As non-renewable resource, the recovery and utilization of phosphorus from wastewater is an enduring topic. Stimulated by the advances in research on polyphosphates (polyP) as well as the development of Enhanced Biological Phosphorus Removal (EBPR) technology to achieve the efficient accumulation of polyP via polyphosphate accumulating organisms (PAOs), a novel phosphorus removal strategy is considered with promising potential for application in real wastewater treatment processes. This rentryview mainly focuses on the mechanism of phosphorus aggregation in the form of polyP during the phosphate removal process. Further discussion about the reuse of polyP with different chain lengths is provided herein so as to suggest possible application pathways for this biosynthetic product.

- EBPR

- PAOs

- polyP

- phosphorus reuse

- wastewater

1. Introduction

2. Enrichment of PolyP in PAOs during EBPR Process

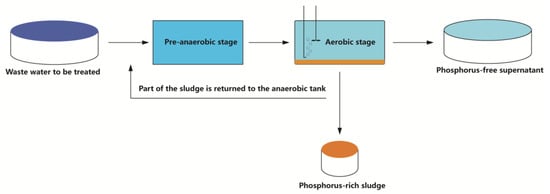

EBPR is a biological phosphorus removal technology that was developed in the 1970s and is now widely used in sewage treatment plants around the world [11][20]. Relying on PAOs or denitrifying phosphorous accumulating bacteria (DPAOs) [12][21], EBPR technology can remove P by having the free P absorbed by functional microbes for the purpose of growth and accumulated within the cell in the form of polyphosphate particles [13][22]. The traditional EBPR process diagram is illustrated in Figure 1. Generally, by alternating anaerobic and aerobic conditions, PAOs absorb the volatile fatty acids (VFAs) in sewage during the anaerobic stage and store them as poly-β-hydroxyalkanoic acid (PHA). This stored energy substance then serves as the carbon source and provides the energy required for the phosphorus accumulation and polyphosphate synthesis in the sewage by the PAOs during the aerobic stage [14][15][23,24]. P is subsequently removed from the system when the abovementioned phosphorus-containing microorganisms are discharged as phosphorus-rich sludge from the EBPR system [16][25]. The content of polyphosphate can be as high as 20% of its dry weight in PAO-rich sludge [17][26], while it accounts for no more than 2% in normal wastewater treatment sludge. Hence, this phosphorus-rich sludge produced in the EBPR process could be considered as having the potential to be applied as the resource for phosphorus collection and further reuse. In addition, efforts could be put into introducing PAOs with enhanced capabilities for phosphate accumulation so as to have more P recycled in the form of polyP.

3. PolyP Recovery from Phosphorus Removal System

Traditionally, the phosphorus-rich sludge produced from EBPR is directly used as fertilizer or dehydrated for incineration [21][22][52,53], although chemical and biological pollution accompany these operations. Instead, there may be less of an environmental impact and more economical benefits if polyP is recovered properly from the phosphorus-rich sludge. To develop an applicable polyP recovery process, the effect of the treatment on the type and chain length of polyP should be taken into consideration as the performance of polyP is largely dependent on these properties [23][54]. In general, the type of polyP is determined by the type of PAOs and the culture conditions, while the recovery method will affect the chain length of the obtained polyP. Herein, two recovery strategies are reviewed to provide information regarding the practical requirements for further polyP reuse.4. Application Prospects of Biosynthetic PolyP

Until now, although polyP has been suggested as being a significant participant in various biochemical activities, such as being the activator of mitochondrial respiration regulation [24][25][57,58], the accelerating inducer of HUVEC endothelial cell tube formation [26][59], and the scaffold for multifunctional polyanionic protein [27][60], the mechanism of the biosynthesis of polyP in mammals has remained uncertain [28][18]. Among the various scattered functions, applying polyP as a generator and storage of metabolizable energy in the extracellular matrix (ECM) [29][74] in the osteoblast-led bone mineralization process [30][16] and supplying polyP as a functional substance for preparing procoagulants and anticoagulants in endogenous coagulation pathways [31][32][75,76] are considered as the most promising application directions of biosynthetic polyP.