Over the past few decades, the production and consumption of clothing has increased exponentially, leading to a dramatic increase in the negative environmental consequences produced by the fashion industry. Given the rising pace of global warming and the rising concern about the fashion industry’s contribution to the climate crisis and its exploitative social dimensions, decision makers, politicians and government officials have begun to promote sustainable fashion through public policy. This article reviews the main barriers facing a circular economy in general and the fashion industry in particular. It considers nascent regulations emerging throughout the world in the field of sustainable fashion, applying circular economic principles to the fashion industry.

- sustainable fashion

- circular economy

- sustainability

- regulation

- public policy

- economic barriers

- policy proposals

- Fashion

- Sustainable fashion

1. The Circular Economy

2. Dilemmas Pertaining to Sustainable Fashion and Its Expression in the Business World

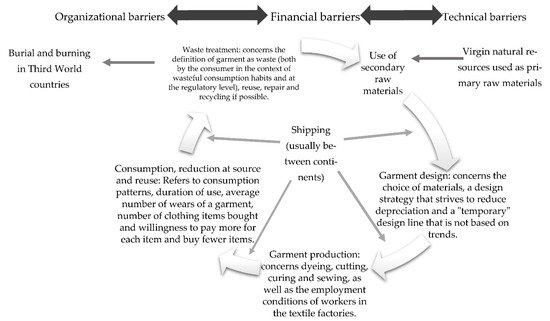

3. Barriers to a Circular Economy

-

Common depreciation standards in accountancy incentivize organizations to regard a product’s value as declining rapidly toward EUR 0. This stimulates a take-make-waste model [21][6]. Present rules serve to increase the tax benefits that producers can obtain. Rapid depreciation rates lower the perceived market value of used products, which constitutes a barrier to the development of a circular economy for which used product value is a necessary precondition. Furthermore, depreciation standards also limit the maximum length of rental, lease or pay-per-use periods [33][19].

-

VAT favors the traditional sales model over the more circular rent-purchase model. In a linear economy, most producer–user relationships rely on traditional sales relationships that involve paying the full value of the product at the time of sale. As a result, manufacturers are required to pay VAT on the income earned at the time of sale. Producers, however, operating rent-purchase relationships with customers, still need to pay VAT on all projected revenues obtained during the rental period, as rent-purchase is seen as the deferred supply of goods [30,35][16][21]. This results in negative business dynamics. If entire businesses are built on this relationship, upfront costs will have negative impacts on liquidity and business viability.

-

VAT currently does not favor used products and materials over new ones. In addition to the barriers described above, concerning VAT, in B2C transactions, new, second-hand and recycled products are all taxed equally. This means that for all products that are not new, the sales tax is paid twice or even more by users—once at every transaction of the product. This reduces business competitiveness, especially considering the extra costs incurred in creating take-back systems [36][22].

-

Common financial assessment practices favor linear economic models over circular economic models. The less-certain financial nature of circular revenue models (CRMs) makes them riskier from a traditional financial risk assessment’s point of view. CRMs are characterized by recurring periodic revenue streams and therefore longer payback periods. They also represent a value shift from assets to contracts [21,34,37][6][20][23].

4. Barriers to a Circular Economy in Fashion

References

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380.

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32.

- Kneese, A. The Economics of Natural Resources. Popul. Dev. Rev. 1988, 14, 281–309.

- Stahel, W.R. Policy for material efficiency—Sustainable taxation as a departure from the throwaway society. R. Soc. Publ. 2013, 371, 1–19.

- Bruntland Report. Our Common Future: The Report of the World Commission on Environment and Development; Oxford University Press: New York, NY, USA, 1987; pp. 127–134.

- The Ellen MacArthur Foundation. Towards the Circular Economy Vol. 1: An Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013; Available online: https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an (accessed on 23 November 2021).

- Hysa, E.; Kruja, A.; Rehman, U.R.; Laurenti, R. Circular Economy Innovation and Environmental Sustainability Impact on Economic Growth: An Integrated Model for Sustainable Development. Sustinability 2020, 12, 4831.

- Pheifer, A.G. Barriers & Enablers to Circular Business Models 2017. Available online: https://bit.ly/3x305qF (accessed on 23 November 2021).

- Niinimäki, K. Sustainable Fashion in a Circular Economy; Aalto University: Espoo, Finland, 2018.

- Jung, S. A theoretical investigation of slow fashion: Sustainable future of the apparel industry. Int. IJC 2014, 38, 5.

- Ecologist Informed by Nature—Slow Fashion. Available online: https://theecologist.org/2007/jun/01/slow-fashion (accessed on 23 November 2021).

- STAND Earth. Available online: https://www.stand.earth/ (accessed on 23 November 2021).

- Extinction Rebellion Call on Fashion to Transform Our Culture of Consumption and Destruction. Available online: https://extinctionrebellion.uk/2020/09/29/extinction-rebellion-call-on-fashion-to-transform-our-culture-of-consumption-and-destruction/ (accessed on 23 November 2021).

- WRAP—Textiles 2030, A New Ground-Breaking, Expert-Led Initiative. Available online: https://wrap.org.uk/taking-action/textiles/initiatives/textiles-2030 (accessed on 23 November 2021).

- Kent, S. Fashion Steps Up Climate Commitments the UN Fashion Charter Upgraded Its Targets to Drastically Slash Emissions by the End of the Decade and Added LVMH as a Signatory. Business of Fashion 2021. Available online: https://www.businessoffashion.com/articles/sustainability/fashion-steps-up-climate-commitments?utm_source=newsletter_dailydigest&utm_medium=email&utm_campaign=Daily_Digest_091121&utm_term=S43O7PIDDJA2LD67GQT4SORDLA&utm_content=top_story_1_cta (accessed on 23 November 2021).

- Van der Laan, K. Circular Revenue Models—Required Policy Changes for the Transition to a Circular Economy; Copper8; KPMG Advisory N.V: Amsterdam, The Netherland, 2019; pp. 2–20.

- SDG’s for Better Fashion. Available online: https://sustainabledevelopment.un.org/partnership/?p=28041 (accessed on 23 November 2021).

- Palea, V. Fair Value Accounting and Its Usefulness to Financial Statement Users. J. Financ. Report. Account. 2014, 12, 102–116.

- Kraaijenhagen, C.; van Oppen, C.; Bocken, N. Circular Business: Collaborate and Circulate; Ecodrukkers: Nieuwkoop, The Netherlands, 2016.

- ING Economics Department. Rethinking Finance in a Circular Economy-Financial Implications of Circular Business Models 2015. Available online: https://think.ing.com/reports/rethinking-finance-in-a-circular-economy-financial-implications-of-circular-business-models (accessed on 23 November 2021).

- EUR—Lex Access to European Union Law—COUNCIL DIRECTIVE 2006/112/EC 2006. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32006L0112 (accessed on 23 November 2021).

- Overheid.nl-Omzetbelasting, Margeregeling; Regeling Voor Gebruikte Goederen, Kunstvoorwerpen, Voorwerpen Voor Verzamelingen en Antiquiteiten—2019. Available online: https://wetten.overheid.nl/BWBR0035390/2019-01-01 (accessed on 23 November 2021).

- The Ex’tax Project. New Era. New Plan. Europe. A Fiscal Strategy for an Inclusive, Circular Economy; The Ex’tax Project Foundation: Houten, The Netherlands, 2016; Available online: www.ex-tax.com (accessed on 23 November 2021).

- How Can the Industry and Education Foster Sustainable SKILLS to Ensure New Talent Entering Industry Has the Expertise and Knowledge Required to Champion Sustainability? In Addressing Sustainable Goals in the Fashion Industry through Education and Employability, Glasgow, Scotland, 4 November 2021. Available online: https://www.youtube.com/watch?v=lnx7ExFOJuw&t=1581s (accessed on 23 November 2021).

- Peleg-Mizrachi, M.; Tal, A. Caveats in Environmental Justice, Consumption and Ecological Footprints: The Relationship and Policy Implications of Socioeconomic Rank and Sustainable Consumption Patterns. Sustainability 2019, 12, 231.

- Sunhildez, C.; Simona, T. Fast Fashion and Second Hand Clothes between Ecological Concerns and Global Business. Annals of the University of Oradea: Fascicle of Textiles, Leatherwork, 2014, Volume XV, pp. 163–166. Available online: https://www.researchgate.net/publication/304626238_FAST_FASHION_AND_SECOND_HAND_CLOTHES_BETWEEN_ECOLOGICAL_CONCERNS_AND_GLOBAL_BUSINESS (accessed on 21 November 2021).

- MUD JEANS. Available online: https://mudjeans.eu/ (accessed on 23 November 2021).

- ThredUP. Available online: https://www.thredup.com/ (accessed on 23 November 2021).

- UK Parliament. Fixing Fashion: Clothing Consumption and Sustainability: Sixteenth Report of Session 2017–19. National House of Commons 2019. Available online: https://publications.parliament.uk/pa/cm201719/cmselect/cmenvaud/2311/231102.htm (accessed on 24 November 2021).

- UN Alliance for Sustainable Fashion Addresses Damage of ‘Fast Fashion’. Available online: https://www.unep.org/news-and-stories/press-release/un-alliance-sustainable-fashion-addresses-damage-fast-fashion (accessed on 20 November 2021).

- Ütebay, B.; Çelik, P.; Çay, A. Textile Industry and Waste, 3rd ed.; Open Access Books: London, UK, 2020; pp. 1–19.

- European Circular Economy Stakeholder Platform-EU Report. Recycled Post-Consumer Textiles—An Industry Perspective; Interreg NWE Fibersort Project: Lille, France, 2020; Available online: https://circulareconomy.europa.eu/platform/en/knowledge/recycled-post-consumer-textiles-industry-perspective (accessed on 24 November 2021).

- European Commission. Sustainable Garment Value Chains 2019. Available online: https://www.switch-asia.eu/resource/sustainable-garment-value-chains/ (accessed on 20 November 2021).

- Hvass, K. Post-retail responsibility of garments—A fashion industry perspective. J. Fash. Mark. Manag. 2014, 18, 413–430.

- Payne, A. Open-and closed-loop recycling of textile and apparel products. In Handbook of Life Cycle Assessment (LCA) of Textiles and Clothing, 1st ed.; Muthu, S., Ed.; Woodhouse Publishing: Cambridge, UK, 2015; pp. 103–123.

- Bouzon, M.; Govindan, K. Reverse logistics as a sustainable supply chain practice for the fashion industry: An analysis of drivers and the Brazilian case. In Sustainable Fashion Supply Chain Management: From Sourcing to Retailing; Choi, T.M., Cheng, T.C.E., Eds.; Springer: Heidelberg, Germany, 2015; pp. 85–104.

- Leonas, K.K. The use of recycled fibers in fashion and home products. In Textiles and Clothing Sustainability, Textile Science and Clothing Technology; Muthu, S.S., Ed.; Springer: Singapore, 2017; pp. 55–77.

- Fontell, P.; Heikkilä, P. Model of Circular Business Ecosystem for Textiles; VTT Technology: Espoo, Finland, 2017; p. 313. Available online: http://www.vtt.fi/inf/pdf/technology/2017/T313.pdf (accessed on 22 November 2021).

- Webster, K. The Circular Economy. A Wealth of Flows, 2nd ed.; Ellen MacArthur Foundation: Cowes, UK, 2017.

- Sherman, L. How Can New Technologies Help Make Fashion More Sustainable? Business of Fashion 2019. Available online: https://www.businessoffashion.com/articles/sustainability/how-can-new-technologies-help-make-fashion-more-sustainable (accessed on 24 November 2021).

- Ellen MacArthur Foundation—Redesigning the Future of Fashion. Available online: https://ellenmacarthurfoundation.org/topics/fashion/overview (accessed on 23 November 2021).

- Anner, M. Binding Power: The Sourcing Squeeze, Workers’ Rights, and Building Safety in Bangladesh since Rana Plaza. Research Report 2018. Available online: Chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/viewer.html?pdfurl=https%3A%2F%2Fwww.wiwiss.fu-berlin.de%2Fforschung%2FGarments%2FMedien%2F2018-Anner-Research-Report-Binding-Power.pdf&clen=1827523 (accessed on 24 November 2021).

- Clean Clothes Campaign Deaths and Injuries in the Global Garment Industry. Available online: https://cleanclothes.org/campaigns/protect-progress/deaths-and-injuries-in-the-global-garment-industry (accessed on 23 November 2021).