You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 2 by Lindsay Dong and Version 1 by Helge Liltved.

Hydroponic rooftop-grown lettuce can be competitive with their indoor counterparts if the rooftop hydroponic system is protected from extreme weather conditions.

- rooftop hydroponic

- nutrient film technique

- indoor hydroponic

1. Introduction

Urban farming may tackle many challenges that conventional agriculture is facing, including loss of arable land, water and nutrients depletion, fast population growth, soil contamination, rapid urbanization, and climate change [1]. One type of urban farming is rooftop farming, which is the practice of growing edible or ornamental plants on top of commercial, residential, and industrial buildings [2]. The majority of the roof space in most buildings is vacant. If this space is used for agriculture, it could meet up to 77% of inhabitants’ vegetable requirements [3]. Liu et al. reported that [4] they grew seven leafy vegetables in rooftop hydroponic systems and reported that rooftop hydroponic vegetables were less contaminated and were competitive in quality and cost compared with farm-grown leafy vegetables. Another study reported that 32% of the needed fresh produce in Cleveland USA could be satisfied if 62% of industrial and commercial rooftops were used to grow plants [5].

Rooftop farming could also alleviate environmental pollution by reducing the carbon dioxide in the atmosphere and helping clear the air of smog and dust [4]. Further environmental benefits of rooftop farming include water runoff management, reduction in the urban heat island effect, biodiversity conservation, and reduction in noise pollution [6].

Contrary to indoor urban farming, which relies on artificial lightning, rooftop farming can be cost effective because it uses only sunlight. Despite the advantages of rooftop farming and worldwide interest, commercial rooftop farms are very limited and most of extant roof farms are social–educational farms [7]. One reason for this could be the challenges that roof farming may face, including amplified climate conditions that can occur on rooftops, such as high wind speed, heavy rains, and extreme temperatures [6]. In addition, roofs are not designed, generally, for urban farming, which poses many obstacles that must be overcome before rooftop farming can spread more widely, such as roof weight limitations and installation and maintenance costs [8]. Another reason could be the lack of assessment studies on the practicality of rooftop farming compared with conventional or indoor urban farming.

2. Quality/Yield of Lettuce in Open-Air Rooftop Hydroponic System

2.1. Lettuce Growth and Yield

Shoot fresh weights and yields of the harvested rooftop and indoor hydroponic lettuce are presented in

Urban farming may tackle many challenges that conventional agriculture is facing, including loss of arable land, water and nutrients depletion, fast population growth, soil contamination, rapid urbanization, and climate change [1]. One type of urban farming is rooftop farming, which is the practice of growing edible or ornamental plants on top of commercial, residential, and industrial buildings [2]. The majority of the roof space in most buildings is vacant. If this space is used for agriculture, it could meet up to 77% of inhabitants’ vegetable requirements [3]. Liu et al. reported that [4] they grew seven leafy vegetables in rooftop hydroponic systems and reported that rooftop hydroponic vegetables were less contaminated and were competitive in quality and cost compared with farm-grown leafy vegetables. Another study reported that 32% of the needed fresh produce in Cleveland USA could be satisfied if 62% of industrial and commercial rooftops were used to grow plants [5].

Rooftop farming could also alleviate environmental pollution by reducing the carbon dioxide in the atmosphere and helping clear the air of smog and dust [4]. Further environmental benefits of rooftop farming include water runoff management, reduction in the urban heat island effect, biodiversity conservation, and reduction in noise pollution [6].

Contrary to indoor urban farming, which relies on artificial lightning, rooftop farming can be cost effective because it uses only sunlight. Despite the advantages of rooftop farming and worldwide interest, commercial rooftop farms are very limited and most of extant roof farms are social–educational farms [7]. One reason for this could be the challenges that roof farming may face, including amplified climate conditions that can occur on rooftops, such as high wind speed, heavy rains, and extreme temperatures [6]. In addition, roofs are not designed, generally, for urban farming, which poses many obstacles that must be overcome before rooftop farming can spread more widely, such as roof weight limitations and installation and maintenance costs [8]. Another reason could be the lack of assessment studies on the practicality of rooftop farming compared with conventional or indoor urban farming.

2. Quality/Yield of Lettuce in Open-Air Rooftop Hydroponic System

2.1. Lettuce Growth and Yield

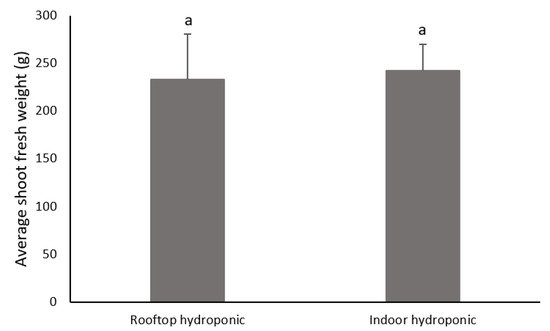

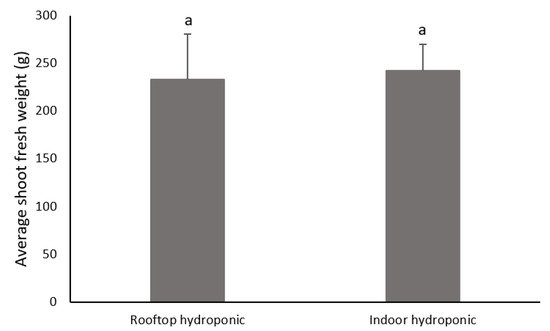

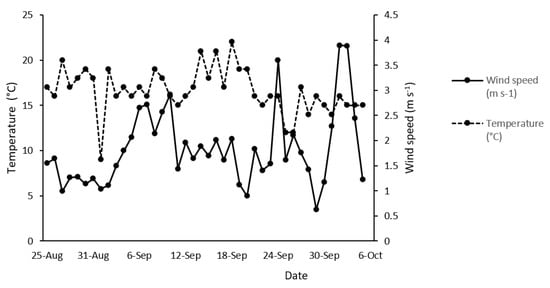

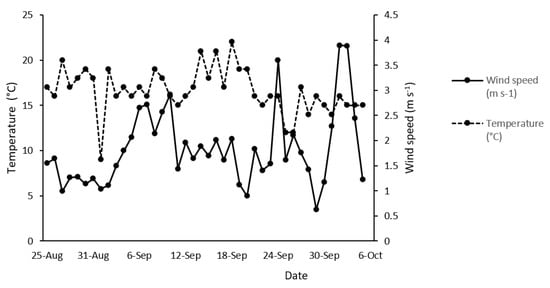

Shoot fresh weights and yields of the harvested rooftop and indoor hydroponic lettuce are presented in Figure 1. The lettuce grown in the indoor hydroponic system and in the rooftop hydroponic system had an average shoot weight of 243 g and 233 g, respectively. The maximum and the minimum shoot fresh weights of the indoor and rooftop hydroponic lettuce were 322 g and 196 g, and 781 g and 36 g, respectively. Although the average shoot fresh weight of the rooftop hydroponic lettuce was higher than the marketable fresh weight of 150 g, 25% of the total lettuce heads were below the marketable fresh weight. This variation was probably due to the high wind speed experienced during the beginning and at the end of the growth period, as shown in

Figure 4. The lettuce grown in the indoor hydroponic system and in the rooftop hydroponic system had an average shoot weight of 243 g and 233 g, respectively. The maximum and the minimum shoot fresh weights of the indoor and rooftop hydroponic lettuce were 322 g and 196 g, and 781 g and 36 g, respectively. Although the average shoot fresh weight of the rooftop hydroponic lettuce was higher than the marketable fresh weight of 150 g, 25% of the total lettuce heads were below the marketable fresh weight. This variation was probably due to the high wind speed experienced during the beginning and at the end of the growth period, as shown in

2.

Figure 3.

1. Average shoot fresh weight of rooftop and indoor hydroponic lettuce (bars represent standard deviation of the mean of 60 lettuce heads).

Figure 42. Average shoot fresh weight of rooftop and indoor hydroponic lettuce (bars represent standard deviation of the mean of 60 lettuce heads).

2.2. Nutrient Consumption and Concentration in Lettuce Leaves

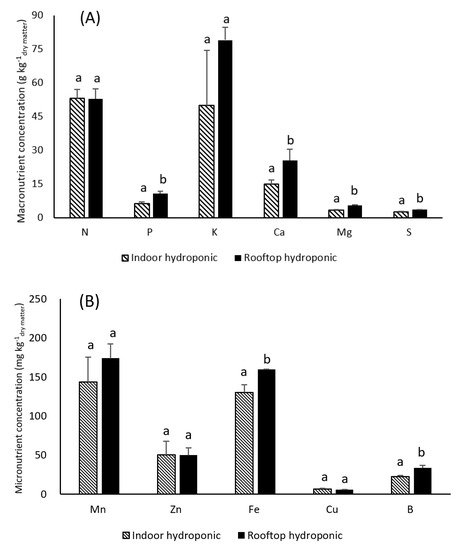

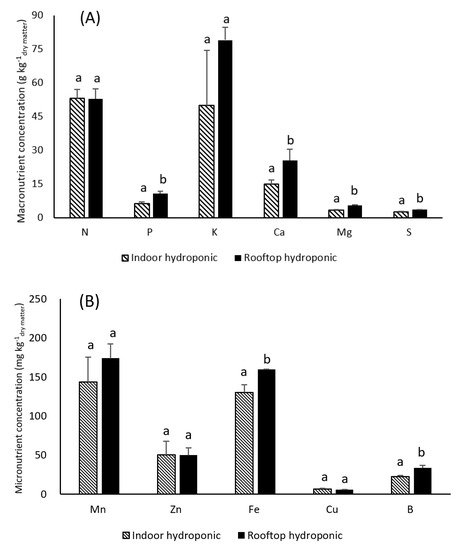

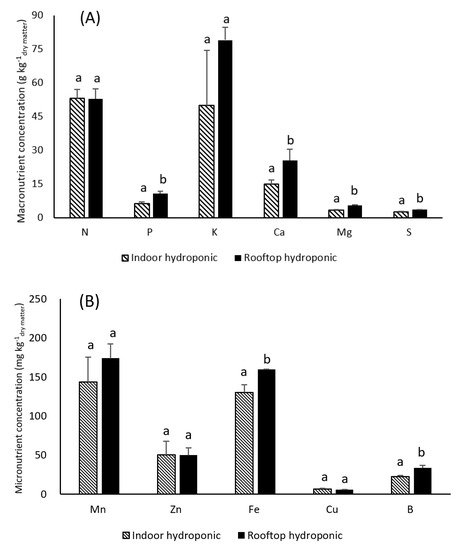

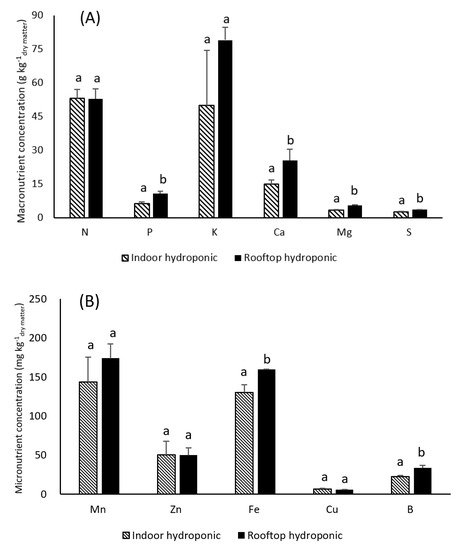

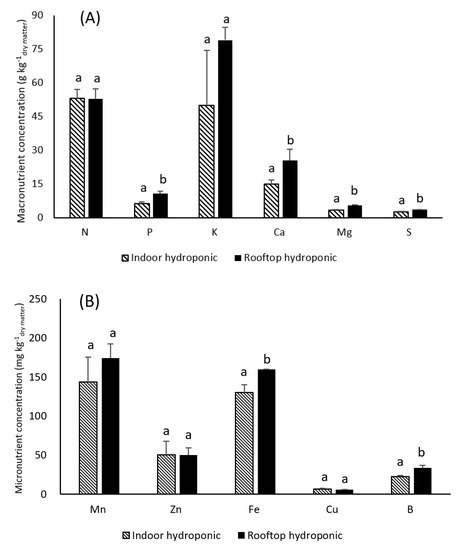

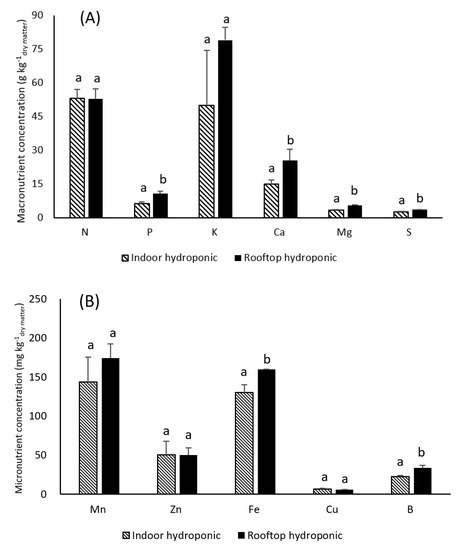

Leaf macro- and micro-nutrient concentrations in harvested rooftop hydroponic lettuce, compared to their concentrations in harvested indoor hydroponic lettuce, are shown in

Daily average temperature and daily average wind speed (m s−1) from 25 August to 5 October 2020.

2.2. Nutrient Consumption and Concentration in Lettuce Leaves

Leaf macro- and micro-nutrient concentrations in harvested rooftop hydroponic lettuce, compared to their concentrations in harvested indoor hydroponic lettuce, are shown inFigure 5. The foliar analysis of the macro-nutrients shows that the elements with highest accumulation in leaf tissue of the rooftop hydroponic lettuce were K, followed by N, Ca, P, Mg, and S, which conform to the norm-values of Hartz et al. However, macro-nutrients content in the leaves of the indoor hydroponic lettuce deviates from these norm-values by a higher N value than K value.

3. The foliar analysis of the macro-nutrients shows that the elements with highest accumulation in leaf tissue of the rooftop hydroponic lettuce were K, followed by N, Ca, P, Mg, and S, which conform to the norm-values of Hartz et al. However, macro-nutrients content in the leaves of the indoor hydroponic lettuce deviates from these norm-values by a higher N value than K value.

Figure 53.

Leaf macro-nutrient (

A

) and micro-nutrient (

B

) concentrations in harvested rooftop and indoor hydroponic lettuce (bars represent standard deviation of the mean of three replicas).

The highest accumulation of micro-nutrient elements in the leaf tissue of both the rooftop and indoor hydroponic lettuce were Mn, Fe, Zn, B, and Cu.

As shown in

Figure 5, the rooftop hydroponic lettuce accumulated more nutrients than the indoor hydroponic lettuce. The rooftop lettuce had a significantly higher concentrations of P, Ca, S, Mg, Fe, and B compared with the indoor lettuce. There were no significant differences in the other nutrient concentrations. Explanation for this higher uptake could be the positive effect of daylight on nutrients uptake. The intensity of light causes more transpiration in plants which affects nutrients [32].

Generally, the nutrient content of the indoor hydroponic lettuce was closer to the norm-values than the nutrient content of the rooftop hydroponic lettuce. Ca, P, K, and Mg all accumulated in the leaves of the rooftop lecttuce, to concentrations 3, 2, 1.5, and 1.5 times the norm-values [35]. This higher absorption of nutrients did not affect lettuce yield for better, nor for worse, as shown in

3, the rooftop hydroponic lettuce accumulated more nutrients than the indoor hydroponic lettuce. The rooftop lettuce had a significantly higher concentrations of P, Ca, S, Mg, Fe, and B compared with the indoor lettuce. There were no significant differences in the other nutrient concentrations. Explanation for this higher uptake could be the positive effect of daylight on nutrients uptake. The intensity of light causes more transpiration in plants which affects nutrients [9].

Generally, the nutrient content of the indoor hydroponic lettuce was closer to the norm-values than the nutrient content of the rooftop hydroponic lettuce. Ca, P, K, and Mg all accumulated in the leaves of the rooftop lecttuce, to concentrations 3, 2, 1.5, and 1.5 times the norm-values [10]. This higher absorption of nutrients did not affect lettuce yield for better, nor for worse, as shown in

Figure 4.

In order to avoid a possible luxury absorption of nutrients, an alternative NS may be used to grow rooftop hydroponic lettuce exposed to the same environment conditions as those in the current study. The estimation of the required nutrient concentrations of the alternative NS should take into account that not all the available nutrients will be taken up by lettuce leaves. The nutrient consumption and the nutrient uptake in leaves are presented in

1.

In order to avoid a possible luxury absorption of nutrients, an alternative NS may be used to grow rooftop hydroponic lettuce exposed to the same environment conditions as those in the current study. The estimation of the required nutrient concentrations of the alternative NS should take into account that not all the available nutrients will be taken up by lettuce leaves. The nutrient consumption and the nutrient uptake in leaves are presented in

Table 2, as percentages of the amount of nutrients added to the system.

1, as percentages of the amount of nutrients added to the system.

Table 21.

Nutrient consumption in rooftop hydroponic system and nutrient uptake by letuce leaves.

| Nutrient Consumption * | |

|---|---|

| 1 | |

| (g/kgdry matter) | Nutrient Uptake * |

| 2 | |

| (%) |

| Macro-nutrients | ||

| N | 2.95 | 63.27 |

| P | 0.44 | 87.74 |

| K | 4.2 | 67.4 |

| Mg | 0.43 | 44.8 |

| Ca | 2 | 46.86 |

| S | 0.67 | 19 |

| Micro-nutrients | ||

| B | 0.003 | 40.52 |

| Cu | 0.00043 | 47.5 |

| Mn | 0.012 | 54.57 |

| Mo | 0.00053 | 10.7 |

| Zn | 0.003 | 52.7 |

| Fe | 0.03 | 19.13 |

1

Nutrient consumption (

g/kgdry matter

) is calculated by subtracting the quantity of nutrient left in the nutrient tank from the total supplied nutrient, then divided by the quantity of the produced dry matter.*

2

Nutrient uptake is calculed by dividing nutrient content in lettuce leaves by nutrient consumption.

2.3. Nutrient Dynamic of the Recycled Solution

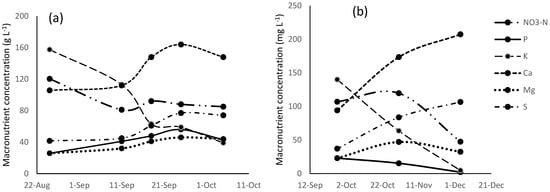

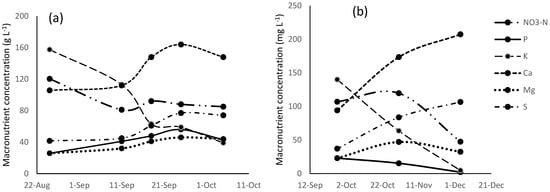

Figure 6 shows the fate of macro-nutrients during the growth period of the rooftop and indoor hydroponic lettuce. As indicated, a continous decrease in the concentration of P was observed in the NS used for indoor lettuce growth. However, the concentration of P in the NS used for rooftop lettuce growth increased gradually from 26 mg L

4 shows the fate of macro-nutrients during the growth period of the rooftop and indoor hydroponic lettuce. As indicated, a continous decrease in the concentration of P was observed in the NS used for indoor lettuce growth. However, the concentration of P in the NS used for rooftop lettuce growth increased gradually from 26 mg L

−1

to 43 mg L

−1

, despite the high accumulation of P in the rooftop lettuce leaves compared with norm-values and to the indoor lettuce (

Figure 5

). The N concentration in the NS used for indoor lettuce growth was reduced by 55% compared with the initial concentration, while the concentration of N in the NS used for rooftop lettuce growth remained nearly stable throughout the growth period. The N accumulation in leaf tissue was approximately equal to the accumulation in the leaves of the indoor hydroponic lettuce. The concentration of K experienced a continous decrease to final concentrations of 4.7 mg L

−1

and 39 mg L

−1

, in the NS used for indoor hydroponic lettuce and rooftop hydroponic lettuce, respectively, which corresponds to a reduction by 96% and 75%, respectively. Again, rooftop hydroponic leaf tissue accumulated more K than the indoor hydroponic leaf tissue.

Figure 64.

Concentrations of macro-nutrients in the recirculating nutrient solution in rooftop hydroponic system (

a

) and indoor hydroponic system (

b).

To summarize, except for Ca and S, rooftop lettuce accumulated more nutrients than the indoor lettuce. The concentration of nutrients in the NS used for rooftop lettuce growth were slightly higher at the end of the cultivation period compared with the concentration in the NS used for indoor lettuce growth. Hence, we may deduce two conclusions.

First, the nutrient uptake in rooftop hydroponic lettuce were more efficient than the uptake of indoor lettuce.

Secondly, nutrients were more likely to be wasted (not used by plants) in the indoor hydroponic system. Potentially, this could be partly explained by higher micobial activity due to higher temperature in the indoor hydroponic system compared with the outdoor hydroponic system. However, our literature search found no studies supporting this hypothesis.

Rooftop hydroponic systems could not only contribute to urban food production, but could also have a lower environmental footprint, since they use only sunlight and consume less nutrients compared with indoor systems and conventional agriculture, which make them more economical in the long term.

).

Figure 5. Leaf macro-nutrient (A) and micro-nutrient (B) concentrations in harvested rooftop and indoor hydroponic lettuce (bars represent standard deviation of the mean of three replicas).

To summarize, except for Ca and S, rooftop lettuce accumulated more nutrients than the indoor lettuce. The concentration of nutrients in the NS used for rooftop lettuce growth were slightly higher at the end of the cultivation period compared with the concentration in the NS used for indoor lettuce growth. Hence, we may deduce two conclusions.

First, the nutrient uptake in rooftop hydroponic lettuce were more efficient than the uptake of indoor lettuce.

Secondly, nutrients were more likely to be wasted (not used by plants) in the indoor hydroponic system. Potentially, this could be partly explained by higher micobial activity due to higher temperature in the indoor hydroponic system compared with the outdoor hydroponic system. However, our literature search found no studies supporting this hypothesis.

Rooftop hydroponic systems could not only contribute to urban food production, but could also have a lower environmental footprint, since they use only sunlight and consume less nutrients compared with indoor systems and conventional agriculture, which make them more economical in the long term.

References

- Kozai, T.; Niu, G. Resource- saving and resource-consuming characteristics of PFALs. In Plant Factory an Indoor Vertical Farming System for Efficient Quality Food Production; Kozai, T., Niu, G., Takano, M., Eds.; Academic Press: Cambridge, MA, USA, 2016; pp. 395–400. ISBN 9780128017753.

- Sabeh, N. Rooftop plant production systems in urban areas. In Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production; Kozai, T., Niu, G., Takagaki, M., Eds.; Elsevier Inc.: New York, NY, USA, 2019; pp. 129–135. ISBN 9780128166918.

- Orsini, F.; Gasperi, D.; Marchetti, L.; Piovene, C.; Draghetti, S.; Ramazzotti, S.; Bazzocchi, G.; Gianquinto, G. Exploring the production capacity of rooftop gardens (RTGs) in urban agriculture: The potential impact on food and nutrition security, biodiversity and other ecosystem services in the city of Bologna. Food Secur. 2014, 6, 781–792.

- Liu, T.; Yang, M.; Han, Z.; Ow, D.W. Rooftop production of leafy vegetables can be profitable and less contaminated than farm-grown vegetables. Agron. Sustain. Dev. 2016, 36, 41.

- Grewal, S.S.; Grewal, P.S. Can cities become self-reliant in food? Cities 2012, 29, 1–11.

- Appolloni, E.; Orsini, F.; Specht, K.; Thomaier, S.; Sanyé-Mengual, E.; Pennisi, G.; Gianquinto, G. The global rise of urban rooftop agriculture: A review of worldwide cases. J. Clean. Prod. 2021, 296, 126556.

- Su, Y.L.; Wang, Y.F.; Ow, D.W. Increasing effectiveness of urban rooftop farming through reflector-assisted double-layer hydroponic production. Urban For. Urban Green. 2020, 54, 126766.

- Walters, S.A.; Midden, K.S. Sustainability of urban agriculture: Vegetable production on green roofs. Agriculture 2018, 8, 168.

- Ainun, N.; Maneepong, S.; Suraninpong, P. Effects of Photoradiation on the Growth and Potassium, Calcium, and Magnesium Uptake of Lettuce Cultivated by Hydroponics. J. Agric. Sci. 2018, 10, 253.

- Hartz, T.K.; Johnstone, P.R.; Williams, E.; Smith, R.F. Establishing lettuce leaf nutrient optimum ranges through DRIS analysis. HortScience 2007, 42, 143–146.

More