The abuse and misuse of antibiotics have led to the emergence of a large number of drug-resistant bacteria in recent decades, which has introduced severe challenges into the medical and health field

[1][80]. As a consequence, it is urgent to develop new substitutes for antibiotics. The development of nanoscience and nanotechnology provides many new ideas and methods for the development of new antibacterial materials. It has become a new trend to use metal nanoparticles, such as silver nanoparticles (AgNPs) and copper nanoparticles (CuNPs), as antibacterial materials

[2][3][4][5][6][81,82,83,84,85]. Metal nanoparticles have many antibacterial properties including ultra-high specific surface area, positive surface charge, and being easy to combine with negatively charged microorganisms to inhibit their growth

[7][8][9][10][11][86,87,88,89,90]. However, metal nanoparticles are easy to agglomerate, dissociate, and oxidize, and these defects greatly limit their antibacterial applications

[12][13][91,92]. As a result, it is necessary to combine metal nanoparticles with other materials to prevent their agglomeration, dissociation, and oxidation. Cellulose-based hydrogels happen to be an excellent carrier for carrying metal nanoparticles

[14][78]. Since their incredible modifiability and slow-release, cellulose hydrogels are appropriate platforms for metal nanoparticle carriage. Metal nanoparticles can be helpfully embellished into cellulose hydrogels and then can be slow release. Notwithstanding the slow release of metal nanoparticles themselves, metal ions will also be gradually released, which will bring a lasting antibacterial result to the hydrogel

[15][16][14,57].

Among the common metal nanoparticles combined with cellulose-based hydrogels, AgNPs are widely adopted due to their excellent broad-spectrum antibacterial properties

[17][93], easy synthesis, and good biocompatibility

[18][94]. Lin et al.

[19][95] modified tannic acid (TA) and AgNPs onto the surface of cellulose nanocrystals and combined with PVA to prepare a cellulose-based antibacterial biomimetic hydrogel containing TA, PVA, and AgNPs. After determining its antibacterial activity by bacteriostatic zone method, it was found that the hydrogel was an effective antibacterial agent. The bacteriostatic zone diameters of

Escherichia coli (

E. coli) and

S. aureus were 7.2 mm and 6.8 mm, respectively, when the addition of AgNPs-TA-cellulose nanocrystals in the hydrogel was 4.0 wt%, showing good bacteriostatic effects. In another study, Bundjaja et al.

[20][96] adopted cellulose carbamate hydrogel loaded with AgNPs and studied the effect of surfactant rarasaponin on the antibacterial activity of AgNPs cellulose carbamate hydrogel. It was found that the addition of surfactant helped to prevent the accumulation of AgNPs and increased the dispersion of AgNPs compared with the hydrogel without modified surfactant. It also increases the contact probability between AgNPs and bacteria, thus increasing the antibacterial activity of the hydrogel. The antibacterial activity of the hydrogel was determined by bacteriostatic zone method, and it was found that the hydrogel had excellent antibacterial activity against

E. coli and

S. aureus. The cytotoxicity of hydrogel was evaluated by skin fibroblast L929, and it was found that hydrogel had good biocompatibility. Combined with its excellent antibacterial properties, the hydrogel was confirmed to be a promising wound dressing. In the meantime, some researchers adopted silver nanoclusters (AgNCs) with smaller particle size to provide antibacterial activity for composite hydrogel. Liu et al.

[21][97] prepared an antibacterial cellulose hydrogel containing AgNCs by in-situ synthesis of AgNCs on the nanofibers of bacterial cellulose hydrogel. The antibacterial activity of AgNCs hydrogel with different loading doses was tested by bacteriostatic zone method using Gram-positive bacteria

S. aureus as model bacteria. The results showed that the antibacterial effect of AgNCs hydrogel prepared by 10 mmol/L AgNO

3 solution was the best. The amount of Ag loading of hydrogel under this condition was determined to be 11.25 mg/g by inductively coupled plasma mass spectrometry, and the diameter of bacteriostatic zone of hydrogel to

S. aureus was 4 cm. In the meantime, it was also found that the antibacterial activity of the hydrogel prepared by this method against Gram-positive bacteria and Gram-negative bacteria was better than that of AgNCs alone.

Besides, different from simply using AgNPs, some researchers adopted aminated AgNPs (AgNPs-NH

2) to provide antibacterial activity for composite hydrogel. For instance, Liu et al.

[22][108] crosslinked aminated AgNPs, gelatin and carboxylated cellulose nanofibers through dynamic ion bridges to form hydrogel. The antibacterial activity of the hydrogel against

S. aureus and

Pseudomonas aeruginosa (

P. aeruginosa) was analyzed by turbidimetry and bacteriostatic zone method. It was found that the hydrogel had inhibitory effect on the two most common bacteria, and the hydrogel containing 0.5 mg/mL AgNPs-NH

2 had the best antibacterial effect. In addition, the hydrogel has the advantages of water retention, hemostasis, and good biocompatibility, which can promote wound healing.

In addition to using AgNPs to provide antibacterial activity for composite hydrogel, CuNPs were also used to provide antibacterial activity for composite hydrogel. Al-Enizi et al.

[14][78] prepared cellulose hydrogel containing CuNPs by polymer cross-linking method. Bacteriostatic zone method was adopted to determine the antibacterial activity of the hydrogel against pathogens of urinary tract infection. It was found that the antibacterial activity of hydrogel increased with the increase of CuNPs loading. When the concentration of CuNPs in the hydrogel is 5 mg/mL, the diameter of the bacteriostatic zone to

E. coli,

Klebsiella pneumoniae (

K. pneumoniae),

P. aeruginosa,

Proteus vulgaris,

S. aureus and

Proteus mirabilis is 16.0 mm, 15.2 mm, 16.4 mm, 15.8 mm, 15.6 mm and 15.8 mm, respectively. The experimental results showed that the composite hydrogel had excellent bacteriostatic effect. In the meantime, it was found that the hydrogel also had good biocompatibility by evaluating the cytotoxicity of the hydrogel to human cervical cancer cell line. As a consequence, based on the water absorption, antibacterial, and biocompatibility of the hydrogel, the hydrogel has the potential to be developed into sanitary napkins, diapers, and other related care products.

In general, some metal nanoparticles can bring high efficiency, low drug resistance and broad-spectrum antibacterial activity to cellulose-based hydrogels. Cellulose-based hydrogels containing metal nanoparticles, as an antibacterial material, indeed have ideal antibacterial effect and has a wide range of applications. However, the high cost of preparation, long-term biological toxicity, and environmental cumulative toxicity of metal nanoparticles are still problems that need to be further clarified and solved. Simultaneously, the stability and durability of the antibacterial effect of hydrogels are associated with the even distribution and long-term stable presence of nanometals in hydrogels, which need to be further discovered. Additionally, most metal nanoparticles are presently bonded to cellulose-based hydrogels by physical interaction, which is not powerful enough and cannot be fixed-point modified. Consequently, developing more reliable and controllable modification methods in the subsequent research is required.

2. Cellulose-Based Antibacterial Hydrogels Loaded with Metal Oxide Nanoparticles

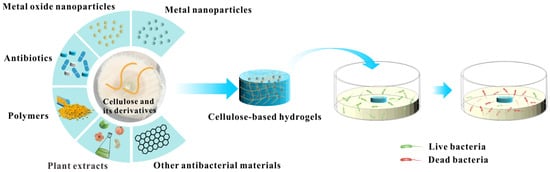

In addition to the antibacterial properties brought by the combination of metal nanoparticles and cellulose-based hydrogels, as the further development of nanoscience and nanotechnology, it has been reported that metal oxide nanoparticles, antibiotics, polymers plant extracts and other antibacterial materials are combined with cellulose-based hydrogels (

Figure 1). Metal oxides (such as ZnO, TiO

2, and CuO) act as enhancers for cellulose-based hydrogels and provide excellent antibacterial properties for cellulose composite hydrogels. The inclusion of metal oxides increased the density of the hydrogel network. In the meantime, the dense hydrogel network turns into a nanoscale reservoir layer for drugs, further improving the effect of hydrogel loading and slow-release antibacterial agents, then extending the antibacterial timeliness of hydrogels

[23][109]. Similar to metal nanoparticles, metal oxides also have broad-spectrum antibacterial and low drug resistance. Moreover, metal oxide nanoparticles have stronger chemical stability and antioxidant capacity

[24][25][26][27][28][29][110,111,112,113,114,115].

Figure 1. Antibacterial schematic diagram of cellulose-based hydrogels loaded with different antibacterial agents.

Zinc oxide nanoparticles (ZnONPs) were developed to provide antibacterial activity for cellulose-based hydrogels. For example, Yadollahi et al.

[30][116] prepared carboxymethyl cellulose-ZnONPs composite hydrogel by in-situ synthesis of ZnONPs in expanded carboxymethyl cellulose hydrogel. The antibacterial activity of the hydrogel against

E. coli and

S. aureus was tested by bacteriostatic zone method. The antibacterial circle diameter of the hydrogel to

E. coli (20 ± 2 mm) and

S. aureus (28 ± 2 mm) is the largest when the zinc nitrate concentration is 0.03 mol/L. It has been proven that the hydrogel has excellent antibacterial activity against these two kinds of bacteria, and its antibacterial activity increases with the increase of ZnONPs concentration in the hydrogel.

In another study, George et al.

[31][117] prepare cellulose composite hydrogel containing ZnONPs using crosslinked dialdehyde cellulose prepared from sugarcane cellulose with chitosan, and mixed with ZnONPs synthesized from muskmelon seed extract. The antibacterial potential of the hydrogel was determined by bacteriostatic zone method, and its antibacterial activity against common skin infection pathogens

S. aureus and

Trichophyton rubrum was studied. It was found that the chitosan cellulose hydrogel without ZnONPs had certain antibacterial properties, and the antibacterial activity came from chitosan. In contrast, it was found that the antibacterial activity of the hydrogel added with ZnONPs was significantly improved. Besides, it was also found that the hydrogel can be adopted as a carrier of curcumin, and the loading rate can reach at 89.68%. In the meantime, the antibacterial activity of curcumin is well preserved.

Tungsten oxide nanoparticles (WO

3NPs) were adopted to provide antibacterial activity for cellulose-based hydrogels. Based on hydroxyethyl cellulose and adding WO

3NPs, Fawal et al.

[32][40] prepared a new WO

3NPs-hydroxyethyl cellulose hydrogel by casting method for wound treatment. The wound healing activity of the hydrogel was studied by human dermal fibroblast scratch test. The biocompatibility, anti-inflammatory activity, and antibacterial activity of the hydrogel were tested by methyl thiazolyl tetrazolium (MTT) method, enzyme-linked immunosorbent assay and bacteriostatic circle method. The results showed that the hydrogel had good wound healing activity, biocompatibility, anti-inflammatory activity and antibacterial effect. The diameter of the bacteriostatic zone against the five kinds of

Shigella sp.,

Salmonella sp.,

P. aeruginosa,

Bacillus cereus,

S. aureus was 19 ± 0.12 mm, 26 ± 0.2 mm, 20 ± 0.13 mm, 17 ± 0.15 mm, and 14 ± 0.13 mm, respectively, when the concentration of WO

3NPs in the hydrogel was 0.08 wt%. Besides, it was found that the hydrogel increased the activity of human normal cells (leukocytes and human dermal fibroblasts) and reduced the cytotoxicity of WO

3NPs. Combining these research results, it can be found that the hydrogel has the potential to become an excellent wound dressing.

Titanium dioxide nanoparticles (TiO

2NPs) were used to provide antibacterial activity for cellulose-based hydrogels. TiO

2NPs sol was synthesized by Zhang et al.

[33][118] in β-cyclodextrin cellulose solution via sol-gel method, and then crosslinked the mixture with epichlorohydrin to prepare a new type of TiO

2NPs-β-cyclodextrin-cellulose hydrogel composites. Using

E. coli and

S. aureus as model bacteria, the antibacterial activity of the hydrogel was investigated under natural light and dark conditions, respectively. Curcumin was adopted as a model drug to test the sustained release behavior of curcumin in phosphate buffer. The results showed that the hydrogel had good antibacterial activity under light condition, but its antibacterial activity was negligible under no light condition. In the meantime, through the drug sustained release experiment, it was found that curcumin could be completely released from the hydrogel after 120 h.

Copper oxide nanoparticles (CuONPs) were exploited to provide antibacterial activity for composite hydrogel. Dharmalingam et al.

[34][119] combined sodium carboxymethyl cellulose and hydroxypropyl methyl cellulose with CuONPs to form cellulose composite hydrogel using citric acid as non-toxic cross-linking agent. The bacteriostatic activity of the hydrogel against

S. aureus and

E. coli was determined by the bacteriostatic zone method. It was found that, the bacteriostatic effect was the best, and the diameter of bacteriostatic zone for

S. aureus and

E. coli was about 12 mm when the addition of citric acid in the hydrogel was 20%. In the meantime, it was also found that the hydrogel had biocompatibility for the proliferation of HaCaT cells.

Similar to metal nanoparticles, cellulose-based hydrogels containing metal oxide nanoparticles has high efficiency, low drug resistance and broad-spectrum antibacterial properties. As a consequence, it has a very broad application prospect. However, for metal oxide nanoparticles, the problems of long-term biological toxicity and environmental cumulative toxicity are also that need to be further clarified and solved. Despite the fact that metal oxide nanoparticles are more challenging to be oxidized and more stable than metal nanoparticles, metal oxide nanoparticles have the disadvantage of being harder to release metal ions. This drawback will diminish the antibacterial effect of metal oxide nanoparticles, so how to make metal oxide nanoparticles that can release metal ions in hydrogels consistently and steadily deserves further investigation. Correspondingly, metal oxide nanoparticles also have the disadvantage of easy aggregation, and new modification methods need to be developed to overcome them. Thus, one of the advantages of metal oxide nanoparticles in antibacterial aspects also needs to be thoroughly exploited. That is, metal oxide nanoparticles are more prone to producing reactive oxygen species (ROS) than metal nanoparticles. This is to say that ROS have an awesome antibacterial effect, so it is very worthy of attention and further study.

3. Cellulose-Based Antibacterial Hydrogels Loaded with Antibiotics

Since the 20th century, antibiotics have been the first choice for the treatment of bacterial infections due to their efficient bactericidal ability and low toxicity to mammalian cells

[35][120]. The application of antibiotics is one of the most exciting events in modern medicine, which has saved countless lives and greatly extended the life span of human beings

[36][121]. Direct use of antibiotics may be an effective way to combat many infections, but direct use of antibiotics will have adverse factors such as environmental toxicity, bacterial drug resistance, short duration of antibacterial activity, out of control of local concentration, and degradation in some application scenarios

[35][37][38][39][40][120,122,123,124,125]. Thus, it is necessary to design a drug delivery system with high biocompatibility and good antibacterial effect, which not only meets the requirements of low cytotoxicity, but also meets the antibacterial requirements

[37][41][42][122,126,127].

Linezolid was adopted to provide antibacterial activity for cellulose-based hydrogels. Drug-loaded composite hydrogel was prepared by Forero-Doria et al.

[43][128] from cross-linking cellulose, chalcone and carbon nanotubes. With a single antibiotic as positive control, the inhibitory activity of linezolid-loaded hydrogel on

Enterococcus faecalis (

E. faecium) was studied. The results showed that the antibacterial effect of antibiotics was better in the first hour during the bacteriostatic process. However, with the passage of time, it would lose its effectiveness, and the antibacterial time of the composite hydrogel loaded with linezolid on

E. faecium could be up to 48 h. It was found that the hydrogel can enhance the stability of linezolid after the combination of linezolid and hydrogel, and slowly release it in the solution to play a stronger antibacterial effect. The above findings showed that the drug-loaded composite hydrogel prepared by this method had great potential in promoting wound healing.

Tetracycline was adopted to provide antibacterial activity for cellulose-based hydrogels. Nanocomposite hydrogel containing polyethylene glycol, acrylamide, N, N’-methylene bisacrylamide and cellulose nanofibers was prepared by Iman et al.

[44][129], and then loaded tetracycline into the hydrogel. The bacteriostatic effect of the hydrogel on

S. aureus and

E. coli was determined by bacteriostatic zone method. It was found that the pure hydrogel without tetracycline had no antibacterial activity. When the content of tetracycline was 300 μg/g, the antibacterial circle diameter of the hydrogel against

S. aureus and

E. coli was 33 mm and 25 mm, respectively. The hydrogel containing 4 wt% cellulose nanofibers have the best controlled release effect on tetracycline and does not destroy the stability of tetracycline. Besides, it was found that the hydrogel had good biocompatibility by testing the toxicity of hydrogel to the intestines and stomach of rats.

Minocycline hydrochloride was adopted to provide antibacterial activity for cellulose-based hydrogels. Patwa et al.

[45][130] prepared a magnetic cellulose composite hydrogel using ion cross-linking between alginate and casein and doping bacterial cellulose modified by magnetic nanoparticles. Minocycline hydrochloride was loaded into the composite hydrogel as a model drug, and the composite hydrogel modified by minocycline hydrochloride was prepared. The bacteriostatic effect of the hydrogel on

E. coli and

S. aureus was investigated by bacteriostatic zone test. It was found that the hydrogel had obvious inhibitory effect on

S. aureus and

E. coli at 24 h, 48 h, one week, and two weeks. Through the drug-controlled release experiment, it was found that the hydrogel could release antibiotics continuously and effectively for a long time (more than two weeks). The cytotoxicity of hydrogel was evaluated by mouse embryonic fibroblasts and it was found that the hydrogel did not have any cytotoxicity and was suitable for transdermal administration.

Clindamycin was developed to provide antibacterial activity for cellulose-based hydrogels. Sadeghi et al.

[46][131] prepared cellulose composite hydrogel with sustained release effect on clindamycin using carboxymethyl cellulose and human hair keratin as raw materials, citric acid as cross-linking agent with halloysite nanotubes and clindamycin. The antibacterial activity of the hydrogel against

S. aureus was evaluated by bacteriostatic zone method and colony counting method. The obtained results showed that the antibacterial activity of the hydrogel was the highest when the ratio of keratin to carboxymethyl cellulose in the hydrogel was 0:1, the antibacterial rate against

S. aureus was 99.66 ± 0.7%, and had antibacterial persistence (more than 24 h). Besides, it was also found that hydrogel could significantly promote the attachment, proliferation and diffusion of fibroblasts with the increase of keratin content. It can be found that the composite hydrogel is a promising candidate material to promote skin tissue repair and regeneration.

Herbmedotcin was adopted to provide antibacterial activity for cellulose-based hydrogels. Johnson et al.

[47][132] adopted cellulose nanofibers and κ-carrageenan oligosaccharide nanoparticles as raw materials to prepare Herbmedotcin-κ-carrageenan oligosaccharide-cellulose composite hydrogel, which were adopted to kill periodontitis-associated bacteria. The antibacterial activity of the hydrogel against

Streptococcus mutans,

Porphyromonas gingivalis,

Fusobacterium nucleatum,

and P. aeruginosa was tested by the bacteriostatic zone method. It was found that the hydrogel had strong antibacterial activity against the above four kinds of bacteria, and the bacteriostatic effect was the best when the loading amount of Herbmedotcin in the hydrogel was 4 mg/mL. The diameter of the corresponding bacteriostatic zone was

Streptococcus mutans 26.33 ± 1.52 mm,

Porphyromonas gingivalis 18.33 ± 0.57 mm,

Fusobacterium nucleatum 20.33 ± 0.63 mm,

and P. P. aeruginosaaeruginosa 20.66 ± 1.25 mm. Additionally, hydrogel also reduced the production of ROS in gingival fibroblasts of patients with periodontitis, indicating that hydrogel has antibacterial and anti-inflammatory properties and has the potential to be adopted in the treatment of periodontitis.

Up to now, antibiotics are still the first choice to fight bacterial infection in the biomedical field, protecting human health. However, antibiotics also have fatal shortcomings, resulting in the emergence of a large number of drug-resistant bacteria, which is a serious threat to human health and health safety (Table 1). In the follow-up study on the combination of antibiotics and cellulose hydrogel, on the one hand, it is necessary to pay attention to the development of antibiotics with better antibacterial effect and lower drug resistance. On the other hand, it is necessary to systematically study the effects of the combination of antibiotics and cellulose hydrogel on the stability of antibiotics, antibacterial properties, and bacterial resistance, as well as potential environmental toxicity.

Table 1. The advantages and disadvantages of different antibacterial agents used to modify cellulose-based hydrogels.

| Antibacterial Agents |

Advantages |

Disadvantages |

Typical Applications |

References |

| Metal or oxidized metal nanoparticles |

Broad-spectrum and long-term antibacterial, low bacterial resistance |

Tend to agglomerate, certain cytotoxicity and environmental toxicity |

Wound dressing

Self-healing artificial skin |

[12][19][48][49][50][51][52][91,95,133,134,135,136,137] |

| Antibiotics |

Specific and efficient antibacterial, ideal biocompatibility |

Bacterial resistance and short-term antibacterial activity, prone to degradation and instability |

Clinical antibacterial

Wound healing |

[35][37][53][54][55][56][120,122,138,139,140,141] |

| Polymers |

Biodegradable and nontoxic, high modifiability and biocompatibility |

Poor permeability |

Antibacterial food packaging

Treatment of periodontitis |

[47]132[57][58][,14259,143],144[60],145[61][,146] |

| Plant extracts |

Rich resources, environmentally friendly, anti-drug resistant bacteria |

Difficult to extract and enrich |

Biomedicine

Treatment of chronic infection |

[62][63][64[67][147,148][,14965][,15066],151,152] |