Dealingwithmineral tailings is one of themost important topics for solving the environmental problems in the mining industry. Among the techniques converting stacked molybdenum tailings to reusable cleaner products, one of the most effective ones is to use molybdenum tailings in concrete productions. The physical properties including density, microscopic structure and finesse module, and chemical composition of molybdenum tailings are similar with those of natural sand. The radionuclide assessment of molybdenum tailing meets the requirements for using as structural materials. Therefore, Molybdenum tailing is suitable to be used as the replacement of cement and fine aggregates in mortar

and concrete. Based on the results of strength and duration performance comparison, the usage of molybdenum tailing as a replacement of natural sand is a more feasible way than that of ground super-fine molybdenum tailings in cement binder. It is feasible to use molybdenum tailings as fine aggregate in the preparation of structural concrete. When the amount of ground super-finemolybdenum tailings replacing cement is less than 10%, it is beneficial to improve the freeze-thaw and carbonization resistance of the concrete.

- molybdenum tailings

- cement

- mechanical properties

- fine aggregates

- concrete

1. Introduction

Molybdenum is a widely used metallic alloying agent in stainless steel and super-alloys for resisting corrosion and improving strength [[1]]. The molybdenum world mine production is still increasing over the last three decades, especially after the year of 2002. By 2018, the molybdenum world mine production has risen to 300,000 metric tons while China accounts for more than 1/3 of it [[2]]. Since molybdenum is commonly found in combination with other metals, large amount of molybdenum tailing (MoT) is inevitably produced during smelting [[3]]. About 36 million tons per year of molybdenum tailings are discharged in China [[4]]. A large landfill is required to storage these tailings which would easily bring dissolved metals into surface waters in the presence of snowmelt or infiltrating rainwater. In addition, the tailing dam with high potential energy debris flow is a sustaining threat to the downstream residents and facilities. How to effectively decrease the enormous storage volume of mineral tailings is treated as one of the most imminent task for the sustainable development of mining industry [[5]].

2. Utilization of MoT

Most molybdenite present as low-grade ores is associated with other valuable metals, such as Pb, Ni, W, Cu and Re. Generally, molybdenum concentrates are obtained by selective flotation from low-grade ores and then produce MoO3 or Mo metal through roasting-ammonia leaching process [[5]]. The floatation tailings resulting from this process still contain some valuable metals, such as Mo, Pb and Cu. Several techniques had been adopted to convert stacked MoT to reusable cleaner products, including reclamation of Mo and other metals, preparation of ceramics and building materials.

Liu et al. [[5]] proposed a method for the extraction of both Pb and Mo from MoT flotation associated with galena. Lin et al. [[6]] conducted a test by means of magnetic separation to reclaim the iron mineral from a certain concentrating mill for MoT. Fu et al. [[7]] proposed the appropriate conditions for recovering ultrafine molybdenite from MoT by oil agglomerate flotation. Wang et al. [[8]] conducted an experimental research which may provide the theoretical and experimental basis for phlogopite flotation from MoT.

Zhang et al. [[9]] prepared glass-ceramics by using MoT. The performance of glass-ceramics was superior to the other types of building decoration stone. The tests conducted by Shi et al. [[10]] also confirm the feasibility of preparing glass-ceramics used for decoration from MoT. Teng et al. [[11]] proposed a method to prepare foam ceramic using MoT and SiC. In addition, Bai et al. [[12]] successfully prepared a new kind of water storage material using MoT as main raw material. This new technique was believed to be environmentally friendly, economical and promising for the full utilization of MoT.

Among these techniques, one of the most effective ones is to use MoT in concrete productions, since the rapid developments of the building industry are still happening in many countries, especially in China. Tremendous amounts of concrete are being cast in building industry every day. As one of the solutions towards environment protection, the utilization of MoT in concrete products has been studied and encouraged. This paper reviews some of the studies on the use of MoT in concrete manufacturing, focusing on the effect of MoT on the properties of concrete.

3. Properties of Cement Mortar Containing MoT

3.1. Compressive Strength

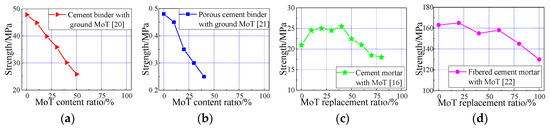

Deng et al. [[13]] reported a test on the compressive strength of cement binder mixed with ground super-fine MoT, whilst Di et al. [[14]] tested the compressive strength of porous cement binder with ground super-fine MoT, as shown in Figure 1. Type I Portland cement 42.5 R was used in both the tests by Deng [[13]] and Di [[14]]. It can be seen that as aggregate in the binder, the content ratio of ground super-fine MoT has remarkable effect on the compressive strength of the cement binder. It should be mentioned that hereinafter the tests in all the references followed the same Chinese testing standards, such as GB/T 50080-2016 for the performance on ordinary fresh concrete, GB/T 50081-2002 for the mechanical properties on ordinary concrete and GB/T 50082-2009 for the long-term performance and durability of ordinary concrete.

On contrary, Luo et al. [[15]] used MoT to replace natural sand as fine aggregates in cement mortar. Type I Portland cement 42.5 R and FM2.45 natural sand were used in the specimens. The compressive strength of cement mortar with MoT increases with the increase of the replacement ratio of MoT, and then shows the best proportion. In fibered cement mortar, Guo et al. [[16]] used MoT to replace natural sand. Type I Portland cement 52.5 R and fly ash were used in the specimens. It can be seen that when the replacement ratio of MoT is 20%, the strength is the highest. After then, with the replacement ratio continues to increase, the compressive strength of fibered cement mortar decreases.

Figure 1. Influence on compressive strength of cement mixture with MoT. (a) cement binder with ground MoT [[13]]; (b) porous cement binder with ground MoT [[14]]; (c) cement mortar with MoT [[15]]; (d) fibered cement mortar with MoT [[16]].

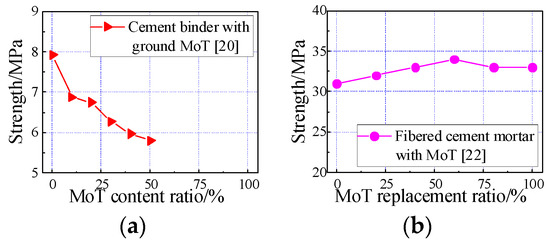

3.2. Bending Strength

Deng et al. [[13]] and Guo et al. [[16]] also reported the bending strength of cement mixture with MoT, as shown in Figure 2. As aggregate in a binder, the content ratio of ground super-fine MoT also has remarkable effect on the bending strength of the cement binder, whilst the replacement ratio of MoT as fine aggregate has little effect on the bending strength of the fibered cement mortar. It could be concluded that the usage of MoT as a replacement of natural sand is a more feasible way than that of ground super-fine MoT in cement binder.

Figure 2. Influence on bending strength of cement mixture with MoT. (a) Cement binder with ground MoT [20]; (b) fibered cement mortar with MoT [[16]].

3.3. Microstructure

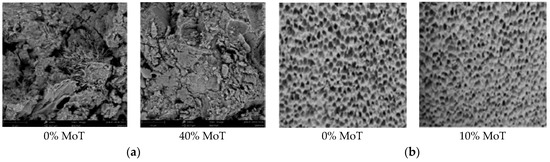

From the SEM images in Figure 3 [[13],[14]], it could be seen that in both the normal and porous cement binders, the size of cementitious products becomes smaller whilst the distribution of those is more uniform, with the help of ground super-fine MoT. After grinding, the super-fine MoT contains a large number of submicron and nano-particles, which can be well filled into the pores of ettringite crystal on the pore wall.

Figure 3. Microstructure of cement mixture with MoT. (a) Cement binder with ground MoT [[13]]; (b) porous cement binder with ground MoT [[14]].

4. Properties of Concrete Containing MoT

4.1. Slump

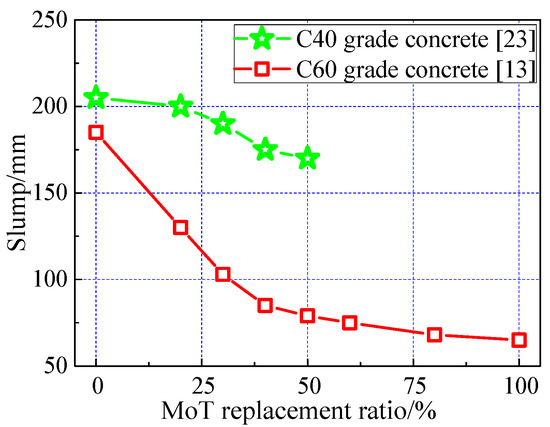

Liu [[12]] and Cao et al. [[16]] both reported the workability of the concrete with MoT as fine aggregates, as shown in Figure 4. It can be seen that the workability (slump value) of the concrete mixture decreases with the increase of MoT replacement ratio. The surface roughness of MoT particles is relatively large. Meanwhile, MoT is ultra-fine sand whose particle size distribution is uneven and containing stone powder. All these features of MoT would cause the extra consumption of water and the increase of the concrete viscosity. It is also worth to notice that below 50% replacement ratio, the usage of MoT has much more influence on the slump of C60 grade concrete with 0.26 water-cement ratio than that of C40 grade concrete with 0.39 water-cement ratio.

Figure 4. Relationship between fresh concrete slump and MoT replacement ratio.

4.2. Compressive Strength

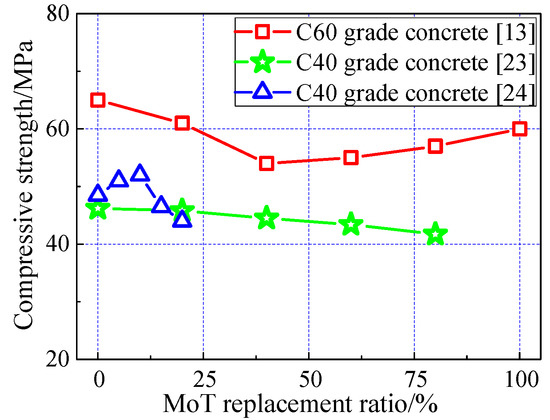

The compressive strength of C40 and C60 grade concrete with MoT as the replacement of natural sand were tested respectively by Liu [[17]] and Cao et al. [[18]] as shown in Figure 6. The mixture proportions of concrete prepared by Liu [[17]] were: cement: 550 kg/m3; coarse aggregate: 1387 kg/m3; fine aggregate: 463 kg/m3; water binder ratio: 0.26. Type I Portland cement 42.5 R and FM2.3 local river sand were used whilst the water content of fine and coarse aggregate is 0.41% and 1.59% respectively. The mixture proportions of concrete prepared by Cao [[18]] were: cement: 435 kg/m3; coarse aggregate: 1113 kg/m3; fine aggregate: 682 kg/m3; water binder ratio: 0.39. Type I Portland cement 42.5 R and FM3.3 local river sand were used whilst the water content of fine and coarse aggregate is 0.2% and 1.4% respectively. As the replacement of natural sand, the replacement ratio of MoT has subtle influence on the compressive strength of concrete. It is feasible to use MoT as fine aggregate in the preparation of structural concrete, in term of compressive strength.

Hu et al. [[19]] reported a test on the concrete mixed with ground super-fine MoT powder as a replacement of cement binder. The mixture proportions of concrete prepared by Hu [[19]] were: cement: 380 kg/m3; coarse aggregate: 1030 kg/m3; fine aggregate: 760 kg/m3; water binder ratio: 0.38. Type I Portland cement 42.5 R and FM2.7 local river sand were used.

It can be seen from Figure 5 that with the increase of the amount of MoT, the compressive strength of concrete increases first and then decreases. Since the activity of MoT itself is much lower than that of cement. When the content of ground MoT increases to a certain limit, the cement content of cementitious material in unit volume decreases, which weakens the bonding performance between cementitious material and aggregate interface and causes the decrease of concrete strength.

Figure 5. Influence on compressive strength of concrete with MoT.

4.3. Freeze-Thaw Resistance

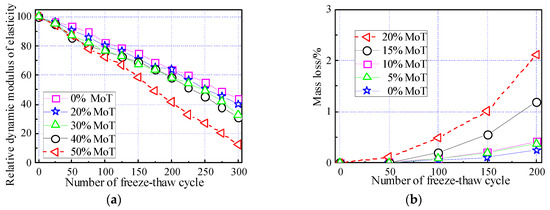

Cao et al. [[18]] reported the influence of MoT replacement ratio on the relative dynamic modulus of elasticity of concrete, as shown in Figure 6 (a). With the increase of MoT replacement ratio, the relative dynamic modulus of elasticity decreases slightly under the same freeze-thaw cycle times. It addresses that if the content of MoT is controlled within a certain range, the dynamic modulus of elasticity of concrete under the freeze-thaw cycle can meet the requirements.

Hu et al. [24] reported the freeze-thaw resistance of concrete mixed with ground super-fine MoT powder as a replacement of cement binder in the same test mentioned above, as shown in Figure 6 (b). When the replacement ratio of MoT is more than 10%, the mass loss under freeze-thaw is accelerated rapidly. When the amount of ground super-fine MoT replacing cement is small, it is beneficial to improve the compactness of the system. When the replacement ratio of MoT is more than 10%, the hydration product of cement in unit volume concrete decreases, and the freeze-thaw resistance of the system decreases with the increase of the replacement ratio.

Figure 6. Influence on freeze-thaw resistance of concrete with MoT. (a) Relative dynamic modulus of elasticity [23]; (b) mass loss [24].

4.4. Carbonization Resistance

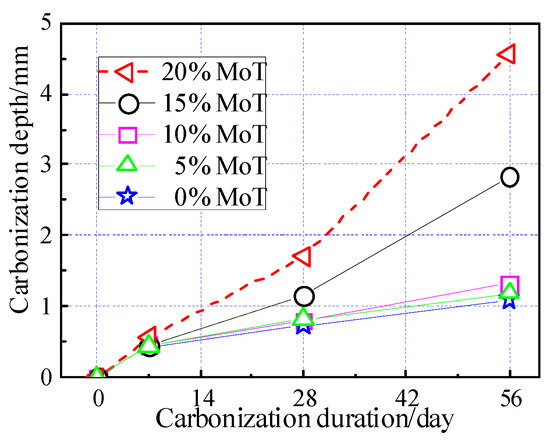

Hu et al. [[19]] also reported the carbonization resistance of concrete mixed with ground super-fine MoT powder as shown in Figure 7. Similar with the freeze-thaw resistance, a small amount of ground MoT can improve the carbonization resistance of the concrete, due to the fact that the super-fine MoT is beneficial to reduce the porosity of concrete, improve the compactness of the system and slow down the carbonization. With the increase of replacement amount, the alkalinity of concrete system decreases, which makes carbonization reaction easier to carry out, and offsets the effect of reducing porosity brought by adding ground MoT, which causes the decrease of carbonization resistance of concrete.

Figure 7. Influence on carbonization resistance of concrete with ground MoT. [[19]].

5. Results & Discussion

Based on the above analysis, it can be seen that the usage of MoT in building material that is feasible is mainly in the form of cement mortar and concrete. The studies in this area are still in a great deficiency. Present studies mainly focused on basic mechanical properties and duration performance, such as compressive strength and freeze-thaw cycles. More studies on the influence of MoT replacement ratio on the split tensile strength, elastic modulus, sulfate attack and drying shrinkage still need to be conducted in the future to provide reference for the usage of MoT in concrete manufacturing. Moreover, the application of MoT in structural concrete members, such as column, beam, joint and even structure systems has not been reported publicly and still needs to be carried forward along with the studies on material itself. Otherwise, the consumption of stacked MoT could not be maximized authentically to resolve the environmental problems due to the discharging and storage of MoT.

6. Conclusions

This paper has reviewed the various properties of cement mortar and concrete in which binder or fine aggregates have been replaced with MoT at different proportions. The properties of MoT and the performance of cement mortar and concrete mixed with MoT have been analyzed from the reported results. The following conclusions are drawn:

(a) The physical properties including density, microscopic structure and finess module, and chemical composition of molybdenum tailings are similar with those of natural sand whilst the radionuclide assessment of molybdenum tailing meets the requirements for using as structural materials. These basic properties assessment of MoT indicates that MoT is suitable to be used as the replacement of cement and fine aggregates in mortar and concrete;

(b) As aggregates in binder, the content ratio of ground super-fine MoT has remarkable effect on the compressive strength of the cement binder while as fine aggregates in cement mortar, the replacement ratio of MoT has little effect on the strength of the cement mortar. It indicates that the usage of MoT as a replacement of natural sand is a more feasible way than that of ground super-fine MoT in cement binder;

(c) As the replacement of natural sand, the replacement ratio of MoT has subtle influence on the compressive strength of concrete. It is feasible to use MoT as fine aggregate in the preparation of structural concrete, in term of compressive strength;

(d) When the amount of ground super-fine MoT replacing cement is less than 10%, it is beneficial to improve the compactness of the system; hence the freeze-thaw and carbonization resistance of the concrete are barely affected. On contrary, when the replacement ratio of MoT is more than 10%, the hydration product and alkalinity of cement in unit volume concrete decreases, and the freeze-thaw and carbonization resistance of the system decreases with the increase of the replacement ratio.

References

- M.L.C.M. Henckens; P.P.J. Driessen; E. Worrell; Molybdenum resources: Their depletion and safeguarding for future generations. Resources, Conservation and Recycling 2018, 134, 61-69, 10.1016/j.resconrec.2018.03.002.

- USGS Mineral Commodity Summaries, Molybdenum. February 2019. Available online: www.usgs.gov/centers/nmic/mineral-commodity-summaries (accessed on 1 October 2019)

- Kropschot, S.J. Molybdenum—A Key Component of Metal Alloys: U.S. Geological Survey Fact Sheet; US Geological Survey: Reston, VA, USA, 2010; Volume 2009–3106, 2p

- Hu, B.L.; Wang, K.S.; Hu, P.; Yang, F.; Yu, Z.T.; Tan, J.F.; Song, R.; Zhao, B.H.; Cao, W.C. Research progress of molybdenum tailings resource recycling and utilization. Mater. Rep. 2015, 29, 123–128

- Yan Liu; Yifei Zhang; Fangfang Chen; Yi Zhang; The alkaline leaching of molybdenite flotation tailings associated with galena. Hydrometallurgy 2012, 129, 30-34, 10.1016/j.hydromet.2012.07.017.

- Li Lin; Lv Xianjun; Qiu Jun; Li Peng; The Study on the Flotation of Tailings of Molybdenum Minerals for the Reclamation of Iron. Procedia Environmental Sciences 2012, 12, 453-458, 10.1016/j.proenv.2012.01.303.

- Fu Jiangang; Chen Kaida; Wang Hui; Guo Chao; Liang Wei; Recovering molybdenite from ultrafine waste tailings by oil agglomerate flotation. Minerals Engineering 2012, 39, 133-139, 10.1016/j.mineng.2012.07.006.

- Xiu Lan Wang; Jian Ming Wang; Zhi Jun Ma; Experimental Research on Recycling Phlogopite from Molybdenum Tailings. Advanced Materials Research 2014, 1010, 1609-1612, 10.4028/www.scientific.net/amr.1010-1012.1609.

- Jin Rui Zhang; Ru Wang; Preparation of Glass-Ceramics Using Molybdenum Tailings. Advanced Materials Research 2011, 284, 1431-1434, 10.4028/www.scientific.net/amr.284-286.1431.

- Jiang Shi; Feng He; Chuqiao Ye; Lan Hu; Junlin Xie; Hu Yang; Xiaoqing Liu; Preparation and characterization of CaO–Al2O3–SiO2 glass-ceramics from molybdenum tailings. Materials Chemistry and Physics 2017, 197, 57-64, 10.1016/j.matchemphys.2017.05.028.

- Zhiheng Tang; Mingxing Zhang; Xuefeng Zhang; Jianli He; Xiaolin Jia; Leibo Deng; Effect of SiC content on viscosity and thermal properties of foam ceramic prepared from molybdenum tailings. Journal of Non-Crystalline Solids 2019, 513, 15-23, 10.1016/j.jnoncrysol.2019.02.024.

- Zhanying Bai; Kun Li; Xiaopeng Ma; Zhongying Yang; Xintong Ma; Preparation and characterization of molybdenum tailings-based water storage material. Materials Chemistry and Physics 2019, 236, 121791, 10.1016/j.matchemphys.2019.121791.

- Deng, J.P.; Liu, X.C.; Yan, W. The regulation of pore structure of foamed cement insulation panel with high content molybdenum tailings. New Build. Mater. 2019, 2, 85–88

- Di, Y.Q.; Cui, X.W.; Li, C.; Nan, N.; Li, K.B.; Zhou, C.S.; Study on preparation of porous insulation materials with molybdenum tailings. New Build. Mater. 2016, 4, 10-13.

- Luo, Z.T.; Liu, Z.H.; Si, Z.K.; Chen, X.; Kang, S.; Study of tail molybdenum ore mixed sand distribution optimization and the performance on the cement mortars. Concrete 2018, 4, 107–110.

- Guo, Q.S.; Geng, C.L.; Study on the effect of molybdenum tailingson on mechanical strength of fiber cement board. China Concr. Cem. Prod. 2019, 8, 41-44.

- Liu, S.C. Study on Preparation of High Strength Concrete by Ultrafine Particle Molybdenum Tailings. Master’s Thesis, Hebei University of Engineering, Handan, China, 2016

- Cao, X.R.; Liu, D.; Li, J.W.; Xu, S.Y.; Preparation of concrete using Molybdenum tailing. Henan Build. Mater 2016, 4, 268–270.

- Hu, J.B.; Zhu, L.; Zhang, W.; Study on the performance of concrete using ground molybdenum tailing powder. China Concr. Cem. Prod. 2016, 12, 88–91.