Nowadays, oil spills are considered a serious worldwide environmental crisis. To deal with this global issue, Meng et al.

[28][111] synthesized a super-lipophilic and super-hydrophobic functionalized graphene oxide/polyurethane (FGP) sponge via a simple and cost-effective dip coating method. The synthesized FGP sponge by the authors demonstrated a great absorption capacity for a wide variety of oils and organic solvents from water, reaching 35 times its own mass. In addition, the FGP sponge demonstrated a good reusability. Therefore, this study provides a simple approach for the removal of oil spills and organic solvents from water

[28][111]. Sun et al.

[29][52] mentioned that modifying the commercial melamine sponge (MS) with graphene oxide (GO) or GO-based nanocomposites (NCs) is a facile, efficient, and low-cost method to synthesize three-dimensional (3D) porous materials with multifunctionality. Sun et al.

[29][52] synthesized two types of 3D MSs that were separately functionalized via the reduced GO (RGO) sheets and Ag/RGO NC using combined methods of immersion process and chemical reduction. The results of the study demonstrated that, owing to the high porosity and unique surface topography, the RGO-MS exhibited a high absorption capacity, reaching 41 to 91 times its own weight for several types of oils and organic solvents. Furthermore, both the Ag/RGO-MS and RGO-MS showed high oil/water separation efficiencies. Thus, Ag/RGO-MS and RGO-MS are very promising candidates for potential applications in oil-spill removal and water disinfection

[29][52]. Zhang

[13][98] proposed a facile method to synthesize superhydrophobic polyurethane sponge for oil/water separation using a simple dipping-drying process. The results of the authors’ study showed that the GSH-based superhydrophobic sponge exhibited high absorption selectivity for a wide range of oils and organic solvents. This study demonstrated a new effective way to synthesize superhydrophobic materials for oil/water separation, with a great potential in large-scale industrial practical application

[13][98]. Periasamy et al.

[1][86] synthesized polyurethane dish-washing (PU-DW) sponges functionalized sequentially via polyethylenimine (PEI) and graphene oxide (GO) producing PEI/reduced graphene oxide (RGO) PU-DW sponges. The PEI/RGO PU-DW sponge was coated with 20% phenyltrimethoxysilane (PTMOS) to further enhance the absorption capacity and hydrophobicity of oil. The results of the authors’ study showed that the PTMOS/PEI/RGO PU-DW sponge absorbed a wide range of oils within 20 s and efficiently separated oil/water mixtures through a flowing system. Thus, with the merits of a fast absorption rate, low cost, and reusability, the PTMOS/PEI/RGO PU-DW sponge has a great potential as a superabsorbent for highly efficient removal and recovery of oil spills as well as for the separation of oil/water mixtures

[1][86]. Zhou et al.

[30][112] synthesized graphene/polyurethane (PU) sponges with superhydrophobicity via the one-pot solvothermal technique. The synthesized graphene/polyurethane (PU) sponge can act as a selective filter to effectively and continuously separate oil from water. Owing to the functionalized PU sponge’s structural integrity, the material was capable of separating oil up to 53,000 times its own mass with an oil–water separation efficiency greater than 99.5%. This study shows that the functionalized PU sponge and the integrated oil–water separation system provided have a great potential in industrial scale oil–water separation processes

[30][112]. Zhao et al.

[31][113] fabricated graphene-coated melamine sponges (GCMSs) via a one-step method. The GCMSs synthesized by the authors are hydrophobic, oleophilic, and demonstrated high absorption for oil liquids. The results of the study showed that the absorption capacities for diesel oil and gasoline were greater than 105 g g

−1. Thus, GCMS has great application potential in the field of oil spillage cleanup

[31][113]. Yang et al.

[32][56] synthesized a hydrophobic and superoleophilic nitrogen-doped graphene (NG) sponge with a three-dimensional (3D) structure via a facile hydrothermal method without further surface modification or pretreatments. The as-prepared NG by the authors exhibited a good porosity, low density, and high specific surface area. The results of the study show that the NG sponges have strong absorption capacities, reaching 200 times its own weight in a short time for a wide range of oils and organic solvents. Thus, this study demonstrates that the NG sponge is a promising candidate in the field of spilled oil recovery owing to its feasibility, cost-effectiveness, and scalability

[32][56]. In addition, Wu et al.

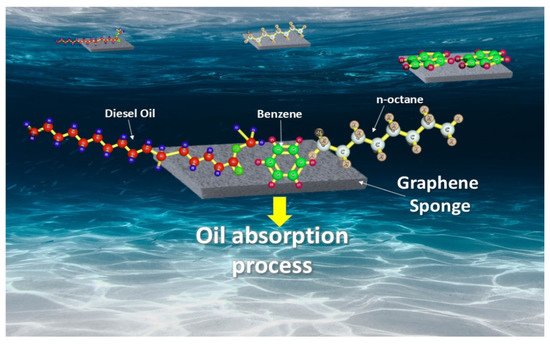

[16][101] mentioned that the graphene sponge (GS) has many applications in oil removal owing to the hydrophobic nature of graphene sheets. However, current hydrothermal preparations of GS require the application of toxic reducing reagents that cause environmental pollution. Hence, several studies focused their work on finding an environmentally friendly methods to synthesize graphene sponge (GS). Wu et al.

[16][101] reported that graphene oxide (GO) can be hydrothermally reduced by glucose forming GS for the adsorption of various oils and organic solvents. The authors have reduced the graphene sheets by glucose during the hydrothermal treatment and produced a 3D porous structure. The study results demonstrated that GSs have efficiently adsorbed oils and organic solvents with competitive adsorption capacities. Thus, GSs can be efficiently used for the remediation of oils from water

[16][101].