to fill out the questionnaire with the use of the defined linguistic variables. Notably, due to the fact that triangular fuzzy sets are considered, each fuzzy set is comprised of three values, namely the lowest possible value, the most likely values, and the highest possible value. As can be seen, the bounds (the lower and the upper) are considered within the range of 1 and 5, while the membership functions are within the range of 0 and 1. It is worth mentioning that based on the qualifications of the experts participating, all were fully aware of the challenges associated with the adoption of IoT-based technologies with regard to CSSM.

Tabl

Table 1. Linguistic variables used for determining the importance of the barriers towards the adoption of IoT in CSSM.

12. Linguistic variables used for determining the importance of the barriers towards the adoption of IoT in CSSM.

| Variables | Fuzzy Numbers |

|---|---|

| Very low importance | (1,1,1.5) |

| Low importance | (1.5,2,2.5) |

| Medium importance | (2.5,3,3.5) |

| High importance | (3.5,4,4.5) |

| Very high importance | (4.5,5,5) |

| Variables | Fuzzy Numbers |

|---|---|

| Very low importance | (1,1,1.5) |

| Low importance | (1.5,2,2.5) |

| Medium importance | (2.5,3,3.5) |

| High importance | (3.5,4,4.5) |

| Very high importance | (4.5,5,5) |

Step

Step 2. Checking the consensus of the responses provided. Once the questionnaires had been filled out by the experts, then there was a need to check whether the consensus among the pool of experts had been reached or not. To this end, the following two rules were considered, as proposed in [

Checking the consensus of the responses provided. Once the questionnaires had been filled out by the experts, then there was a need to check whether the consensus among the pool of experts had been reached or not. To this end, the following two rules were considered, as proposed in [

]:- (a) If the standard deviation to mean ratio (SDMR) for each barrier is less than 30%, then a good level of consensus among the pool of experts for that specific barrier is deemed reached. On the other hand, if the SDMR for each barrier is equal to or more than 30%, then the level of consensus among the pool of experts for that specific barrier is considered poor. Accordingly, the respective experts need to adjust their responses. It is notable that the SDMR needs to be calculated for each barrier separately, based on all of the questionnaires filled out by the pool of experts.

- (b) If the Cronbach reliability test corresponding to the responses of an expert is less than 0.7, then the answers provided are not prudent and, consequently, need to be done again; otherwise, the provided responses are concluded to be sagacious and consistent. It is worth mentioning that the Cronbach reliability test needs to be calculated for checking the consistency of the responses of an expert in filling out the respective survey.

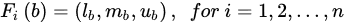

Step 3. Determining the critical barriers. After reaching consensus among the experts, then the answers provided needed to be quantified. The used FDM makes use of triangular fuzzy numbers (TFNs) to retain the key barriers so as to quantify the variables assigned to the identified barriers. Therefore, the max and min values of the experts’ opinions are considered the two terminal points of the TFNs. The arithmetic mean is considered the membership degree of the TFNs when deriving the statistical unbiased impact. In addition, it helps evade the effects of extreme values. For that reason, the use of TFNs brings simplicity, since it covers the opinions of all of the participating experts in a single investigation [25]. After the questionnaire was filled out by the experts, the linguistic variables allocated to each barrier were quantified by the research team. To this end, Equations (1) and (2) were utilized for the calculation of the aggregation of the experts’ feedback for g barriers:

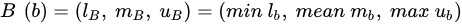

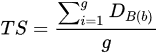

where Fi (b) stands for the TFN response of expert i for barrier b, while B(b) denotes the aggregation of the responses of all of the experts for barrier b, represent the minimum lower bound value allocated by the experts, the mean of the most likely value allocated by the experts based on the arithmetic mean, and the maximum upper bound value allocated by the experts, respectively). Following this, the responses aggregation was subjected to the defuzzification process for the purpose of achieving a crisp value as the significance of each barrier (Equation (3)). To choose the significant barriers, there is a need to calculate a threshold value (Equation (4)) as suggested in [26]:

where D B(b) stands for the defuzzified number of the aggregated responses for barrier b, and TS signifies the threshold value. If the defuzzuifed value of a particular barrier exceeds the specified threshold value, then the barrier will be chosen as a critical one; otherwise, it will be considered non-critical. Notably, for the sake of prioritization, the higher the final weights of barriers ,the more critical the respective barrier.

2.4. Validation Stage

To gauge the external validity of the results obtained, further interviews were held with five experts, who were not in the list of the nine experts formerly selected. To this end, semi-structured interviews were held with five qualified experts for the purpose of validating the obtained results, as suggested in the literature (e.g., [23][27]). These experts were expected to check the applicability of the findings to a bigger picture by giving their opinions in regard to the identified barriers presented to them through some open discussions. Notably, some of the interviews were carried out orally, and others using a questionnaire. Moreover, these five experts were invited to rate the significance of the identified barriers with the help of a five-point Likert scale. The purpose of the validation was to check the “external validity”—which refers to the generalization of the findings.

References

- Zhou, C.; Ding, L.Y. Safety Barrier Warning System for Underground Construction Sites Using Internet-of-Things Technologies. Autom. Constr. 2017, 83, 372–389.

- Antwi-Afari, M.F.; Li, H.; Yu, Y.; Kong, L. Wearable Insole Pressure System for Automated Detection and Classification of Awkward Working Postures in Construction Workers. Autom. Constr. 2018, 96, 433–441.

- Sigcha, L.; Pavón, I.; Arezes, P.; Costa, N.; de Arcas, G.; López, J.M. Occupational Risk Prevention through Smartwatches: Precision and Uncertainty Effects of the Built-in Accelerometer. Sensors 2018, 18, 3805.

- Soltanmohammadlou, N.; Sadeghi, S.; Hon, C.K.H.; Mokhtarpour-Khanghah, F. Real-Time Locating Systems and Safety in Construction Sites: A Literature Review. Saf. Sci. 2019, 117, 229–242.

- Costin, A.; Wehle, A.; Adibfar, A. Leading Indicators—A Conceptual IoT-Based Framework to Produce Active Leading Indicators for Construction Safety. Safety 2019, 5, 86.

- Zhang, M.; Cao, T.; Zhao, X. Using Smartphones to Detect and Identify Construction Workers’ Near-Miss Falls Based on ANN. J. Constr. Eng. Manag. 2019, 145, 04018120.

- Zhou, C.; Luo, H.; Fang, W.; Wei, R.; Ding, L. Cyber-Physical-System-Based Safety Monitoring for Blind Hoisting with the Internet of Things: A Case Study. Autom. Constr. 2019, 97, 138–150.

- Chung, W.W.S.; Tariq, S.; Mohandes, S.R.; Zayed, T. IoT-Based Application for Construction Site Safety Monitoring. Int. J. Constr. Manag. 2020, 1–17.

- Okpala, I.; Parajuli, A.; Nnaji, C.; Awolusi, I.; Student, P.D. Assessing the Feasibility of Integrating the Internet of Things into Safety Management Systems: A Focus on Wearable Sensing Devices. In Construction Research Congress 2020: Computer Applications; American Society of Civil Engineers: Reston, VA, USA, 2020; pp. 236–245.

- Asadzadeh, A.; Arashpour, M.; Li, H.; Ngo, T.; Bab-Hadiashar, A.; Rashidi, A. Sensor-Based Safety Management. Autom. Constr. 2020, 113, 103128.

- Yang, X.; Yu, Y.; Shirowzhan, S.; Sepasgozer, S.; Li, H. Automated PPE-Tool Pair Check System for Construction Safety Using Smart IoT. J. Build. Eng. 2020, 32, 101721.

- Häikiö, J.; Kallio, J.; Mäkelä, S.-M.; Keränen, J. IoT-Based Safety Monitoring from the Perspective of Construction Site Workers. Int. J. Occup. Environ. Saf. 2020, 4, 1–14.

- Rey-Merchán, M.D.C.; Gómez-de-Gabriel, J.M.; López-Arquillos, A.; Fernández-Madrigal, J.A. Virtual Fence System Based on IoT Paradigm to Prevent Occupational Accidents in the Construction Sector. Int. J. Environ. Res. Public Health 2021, 18, 6839.

- Ghosh, A.; Edwards, D.J.; Hosseini, M.R. Patterns and Trends in Internet of Things (IoT) Research: Future Applications in the Construction Industry. Eng. Constr. Archit. Manag. 2021, 28, 457–481.

- Huang, Y.; Trinh, M.T.; Le, T. Critical Factors Affecting Intention OfUse of Augmented Hearing Protection Technology in Construction. J. Constr. Eng. Manag. 2021, 147.

- Tabatabaee, S.; Ashour, M.; Mohandes, S.R.; Sadeghi, H.; Mahdiyar, A.; Hosseini, M.R.; Ismail, S. Deterrents to the Adoption of Green Walls: A Hybrid Fuzzy-Based Approach. Eng. Constr. Archit. Manag. 2021. ahead of print.

- Durdyev, S.; Mohandes, S.R.; Mahdiyar, A.; Ismail, S. What Drives Clients to Purchase Green Building?: The Cybernetic Fuzzy Analytic Hierarchy Process Approach. Eng. Constr. Archit. Manag. 2021.

- Mohandes, S.R.; Zhang, X. Developing a Holistic Occupational Health and Safety Risk Assessment Model: An Application to a Case of Sustainable Construction Project. J. Clean. Prod. 2021, 291, 125934.

- Zhang, X.; Mohandes, S.R. Occupational Health and Safety in Green Building Construction Projects: A Holistic Z-Numbers-Based Risk Management Framework. J. Clean. Prod. 2020, 275, 122788.

- Mahdiyar, A.; Mohandes, S.R.; Durdyev, S.; Tabatabaee, S.; Ismail, S. Barriers to Green Roof Installation: An Integrated Fuzzy-Based MCDM Approach. J. Clean. Prod. 2020, 269, 122365.

- Tabatabaee, S.; Mahdiyar, A.; Durdyev, S.; Mohandes, S.R.; Ismail, S. An Assessment Model of Benefits, Opportunities, Costs, and Risks of Green Roof Installation: A Multi Criteria Decision Making Approach. J. Clean. Prod. 2019, 238, 117956.

- Mohandes, S.R.; Zhang, X. Towards the Development of a Comprehensive Hybrid Fuzzy-Based Occupational Risk Assessment Model for Construction Workers. Saf. Sci. 2019, 115, 294–309.

- Tabatabaee, S.; Mahdiyar, A.; Mohandes, S.R.; Ismail, S. Towards the Development of a Comprehensive Lifecycle Risk Assessment Model for Green Roof Implementation. Sustain. Cities Soc. 2022, 76, 103404.

- Gunduz, M.; Elsherbeny, H.A. Operational Framework for Managing Construction-Contract Administration Practitioners’ Perspective through Modified Delphi Method. J. Constr. Eng. Manag. 2020, 146, 4019110.

- Mohandes, S.R.; Sadeghi, H.; Mahdiyar, A.; Durdyev, S.; Banaitis, A.; Yahya, K.; Ismail, S. Assessing Construction Labours’ Safety Level: A Fuzzy MCDM Approach. J. Civ. Eng. Manag. 2020, 26, 175–188.

- Bouzon, M.; Govindan, K.; Rodriguez, C.M.T.; Campos, L.M.S. Identification and Analysis of Reverse Logistics Barriers Using Fuzzy Delphi Method and AHP. Resour. Conserv. Recycl. 2016, 108, 182–197.

- Rajendran, S.; Gambatese, J.A. Development and Initial Validation of Sustainable Construction Safety and Health Rating System. J. Constr. Eng. Manag. 2009, 135, 1067–1075.

More