Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 3 by Bruce Ren and Version 2 by Bruce Ren.

n this study, we developed a new facial recognition system using thin-film solar cells as sensors. When the face of a user is illuminated by LED lights on the left and right sides of the system and the reflected light enters the cells at the corresponding positions, differences in facial skin colors and 3D contours lead to different output voltages and currents of the thin-film solar cells. This is the basis of facial feature identification.

- hin-film solar cell

- sensor

- LED

- facial recognition

1. Introduction

In recent years, facial recognition has become the most widely accepted biometric technology. Presently, it is the only technology among the various biometric techniques with a long-range performance. This recognition technology is realized by capturing facial images with photographic equipment for face model calibration, facial feature extraction, and feature matching. The most complex procedure, namely, feature matching, is performed by analyzing features in 2D images using a series of complicated algorithms, such as Eigenface [1], Fisherface [2], and Local Binary Pattern (LBP) [3][4], to determine whether there is a match.

However, facial recognition is a controversial biometric technology because facial feature matching is based on images captured by cameras across public spaces. Therefore, people may be monitored and photographed for face matching without their knowledge and consent. Such practices violate privacy and human rights [5]. WThe researchers developed a facial recognition technology that does not rely on photographs or facial recognition algorithms to address this problem. Furthermore, wethe researchers considered the global trend of green energy development and carbon-emissions reduction [6][7]. Thus, wthe researchers selected thin-film solar cells as sensing elements to replace traditional camera lenses, thereby introducing a new technique for facial recognition.

In addition to the advantage of high photoelectric conversion efficiency in low light conditions [8][9], thin-film solar cells can be utilized as detectors, as demonstrated in several studies. In 2017, Orgiu et al. [10] developed a perovskite-based oxygen sensor to detect variations in oxygen concentration in a closed environment. The perovskite element in the sensor could increase the current with increasing oxygen concentration. Jong-Min Oh found that perovskite elements could also be fabricated into humidity sensors [11]. The author successfully detected humidity changes through the capacitance variations of the perovskite element. Perovskite solar cells (PSCs) have been employed as refractometric sensors [12]. Similar light sensors also include the DSSC-based optical sensor developed by Rahmadwati et al. [13] and the wide-band photodetector composed of flexible CIGS, which was developed by Qiao et al. [14].

These studies were based on a single thin-film solar cell element, which can be easily customized into small- and medium-sized modules. The application of thin-film solar cells in small- and medium-sized self-powered products has not yet been realized but is anticipated.

The facial recognition system developed in this study uses a 4 × 3 thin-film solar cell array as the sensing element, with an overall sensing area of approximately B5 size. The thin-film solar cell array is self-powering because it absorbs ambient light to generate electricity for storage when the system is not operational. During the operation, the 4 × 3 array receives reflected light after the user’s face is illuminated by LEDs. The higher the intensity of the reflected light received, the greater the generated voltage or current. Twelve sets of voltage data were measured and then compared with pre-stored user data. This facial recognition system successfully distinguished six users, indicating the system’s suitability for domestic biometric door locks. In such applications, thin-film solar cells can realize their new value, while reducing energy consumption.

2. Experimental Design

2.1. Fabricating the Facial Recognition System Based on Thin-Film Solar Cells

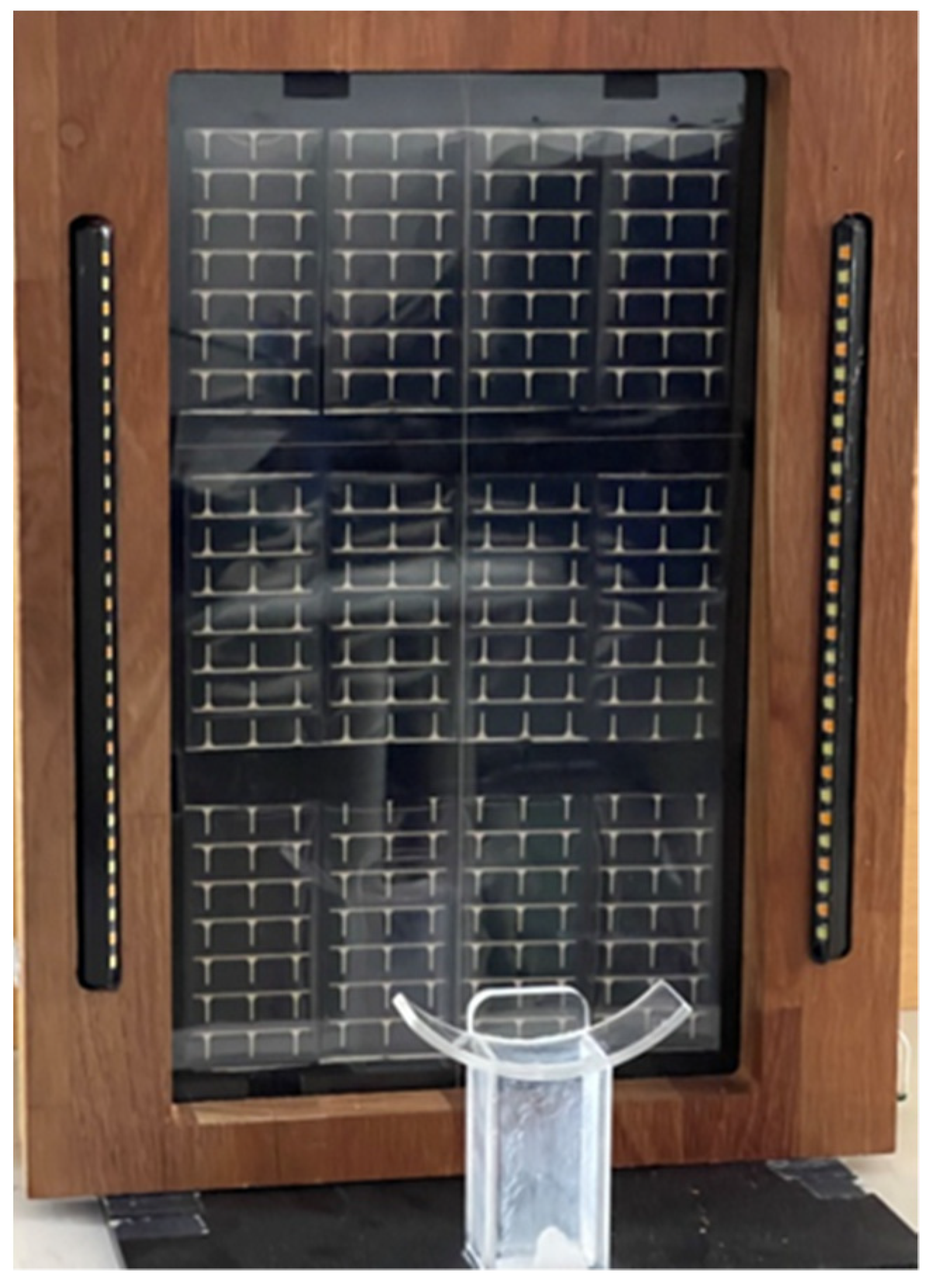

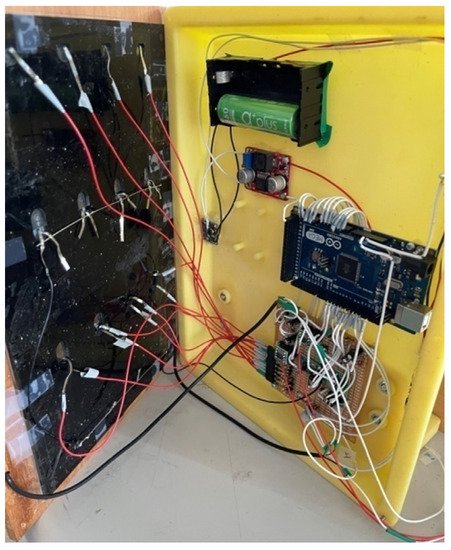

Twelve SP4.2-37 silicon thin-film solar panels (PowerFilm Inc., Ames, IA, USA) were arranged in a 4 × 3 array (Figure 1). Each panel was 84.0 mm × 36.5 mm and could generate 21 mW of power under 1/4 sun. In the top row, the solar cells from right to left were numbered as SC01 to SC04, respectively. The middle row comprised cells SC05 to SC08, and the bottom row comprised cells SC09 to SC12 (Figure 1). This array served as the sensor for facial recognition and was also part of the system’s power source. When the system was not in operation, the array generated electricity to be utilized during operation. Arduino MEGA2560 microcontroller board (https://store-usa.arduino.cc/) (1 December 2021) was used as the system’s core for data processing (Figure 2), which reads the voltage generated by each solar cell through 12 analog inputs. The lithium battery stores electricity generated by the solar cells and supplies it to the system and LEDs, distinguishing this system from other biometric technologies requiring external power supplies.

Figure 1. Appearance of the facial recognition system.

Appearance of the facial recognition system.

Figure 2.

Internal configuration of the facial recognition system.

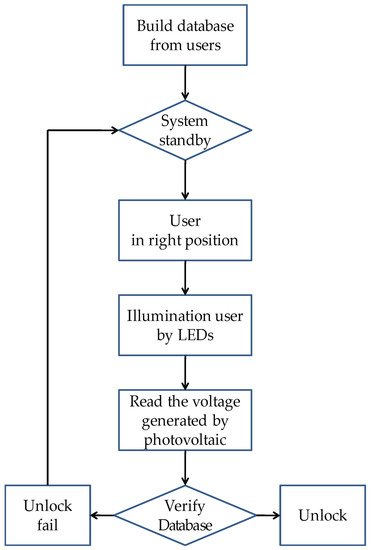

The facial recognition mechanism of this system used two commercially available LED light strips on the left and right sides of the thin-film solar cell array to illuminate the face of the tester at 45°. The Arduino MEGA2560 read the voltage of the twelve thin-film solar cells in the array. The voltage values were affected by the intensity of the reflected light after the LEDs illuminated the face of the user, which served as the basis for facial feature identification. The detection process is demonstrated in Figure 3. WThe researchers first established a user database and then selected the user’s data as a reference. The system could be unlocked if the tester and the reference user were recognized as the same person. When a tester reached the correct physical position for facial recognition, the LEDs were activated for auxiliary illumination. As facial features and skin colors differ between individuals, the intensity of the reflected light entering the thin-film solar cell array after the LED illumination also differ. Accordingly, the voltage values read by the Arduino MEGA2560 differed. The measured voltage values were compared with the documented reference data. If the two sets of values matched, the tester and the reference user were recognized as the same person, and the system was unlocked. Alternatively, if the tester was recognized as a different person, the system could not be unlocked.

Figure 3.

Facial recognition flow diagram.

2.2. LED Illumination Control

The LED lights on the two sides of the facial recognition system were essential because they illuminated the users’ faces to identify differences in facial features. Therefore, the stability of the LED light source was one of the most critical considerations in this study, and the quality of the test values was directly related to the stability of the LED light source. Appropriate LED illuminance can emit sufficient light to be reflected and absorbed by the thin-film solar cells. Thus, precisely controlling the stability of the LED illumination was a primary technical issue.

In this study, the weresearchers used CAT4104 LED driver IC (onsemi, Phoenix, AZ, USA) to precisely control the LED light source of the facial recognition system. CAT4104 is a four-channel LED driver IC that can provide up to 175 mA of current per channel, with the output current controlled by an RSet pin. After assembling the circuit, CAT4104 was used for testing. To evaluate the stability of the LED illumination, the illuminance of the left and right LED light strips was measured in a laboratory environment by using a YFE YF-1065 digital light meter placed 8.5 cm away from the facial recognition system. WThe researchers repeatedly drove the left and right LED light strips with 131 mA (20 times). The measurement results are listed in Table 1. Although the illuminance of commercially available LED light strips is non-uniform, the left and right LED light strips can still provide stable illumination, indicating that the performance of the CAT4104 LED driver IC on illumination control is satisfactory.

Table 1. Illuminance stability of the left and right LED light strips tested 20 times under 131 mA.

| Data 1 | Data 2 | Data 3 | Data 4 | Data 5 | Data 6 | Data 7 | Data 8 | Data 9 | Data 10 | |

| Left light strip | 658 | 658 | 656 | 657 | 656 | 657 | 657 | 656 | 657 | 656 |

| Right light strip | 694 | 694 | 694 | 694 | 695 | 695 | 696 | 694 | 694 | 693 |

| Data 11 | Data 12 | Data 13 | Data 14 | Data 15 | Data 16 | Data 17 | Data 18 | Data 19 | Data 20 | |

| Left light strip | 656 | 657 | 656 | 658 | 656 | 657 | 656 | 657 | 658 | 657 |

| Right light strip | 694 | 696 | 696 | 696 | 693 | 694 | 695 | 695 | 694 | 693 |

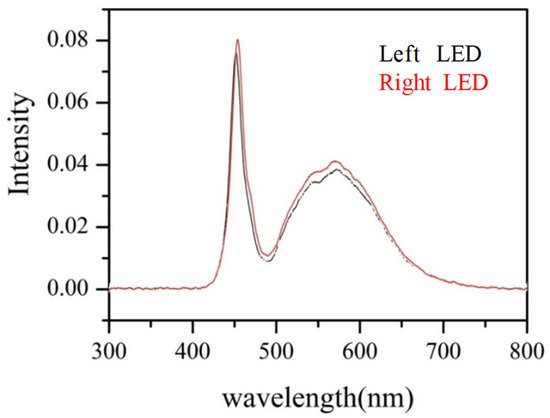

WThe researchers measured the spectrum of the white LED light (Figure 4). The spectra in the wavelength range of 400 nm to 500 nm belong to blue light, and those between 500 nm and 600 nm belong to yellow light. Therefore, the white light of the LEDs used in this study was obtained using blue light with yellow fluorescent powder. The spectrogram indicated that the spectra of the left and right LED lights were similar, and their illumination was stable in practical applications. Further experiments with stably controlled LED light sources revealed that appropriate LED illuminance could help improve the recognition rate of the facial recognition system based on the thin-film solar cells.

Figure 4.

White light spectra of the left and right LED light strips.

2.3. Facial Recognition Test Parameters

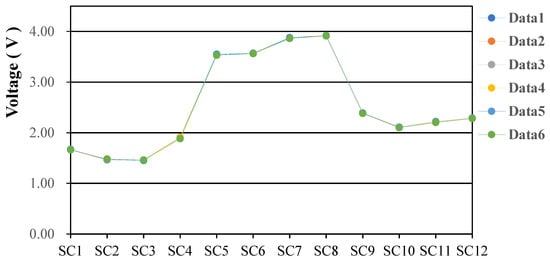

After confirming the test procedure and the reliability of the LED illumination, wthe researchers drove the LEDs with 131 mA and collected six sets of test data for averaging within 1.5 s of illumination. The data were subsequently compared. The six sets of data are illustrated in Figure 5, and the values are found to be reasonably stable.

Figure 5.

Comparisons of six consecutive sets of test data.

References

- Turk, M.; Pentland, A. Eigenfaces for recognition. J. Cogn. Neurosci. 1991, 3, 71–86.

- Belhumeur, P.N.; Hespanha, J.P.; Kriegman, D.J. Eigenfaces vs. Fisherfaces: Recognition using class specific linear projection. IEEE Trans. Pattern Anal. Mach. Intell. 1997, 19, 711–720.

- Ahonen, T.; Hadid, A.; Pietikäinen, M. Face description with local binary patterns: Application to facial recognition. IEEE Trans. Pattern Anal. Mach. Intell. 2006, 28, 2037–2041.

- Boutella, E.; Harizi, F.; Bengherabi, M.; Ait-Aoudia, S.; Hadid, A. Face verification using local binary patterns and generic model adaptation. Int. J. Biomed. 2015, 7, 31–44.

- Leibold, J. Surveillance in China’s Xinjiang Region: Ethnic Sorting, Coercion, and Inducement. J. Contemp. China 2020, 29, 46–60.

- Almalki, F.A.; Alsamhi, S.H.; Sahal, R.; Hassan, J.; Hawbani, A.; Rajput, N.S.; Saif, A.; Morgan, J.; Breslin, J. Green IoT for eco-friendly and sustainable smart cities: Future directions and opportunities. Mob. Netw. Appl. 2021, 1–25.

- Kabir, E.; Kumar, P.; Kumar, S.; Adelodun, A.A.; Kim, K. Solar energy: Potential and future prospects. Renew. Sustain. Energy Rev. 2018, 82, 894–900.

- Venkatesan, S.; Lin, W.H.; Teng, H.; Lee, Y.L. High-efficiency bifacial dye-sensitized solar cells for application under indoor light conditions. ACS Appl. Mater. Interfaces 2019, 11, 42780–42789.

- Lin, L.; Ravindra, N.M. CIGS and perovskite solar cells an overview. Emerg. Mater. Res. 2020, 9, 13.

- Stoeckel, M.A.; Gobbi, M.; Bonacchi, S.; Liscio, F.; Ferlauto, L.; Orgiu, E.; Samori, P. Reversible, fast, and wide-range oxygen sensor based on nanostructured organometal halide perovskite. Adv. Mater. 2017, 29, 1702469.

- Cho, M.Y.; Kim, S.; Kim, I.S.; Kim, E.S.; Wang, Z.J.; Kim, N.Y.; Kim, S.W.; Oh, J.M. Perovskite-induced ultrasensitive and highly stable humidity sensor systems prepared by aerosol deposition at room temperature. Adv. Funct. Mater. 2019, 31, 1907449.

- Elshorbagy, M.H.; Cuadrado, A.; Alda, J. Narrow Absorption in ITO-free perovskite solar cells for sensing applications analyzed through electromagnetic simulation. Appl. Sci. 2019, 9, 4850.

- Rahmadwati, R.; Sari, S.N.; Maulana, E.; Sabarudin, A. Optical sensor based on dye-sensitized solar cell (DSSC). Indones. J. Electr. Eng. Comput. Sci. 2018, 12, 685.

- Qiao, S.; Liu, J.; Liang, B.; Fu, G.; Li, Z.; Wang, S.; Ren, K.; Pan, C. Piezophototronic effect enhanced photoresponse of the flexible Cu(In, Ga)Se2(CIGS) heterojunction photodetectors. Adv. Funct. Mater. 2018, 28, 1707311.

More