A dependence of Brinell hardness and thermal diffusivity tensor components upon humidity for common pine wood is found. The results of the measurement of Brinell hardness, microhardness, Young’s modulus, and main components of thermal diffusivity tensor for three perpendicular cuts are found to be correlated. It is shown that the mechanical properties correlate better with the ratio of longitude to transversal thermal diffusivity coefficients than with the respective individual absolute values. The mechanical characteristics with the highest correlation with the abovementioned ratio are found to be the ratio of Young’s moduli in longitude and transversal directions. Our technique allows a comparative express assessment of wood mechanical properties by means of a contactless non-destructive measurement of its thermal properties using dynamic thermal imaging instead of laborious and material-consuming destructive mechanical tests

- thermal diffusivity

- dynamic thermal imaging

- mechanical properties

- Brinell hardness

- microhardness

- Young’s modulus

1. Introduction

2.Relationship between Thermal Diffusivity and Mechanical Properties of Wood

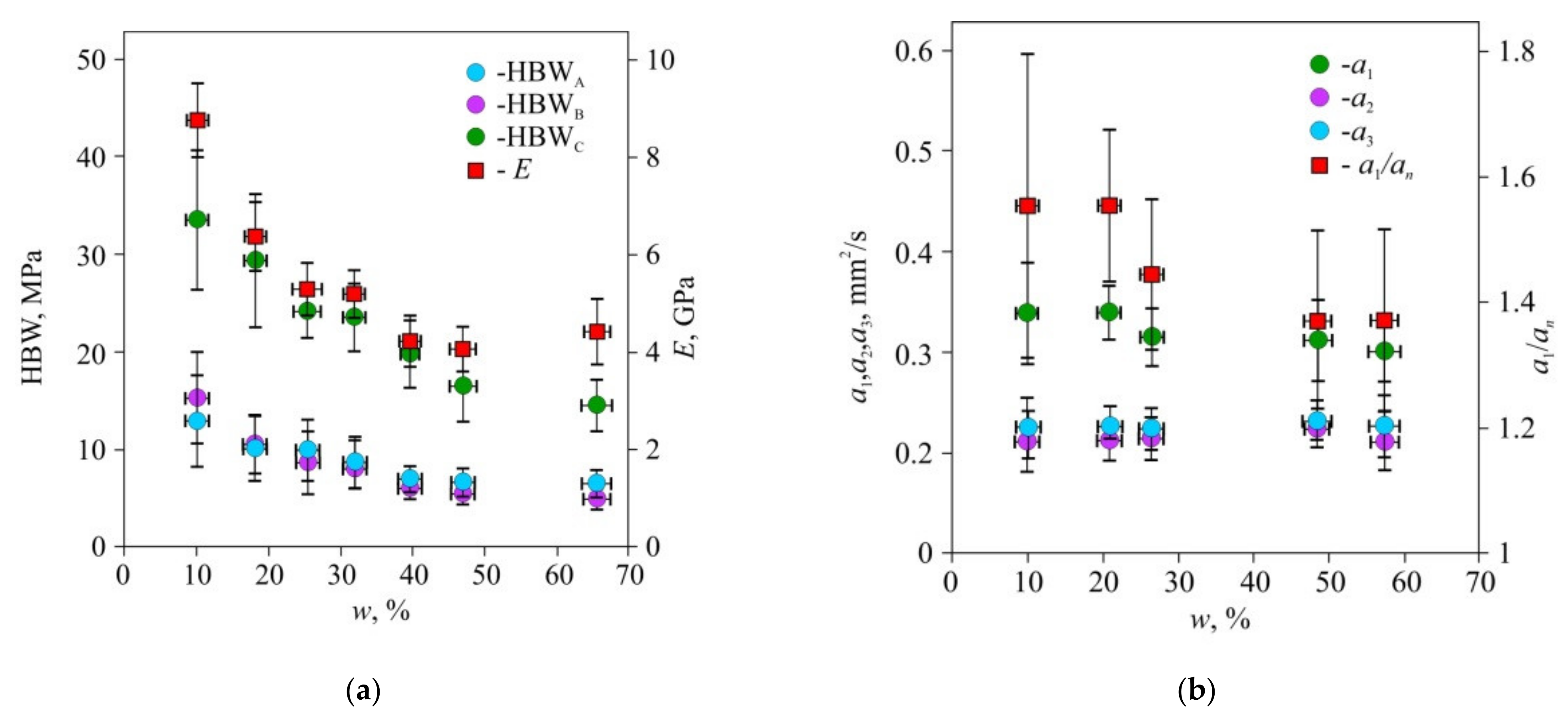

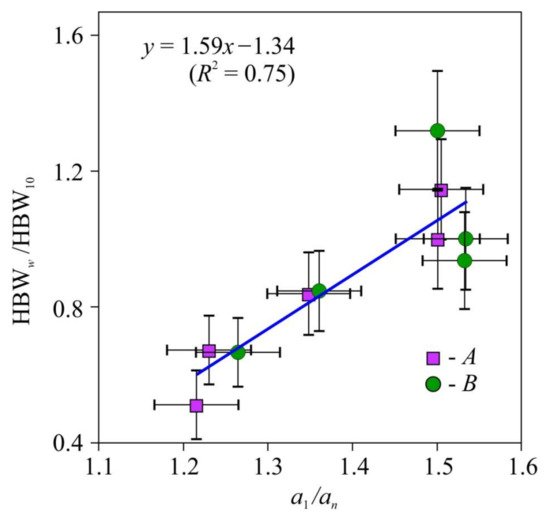

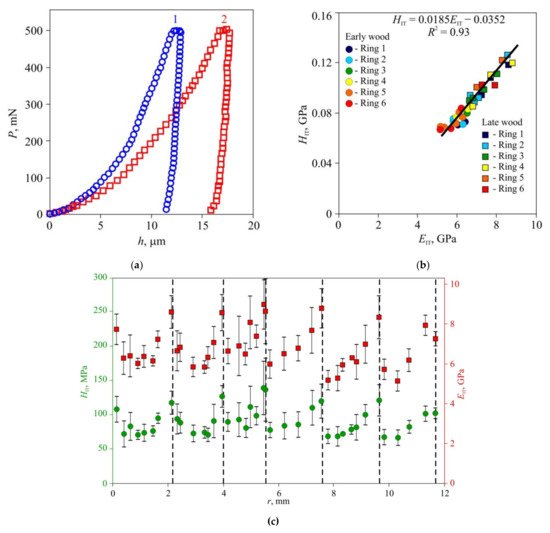

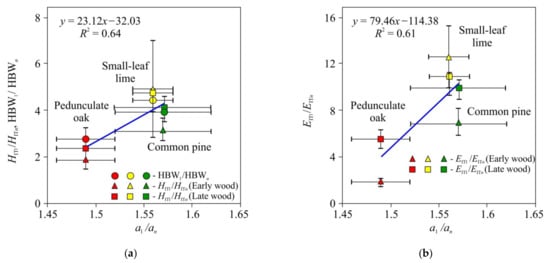

In the first stage of the experiments, wthe researchers studied Brinell hardness HBW, Young’s modulus E (Figure 1a), and the main components a1, a2, and a3 of thermal diffusivity tensor (Figure 1b) dependencies in common pine wood on its humidity w. The absolute and relative values of a1, a2, and a3 are affected by w differently. The a1 component displayed significant dependence on w along the fibers, while across the fibers, the dependence of the components a2 and a3 upon w was weak, and they were statistically indistinguishable. Hence, it was reasonable to introduce the averaged value an = (a2 + a3)/2 of thermal diffusivity normal to the fibers. The relative values al/an that characterize thermal diffusivity anisotropy were even more sensitive to humidity change than the absolute ones (Figure 1b).

| Type of Wood | Micromechanical Properties (Obtained by Nanoindentation with Pmax = 500 mN) |

Macromechanical Properties | TPP | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| EIT1, GPa | EITn, GPa | EIT1/EITn | HIT1, MPa | HITn, MPa | HIT1/HITn | HBW1, MPa | HBWn, MPa | HBW1/HBWn | a1/an | |

| Common pine (Pinus sylvestris L.) | ||||||||||

| Early wood | 4.39 ± 0.04 |

0.44 ± 0.04 |

10 ± 1 |

57 ± 2 |

14 ± 1 |

4.0 ± 0.5 |

42 ± 2 | 11 ± 1 | 3.9 ± 0.7 | 1.57 ± 0.05 |

| Late wood | 12.4 ± 0.7 |

1.8 ± 0.2 |

7 ± 1 |

180 ± 10 |

58 ± 4 |

3.1 ± 0.4 |

||||

| Pedunculate oak (Quercus robur L.) | ||||||||||

| Early wood | 3.1 ± 0.2 |

1.7 ± 0.2 |

1.9 ± 0.3 |

64 ± 3 |

34 ± 5 |

1.9 ± 0.4 |

67 ± 4 | 24 ± 3 | 2.8 ± 0.5 | 1.49 ± 0.03 |

| Late wood | 11.1 ± 0.8 |

2.0 ± 0.2 |

5.6 ± 0.8 |

190 ± 20 |

80 ± 8 |

2.4 ± 0.4 |

||||

| Small-leaf Lime (Tilia cordata Mill.) | ||||||||||

| Early wood | 6.7 ± 0.1 |

0.61 ± 0.08 |

11 ± 2 |

75 ± 4 |

16 ± 3 |

5 ± 1 |

39.4 ± 1.5 | 8.9 ± 0.6 | 4.4 ± 0.5 | 1.56 ± 0.02 |

| Late wood | 8.6 ± 0.8 |

0.68 ± 0.08 |

13 ± 3 |

120 ± 20 |

24 ± 7 |

5 ± 2 |

||||

References

- Hsueh, C.-H.; Schmauder, S.; Chen, C.-S.; Chawla, K.K.; Chawla, N.; Chen, W.; Kagawa, Y. (Eds.) Handbook of Mechanics of Materials; Springer Nature Singapore Pte Ltd.: Gateway East, Singapore, 2019; 2464p.

- Krištak, L.; Igaz, R.; Ružiak, I. Applying the EDPS Method to the Research into Thermophysical Properties of Solid Wood of Coniferous Trees. Adv. Mater. Sci. Eng. 2019, 2019, 2303720.

- Kristak, L.; Ruziak, I.; Tudor, E.M.; Barbu, M.C.; Kain, G.; Reh, R. Thermophysical Properties of Larch Bark Composite Panels. Polymers 2021, 13, 2287.

- Suleiman, B.; Larfeldt, J.; Leckner, B.; Gustavsson, M. Thermal conductivity and diffusivity of wood. Wood Sci. Technol. 1999, 33, 465–473.

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667.

- Hassani, N.J.M. Physical and Mechanical Properties of Wood. 2018. Available online: https://forestrypedia.com/physical-and-mechanical-properties-of-wood/ (accessed on 12 August 2021).

- Chen, C.; Kuang, Y.; Zhu, S.; Burgert, I.; Keplinger, T.; Gong, A.; Li, T.; Berglund, L.; Eichhorn, S.J.L.; Hu, L. Structure–property–function relationships of natural and engineered wood. Nat. Rev. Mater. 2020, 5, 642–666.

- Ross, R. Forest Products Laboratory. In Wood handbook—Wood as an Engineering Material; General Technical Report FPL-GTR-282; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2021; 543p.

- Luan, C.; Movva, S.; Wang, K.; Yao, X.; Zhang, C.; Wang, B. Towards next-generation fiber-reinforced polymer composites: A perspective on multifunctionality. Funct. Compos. Struct. 2019, 1, 042002.

- Senalik, C.A.; Farber, B. Mechanical Properties of Wood. Ch. 5. In Wood Handbook—Wood as an Engineering Material; General Technical Report FPL-GTR-282; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2021; pp. 5.1–5.46.

- Golovin, D.Y.; Divin, A.G.; Samodurov, A.A.; Tyurin, A.I.; Golovin, Y.I. Temperature diffusivity measurement and nondestructive testing requiring no extensive sample preparation and using stepwise point heating and IR thermography. In Failure Analysis; Huang, Z.-M., Hemeda, S., Eds.; InTech: London, UK, 2019; pp. 124–160.

- Golovin, D.Y.; Samodurov, A.A.; Tyurin, A.I.; Golovin, Y.I.; Divin, A.G. A new rapid method of determining the thermal diffusivity of materials and finished articles. J. Eng. Phys. Thermophys. 2020, 93, 234–240.

- Golovin, D.Y.; Tyurin, A.I.; Samodurov, A.A.; Divin, A.G.; Golovin, Y.I. Dinamicheskiye termograficheskiye metody nerazrushayushchego ekspress-kontrolya (Dynamic Thermographic Methods of NDT); Technosfera: Moscow, Russia, 2019; 214p. (In Russian)

- Thybring, E.E.; Fredriksson, M. Wood modification as a tool to understand moisture in wood. Forests 2021, 12, 372.

- Edgars, L.; Kaspars, Z.; Kaspars, K. Structural performance of wood based sandwich panels in four point bending. Procedia Eng. 2017, 172, 628–633.

- Hao, J.; Wu, X.; Oporto, G.; Liu, W.; Wang, J. Structural analysis and strength-to-weight optimization of wood-based sandwich composite with honeycomb core under three-point flexural test. Eur. J. Wood Prod. 2020, 78, 1195–1207.

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos.-A Appl. Sci. Manuf. 2016, 83, 98–112.

- Syduzzaman, M.; Al Faruque, M.A.; Bilisik, K.; Naebe, M. Plant-based natural fibre reinforced composites: A review on fabrication, properties and applications. Coatings 2020, 10, 973.

- Huang, X.; Yang, L.; Meng, L.; Lu, J. Mechanical and thermal properties of cellulose nanocrystals from jute fibers reinforced epoxy composites. J. Text. Inst. 2021, 1–5.

- Shah, D.U.; Bock, M.C.D.; Mulligan, H.H.; Ramage, M.H. Thermal conductivity of engineered bamboo composites. J. Mater. Sci. 2016, 51, 2991–3002.

- Shah, D.U.; Konnerth, J.; Ramage, M.H.; Gusenbauer, C. Mapping thermal conductivity across bamboo cell walls with scanning thermal microscopy. Sci. Rep. 2019, 9, 16667.

- Toumpanaki, E.; Shah, D.U.; Eichhorn, S.J. Beyond what meets the eye: Imaging and imagining wood mechanical–structural properties. Adv. Mater. 2021, 33, 2001613.

- Catena, A. Thermography reveals hidden tree decay. Arboric. J. 2003, 27, 27–42.

- Catena, A.; Catena, G. Overview of thermal imaging for tree assessment. Arboric. J. 2012, 30, 259–270.

- Vidal, D.; Pitarma, R. Infrared thermography applied to tree health assessment: A review. Agriculture 2019, 9, 156.

- Palumbo, D.; Cavallo, P.; Galietti, U. An investigation of the stepped thermography technique for defects evaluation in GFRP materials. NDT E Int. 2019, 102, 254–263.

- Addepalli, S.; Zhao, Y.; Roy, R.; Galhenege, W.; Colle, M.; Yu, J.; Ucur, A. Nondestructive evaluation of localized heat damage occurring in carbon composites using thermography and thermal diffusivity measurement. Measurement 2019, 131, 706–713.

- Meola, C.; Toscano, C. Flash thermography to evaluate porosity in carbon fiber reinforced polymer (CFRPs). Materials 2014, 7, 1483–1501.

- Guo, J.; Gao, X.; Toma, E.; Netzelmann, U. Anisotropy in carbon fiber reinforced polymer (CFRP) and its effect on induction thermography. NDT E Int. 2017, 91, 1–8.

- Adamczyk, W.; Ostrowski, Z.; Ryfa, A. Development of a non-destructive technique for measuring thermal conductivity of material with small anisotropy based on application of the reduced order technique. Measurement 2020, 165, 108078.

- Lages, E.N.; Marques, S.P.C. Prediction of effective thermal conductivity of multiphase composites with periodic microstructures using an expanded micromechanical model. Int. J. Therm. Sci. 2022, 171, 107226.

- Carrillo-Varela, I.; Valenzuela, P.; Gasitua, W.; Mendoca, R.T. An evaluation of fiber biometry and nanomechanical properties of different eucalyptus species. Bioresources 2019, 14, 6433.