The operating principle of 3D printing is the layer-by-layer fabrication of objects, using a digital design. Before printing, a 3D digital model of the object is created with a computer-aided design (CAD) software, offering the ability of designing various complex final structures. The structure is then “sliced” in 2D layers which are printed one by one, on top of each other, in order to finally afford the 3D object. Stereolithography, which is based on the selective photo-polymerization of a liquid resin, was the first technique developed for 3D printing technology. Two other methods have mainly been employed for printing polysaccharides: fused deposition modeling (FDM), mostly for cellulose and its derivatives, owing to the good processing window between their glass transition temperature and the onset of thermal degradation temperature; and extrusion-based printing, which is appropriate for hydrogels. A short overview of the characteristics of these two printing techniques follows.

1. Fused Deposition Modeling (FDM)

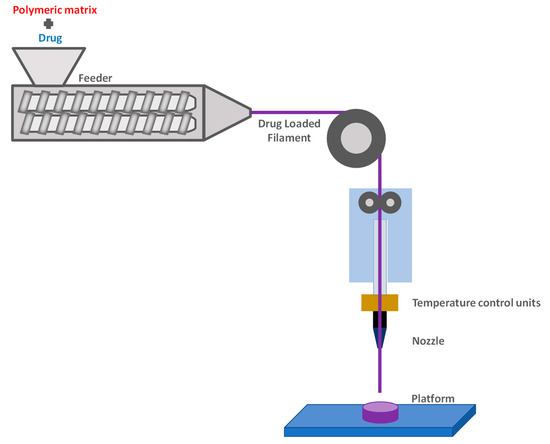

Fused deposition modeling is a 3D printing technology that uses a continuous filament of a thermoplastic material for the fabrication of complete structures (

Figure 13)

[1][2][3][4][48,49,50,51]. The utmost advantage of FDM is the preparation of many shapes in a short time, with a low cost in comparison to traditional manufacturing processes

[5][52]. FDM was developed by S. Scott Crump in the late 1980s and was commercialized in the early 1990s by (Stratasys Inc., Edina, MN, USA)

[6][53]. Its setup is typically composed of a printhead freely movable in X and Y directions, a Z direction movable platform and a raw material in a cylindrical-shaped filament. The printhead consists of a heated nozzle where the polymer is softened/melted and laid down onto the platform as a layer according to the CAD design, where it cools down and hardens

[7][54]. The following layers are deposited on top of the already printed layers and they then fuse with them, building the object in a bottom-up approach, while all the movements of the head and the raw materials are controlled by a computer.

Figure 13.

Simplified scheme illustrating the operating principle of hot-melt extrusion combined with fused deposition modeling.

There are various parameters affecting the quality of FDM 3D printed scaffolds namely the layer thickness, shell and infill pattern. Dimensional accuracy and surface roughness are among the most important characteristics to evaluate an FDM printed object

[6][53]. Concerning dimensional accuracy, the glass transition temperature of the filament’s material determines the overall shrinking behavior of FDM components

[8][55], while the immediate solidifying of the extruded material results in better dimensional accuracy. For the most part, filament materials applied in FDM printing are thermoplastics or, in general, materials able to melt when heated and immediately resolidify when cooling. PLA is commonly printed by FDM for pharmaceutical and medical applications but, progressively, other materials such as cellulose derivatives or Eudragit

® are being investigated

[9][10][11][56,57,58].

Polymer filaments suitable for FDM are generally prepared by hot melt extrusion (HME). HME was first established in the early 1930s and was originally used for the manufacturing of plastics and rubber products in various shapes (films, fibers, granules)

[12][59]. It is a very simple procedure: melted polymeric material is pumped through rotating screws via an extruder barrel resulting in a uniform filament. As expected, the properties of the extruded filament drastically affect the printing process. A fixed diameter throughout the length of the filament ensures uniform printing. Furthermore, the filaments must have an appropriate balance between flexibility and rigidity for continuous 3D printing. Indeed, soft filaments clog the FDM printer while brittle filaments break during printing

[13][60].

FDM has a vast field of applications including automotive, aerospace, industrial and medical areas. For the printing of drug delivery systems, appropriate drug filaments are initially prepared by HME: the drug is dispersed in the polymeric matrix and uniformly distributed while extruded. Alternatively, filaments can be charged by immersion in a drug solution. The filament containing the drug is subsequently fed in an FDM printer to print the final drug-loaded object

[8][55]. One of the assets of FDM is the lack of solvents, while a drawback is the temperature of FDM printing. Indeed, FDM takes place at high temperatures, since the polymeric material must be melted, resulting in a risk of degradation for the incorporated active pharmaceutical ingredients (API)

[6][53]. Nevertheless, many research groups are studying the applicability of FDM in drug delivery systems for less heat-sensitive drugs, while research for the development of systems requiring lower temperatures is ongoing.

2. Extrusion-Based 3D Printing

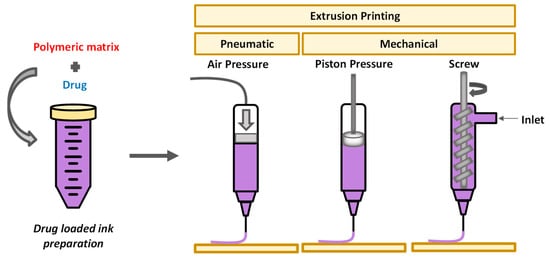

In extrusion-based printing—also known as semi-solid extrusion printing, pressure-assisted microsyringe printing or direct ink writing—a semi-solid material, such as a paste or a gel, is extruded through a movable nozzle or needle under pressure and deposited on a platform (

Figure 24)

[14][15][16][61,62,63]. Similarly to FDM, after the completion of a single layer, the extrusion head either moves up or the build platform moves down for the deposition of the next layer. The materials to be printed, which are commonly called inks, along with the printing conditions, determine the performance of the final products

[17][2].

Figure 24.

Extrusion-based printing systems.

The viscosity and the gel-forming behavior of materials are critically important in extrusion-based 3D printing

[16][18][63,64]. In general, inks with shear-thinning behavior and fast recovery time are required

[19][32]. To be more explicit, materials should be sufficiently viscous to retain their shape during the printing process but not too viscous, in order to obtain uniform strands and avoid nozzle clogging. After printing, the materials must undergo rapid gelation in order to avoid altering the printed construct

[20][21][65,66]. Solidification can be obtained through the formation of non-covalent interactions and hydrogen bonds, crystallization, chain rearrangement, or by chemical crosslinking. The extrusion method enables compatibility with a large number of materials such as molten polymers, pastes, polymer solutions and hydrogels, the latter having received more attention as their viscosity can be carefully controlled

[22][67].

Maintaining the structural integrity of the printed construct and achieving a high printing fidelity are key challenges in extrusion-based printing. Besides viscosity, other important parameters that should be optimized are: (1) the material output, (2) the needle diameter, (3) the nozzle feed rate, (4) the printer head speed, (5) the viscosity of extruded ink, (6) the temperature and (7) the distance between the nozzle and substrate. All these variables depend tightly on each other. For instance, if the needle diameter is decreased, the resultant strand diameter will decrease, and increased pressure might be needed to maintain a uniform strand deposition

[23][68].

Extrusion-based 3D printing offers several advantages, including the ability to print a diversity of inks with a broad range of viscosities, due to the possibility to adjust the pressure used for extrusion as well as the possibility to co-print inks from different polymers, thus allowing easy access to spatially controlled multi-material scaffolds. Additionally, lower temperatures are used compared to FDM, rendering this printing technique particularly appropriate for the printing of drug- or cell-loaded scaffolds.