Adaptive Dynamic Building Envelope (ADBE) is the term used to describe envelope systems that increase the adaptability of the building skin toward changing ambient conditions, resulting in better energy efficiency and thermal comfort. ADBEs exploit the benefits of passive and active technologies that manage the energy and mass transfer between building and outdoor environment. There is a range of technologies that an ADBE can incorporate to enhance a building’s energy performance. According to their usage, they can be sorted into four categories, i.e., technologies for energy harvesting, technologies affecting heat transfer, technologies for air conditioning, and technologies for storage systems. ADBEs vary from one another based on their level of active-passiveness, and user controllability. The first characteristic is the level of how active or passive the technologies used in the final ADBE product perform. The second characteristic is the level of occupant interaction with the envelope, meaning if the user has the ability to operate some functions on the ADBE manually, or through the usage of building energy management systems.

1. Introduction

Buildings consume a share of approximately 30–40% of the primary energy throughout the world and make up for nearly one-third of the greenhouse gas emissions (GHG)

[1]. The European Union policies on building level are moving toward an integrated approach considering energy, costs, and environmental aspects together with enhancement of indoor comfort. In 2018, the European Parliament legislated for an improved 2030 target of reducing domestic greenhouse gas emission by at least 40%

[2]. The European Commission and the Horizon 2020 program promote affordable technologies and solutions at building and district levels to ensure a shift toward the decarbonization of the existing building market

[3]. An effective solution to shift toward decarbonization in the built environment is the improvement of building envelopes. As a result, a growing number of incentives, such as COST Action TU 1403 on adaptive facades

[4], encourage specialized academic research to improve the building envelope with the help of different technologies. Furthermore, the International Energy Agency Solar Heating and Cooling research network (IEA SHC) amends research and practical approaches toward more adaptive façades by initiating two task forces. Task 56

[5] focuses on simulation, laboratory testing, and onsite monitoring of Building Integrated Solar Envelope Systems, while Task 60

[6] provides principals for the system design of photovoltaic thermal hybrid solar collectors (PVT collectors) and explores the performance of existing technologies.

The building envelope is the interface between indoor and outdoor environments and is mainly responsible for mitigating harsh weather conditions outside

[7]. Regardless of how the envelope is designed, it is not possible to avoid undesirable heat, mass, and humidity transfer between indoor and outdoor spaces, mainly because of temperature and humidity differences during most times of the year. This includes heat conduction and radiation exchange from the envelope surfaces, and direct air exchange through ventilation and leakage

[8]. The internal environmental condition is usually maintained through a mix of active and passive measures that can be incorporated into the envelope structure

[9][10][9,10]. Passive measures usually include materials and window constructions that do not require direct energy to perform. The active measures refer to the Heating, Cooling and Air Conditioning systems (HVAC), which transform some means of energy into heating, cooling, or humidification measures. The combination of active and passive systems enables the envelope to dynamically adapt to the outdoor weather conditions more resiliently, which results in improved energy efficiency and occupant thermal comfort. These so-called Adaptive Dynamic Building Envelopes (ADBEs) need to be properly designed in order to lower the heating and cooling loads of the building, either through the use of active technologies, passive technologies, or a combination of both of these technologies.

The passive control of indoor conditions has been a popular intervention by designers throughout history and dates back to the hanging gardens of Babylon. It has mainly consisted of climbing greeneries on walls with cooling and shading effects. This idea had been used in ancient architecture of hot-arid climates where evaporative cooling works most effectively. In modern construction, the same idea was pursued by following the so-called green façade idea, which consisted of climbing plants growing over the walls or on a mesh system attached to the wall

[11], and was heavily promoted in North America in 1920s

[12]. Other creative passive control systems were double-skin façades in the 1850s, which were widely used in the US, Europe, and Japan

[13]. The idea entails a passive façade consisting of layers of glazing and air, where the air could potentially flow freely between the layers

[14]. Another passive design solution seeks to improve the thermal properties of the building Trombe wall system

[15]. The Trombe wall consists of a high thermal mass material as the base and a glazing layer installed in a small distance from it. This system captures the solar radiation, which then transfers part of it to the interior space through convection. Another feature of the Trombe wall is the circulation of air through its gaps. More specifically, the air circulates in the adjacent room through openings at the lower and upper part of the wall, providing a hot stream of air that helps the thermal comfort.

[16].

The use of complex materials in the building envelope revolutionized passive design of the façade. Applying phase change materials (PCM) in the building design began in the mid-1940s

[17]. ‘Smart materials’ as the keywords for such systems are defined as ‘embedded technological functions’ that have a specific response to ambient changes, exploiting the changing physical properties of the materials

[18].

2. Technologies and Typologies of ADBEs

Since the term “ADBE” is newly introduced, the overall ADBE concept is quite abstract and may include a variety of technologies, typologies, etc., depending on their purpose

[19][36].

2.1. Technologies of ADBEs

There is a range of technologies that an ADBE can incorporate to enhance a building’s energy performance. According to their usage, they can be sorted into four categories, i.e., technologies for energy harvesting, technologies affecting heat transfer, technologies for air conditioning, and technologies for storage systems

[20][21][37,38].

2.1.1. Technologies for Energy Harvesting

In general, energy harvesting can be performed through a variety of Renewable Energy Sources (RES), which have minimal environmental impact

[22][39]. However, when it comes to building envelopes, the options may be limited due to space and weight concerns. In literature, the main (but not the only) source utilized for energy harvesting in buildings is solar radiation

[23][40]. A popular technology for electrical energy harvesting in ADBEs is the BIPV system

[24][41]. This practical technology can be added either on the façade of a building, where it may cover a large area, or on its roof, where it may produce power more efficiently due to the tilt angle

[25][42]. In both cases, it produces electrical energy throughout the year, contributing to the self-generation and reduction of additional electricity consumption of the building from the grid

[26][43]. Another popular energy harvesting technology is the solar thermal collector, which collects heat by absorbing solar radiation and is commonly placed on the roof of the building. Water as the circulating medium displaces heat to a separated reservoir that can be used for heating purposes

[27][44]. Furthermore, solar air heater (SAH), which is also powered by solar radiation, can be used for providing heated air for direct use inside the building

[28][45]. However, over the past few years there have been some cases where the ADBE is proposed to harvest wind energy instead of solar energy, which is achieved through the implementation of Wind Turbines (WTs)

[29][46].

2.1.2. Technologies Affecting Heat Transfer

The heat transfer between buildings and ambient environments affects thermal comfort inside buildings, especially in cases of extreme weather conditions. The use of insulation materials is a widespread, cost-efficient, and passive component for ADBEs that influences heat transfer. There is a wide range of insulation materials that differ from one another, mainly in their costs and embodied energy rather than their thermal conductivity. Therefore, it is usually a cost-carbon trade-off when choosing an insulation material to implement in the façade design. On a more advanced level, the insulation effect is produced by absence of materials, in form of vacuum insulation. Another, more modern, approach, which is frequently observed in literature, is the incorporation of PCM in ADBEs

[30][47]. These materials have high latent heat capacities and are able to accumulate and release thermal energy during the melting-freezing cycle

[31][48]. PCMs can be both considered as active and passive technologies in buildings, depending on whether they are triggered by a natural phenomenon such as solar radiation or by an external energy source such as electricity.

When it comes to the windows of the façades, heat transfer is related to the solar radiation entering the building. In this case, the heat transfer is reduced by controlling the sunblinds in front of the windows

[32][49]. The heat transfer can also be reduced by implementing BISPV/T panels on the windows, the semi-transparency of which reduces the solar irradiation entering the building.

2.1.3. Technologies for Air Conditioning

Air conditioning systems control the temperature and/or the flow of the air inside the buildings. For this purpose, the most well-known technologies are heat pumps

[33][50]. Heat pumps transfer thermal energy in the opposite direction of heat transfer, through the refrigeration cycle, and may be air-sourced, water-sourced, or ground-sourced depending on the heat source upon which they rely

[34][51]. Small-scale heat pump units are usually implemented in the façades of buildings and are capable of heating/cooling adequately a room or a zone of the building. Another cost-efficient technology for air conditioning is the mechanical ventilator

[35][52], which circulates the air in the building and may also be coupled with a heat exchanging unit to recover some part of the heating or cooling energy

[36][53]. Decentralized mechanical ventilation units can, in general, be placed in single rooms. However, in an ADBE (including appropriately designed pipes, etc.) one central mechanical ventilation unit may supply several rooms. Furthermore, thermoelectric walls are considered to be a solution for the air conditioning of a building, although they are not so frequently observed in literature. Thermoelectric walls convert electricity to heat through different types of semi-conductors (Peltier effect) and may be used to cool or heat a room

[37][54]. Another solution, relevant to building skins, is the use of radiant heating/cooling systems. This is a category of HVAC technologies that can exchange heat through both convection and radiation with the spaces that they are designed to heat or cool. These systems have gained acceptance as HVAC solutions due to their energy saving potential while achieving adequate thermal comfort and maintaining acceptable indoor air quality.

2.1.4. Storage Systems

The energy harvested by an ADBE may not be directly consumed, depending on the demand curve of the occupants and the building’s operation. Yet, the mismatch between the energy production and demand can be reduced when storage systems are deployed

[38][55]. For the storage of electrical energy, the most popular technology used is the battery energy storage system (BESS), which can be based on lithium, lead-acid, etc.

[39][56]. At this point, it should be noted that BESS are geographically independent, in contrast to the majority of active ADBE elements

[40][57]. On the other hand, for excessive thermal energy, thermal energy storage (TES) technologies can be deployed. This category is comprised of sensible heat storage technologies

[41][58], such as water tanks, and latent heat storage technologies, such as PCM storage units

[42][43][59,60]. It should be noted that since the façades of ADBEs can only support limited weight, only small and light storage systems are usually implemented on them (with small capacity). On the contrary, the common practice is to place the storage units on the top or bottom part of the ADBE. Nonetheless, special attention to safety requirements, in particular fire protection standards, must be met for installation of BESS in south façades.

2.1.5. Synopsis of ADBE Technologies

The main technologies that compose most ADBEs are presented in Table 1. It is noted that there is a variety of technologies related to energy harvesting, heat transfer, air conditioning, and storage. In many cases their base is solar radiation, which is relatively easy to harvest in buildings

[23][40]. Their technologies may be simple and commonly used, such as insulation

[44][61] and solar thermal collectors

[27][44], or advanced and rarely implemented, such as thermoelectric walls

[37][54] and PCM storage units

[43][60]. The purpose of each technology may be related to the building’s thermal needs, e.g., heat pumps and sensible heat storage, or electrical needs, e.g., BIPV panels and BESS

[45][62]. Of course, the presented technologies may be combined in a variety of ways, such as energy harvesting coupled with storage

[46][63] or energy harvesting coupled with air conditioning

[47][64], depending on the building’s location, operation, etc.

Table 1. Main technologies for ADBEs [24][25][26][27][28][29][30][31][32][33][34][35][36][37][38][39][40][41][42][43].

Main technologies for ADBEs [41–60].

|

|

Technology

|

Description

|

Benefits

|

Limitations

|

Base

|

Purpose

|

|

Active Technologies

|

BIPV

|

Building integrated photovoltaics

|

Self-generation

|

Suitable for areas with high exposure to sunlight

|

Solar radiation

|

Electrical needs

|

|

Solar thermal collector

|

Converts solar radiation to heat

|

Thermal load reduction, easy implementation

|

Suitable for areas with high exposure to sunlight

|

Solar radiation

|

Thermal needs

|

|

SAH

|

Converts solar radiation/heat to heated air inside the building

|

Thermal energy harvesting

|

Suitable for areas with high exposure to sunlight

|

Solar radiation/heat

|

Thermal needs

|

|

WT

|

Converts wind energy to electricity

|

Self-generation

|

Suitable if wind speed is sufficient, heavy system

|

Wind

|

Electrical needs

|

|

Heat pump

|

Transfers heat against natural temperature gradient, used for either heating or cooling

|

Applicable in any condition

|

Not entirely carbon-neutral

|

Air-sourced

water-sourced,

ground-sourced

|

Thermal needs

|

|

Mechanical ventilation

|

Utilization of fans for the circulation of air in buildings

|

Cost effective solution, easy implementation

|

Limited effect

|

Air

|

Thermal needs

|

|

Thermoelectric wall

|

Utilization of the Peltier effect for heating/cooling purposes

|

Advanced air conditioning system

|

Rarely implemented technology

|

Electricity (Peltier)

|

Thermal needs

|

|

BESS

|

Lithium-based storage of electricity

|

Increase of electrical self-generation

|

Heavy system

|

Electricity

|

Electrical needs

|

|

Hybrid Technologies

|

PCM

|

Phase Change Material

|

Efficient reduction of heat transfer

|

More expensive than usual insulation, high embodied energy

|

High latent heat capacity

|

Thermal needs

|

|

PCM storage unit

|

Storage of thermal energy using PCM

|

Advanced storage system, thermal load reduction

|

Rarely implemented technology

|

PCM

|

Thermal needs

|

|

Passive Technologies

|

Insulation

|

Decrease in heat losses through low thermal conductivity

|

Cost-effective solution, easy implementation

|

Only passive technology

|

Low thermal conductivity

|

Thermal needs

|

|

Sensible heat storage

|

Water-based heat storage

|

Efficient mitigation of thermal needs

|

Heavy system

|

Water

|

Thermal needs

|

|

Sunblind

|

Shading for windows

|

Cost-effective solution

|

Limited effect, only applicable in windows

|

Solar radiation, windows

|

Thermal needs

|

2.2. Typologies of ADBEs

An ADBE may be designed and implemented with special focus on a certain need of the building, e.g., reduction of heating/cooling loads, improvement of user comfort, or self-generation requirements

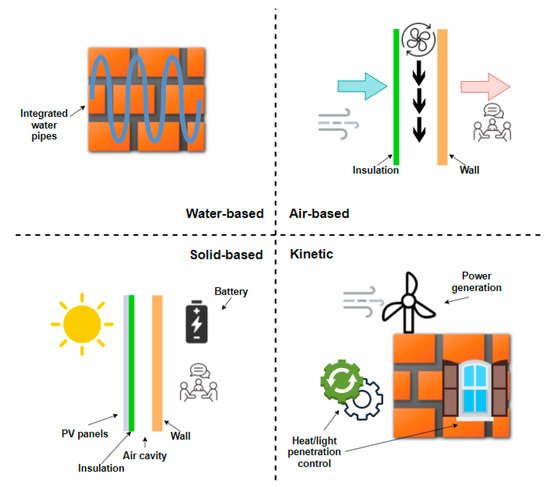

[12][48][12,65]. Therefore, an ADBE neither has a standard design nor serves the same purpose. Nevertheless, based on the most frequent configurations, four main typologies of ADBEs are distinguished i.e., water-based, air-based, solid-based, and kinetic

[49][35] As presented in

Figure 1. This sub-section aims to highlight the distinctive features of each typology and compare them, considering key parameters.

Figure 1.

Typologies of ADBEs.

2.2.1. Water-Based ADBE

Water is frequently utilized as a working medium in ADBE design, thanks to its high specific heat capacity, low cost, abundance, and non-toxicity

[42][50][51][52][53][54][59,66,67,68,69,70]. There are several options regarding its utilization in the literature

[55][56][71,72]. This tested-in-time concept has low construction and maintenance costs

[57][73] and allows for heated or cooled water to pass through the pipes efficiently, providing the building with extra thermal insulation in winter or summer, respectively.

Another approach of water-based ADBE is presented in

[58][59][74,75]. In this case, the construction consists of (a) an outer insulation level, (b) a gap, and (c) the existing external wall. Water is sprayed inside the gap between the outer insulation layer and the existing wall and then evaporated in order to cool the room. The proposed system is mostly implemented for the mitigation of cooling loads during summer and may preserve thermal comfort of the occupants, even when the outdoor temperature reaches 40 °C, according to

[60][76]. Using the evaporative cooling effect of water was even common in traditional architecture of hot arid climates such as Iran and Egypt, where the temperature exceeds 40 °C. Furthermore, for cooling purposes, alternative approaches have been developed, including constructions such as water-glazing windows

[54][70]. In this case, water flows between glass layers that separate the outside environment from the building interior, thus reducing the cooling load of the room while allowing sunlight to enter it.

2.2.2. Air-Based ADBE

Air-based ADBEs constitute a popular option as they are efficient and can be combined with a variety of technologies. The basic design of an air-based ADBE comprises an insulation layer placed in front of the existing wall’s surface, forming an air cavity, as presented in

Figure 1. The air cavity provides the building with extra thermal insulation, thus reducing its thermal/cooling loads. Although the cavity can be plain, considering only natural ventilation

[61][77], more advanced options (including mechanical ventilation, and heat recovery) can be adopted. For example, mechanical ventilation with heat recovery in air-based ADBEs has been studied in

[62][63][78,79] to reduce energy losses of the envelope. Furthermore, either with or without mechanical ventilation, it is proposed to close the air cavity during certain occasions in order to avoid negative effects on occupants’ thermal comfort caused by undesired ambient conditions

[64][80]. Additionally, given the fact that the pre-heating of the air flowing in the cavity increases the efficiency of the air-based ADBE, geothermal energy systems are proposed to be integrated into the overall system

[65][66][81,82].

2.2.3. Solid-Based ADBE

Solid-based ADBEs constitute a modern approach toward energy-efficient buildings as they can not only reduce the building’s thermal losses but also reduce its electrical energy consumption. The main technology of this typology is the BIPV system

[67][68][83,84]. This key element is the distinguishing factor of solid-based ADBEs compared to conventional façades

[49][35]. More specifically, the BIPV is proposed to be placed on the outer surface of the façade, followed by an insulation layer, and (optionally) an air cavity between the aforementioned configuration and the existing wall, as presented in

Figure 1. For the buildings located in the Northern Hemisphere, it is proposed to install the BIPV on the southern wall, whereas for the buildings located in the Southern Hemisphere, it is proposed to install BIPV on the north wall in order for the panels to produce maximum possible energy

[69][85]. The panels can be either opaque or semi-transparent. The latter technology is also known as building-integrated semi-transparent photovoltaics (BISPVs), and it is beneficial to install it upon a window since it allows sunlight to enter the building through the respective glazing

[70][86]. Furthermore, the excessive PV production can be stored in BESS with the utilization of the appropriate energy management system (EMS)

[71][87].

The solid-based façades are often combined with BIPV/T, which produces heat through air-based systems

[72][88]. The panels of the BIPV/T are generally semi-transparent and can be combined with many HVAC systems, PCMs, and other technologies

[67][72][73][83,88,89]. This combination is highly promising as the building not only attains high rates of renewable electricity self-generation owing to the PV production but also substantially reduces its thermal loads because of the energy of the air flow inside the cavity, which can be further recovered through the respective systems.

2.2.4. Kinetic ADBE

The typology of kinetic ADBEs differs from the ones previously presented as it requires no working medium and is strongly dependent on control systems. More specifically, kinetic ADBEs may adjust the building’s envelope through control systems so as to adjust the solar heat or light penetration to a desirable level, thus enhancing the thermal comfort and reducing the electricity consumption of the building. For this purpose, they may have a reconfigurable geometry or even rotate. In this vein, they may control the sunblinds and openings of the windows, as presented in

[49][35]. The advanced possibilities of this typology include (amongst others) polarized film-systems covering the building’s envelope, cellular automata, dynamic shading, and interactive designs that improve the daylight performance based on the occupant’s position

[8][74][8,90]. Furthermore, kinetic ADBEs may incorporate wind turbines (WTs) mounted on the façades of the building and generate electricity through wind energy, thus reducing the electricity consumption from the grid

[75][91].

2.2.5. Comparison of ADBE Typologies

Water-based and air-based ADBEs use more mature and simpler technologies than the rest of the typologies, which also results in their lower cost, while kinetic ADBEs require more advanced configurations and materials and have complex control systems

[61][74][76][77,90,92]. Although all typologies enhance the thermal comfort of buildings, it should be noted that solid-based ADBEs also increase buildings’ self-generation as they include PV panels. The building’s self-generation may also be increased by kinetic ADBEs in the case where suitable WTs are part of the technical configuration. Solar radiation may enter the building through BISPV panels (which are part of the solid-based typology), water-glazing windows (which are part of the water-based typology), and specialized kinetic ADBEs. Finally, modern research focuses on solid-based ADBEs combined with air-based systems. The BIPVT systems produce electricity and at the same time utilize the heated air behind PV panels and the additional insulation layer to further improve the thermal comfort inside the building and reduce energy costs.

3. Terminologies of ADBEs

Throughout the literature, studies use different terminologies to point out the similar idea of an adaptive dynamic façade that responds to the changes of weather conditions. Adaptive facades enhance the energy efficiency properties of buildings through their resilient response to interior and exterior changing parameters, normally by implementing complex materials, technologies, and systems

[77][93]. Loonen argues that the adaptive façades incorporate adaptive multifunctional technologies and materials, so that the entire envelope responds interactively to the changing indoor demand and outdoor ambient conditions in order to improve building performance

[78][94]. Similarly, Davis uses the term climate adaptive building shell (CABS) to address the kind of envelope that interacts with different climate-related conditions

[79][80][95,96]. The core concept of a Responsive Building Envelopes (RBEs) as extensions from CABS is that they mimic the responses of the building to climate-related changes based on physiological responses found in nature

[80][81][96,97]. RBEs exploit the potentials of combining active, passive, and controlling systems to replicate these natural phenomena in buildings and respond to indoor and outdoor triggers

[82][98].

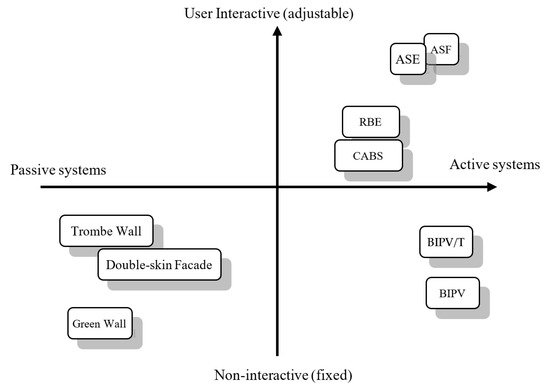

All the terms mentioned so far promote similar concepts and systems, with the keywords of multifunctional, adaptive, dynamic, and responsive, which overlap with one another. The concept of an ADBE lies in the domain of using active systems, passive systems, and a combination of both. However, with the wide variety of technologies being used,

thwe

researchers identify two differentiating characteristics in order to be able to classify them for easier understanding. The first characteristic is the level of how active or passive the technologies used in the final ADBE product are. ADBE spans a wide variety of active building technologies, including technologies that exploit renewable energies such as PVs or solar air heaters, passive systems such as sunblinds, insulations, some types of storages, and PCM. Another differentiating factor among ADBE systems is the level of user controllability and occupant interaction with the façade, meaning if the user has the ability to operate some functions on the ADBE manually, or through the usage of building energy management systems (BEMS).

Figure 2 shows the distribution of active and passive systems used in the ADBE research. The horizontal axis of the diagram ranges from passive to more active technologies and the vertical axis varies from completely fixed structures that the user cannot adjust to a totally adjustable system where the user can interact with the façade continuously. It appears that the passive systems are less interactive with the user, compared to more modern active technologies that benefit from BEMS. Additionally, it is clear that the more recent ADBEs developed are shifting towards the extensive usage of active technologies, mainly because of their energy harvesting potential, as well as the adaptiveness brought to the user through BEMS.

Figure 2.

Distribution of ADBE systems using active and passive systems.

The efficiency of ADBEs varies widely because of the variety of systems coupled in them. Harish

[83][29] states that HVAC systems contribute to an overall 20–60% reduction in energy demand, 20–50% in lighting demand, and 20–70% in water heating and refrigeration demand. Some studies suggest even higher energy saving potential as high as 170% compared to a mass wall, when implementing a PV thermoelectric system

[84][103]. Similarly, Luo integrates a PV thermoelectric module with a battery system in the envelope and shows that the proposed BIPV/T system achieved 72–92% energy savings compared to a simple mass wall in a cold climate zone in China, while it increased to 88–100% in a mixed zone and topped 100% in a cooling dominant zone

[85][104]. Hammad explored the energy consumption of an office building that devised their proposed external dynamic louvers and reported 34%, 28% and 30% energy savings in southern, eastern and western facades

[86][105]. Nagy et al. demonstrated and tested a novel ASF in order to balance the energy and emissions with the investment and operational costs in a prototype building and achieved a total energy saving of 25% compared to the fixed louver case with their proposed ASF

[87][100].

4. Requirements of ADBE

Various requirements must be considered in the design of ADBE. These requirements mainly comply with European EN standards and can be classified into the following categories:

- Energetic requirements;

- Static requirements;

- Moisture protection requirements;

- Ecological requirements;

- Aesthetic requirements.

-

Energetic requirements;

-

-

Ecological requirements;

-

Aesthetic requirements.

4.1. Energetic Requirements

Emissions caused due to building operation can be reduced either by reducing the final energy demand or by substituting fossil fuels with renewable energy sources (RES). Towards these objectives, ADBE can play a critical role through the improvement of the building’s shell thermal properties and the harvesting of RES. As regards the first point, transmission losses influence the overall energy demand of a building. A German study suggests that improved qualities of glazing and exterior walls can result in up to 50% less energy savings

[88][108]. Especially in office buildings, a great portion of the façade often has very high U-value, which is three to four times more than a standard U-value for a new constructed building’s minimum requirement. Great energy-saving potential can be inferred from this. Depending on the climate region that a country is located in, certain U-value requirements are developed to comply with its specific climate needs. For example, in Germany, the building energy act GEG

[89][109] prescribes a maximum U-value of 0.24 W/m

2/K for outer walls of renovated buildings. In England, the UK building regulations

[90][110] provide a maximum U-value of 0.30 W/m

2/K for the refurbishment of outer walls with internal or external wall insulation. ADBEs can lower the U-value of the outer wall by integrating insulation and increasing the thermal resistance of the wall.

Besides requirements regarding the U-values, additional restrictions on a building’s primary energy demand and emission are made by each country. Those restrictions vary depending on the country. For example, in Germany, the building energy act GEG

[89][109] defines a maximum value for the primary energy demand of a retrofitted building, in comparison with a reference building. To meet the requirements corresponding to the primary energy demand or emissions, the remaining energy demand can be covered by renewable energies. RES harvested on the façade can supply electricity or heat directly to the building and lower its primary energy demand.

Section 3 therefore shows different technologies for energy harvesting in an ADBE as well as technologies for air conditioning, which can be operated with the generated renewable energy. Differences in the climate of each region influence the design of the ADBE. For example, in the Mediterranean climate, preventing overheating during long summer solar radiation may come be more important than heating. Therefore, sun protection in this region is of utmost importance. Furthermore, optimized ventilation, e.g., that is demand-led or with heat recovery, can reduce heat losses while maintaining or enhancing indoor thermal comfort.

4.2. Static Requirements

The possibility to assemble an additional façade with included technical components in front of the existing facade highly depends on the existing load-bearing structural system and how much extra weight it can bear. In Europe, the design bases are given by the series of Eurocodes

[91][111]. Eurocode 0

[92][112] and 1

[93][113] specify the basic principles of structural design and the calculations of load effects. Eurocode 2–6 and 9 give the further calculation bases depending on the material used in the load-bearing structure of the ADBE. Special attention must be paid if an ADBE is used for retrofitting. In that case, the possibility to assemble an additional façade with included technical components in front of the existing one is directly related to the existing load-bearing structures and their remaining capacity.

Massive wall constructions are part of the primary load-bearing structure and can directly bear additional loads from the ADBE system. In contrast, skeleton structures transfer loads horizontally to the primary load-bearing structure, which might result in limitations for the structural implementation of ADBE elements. However, regardless of the design, it is necessary that potential fixing points of the load bearing structure are accessible. If the load-bearing capacity of a façade is sufficient, fixing to the ceiling construction could be a suitable solution for both skeleton and massive constructions. Furthermore, material-specific aspects must be considered. The effect of temperature results in changes in length, which needs to be considered in the design and construction.

In addition to the load applied to the existing buildings, wind loads have to be calculated in the planning of ADBEs. Both the anchoring to the building and the fastening of the façade elements in the façade module must meet these requirements. The wind load is recorded by wind pressures and wind forces. Wind pressures can act both on external surfaces of structures (external pressure) and on internal surfaces (internal pressure) when the external envelope is permeable. The wind pressure acts perpendicular to the surface in question and is referred to as positive pressure in the case of compressive loading and negative pressure in the case of suction loading. In Europe, wind loads are considered according to Eurocode EN 1991-1-4

[93][113] and the respective national annexes.

Under seismic loading, the performance of the fasteners in a structure is crucial to its stability in order to avoid accidents and major economic impacts due to the collapse of non-structural elements. Seismic resistance of the façade elements and their connections and anchorages are to be determined in accordance with the national regulations of each country where the ADBE system is installed. In Europe, Eurocode 8

[94][114] regulates the requirements for earthquake safety.

4.3. Safety Requirements

Safety requirements mainly concern fire safety regulations. The requirements placed on a façade, from a fire protection point of view, depend on the type of construction and the type of building. The building regulations vary from country to country. According to the UK’s building regulations schedule 1 B3 (1)

[90][110] “the building shall be designed and constructed so that, in the event of fire, its stability will be maintained for a reasonable period”. Other countries have comparable regulations. The Swedish Building Regulations

[95][115] add the requirement that the risk of injuries to persons resulting from materials falling from the building façade must be limited. In Germany, the building regulation MBO § 28

[96][116] sets more detailed requirements to fire protections: in general, exterior walls and the elements devised in them should be designed in a way that the spread of fire on and in these components is sufficiently limited (MBO § 28 (1)). Non-load-bearing exterior walls and the elements and parts that are devised or attached to them, for example, technical components of an ADBE, shall consist of non-combustible building materials. If they are fire-retardant, they shall be permissible in flammable building materials (MBO § 28 (2)). Surfaces of external walls and coverings, including insulation materials and sub-structures, shall be of low flammability, but substructures of normally flammable mate-rials shall be permitted. In the planning of an ADBE, it must be checked if parts of the ADBE itself meet the requirements. The use of some technologies in ADBE, such as PCM or batteries, presents a challenge as they are flammable. For fire safety aspects of PCM, the work of Asimakopoulou et al.

[97][117] describes the problems if the encapsulation of a PCM shells fail in case of fire. If technologies like PCM are used, it must be ensured that the ADBE maintains its stability for a reasonable period by protecting the technical components with layers of non-combustible building materials. Because of fire protection requirements, batteries are mostly not situated in the façade but inside the building. In some research, as in Luo et al.

[85][104], implementation of batteries in the ADBE systems is discussed without referring to physical integration. Regarding BIPV, the work of Huang et al.

[98][118] shows that there are possible designs to ensure the stability of PV systems for a reasonable period of time. Fire protection is an important point in the design of ADBE and should be part of any planning.

4.4. Moisture Protection Requirements

Moisture can affect a structure in either a liquid or gaseous state, affecting the longevity of a building and causing damage to the interior. Therefore, rainwater must be kept off by constructive measures that ensure drainage of the façade. Furthermore, care must be taken to ensure that all façade elements are rainproof and sealed. Particular attention must therefore be paid to the joint sealing. In addition to direct rainwater contamination, condensation of gaseous water can cause damage to a building. The sources of moisture can be manifold

[99][119]: internal moisture sources such as those emitted by persons, the moisture content of outdoor air, and actively emitted moisture in evaporative cooled ADBEs with double skin facades, which are, for example, examined in the studies of Sotelo-Salas et al.

[100][120] and Shen et al.

[101][121] In such ADBEs, water is sprayed into the air cavity of a double skin façade and the evaporative effect is used to cool the building.

Water vapor can enter a building, if not directly emitted in the building, via the supply of air or diffuses through the building envelope. Condensation can form on the surface or inside of a building component if the temperature lays below the dew point temperature. This condensation leads to mould growth and results in health risks for users and residents. In addition, however, damage to the component or changes to its structural physics and structural functionality can also occur. Therefore, the occurrence of condensation on or in the building component should generally be avoided, or suitable measures should be taken or planned to prevent such consequences. On the one hand, this can be done by preventing the temperatures at the components’ surfaces from falling below the dew point temperatures by installing an external insulation or increasing the room temperature. On the other hand, diffusion through the building components can be prevented by a vapor-diffusion-tight construction method to avoid condensation inside the building envelope. Special attention on the vapor-diffusion-tightness must be paid in ADBEs with additional moisture emission as in evaporative cooled double skin facades. The building physics requirements for moisture protection vary from country to country. For example, DIN 4108-3

[95][115] defines requirements on climate-related moisture protection in Germany. Here, inter alia, requirements are formulated for the sealing of joints and façade surfaces for moisture protection. Comparable standards can be found in other countries, as for example the BS 5250

[102][122] in the UK.

4.5. Ecological Requirements

Regarding the ecological requirements, the entire life cycle of an ADBE is of interest. To ensure the best ecological performance, some prerequisites need to be met. Firstly, the overall use of raw materials should be minimized. Secondly, the production procedure is needed to present low energy demands and emissions. Thirdly, the whole system, or at least some parts of it, must be characterized by reusability or recyclability. During the definition of the ecological requirements, all phases of the life cycle of the ADBE should be considered: design, construction, use, repair and replacement, demolition, disposal, or (in the best-case scenario) deconstruction and reuse. In Europe, EN 15804

[96][116] establishes the basic rules for the sustainability of buildings.

4.6. Aesthetic Requirements

In addition to technical requirements, aesthetic concerns comprise a set of requirements regarding the appearance of ADBEs. Guidelines from local building authorities might define requirements to the aesthetic design of a building for certain districts. Despite those requirements, aesthetic ADBE design is not defined by sharp regulations and is in the eye of the beholder in each individual case. In general, the appearances of residential and non-residential buildings differ. Residential buildings tend to adapt the appearance of the surroundings with subdued and natural colours and low reflections. Non-residential building façades tend to implement a design with more modern elements, such as glazing; aluminium; or partially exposed technologies, such as PV-cells.