Variable Speed Diesel Generators (VSDGs) is a solution to optimize engine consumption and increase system efficiency during different regimes. It improves system behavior by adapting diesel generators (DGs) speed with demanded mechanical load from the generator. VSDG improves efficiency, increases engine lifetime, reduces fuel consumption, and GHG emissions. Conventional fixed speed DG can rarely operate at less than 50% of the maximal load, while VSDGs can operate for a long period at low rotational speed to support lower loads.

1. Electrical Approach to VSDG

Rotational speed and the output voltage of the DG are directly related. Moreover, the sinusoidal waveform produced by the generator itself may be distorted and affected due to the reduction of DE speed or even by nonlinear load or load oscillations

[1][19]. One technique to adjust and control the output voltage frequency and amplitude is to use power electronics. Two different configurations exist to couple a power converter with a DG

[2][14].

For the first, the power treatment uses a full-power converter connected to the power generator output. In this method, DE speed is adjusted to load variation. However, this configuration has shown fragile control system capability since there is no connection between the power converter output and the generator magnetic field

[3][20]. Instead, a robust DC-link is placed in parallel with two series of power switches to create constant, reliable DC voltage with power drives. The power is then converted to the desired three-phase AC voltage and frequency using a high-power PWM inverter. However, this technique has no control over the performance of the power switches

[3][20].

The power generator and the converter are arranged to produce power based on the stator field or rotor position calculation in the second configuration. A robust but sophisticated control strategy made this technique popular. For example, in study

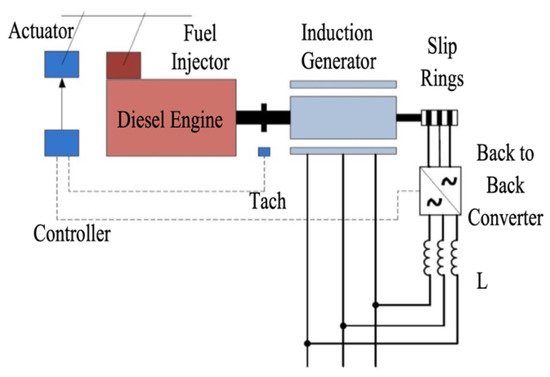

[4][21], a variable speed diesel generator uses a back-to-back PWM voltage-fed inverter.

This inverter is integrated with the generator and connects the stator windings with the rotor shaft to regulate rotor magnetic flux based on load fluctuations. The magnitude of the produced voltage is controlled using a stator flux orientation strategy (Figure 13). In this topology, DE speed variation depends on the capacity of the back-to-back converter, and it could cover a similar range of operation regimes as the first technique.

Figure 13. Variable speed diesel engine with DFIG [2]. Variable speed diesel engine with DFIG [14].

VSDG using a power converter reduces fuel consumption by 20 to 50%

[5][10]. Accordingly, this increases system efficiency, reduces GHG emissions, and improves fuel combustion. Maintenance fees decrease as fewer cylinder glazing, typical for engine operation in a low load regime, occurs

[6][22].

2. Mechanical Approach to VSDG

A DG consists of two main components, a DE, and an electric generator. Ambient temperature, fuel quality, air injection, and load variation are the main parameters that affect DG performance. The operation of the DG outside prescribed values of these parameters may result in high unintentional fuel consumption, higher engine overall maintenance fee, and poor-quality electric production

[7][23]. Mechanical techniques are available to maximize DG efficiency according to the variation of these parameters. Multi-cylinder ignition or cylinder deactivation management have extended engine life and optimized engine fuel profile compared to the conventional configurations. The load variation is a critical parameter that significantly affects the DE operation and performance. A mechanical converter or a flywheel storage system are used to improve DG efficiency during variable load conditions

[8][9][10][11][24,25,26,27]. The mechanical techniques analyzed in this paper are already available in the industry sector. These methods concentrate on the diesel engine, such as maintaining a fixed speed at the electrical generator shaft, and do not require power electronics to stabilize the voltage frequency and amplitude.

3. Conclusion

Grid power quality, system stability, and production efficiency are three major challenges of every modern power system. Turning to a future energy production perspective, modern DEs operating to meet emergency conditions or, in worse cases, regulating system parameters (voltage, frequency). High penetration of renewable energy sources into hybrid power systems keeps modern DG on-hold for particular operations such as backup or SSM. In such a system, synchronizing variable speed techniques into an electric power grid would be a new challenge. This strategy especially helps the conventional power sources reduce their fuel consumption and minimize additional expenses. Among proposed production systems, some techniques are able to save more fuel and produce more reliable outputs. However, these methods are not suitable for all applications, specifically with sudden and large load oscillations. On the other hand, some techniques demonstrate reliable performance during load variation even in remote areas but not too efficiently for small communities as they need a high initial investment.