Since the introduction of Nickel-Titanium alloy as the material of choice for the manufacturing of endodontic rotary instruments, the success rate of the root canal therapies has been significantly increased. This success mainly arises from the properties of the Nickel-Titanium alloy: the biocompatibility, the superelasticity and the shape memory effect. Those characteristics have led to a reduction in time of endodontic treatments, a simplification of instrumentation procedures and an increase of predictability and effectiveness of endodontic treatments. Nevertheless, the intracanal separation of Nickel-Titanium rotary instruments is still a major concern of endodontists, with a consequent possible reduction in the outcome rate.

As thoroughly demonstrated, the two main causes of intracanal separation of endodontic instruments are the cyclic fatigue and the torsional loads. As results, in order to reduce the percentage of intracanal separation researches and manufacturers have been focused on the parameters that directly or indirectly influence mechanical properties of endodontic rotary instruments.

This revientryw describes the current state of the art regarding the Nickel-Titanium alloy in endodontics, the mechanical behavior of endodontic rotary instruments and the relative stresses acting on them during intracanal instrumentation, highlighting the limitation of the current literature.

- endodontics

- endodontic rotary instruments

- Nickel-Titanium alloy

- root canal treatment

1. Introduction

2. Advantages in Using NiTi Rotary Instruments

Reduction in time of endodontic treatments: Instrumentation technique with manual SS files requires a larger number of tools and longer operating times. Instead, the increased cutting efficiency of NiTi rotary instruments and the use of increased taper instruments allow clinicians to improve these parameters of endodontic treatment [2][3][4].

Simplification of instrumentation procedures: The special properties of the NiTi instruments have made it possible to considerably simplify the instrumentation technique compared to the traditional procedural steps carried out through the use of SS files [3][5][6]. Thanks to the better mechanical characteristics of rotary instruments than manual ones, it’s possible to shape the root canals respecting their original trajectories not altering their original anatomy [7][8].

Increase of predictability and effectiveness of endodontic treatments: The superelasticity of NiTi alloy ensures the use of endodontic instruments with an increased taper without an excessive risk of fracture due to bending or cyclic fatigue, improving the process of root canal shaping and therefore of root canal filling [9]. For all these reasons, the success rates of endodontic treatments performed with NiTi rotary instruments is significantly greater than those performed with SS manual instruments [10][11][12][13][14].

3. Nickel-Titanium Alloy

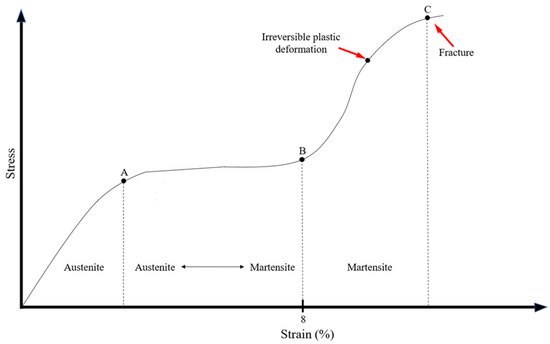

The mechanical responses of the NiTi alloy under certain load can be represented through a stress/deformation graph (Figure 1). The stress and strain curve could be divided by three vertical line (A, B and C in Figure 1) that individuate on the graph three different areas according to the crystallographic organization of the NiTi alloy: the austenitic region in which the alloy is composed by austenite; the austenitic/martensitic region (also called R-phase) in which there is a partially transformation of austenite in martensite, according to the application of stress; the martensite region in which the total amount of austenite is transformed in martensite above certain loads [15][16]. Below certain load, the transformation induced by mechanical stress is totally reversible (elastic deformation) as a direct consequence of the superelasticiy, however if a yield strength is exceeded the deformation becomes irreversible (plastic deformation) and the endodontic instrument is permanently damaged [17].

4. Evaluation of Mechanical Properties of NiTi Endodontic Rotary Instruments

4.1. Cyclic Fatigue Resistance

4.2. Torsional Resistance

4.3. Combined Torsional and Flexural Stresses

4.4. Bending Ability

5. Centering Ability, Canal Transportation and Shaping Ability

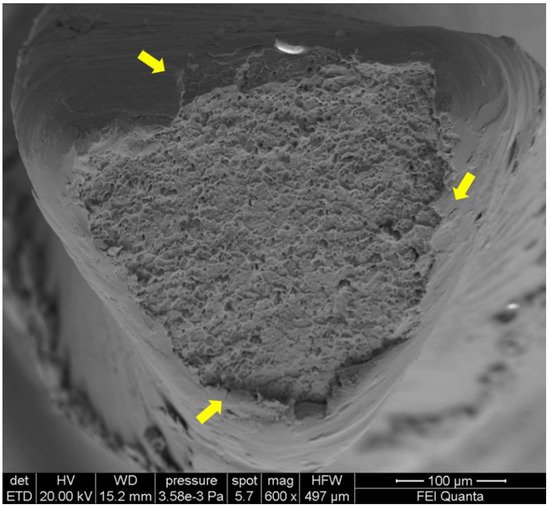

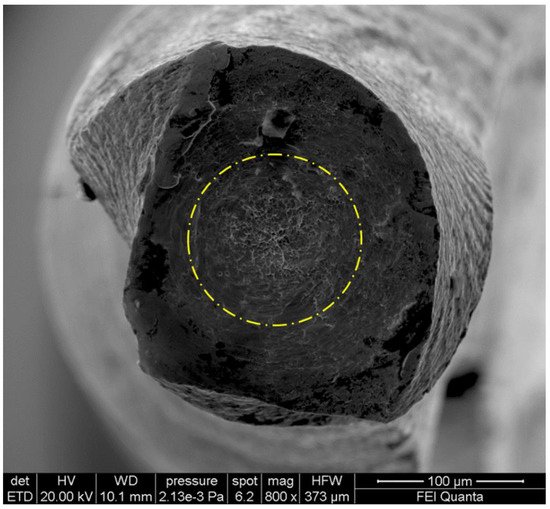

The main goal of shaping procedure is undoubtedly the mechanical removal of vital and/or necrotic tissues form the root canal system, simultaneously allowing the creation of an adequate space for the chemical disinfection and obturation [67]. According to this, root canal instrumentation could be considered as the most crucial phase during root canal treatment, in which clinicians must avoid any procedural error in order to not compromise the outcome of the endodontic treatment [68][69]. As stated by Gorni et al. the alteration of the root canal morphology is one of the most significant parameters in determining the outcome of endodontic retreatments, since inferior cleansing can be performed specifically aimed at the anatomical irregularities created by previous treatment [70]. Regarding this, the most common procedural errors during root canal treatments could be synthetized in: ledges, strip perforations, excessive thinning of canal walls, and canal transportation [1][71][72]. Considering the above-mentioned reasons, the preservation of the original root canal morphology is one of the most important features that characterized endodontic instruments. In fact, during the evaluation of the performance of NiTi rotary instruments the shaping ability should be considered. The two main popular and thoroughly validated methods used to evaluate these factors are the Micro-Computed Tomography (CT) and the SEM analysis, singularly used or in combination, that allow a precise calculation of the interested measurement trough the aid of digital software [73][74]. In our opinion Micro-CT imaging should be preferred because it is non-destructive 3-dimensional analysis and gives high-resolution images to precisely evaluate the untouched area, volume changes, and transportation in comparison to SEM analysis that requires the split of the teeth [73]. However, the SEM analysis could be used to evaluate debris and smear layer removal since it allows their direct measurement without using complex software for the voxel interpretation of Micro-CT images, nevertheless, also those measurements have some limitation, such as the bi-dimensional analysis of debris and smear layer, that does not allow measurement of the thickness of both parameters analyzed [75][76][77]. The most widely used centering ability and canal transportation evaluation method is the superimposition of root canal anatomy images before and after instrumentation [8][73][78][79]. The differences reside in the acquisition method used. Obviously the most accurate is the Micro-CT, followed by the CBCT and bi-dimensional radiograph. During Micro-Ct analysis, scans of each specimen before and after shaping procedures are overlapped using algorithms, allowing a consistent location of various dimensional measurements, such as the measurement of transportation across different (pre- and post-shaping) CT scans [80]. Despite the recent advances and innovations in kinematics and metallurgical and mechanical characteristics, none of the NiTi instrument systems are capable of shaping root canals to the ideal form, leaving a certain percentage of untouched canal [81][82][83].References

- Walia, H.M.; Brantley, W.A.; Gerstein, H. An initial investigation of the bending and torsional properties of Nitinol root canal files. J. Endod. 1988, 14, 346–351.

- Weiger, R.; Brückner, M.; ElAyouti, A.; Löst, C. Preparation of curved root canals with rotary FlexMaster instruments compared to Lightspeed instruments and NiTi hand files. Int. Endod. J. 2003, 36, 483–490.

- Vaudt, J.; Bitter, K.; Neumann, K.; Kielbassa, A.M. Ex vivo study on root canal instrumentation of two rotary nickel-titanium systems in comparison to stainless steel hand instruments. Int. Endod. J. 2009, 42, 22–33.

- Govindaraju, L.; Jeevanandan, G.; Subramanian, E. Clinical Evaluation of Quality of Obturation and Instrumentation Time using Two Modified Rotary File Systems with Manual Instrumentation in Primary Teeth. J. Clin. Diagn. Res. 2017, 11, Zc55–Zc58.

- Sadeghi, S. Shaping ability of NiTi rotary versus stainless steel hand instruments in simulated curved canals. Med. Oral Patol. Oral Cir. Bucal. 2011, 16, e454–e458.

- Htun, P.H.; Ebihara, A.; Maki, K.; Kimura, S.; Nishijo, M.; Tokita, D.; Okiji, T. Comparison of torque, force generation and canal shaping ability between manual and nickel-titanium glide path instruments in rotary and optimum glide path motion. Odontology 2020, 108, 188–193.

- Kandaswamy, D.; Venkateshbabu, N.; Porkodi, I.; Pradeep, G. Canal-centering ability: An endodontic challenge. J. Conserv. Dent. 2009, 12, 3–9.

- Gergi, R.; Rjeily, J.A.; Sader, J.; Naaman, A. Comparison of canal transportation and centering ability of twisted files, Pathfile-ProTaper system, and stainless steel hand K-files by using computed tomography. J. Endod. 2010, 36, 904–907.

- Donfrancesco, O.; Del Giudice, A.; Zanza, A.; Relucenti, M.; Petracchiola, S.; Gambarini, G.; Testarelli, L.; Seracchiani, M. SEM Evaluation of Endosequence BC Sealer Hiflow in Different Environmental Conditions. J. Compos. Sci. 2021, 5, 99.

- Namazikhah, M.S.; Mokhlis, H.R.; Alasmakh, K. Comparison between a hand stainless-steel K file and a rotary NiTi 0.04 taper. J. Calif Dent. Assoc. 2000, 28, 421–426.

- Taşdemir, T.; Aydemir, H.; Inan, U.; Unal, O. Canal preparation with Hero 642 rotary Ni-Ti instruments compared with stainless steel hand K-file assessed using computed tomography. Int. Endod. J. 2005, 38, 402–408.

- Cheung, G.S.; Liu, C.S. A retrospective study of endodontic treatment outcome between nickel-titanium rotary and stainless steel hand filing techniques. J. Endod. 2009, 35, 938–943.

- Del Fabbro, M.; Afrashtehfar, K.I.; Corbella, S.; El-Kabbaney, A.; Perondi, I.; Taschieri, S. In Vivo and In Vitro Effectiveness of Rotary Nickel-Titanium vs Manual Stainless Steel Instruments for Root Canal Therapy: Systematic Review and Meta-analysis. J. Evid. Based Dent. Pract. 2018, 18, 59–69.

- Makanjuola, J.O.; Umesi, D.C.; Oderinu, O.H. Treatment outcome of manual versus rotary techniques in single-visit endodontics for patients in a Nigerian Teaching Hospital: A randomized clinical trial. J. West Afr. Coll. Surg. 2018, 8, 44–75.

- Thompson, S.A. An overview of nickel-titanium alloys used in dentistry. Int. Endod. J. 2000, 33, 297–310.

- Zhou, H.; Peng, B.; Zheng, Y.-F. An overview of the mechanical properties of nickel–titanium endodontic instruments. Endodontic Topics. 2013, 29, 42–54.

- Hamilton, R.F.; Sehitoglu, H.; Chumlyakov, Y.; Maier, H.J. Stress dependence of the hysteresis in single crystal NiTi alloys. Acta Materialia 2004, 52, 3383–3402.

- Pruett, J.P.; Clement, D.J.; Carnes, D.L. Cyclic fatigue testing of nickel-titanium endodontic instruments. J. Endod. 1997, 23, 77–85.

- Leonardi Dutra, K.; Haas, L.; Porporatti, A.L.; Flores-Mir, C.; Nascimento Santos, J.; Mezzomo, L.A.; Corrêa, M.; Canto, G.D.L. Diagnostic Accuracy of Cone-beam Computed Tomography and Conventional Radiography on Apical Periodontitis: A Systematic Review and Meta-analysis. J. Endod. 2016, 42, 356–364.

- Reda, R.; Zanza, A.; Mazzoni, A.; Cicconetti, A.; Testarelli, L.; Di Nardo, D. An update of the possible applications of magnetic resonance imaging (Mri) in dentistry: A literature review. J. Imaging 2021, 7, 75.

- Di Nardo, D.; Gambarini, G.; Seracchiani, M.; Mazzoni, A.; Zanza, A.; Giudice, A.; D’Angelo, M.; Testarelli, L. Influence of different cross-section on cyclic fatigue resistance of two nickel-titanium rotary instruments with same heat treatment: An in vitro study. Saudi Endod. J. 2020, 10, 221–225.

- Seracchiani, M.; Miccoli, G.; Reda, R.; Zanza, A.; Obino, F.V.; Bhandi, S.; Gambarini, G.; Testarelli, L. A comprehensive in vitro comparison of mechanical properties of two rotary endodontic instruments. World J. Dent. 2020, 11, 185–188.

- Bhandi, S.; Seracchiani, M.; Donfrancesco, O.; Reda, R.; Mazzoni, A.; Nottola, S.; Familiari, G. Nickel-Titanium Rotary Instruments: An In Vitro Comparison (Torsional Resistance of Two Heat-treated Reciprocating Files). J. Contemp. Dent. Pract. 2021, 22, 361–364.

- Grande, N.M.; Plotino, G.; Pecci, R.; Bedini, R.; Malagnino, V.A.; Somma, F. Cyclic fatigue resistance and three-dimensional analysis of instruments from two nickel-titanium rotary systems. Int. Endod. J. 2006, 39, 755–763.

- Pedullà, E.; La Rosa, G.R.M.; Virgillito, C.; Rapisarda, E.; Kim, H.C.; Generali, L. Cyclic Fatigue Resistance of Nickel-titanium Rotary Instruments according to the Angle of File Access and Radius of Root Canal. J. Endod. 2020, 46, 431–436.

- Kitchens, G.G., Jr.; Liewehr, F.R.; Moon, P.C. The effect of operational speed on the fracture of nickel-titanium rotary instruments. J. Endod. 2007, 33, 52–54.

- Pedullà, E.; Grande, N.M.; Plotino, G.; Gambarini, G.; Rapisarda, E. Influence of continuous or reciprocating motion on cyclic fatigue resistance of 4 different nickel-titanium rotary instruments. J. Endod. 2013, 39, 258–261.

- Pedullà, E.; Corsentino, G.; Ambu, E.; Rovai, F.; Campedelli, F.; Rapisarda, S.; Rapisarda, E.; Grandini, S.; La Rosa, G.R. Influence of continuous rotation or reciprocation of Optimum Torque Reverse motion on cyclic fatigue resistance of nickel-titanium rotary instruments. Int. Endod. J. 2018, 51, 522–528.

- Sattapan, B.; Nervo, G.J.; Palamara, J.E.; Messer, H.H. Defects in rotary nickel-titanium files after clinical use. J. Endod. 2000, 26, 161–165.

- Gambarini, G.; Seracchiani, M.; Zanza, A.; Miccoli, G.; Del Giudice, A.; Testarelli, L. Influence of shaft length on torsional behavior of endodontic nickel–titanium instruments. Odontology 2020, 109, 568–573.

- Peters, O.A.; Peters, C.I.; Schönenberger, K.; Barbakow, F. ProTaper rotary root canal preparation: Assessment of torque and force in relation to canal anatomy. Int. Endod. J. 2003, 36, 93–99.

- Boessler, C.; Peters, O.A.; Zehnder, M. Impact of lubricant parameters on rotary instrument torque and force. J. Endod. 2007, 33, 280–283.

- Gambarini, G.; Seracchiani, M.; Piasecki, L.; Valenti Obino, F.; Galli, M.; Di Nardo, D.; Testarelli, L. Measurement of torque generated during intracanal instrumentation in vivo. Int. Endod. J. 2019, 52, 737–745.

- Roland, D.D.; Andelin, W.E.; Browning, D.F.; Hsu, G.H.; Torabinejad, M. The effect of preflaring on the rates of separation for 0.04 taper nickel titanium rotary instruments. J. Endod. 2002, 28, 543–545.

- Yared, G.; Sleiman, P. Failure of ProFile instruments used with air, high torque control, and low torque control motors. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2002, 93, 92–96.

- Parashos, P.; Messer, H.H. Rotary NiTi instrument fracture and its consequences. J. Endod. 2006, 32, 1031–1043.

- Ha, J.H.; Park, S.S. Influence of glide path on the screw-in effect and torque of nickel-titanium rotary files in simulated resin root canals. Restor. Dent. Endod. 2012, 37, 215–219.

- Tokita, D.; Ebihara, A.; Nishijo, M.; Miyara, K.; Okiji, T. Dynamic Torque and Vertical Force Analysis during Nickel-titanium Rotary Root Canal Preparation with Different Modes of Reciprocal Rotation. J. Endod. 2017, 43, 1706–1710.

- Kwak, S.W.; Ha, J.H.; Cheung, G.S.; Kim, H.C.; Kim, S.K. Effect of the Glide Path Establishment on the Torque Generation to the Files during Instrumentation: An In Vitro Measurement. J. Endod. 2018, 44, 496–500.

- Kimura, S.; Ebihara, A.; Maki, K.; Nishijo, M.; Tokita, D.; Okiji, T. Effect of Optimum Torque Reverse Motion on Torque and Force Generation during Root Canal Instrumentation with Crown-down and Single-length Techniques. J. Endod. 2020, 46, 232–237.

- Di Nardo, D.; Zanza, A.; Seracchiani, M.; Donfrancesco, O.; Gambarini, G.; Testarelli, L. Angle of Insertion and Torsional Resistance of Nickel–Titanium Rotary Instruments. Materials 2021, 14, 3744.

- Seracchiani, M.; Miccoli, G.; Di Nardo, D.; Zanza, A.; Cantore, M.; Gambarini, G.; Testarelli, L. Effect of Flexural Stress on Torsional Resistance of NiTi Instruments. J. Endod. 2021, 47, 472–476.

- Baek, S.H.; Lee, C.J.; Versluis, A.; Kim, B.M.; Lee, W.; Kim, H.C. Comparison of torsional stiffness of nickel-titanium rotary files with different geometric characteristics. J. Endod. 2011, 37, 1283–1286.

- Vivan, R.R.; Alcalde, M.P.; Candeiro, G.; Gavini, G.; Caldeira, C.L.; Duarte, M.A.H. Torsional fatigue strength of reciprocating and rotary pathfinding instruments manufactured from different NiTi alloys. Braz. Oral Res. 2019, 33, e097.

- Gambarini, G.; Cicconetti, A.; Nardo, D.D.; Miccoli, G.; Zanza, A.; Testarelli, L.; Seracchiani, M. Influence of different heat treatments on torsional and cyclic fatigue resistance of nickel-titanium rotary files: A comparative study. Appl. Sci. 2020, 10, 5604.

- Camps, J.J.; Pertot, W.J.; Levallois, B. Relationship between file size and stiffness of nickel titanium instruments. Endod. Dent. Traumatol. 1995, 11, 270–273.

- Kim, H.C.; Kim, H.J.; Lee, C.J.; Kim, B.M.; Park, J.K.; Versluis, A. Mechanical response of nickel-titanium instruments with different cross-sectional designs during shaping of simulated curved canals. Int. Endod. J. 2009, 42, 593–602.

- Berutti, E.; Chiandussi, G.; Gaviglio, I.; Ibba, A. Comparative analysis of torsional and bending stresses in two mathematical models of nickel-titanium rotary instruments: ProTaper versus ProFile. J. Endod. 2003, 29, 15–19.

- Zanza, A.; Seracchiani, M.; Di Nardo, D.; Reda, R.; Gambarini, G.; Testarelli, L. A Paradigm Shift for Torsional Stiffness of Nickel-Titanium Rotary Instruments: A Finite Element Analysis. J. Endod. 2021, 47, 1149–1156.

- Iacono, F.; Pirani, C.; Gatto, M.R.; Prati, C.; Peters, O. Combining apical torsional load and cyclic fatigue resistance of NiTi instruments: New approach to determine the effective lifespan of rotary instruments. Aust. Endod. J. 2021. online ahead of print.

- Santos, C.B.; Simões-Carvalho, M.; Perez, R.; Vieira, V.T.L.; Antunes, H.S.; Cavalcante, D.F.; De-Deus, G.; Silva, E.J.N.L. Torsional fatigue resistance of R-Pilot and WaveOne Gold Glider NiTi glide path reciprocating systems. Int. Endod. J. 2019, 52, 874–879.

- Zanza, A.; Seracchiani, M.; Reda, R.; Di Nardo, D.; Gambarini, G.; Testarelli, L. Role of the Crystallographic Phase of NiTi Rotary Instruments in Determining Their Torsional Resistance during Different Bending Conditions. Materials 2021, 14, 6324.

- Gambarini, G.; Miccoli, G.; D’Angelo, M.; Seracchiani, M.; Obino, F.V.; Reda, R.; Testarelli, L. The relevance of operative torque and torsional resistance of nickel-titanium rotary instruments: A preliminary clinical investigation. Saudi Endod. J. 2020, 10, 260–264.

- Viana, A.C.; Chaves Craveiro de Melo, M.; Guiomar de Azevedo Bahia, M.; Lopes Buono, V.T. Relationship between flexibility and physical, chemical, and geometric characteristics of rotary nickel-titanium instruments. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2010, 110, 527–533.

- Bahia, M.G.A.; Martins, R.C.; Gonzalez, B.M.; Buono, V.T.L. Physical and mechanical characterization and the influence of cyclic loading on the behaviour of nickel-titanium wires employed in the manufacture of rotary endodontic instruments. Int. Endod. J. 2005, 38, 795–801.

- Hamdy, T.M.; Galal, M.; Ismail, A.G.; Abdelraouf, R.M. Evaluation of Flexibility, Microstructure and Elemental Analysis of Some Contemporary Nickel-Titanium Rotary Instruments. Open Access Maced J. Med. Sci. 2019, 7, 3647–3654.

- Glossen, C.R.; Haller, R.H.; Dove, S.B.; del Rio, C.E. A comparison of root canal preparations using Ni-Ti hand, Ni-Ti engine-driven, and K-Flex endodontic instruments. J. Endod. 1995, 21, 146–151.

- Park, H. A comparison of Greater Taper files, ProFiles, and stainless steel files to shape curved root canals. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2001, 91, 715–718.

- de Arruda Santos, L.; López, J.B.; de Las Casas, E.B.; de Azevedo Bahia, M.G.; Buono, V.T. Mechanical behavior of three nickel-titanium rotary files: A comparison of numerical simulation with bending and torsion tests. Mater. Sci. Eng. C Mater. Biol. Appl. 2014, 37, 258–263.

- Razcha, C.; Zacharopoulos, A.; Anestis, D.; Mikrogeorgis, G.; Zacharakis, G.; Lyroudia, K. Micro-Computed Tomographic Evaluation of Canal Transportation and Centering Ability of 4 Heat-Treated Nickel-Titanium Systems. J. Endod. 2020, 46, 675–681.

- Zupanc, J.; Vahdat-Pajouh, N.; Schäfer, E. New thermomechanically treated NiTi alloys—A review. Int. Endod. J. 2018, 51, 1088–1103.

- Yahata, Y.; Yoneyama, T.; Hayashi, Y.; Ebihara, A.; Doi, H.; Hanawa, T.; Suda, H. Effect of heat treatment on transformation temperatures and bending properties of nickel-titanium endodontic instruments. Int. Endod. J. 2009, 42, 621–626.

- Hou, X.; Yahata, Y.; Hayashi, Y.; Ebihara, A.; Hanawa, T.; Suda, H. Phase transformation behaviour and bending property of twisted nickel-titanium endodontic instruments. Int. Endod. J. 2011, 44, 253–258.

- Testarelli, L.; Plotino, G.; Al-Sudani, D.; Vincenzi, V.; Giansiracusa, A.; Grande, N.M.; Gambarini, G. Bending properties of a new nickel-titanium alloy with a lower percent by weight of nickel. J. Endod. 2011, 37, 1293–1295.

- Miccoli, G.; Cicconetti, A.; Gambarini, G.; Del Giudice, A.; Ripanti, F.; Di Nardo, D.; Testarelli, L.; Seracchiani, M. A New Device to Test the Bending Resistance of Mechanical Endodontic Instruments. Appl. Sci. 2020, 10, 7215.

- Silva, E.; Martins, J.N.R.; Lima, C.O.; Vieira, V.T.L.; Braz Fernandes, F.M.; De-Deus, G.; Versiani, M.A. Mechanical Tests, Metallurgical Characterization, and Shaping Ability of Nickel-Titanium Rotary Instruments: A Multimethod Research. J. Endod. 2020, 46, 1485–1494.

- Chugal, N.; Mallya, S.M.; Kahler, B.; Lin, L.M. Endodontic Treatment Outcomes. Dent. Clin. North Am. 2017, 61, 59–80.

- Ng, Y.L.; Mann, V.; Rahbaran, S.; Lewsey, J.; Gulabivala, K. Outcome of primary root canal treatment: Systematic review of the literature—Part 1. Effects of study characteristics on probability of success. Int. Endod. J. 2007, 40, 921–939.

- Ng, Y.L.; Mann, V.; Rahbaran, S.; Lewsey, J.; Gulabivala, K. Outcome of primary root canal treatment: Systematic review of the literature—Part 2. Influence of clinical factors. Int. Endod. J. 2008, 41, 6–31.

- Gorni, F.G.; Gagliani, M.M. The outcome of endodontic retreatment: A 2-yr follow-up. J. Endod. 2004, 30, 1–4.

- Lin, L.M.; Rosenberg, P.A.; Lin, J. Do procedural errors cause endodontic treatment failure? J. Am. Dent. Assoc. 2005, 136, 187–193.

- Song, M.; Kim, H.C.; Lee, W.; Kim, E. Analysis of the cause of failure in nonsurgical endodontic treatment by microscopic inspection during endodontic microsurgery. J. Endod. 2011, 37, 1516–1519.

- Sousa-Neto, M.D.; Silva-Sousa, Y.C.; Mazzi-Chaves, J.F.; Carvalho, K.K.T.; Barbosa, A.F.S.; Versiani, M.A.; Jacobs, R.; Leoni, G. Root canal preparation using micro-computed tomography analysis: A literature review. Braz. Oral Res. 2018, 32, e66.

- Htun, P.H.; Ebihara, A.; Maki, K.; Kimura, S.; Nishijo, M.; Okiji, T. Cleaning and Shaping Ability of Gentlefile, HyFlex, EDM, and ProTaper Next Instruments: A Combined Micro-computed Tomographic and Scanning Electron Microscopic Study. J. Endod. 2020, 46, 973–979.

- Hülsmann, M.; Rümmelin, C.; Schäfers, F. Root canal cleanliness after preparation with different endodontic handpieces and hand instruments: A comparative SEM investigation. J. Endod. 1997, 23, 301–306.

- Garip, Y.; Sazak, H.; Gunday, M.; Hatipoglu, S. Evaluation of smear layer removal after use of a canal brush: An SEM study. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2010, 110, e62–e66.

- Plotino, G.; Özyürek, T.; Grande, N.M.; Gündoğar, M. Influence of size and taper of basic root canal preparation on root canal cleanliness: A scanning electron microscopy study. Int. Endod. J. 2019, 52, 343–351.

- Gambill, J.M.; Alder, M.; del Rio, C.E. Comparison of nickel-titanium and stainless steel hand-file instrumentation using computed tomography. J. Endod. 1996, 22, 369–375.

- Poly, A.; AlMalki, F.; Marques, F.; Karabucak, B. Canal transportation and centering ratio after preparation in severely curved canals: Analysis by micro-computed tomography and double-digital radiography. Clin. Oral Investig. 2019, 23, 4255–4262.

- Kabil, E.; Katić, M.; Anić, I.; Bago, I. Micro-computed Evaluation of Canal Transportation and Centering Ability of 5 Rotary and Reciprocating Systems with Different Metallurgical Properties and Surface Treatments in Curved Root Canals. J. Endod. 2021, 47, 477–484.

- Schneider, S.W. A comparison of canal preparations in straight and curved root canals. Oral Surg. Oral Med. Oral Pathol. 1971, 32, 271–275.

- Setzer, F.C.; Kwon, T.K.; Karabucak, B. Comparison of apical transportation between two rotary file systems and two hybrid rotary instrumentation sequences. J. Endod. 2010, 36, 1226–1229.

- Zhao, D.; Shen, Y.; Peng, B.; Haapasalo, M. Micro-computed tomography evaluation of the preparation of mesiobuccal root canals in maxillary first molars with Hyflex, CM Twisted Files, and K3 instruments. J. Endod. 2013, 39, 385–388.