In order to meet the increasingly complex expectations of customers, many companies must increase efficiency and agility. In this sense, Industry 4.0 technologies offer significant opportunities for improving both operational and decision-making processes. These developments make it possible to consider an increase in the level of operational systems and teams’ autonomy. However, the potential for strengthening the decision-making process by means of these new technologies remains unclear in the current literature. To fill this gap, a Delphi study using the Régnier Abacus technique was conducted with a representative panel of 24 experts. The novelty of this study was to identify and characterize the potential for enhancing the overall decision-making process with the main Industry 4.0 groups of technologies. Our results show that cloud computing appears as a backbone to enhance the entire decision-making process. However, certain technologies, such as IoT and simulation, have a strong potential for only specific steps within the decision-making process. This research also provides a first vision of the manager’s perspectives, expectations, and risks associated with implementing new modes of decision-making and cyber-autonomy supported by Industry 4.0 technologies.

1. Introduction

Socio-economic developments are transforming the way work is done and decisions are made within companies. These developments naturally impact the performance of companies that have become more agile to comply with new market requirements. To this end, many companies are seizing the opportunities offered by emerging technologies, especially those related to Industry 4.0

[1], and many works have studied the relationships between Industry 4.0, lean or continuous improvement and their impact on social systems or, more generally, on sustainability issues

[2][3][4][5][6][2,3,4,5,6].

A German government program to increase the competitiveness of its manufacturing industry is behind Industry 4.0

[7], which was announced at the Hannover Fair in 2011

[8]. Since then, Industry 4.0 concepts have been pushed by various governments under different names and more than 100 definitions have been proposed

[9]. Although different views and distinctions coexist as to which technologies are included in Industry 4.0, the Boston Consulting Group

[10] identifies nine main pillars, namely, autonomous robots, simulation, horizontal and vertical integration of information systems, the Internet of Things, cyber security, the cloud, additive manufacturing, augmented reality, and big data and analytics. Furthermore, cyber-physical systems (CPS) are presented as one of the most significant directions in the development of computer science and information and communication technologies by many authors

[11][12][13][11,12,13]. CPSs integrate other 4.0 technologies and interact with humans and other autonomous subsystems at all production levels through many new modalities

[11]. CPSs contribute to enhancing the collaborative and cognitive aspects associated with the different stages of the decision-making process

[12].

Companies have often started implementing these technologies to increase their profitability and productivity but sometimes neglect the human dimension. If the latter is impacted by the deployment of these new technologies, it turns out that human factors also impact these deployment processes in turn. This is also the case when introducing new technologies to support decision-making processes. While benefits may accrue

[1], they seem to be maximized only if multiple organizational adjustments are integrated, especially those related to dynamic abilities and human factors

[14]. In practice, these adjustments are rarely studied or considered all together.

To identify and understand the adjustments to be made to increase the benefits of Industry 4.0 technologies, it seems important to study the relationship between technologies and their use in decision-making processes. In particular, the question arises to what extent these technologies strengthen the employee’s empowerment and facilitate interactions between employees and managers. These considerations have become more and more prominent so that Industry 4.0 has already given way to Industry 5.0

[15]. Industry 4.0 is considered to be technology-driven whereas the Industry 5.0 concept, announced by the European Commission, is value-driven, with three interconnected core values: human-centricity, sustainability, and resilience

[16]. In this context, a safe and inclusive work environment must be created to, among other things, prioritize autonomy, which is considered one of the fundamental rights of workers

[16][17][18][19][16,17,18,19]. It is to be noted that numerous thinkers or observers see the main characteristic of Industry 5.0 as bringing the human touch back to the center of decision making through the collaboration between humans and machines. In this context, it seems that issues of empowerment and autonomy in decision making carried out by humans assisted by new technologies will become particularly crucial in the future

[20].

From an autonomy perspective, Industry 4.0 technologies are tasked with enabling industrial machines and systems to become context-adaptive and autonomous

[21]. At the same time, employees appear to gain autonomy at work by using such technology. Some works based on the concept of human cyber-physical systems (H-CPS) attempt to identify human–automation symbiosis work systems. For example, Romero et al.

[22] offer a typology of operators 4.0 based on how the physical, sensory, and cognitive capacities are reinforced by Industry 4.0 technologies. However, this work does not specify how these enhanced capacities modify autonomy at work and improve decision making in an operational context. More generally, the advances provided by Industry 4.0 create significant opportunities for better decisions to be made

[23], particularly on the shop floor with effective data-driven decisions

[24][25][24,25].

However, these potential benefits brought about by Industry 4.0 raise new research questions that remain to be clarified:

- What is the potential of all the new technologies associated with Industry 4.0 to strengthen the decision-making process?

- What are managers’ expectations regarding the enhancement of the different parts of the decision-making process with Industry 4.0 technologies?

- Will the enhancement of the decision-making process by Industry 4.0 technologies impact the evolution of the autonomy of operational teams and systems?

- How will the answers to these questions evolve as the level of integration of Industry 4.0 principles within companies increases?

This article aims to answer the first research question mentioned above as a priority.

2. Autonomy 4.0 and Enhancement of Decision-Making Process through Industry 4.0 Technologies.

We carried out a prospective study by consulting experts using the Delphi method. We have also applied the Régnier abacus, an original technique that consists of collecting, using a colored panel, the opinion of experts based on statements expressed in precise, concise, and relevant terms. We present a synthesis of the experts’ answers according to the four themes identified :

- Autonomy 4.0;

- Decision-making process 4.0: managers’ expectations;

- Decision-making process 4.0 and the level of integration of Industry 4.0 principles; and

- Enhancement of the decision-making process through Industry 4.0 technologies.

We used the following formula to reference the elements presented to the experts: (RX-IY): reference to questionnaire X and item Y.

2.1. Autonomy 4.0

The answers to items R1-I1 and R1-I2 allow us to estimate the gap between the current level of autonomy entrusted to operational teams and systems and the expected or desirable level induced by the deployment of Industry 4.0 technologies. The experts indicate that managerial practices differ from one company to another, especially according to their size and governance model (R1-I1). On the other hand, the experts are unanimous in affirming that teams and operational systems will have to be more autonomous in the future, mainly for agility, responsiveness, and efficiency reasons (R1-I2).

The experts mostly believe that Industry 4.0 technologies will help increase the level of autonomy of operational teams and systems (R1-I3). The answers to Item R1-I4 highlight the strong link between enhancing the decision-making process through Industry 4.0 technologies and increasing the level of autonomy.

The experts agree that it is necessary to distinguish the decision-making process steps that will remain entrusted to people from those where Industry 4.0 technologies are expected to either help people achieve them better or to fully automate them (R2-I1). This choice must consider the risk of rejection of these technologies by employees, the degree of maturity and quality of each Industry technology 4.0, which may be more or less advanced, and the level of mastery and integration of these technologies within each company.

The experts identify a number of risks that can lead to the disempowerment of teams and a loss of autonomy (R1-I3). Many repeatedly point out that the level of autonomy depends heavily on the governance model established in the company (items R1-I3, R1-I4, R1-I5, and R1-I8). This raises the question of whether increased autonomy is a prerequisite for the proper deployment of Industry 4.0 and/or whether it is the deployment of Industry 4.0 technologies—which offers new opportunities through enhanced support for better decision making—that will encourage an increase in the autonomy entrusted to teams.

Some experts stated that using Industry 4.0 technologies to enhance decision making could lead to a strong dependence of operators and managers on these technologies (R1-I4, R1-I6). This could lead to a reduction in the decision-making latitude left to operational teams and the inability of managers to make good decisions in the face of the unknown, or when confronted with problems unforeseen, unmeasured, or difficult to identify by these technologies (R1-I4)

The experts explain that Industry 4.0 technologies can broaden the scope of decision/responsibility entrusted to operational teams (R1-I5). However, some emphasize that this is not an end in itself. Whether or not the decision-making scope of operational teams is broadened will depend above all on the governance model established in the company.

Items R1-I6 and R1-I7 make it possible to assess managers’ expectations as perceived by the panel of experts concerning the first dimension of autonomy

[26][27][89,91] which is focused on the task.

The experts almost unanimously believe that, overall, Industry 4.0 technologies will enhance the ability of operational teams and systems to carry out their tasks with maximum autonomy. Some explain it by the fact that the automation of certain repeatable and less complex tasks and decisions will relieve operational teams to whom it will then be possible to entrust more complex decisions inducing a higher level of responsibility and autonomy (R1-I6).

Even if a majority of the experts think that this corresponds to an expectation of managers, the increase in the autonomy left to operational teams and systems in the definition of tasks seems to be less consensual (R1-I7) than in the case of task completion (R1-I6). Several experts stress that the growing autonomy of teams must nevertheless take place in “compliance” with standards (R1-I7). In this sense, some experts specify that Industry 4.0 technologies will allow operational teams and systems to evolve standards or better train themselves. However, according to these same experts, the initial definition of standards or the validation of the evolutions retained thereafter will remain the responsibility of managers.

Items R1-I8, R1-I9, and R1-I10 make it possible to assess the managers’ expectations as perceived by the panel of experts concerning the second dimension of autonomy

[26][27][89,91] focused on the notion of collaboration declined according to three axes: cooperation (R1-I8), communication (R1-I9), and coordination (R1-I10).

On this second dimension of autonomy, the experts’ opinions are the most consensual. The experts widely believe that managers expect Industry 4.0 technologies to enhance the cooperation of operational teams and systems with other organizational entities to increase agility and efficiency (R1-I8). Some issues are highlighted, such as the risk of too much digitalization, the impact of the governance model, or the type of business model (B2B or B2C).

The experts also overwhelmingly believe that managers expect Industry 4.0 technologies to improve communication. They stress that the expectations are strong regarding information sharing and that it will be particularly important to associate meaning with it (R1-I9).

The experts are unanimous that managers expect Industry 4.0 technologies to enable operational teams and systems to more widely manage available resources, synchronize tasks, and align activities (coordination). Some make it a critical success factor. Others point out that the choice of technologies must be aligned with needs that are often unclear or poorly formulated by managers (R1-I10).

Items R1-I11 and R1-I12 make it possible to assess managers’ expectations regarding the third dimension of autonomy

[26][27][89,91] focused on the notion of governance defined according to two axes: the participation of operational teams in social dialogue (R1-I11) and management style (R1-I12). On this third dimension of autonomy, experts’ opinions are most divided.

No consensus for or against emerges regarding managers’ expectations on the interest of mobilizing Industry 4.0 technologies to allow operational teams and systems to participate widely in social dialogue and promote it. Many point out that this directly depends on the governance model established in the company (R1-I11). Some experts believe that social dialogue must accompany the proper implementation of Industry 4.0 technologies but doubt the existence of a will to exploit these technologies to improve social dialogue. Others point out that they present the risk of promoting unilateral top-down communication.

The experts also appear divided regarding managers’ expectations of Industry 4.0 technologies and their ability to promote the implementation of participative management at the operational level (R1-I12). Many experts stress once again that this depends directly on the governance model established in the company. Some believe that new technologies will offer the opportunity to give more autonomy to operational teams and that this will include implementing a more participative management model. Still, other comments establish links with the directive and persuasive management models.

2.2. Decision-Making Process 4.0: Managers’ Expectations

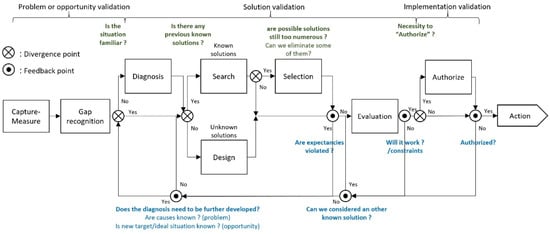

Overall, managers expect Industry 4.0 technologies to evolve and/or enhance the steps of the decision-making process (cf.

Figure 1). Let us consider all the opinions expressed with regard to enhancing the different steps of the decision-making process (items R1-I13 to R1-I20): 77% of the opinions are favorable, 10% are mixed, 8% disagree, and 5% disagree or do not know how to answer.

Figure 1. Proposed decision-making process in an operational context

[28][87].

However, there are strong disparities. The experts are all totally or largely in favor of enhancing the following steps by means of Industry 4.0 technologies:

-

Identification of problems and opportunities (R1-I14);

-

Diagnosis of problems (R1-I15);

-

Real-time “Capture/measure” of information relating to the status and performance of the production system (R1-I13);

-

The search for existing solutions (R1-I16); and

-

The “evaluation” step of the decision-making process, to ensure that the proposed solution is relevant and adapted to the context (R1-I19).

On the other hand, the enhancement of three steps is a source of dissensus:

(The steps are ranked in descending order of consensus in the lists above.)

According to the experts, managers expect Industry 4.0 technologies to contribute to the evolution or enhancement of the first three steps of the decision-making process: “Capture/measure”, “Recognition of a problem or opportunity”, and “Diagnosis”. The experts seem to indicate that these factors correspond to the steps with the highest potential of enhancement for all Industry 4.0 technology groups.

Regarding the “Recognition of a problem or opportunity” step, the experts believe that Industry 4.0 technologies can already offer solutions to enhance the identification of opportunities (and not only problems) through the use of artificial intelligence. However, they point out that this does not systematically correspond to an expectation sustained by all managers. This seems to depend in particular on the degree of maturity of each company in the mastery and knowledge of these technologies (R2-I2).

Then comes the “Evaluation” step, for which the level of expectation of managers and the potential for enhancements are also concerns.

In contrast, according to experts, the “Selection” step is the one for which managers’ expectations are the least important. This seems to be explained by the fact that in an operational context situations are less complex than at the strategic level; if the first steps of the decision-making process are well conducted, then the problem will be properly defined and the number of known solutions available will be relatively small. The mobilization of this “Selection” step is then unnecessary, and it is appropriate to move directly to the “Evaluation” step.

Subsequently, the “Design” and “Authorization” steps are, according to the experts, those for which managers’ expectations are the least important after “Selection”, but also those for which the contribution of Industry 4.0 technologies seems to be the least promising.

2.3. Decision Process 4.0 and Level of Integration of Industry 4.0 Principles

The experts point out that companies involved in Industry 4.0 have unequal levels of integration of Industry 4.0 principles (R2-I4). Many companies with a still too superficial understanding of the principles and challenges of Industry 4.0 remain focused on achieving short-term results through the “use of data to better understand reality”.

With respect to several items (R1-I13 to R1-I15, R2-I4, R2-I7, R2-I9, and R2-I11), the experts stress that it is more important to enhance in priority the steps of “Capture/measure”, “Recognition of a problem/opportunity”, and “Diagnosis”, which lay the foundations for the subsequent steps. However, many experts believe that enhancing the first three decision-making process steps remains reserved for companies that have undertaken an in-depth transformation of their operational governance mode (R2-I4). In particular, they draw attention to the importance of empowering field teams to use these new technologies and associated systems so that they can participate in their evolution and improvement.

Even if some technologies, such as artificial intelligence, offer great potential for improvement, experts generally agree that the majority of manufacturers are not at a sufficient level to consider today the enhancement of the step “Search” for already known solutions, especially in SMEs (R2-I5).

Similarly, and according to the experts, if the enhancement of the “Selection” step does not appear to be a priority today in the eyes of managers (R1-I18), this may change in the future (R2-I3). This is explained by the often too limited number of known solutions currently available and mobilizable within many companies. However, the deployment of Industry 4.0 technologies will enhance the ability to identify solutions and remember them for next time. The number of known solutions is therefore likely to grow. AI also makes it possible to:

-

Improve the quality of the selection of a known solution even within a limited panel of candidate solutions; and

-

Identify a greater number of known possible solutions by recognizing similarities between a priori unrelated situations.

The experts are almost unanimous in saying that most manufacturers have not yet reached a sufficient level of integration of the principles of Industry 4.0 to consider today the enhancement of the “Design” step (R2-I6). Several experts point out that this step will probably be where human intervention will remain the most essential.

According to the experts, the same applies to the enhancement of the “Evaluation” step (R2-I7), but the positions here are much less clear-cut than before. This step nevertheless is the locus of highest consensus with respect to enhancement after the first three steps of the decision-making process, particularly via the use of simulation, performance measurement, or automated reporting systems. Accordingly, if the level of integration of the principles of Industry 4.0 is not yet perceived as sufficient by the panel of experts, expectations remain high (R1-I19), and partial solutions already exist to enhance this step.

Finally, the fact that the actual level of adoption of Industry 4.0 principles is too low to consider the enhancement of the “Authorization” step is also almost unanimous (R2-I8).

The experts remain relatively divided on the future orientations to be given around the enhancement of the “Authorization” step in terms of level of delegation or automation (R2-I9 to R2-I11).

The experts generally remain reluctant to fully automate the “Authorization” step (R2-I11). They are concerned with the risk of disempowerment of managers, loss of initiative of operational teams, and inadequate management systems in place for which the interpersonal component is central (nemawashi, for example, which is the process of consensus-building in a Lean management context

[29][92].

In this sense, several experts believe that it is worthwhile to mobilize Industry 4.0 technologies to facilitate communication and coordination (R2-I9) to make the “Authorization” step more efficient and reduce the implementation time of the validation loop. However, in a more consensual way, the panel of experts thinks that it is better to reinforce the last step “Authorization” to partially or totally delegate this step from the manager to the team or person at the initiative of the proposed solution (R2-I10).

2.4. Enhancement of the Decision-Making Process through Industry 4.0 Technologies

Items R1-I21 to R1-I27 and R2-I24 to R2-I26 aimed to target the steps of the decision-making process likely to evolve or be enhanced by the ten Industry 4.0 technology groups: big data analysis, artificial intelligence, Internet of Things (IoT), simulation, augmented reality, cybersecurity, cloud computing, cyber-physical systems, autonomous robots/machines and inter-machine communication (M2M).

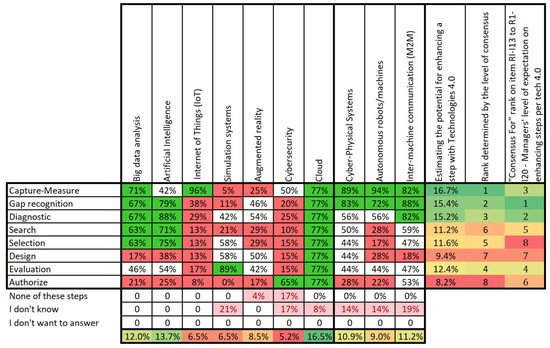

The summary of the results appears

Figure 2 below.

Figure 2. Synthesis of answers to items R1-I21 to R1-I27 and R2-I24 to R2-I26.

Figure 2, above, shows the percentage of experts who believe that one of the steps in the decision-making process listed in the row is likely to evolve or be enhanced by one of the Industry technologies 4.0 listed in the column.

For example, 71% of experts believe that the “Capture/measure” step is likely to evolve or be enhanced by big data analysis:

-

Cells corresponding to a “consensus for” appear in green in the Figure 2 (i.e., responses in agreement with the association of a technology with the evolution or enhancement of one of the steps of the decision-making process ≥60% of all opinions);

-

Cells corresponding to a “consensus against” appear in red in the Figure 2

The last two columns make it possible to compare, based on the opinions formulated by the experts, the level of expectation of managers and the potential offered by the ten Industry 4.0 technology groups to evolve or enhance the steps of the decision-making process.

The three penultimate lines indicate the number of experts:

-

Who believe that one of the technologies listed does not enhance any of the steps in the decision-making process;

(i.e., responses disagreeing with the association of a technology with the evolution or enhancement of one of the steps of the decision-making process ≥60% of all opinions); and

-

Cells corresponding to a “dissensus” appear in white.

The next column gives an indication of the steps in the decision-making process that are most likely to evolve or be enhanced by one of the Industry 4.0 technologies listed in the column. For example, 16.7% of all possibilities for evolution or enhancement of the decision-making process steps by one of the ten Industry 4.0 technology groups listed in the column concern the “Capture/measure” step.

Finally, the last line of the

Figure 2 indicates the technologies most likely to develop or enhance all or part of the steps of the decision-making process. For example, 12% of all opportunities for change or enhancement of the decision-making process steps by one of the ten Industry 4.0 technology groups listed in the column come from big data analysis.

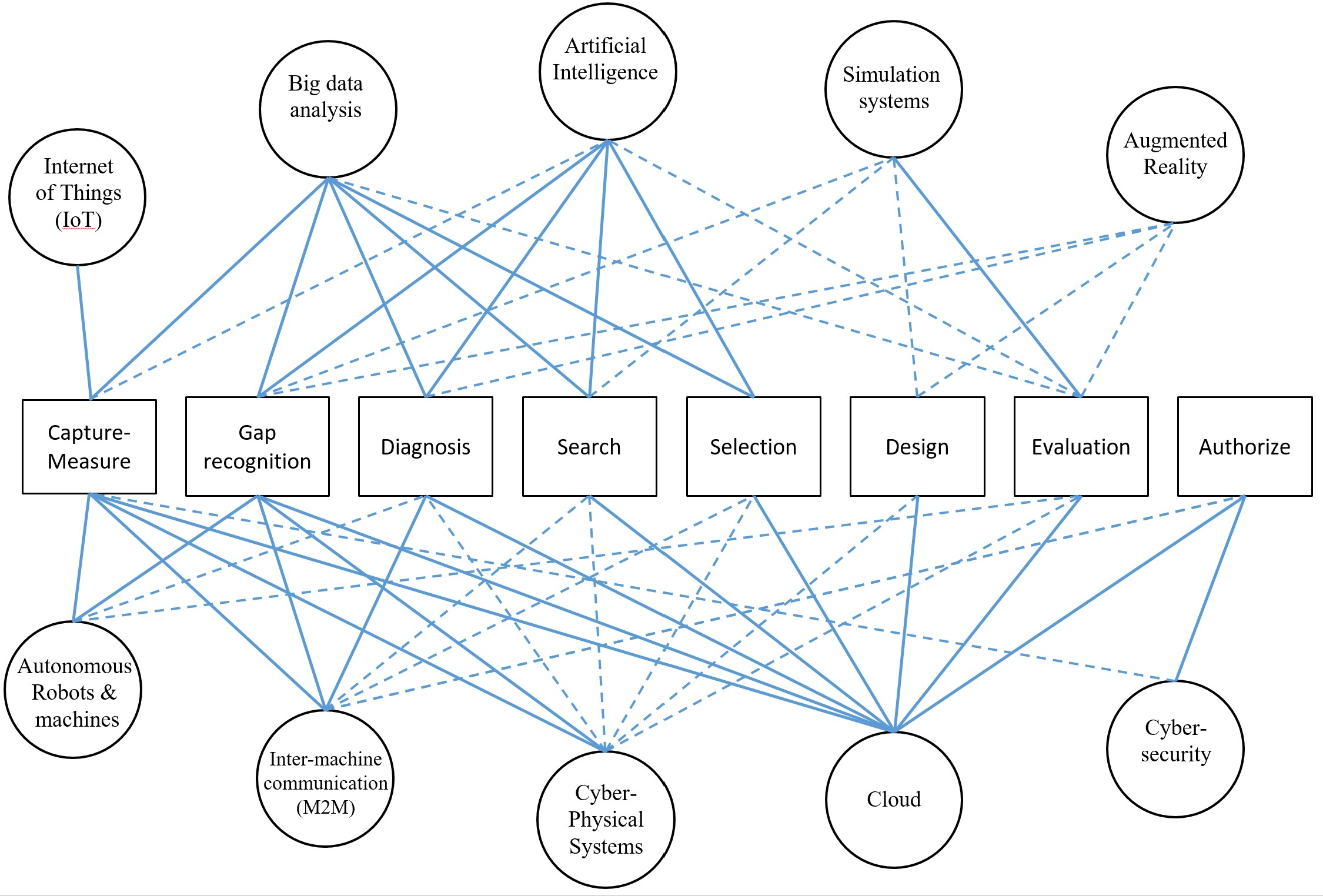

2.4.1. Contribution of Industry 4.0 Technologies to Enhance the Decision-Making Process

The experts stated that the Cloud contributes to the evolution and/or enhancement of all steps of the decision-making process by promoting the pooling and sharing of information and collaboration logic (R1-I27).

The experts’ opinions seem to indicate that among the nine remaining technological groups (

Figure 3), big data analysis and artificial intelligence are the technologies likely to significantly evolve or enhance the largest number of steps of the decision-making process (R1-I21 and R1-I22). According to the results, these two technologies can help to enhance similar steps in the decision-making process, except the “Capture/measure” step. The experts believe that these are particularly promising technologies to enhance:

-

The first steps of “Recognition of a problem or opportunity” and “Diagnosis” of the decision-making process; and

-

The “Search for solutions” and “Selection” steps specific to situations for which solutions are already known.

On the other hand, dissensus remains concerning the enhancement of the “Evaluation” step by these two technologies.

The experts mostly agree that inter-machine communication (M2M) is likely to mainly enhance the first three steps “Capture/measure”, “Recognition of a problem or opportunity”, and “Diagnosis” (R1-I30 and R2-I26).

The experts prioritize the use of cyber-physical systems to enhance the first steps “Capture/measure” and “Recognition of a problem or opportunity” (R2-I24). However, several experts believe it has become an “umbrella term” and a concept perceived as very vague. They specify that these systems result from the amalgamation of several technologies and that they generally integrate themselves into other systems (R1-I28 and R2-I24). Their direct contribution relates more naturally to enhancing the first steps of the decision-making process. Still, they can indirectly contribute to enhancing all the steps of the decision-making process (R2-I24).

The experts’ answers indicate that autonomous robots/machines mainly offer opportunities for enhancement of the first two steps of the decision-making process, “Capture/measure” and “Recognition of a problem or opportunity” (R2-I25). The majority of experts agree that they will contribute little to the direct enhancement of the last six steps of the decision-making process and remain mainly actuators capable of capturing data and communicating with other systems (R1-I29 and R2-I25).

Although often mentioned by experts, “augmented reality” appears to be one of the technologies most suitable for dissensus (R1-I25). Expert opinions seem to indicate that this technology group is not conducive to evolving or enhancing the “Capture/measure”, “Search for already known solutions”, “Selection”, and “Authorization” steps. The experts remain undecided or divided as to the relevance of this technological group to enhance the steps “Recognition of a problem or an opportunity”, “Diagnosis”, “Design”, and “Evaluation”.

In an extremely consensual way, experts believe that the IoT is reserved for enhancing the “Capture/measure” step but does not relate directly to the other steps of the decision-making process (R1-I23).

The experts indicate that simulation systems mainly contribute to enhancing the “Evaluation” step of the decision-making process to assess solutions’ relevance and choose a solution that can be judiciously implemented. However, simulation seems relevant to enhancing the “Design” step, allowing the modelling of several innovative solutions before selecting the most promising one (R1-I24). The same applies to the “Selection” step, but the experts have reservations about the interest of enhancing this step in the short term.

Regarding the enhancement of the different steps by technologies related to “Cybersecurity”, the opinions of experts are quite divided (R1-I26, R2-I22, and R2-I23):

2.4.2. Enhancement of the Steps of the Decision-Making Process

The vast majority of experts agree to highlight the complementarity of IoT and big data analysis to enhance the “Capture/measure” step (R2-I12). The IoT appears as the preferred technology to “capture” real-time data coming back from the field (R1-I23) even if it can be helped in this by cyber-physical systems, inter-machine communication (M2M), and data from autonomous robots/machines (R2-I24 to R2-I26). Several experts specify that the analysis of big data not only contributes to a simple “measurement” of indicators reflecting the state and performance of the production system, but also allows the identification of links between the variables measured and a predictive approach (R2-I12). The experts point out that big data analysis often works in tandem with artificial intelligence, although some experts believe that the latter intervenes rather than strengthens the next steps of the decision-making process (R2-I13).

At the level of the “Recognition of a problem or an opportunity” step, half of the experts agree that the use of augmented reality is mainly considered to alert an operator to a critical situation to which he does not have direct access or that he may not spot (R2-I15). They explain that augmented reality can be used to reveal problems or opportunities by:

At the “Diagnostic” step:

-

A large majority of experts agree that the use of simulation is mainly considered to evaluate the possible consequences of a problem on a future state of the operational system or to estimate the potential offered by an opportunity (R2-I16); and

-

The majority of experts believe that augmented reality must be coupled with simulation to facilitate the visualization and understanding of the current or future state of the operational system. However, some point out that augmented reality involves great efforts in terms of development and that simulation alone is often sufficient (R2-I17).

The experts explain that cloud computing, big data analysis, and/or artificial intelligence offer interesting opportunities to enhance the “Search for already known solutions” step. However, some experts explain that many managers say they are interested in this possibility of enhancement but do not make it a priority today (R1-I16), in particular for the following reasons:

-

The volume of data and the capitalization of knowledge are still too low and/or poorly organized, especially regarding the root causes of each known problem and the solutions that can be brought to it. In this sense, this justifies the prioritization given to the enhancement of the first three steps of the decision-making process (R1-I16);

A number of them believe that these technologies must make all the steps of the decision-making process more reliable and not just one or a few particular steps. They insist that if the slightest link is corrupted, the entire decision-making chain is corrupted (R2-I22 and R2-I23). These experts believe that “Cybersecurity” necessarily accompanies any step in which data is generated, exchanged, transformed, interpreted, or stored (R1-I26); and

-

Others believe that it is advisable to act as a priority at the beginning of the process on capture/measurement so as not to work from corrupted data. Reference is often made here to the expression “garbage in, garbage out” (R2-I22), which refers in computer science to the concept that erroneous or absurd input data (garbage) produces absurd results. However, one of the experts draws attention to the risk of confusion between cybersecurity and corruption of data entering the decision-making process. It considers that this last point is not in the field of cybersecurity but depends more on the quality and robustness of the steering and management processes.

Other experts are more divided on this point and object that simpler solutions to implement are generally possible and preferable. However, this technology seems promising to enhance this step for training or demonstrations.

-

-

The coupling between artificial intelligence and simulation is not systematically necessary; simulation systems can be operated without AI (R2-I20). However, this remains the most widely promoted coupling by the panel of experts (R2-I19 to R2-I21);

Many managers do not believe in the exploitation of technologies such as artificial intelligence to process this data (R1-I16). Yet some experts explain that the use of techniques such as neural networks or case-based reasoning, fuzzy logic, or a combination of these techniques to sort or identify similarities between a priori unrelated situations can already prove useful even if the number of known solutions is relatively small (R2-I3); and

-

When there are several known solutions (even in very limited numbers), the reflex is usually to choose the one that has worked best in the past without resorting to a detailed analysis aimed at comparing the different situations and choosing the best solution taking into account the specificities of each situation. This is generally justified by the limited time available to carry out this analysis (R2-I3).

The coupling of cloud computing, big data analysis, and artificial intelligence seem to offer interesting enhancement opportunities for the “Selection” step. However, the experts’ comments indicate that the situations encountered at the operational level within companies are currently not likely to be able to establish a link with a large number of solutions already known (R1-I18). Therefore, the “Selection” step of the decision-making process seems today to be reserved for decisions at a more tactical or strategic level. Many experts believe that this will change later when the integration of Industry 4.0 will be more effective.

The majority of experts consider that the two most promising technologies to evolve or enhance the “Design” step are simulation and augmented reality (R2-I18). Many experts who agree with this statement point out in their comments that priority should generally be given to simulation to explore new scenarios and solutions and then test them in a pilot, possibly using augmented reality and, more precisely, virtual or mixed reality. It should be noted that some experts believe that the role that AI could play in enhancing this step is underestimated.

At the level of the “Evaluation” step, the analysis of the opinions formulated by the experts makes it possible to identify the following points:

-

The coupling between big data analysis and simulation is not systematically necessary, mainly because the implementation of simulation systems does not always require the use of a very large amount of data (R2-I19);

-

Even more markedly, the coupling between augmented reality and simulation does not appear to be systematically necessary (R2-I21);

-

In some cases, augmented reality can complement simulation systems to facilitate the visualization of the consequences and results of the scenarios and solutions envisaged. However, a large number of experts believe that priority should generally be given to simulation in order to test a solution envisaged (R2-I21);

-

Artificial intelligence can be used, for example, to detect different patterns in datasets and thus highlight relationships or impacts between solutions and problems without going through simulation (R2-I20); and

-

Finally, an expert insists that coupling with other technologies can usefully contribute to the enhancement of this “Evaluation” step and, in particular, augmented reality (R2-I19 and R2-I20).

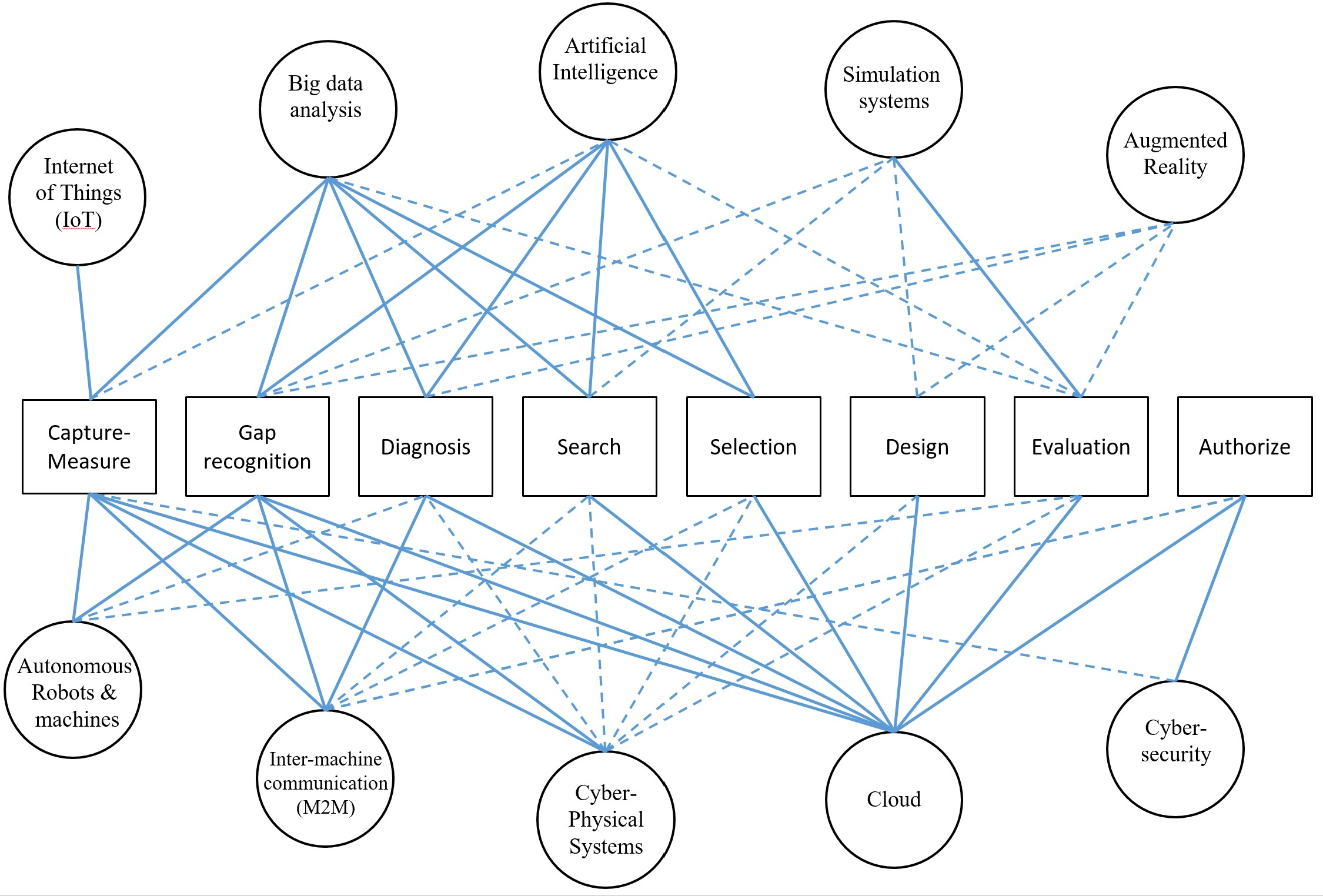

3. Main Results

This research work highlights the technology groups that are most conducive to enhancing each step of the decision process. Figure 4 summarizes the contributions of Industry 4.0 technologies to decision-process enhancement that are in consensus (cf. solid line link on Figure 4) and the contributions that are under debate (cf. dashed links on Figure 4). The latter needs to be clarified in the future as the level of integration of Industry 4.0 principles increases within companies and as the capabilities offered by Industry 4.0 technologies evolve or become more precise.

Figure 4. Contributions of Industry 4.0 technologies to decision-process enhancement that are in consensus or under debate.

The synthesis of the expert comments highlights that a technology group alone can rarely contribute to enhancing a decision step. On the other hand, a given group of technologies may be useful in enhancing one or more steps of the decision process for a given type of a decision but be inappropriate in another case. The complexity of the problem, the nature of the data needed to identify and analyze the situation, the number of known solutions and their characterizations, the evaluation of the implementation of a solution, and the decision-making circuit leading to the implementation of the chosen solution can be very different from one type of decision to another and from one company to another.

Therefore, it seems difficult to identify combinations of technology groups that would be systematically relevant and generalizable to enhance all or part of the decision process for any type of decision and industrial context.

However, some remarkable points concerning each technology group emerge from the study. Cloud computing occupies a special place by potentially contributing to enhancing all decision-making process steps. This technology appears to act as the backbone to any system of global enhancement of the decision-making process. Conversely, the IoT offers potential for enhancement solely focused on the “Capture/measure” step. However, it appears to be an essential and decisive technology for enhancing this step. The autonomous robots/machines and inter-machine communication technologies groups have a marked potential for enhancing the early steps of the decision-making process. Still, their contribution seems much less interesting beyond the “Diagnosis” step. The contribution of cyber-physical systems seems particularly interesting for enhancing the first steps of the decision-making process. Still, this technological group also seems to be able to contribute indirectly to enhancing all the steps of the decision-making process. Simulation systems offer the potential for enhancements focused primarily on the “Evaluation” step. In the long term, this technological group could also play a more marked role in selecting known solutions, designing tailor-made solutions, or even at the “Diagnosis” step. Big data analysis and artificial intelligence are two technological groups whose contributions appear to be closely linked. Their role seems particularly promising in enhancing the first three steps of the decision-making process and searching for and selecting known solutions. They also seem to play an interesting role in the long term to enhance the “Evaluation” step. Their interest seems less obvious today in the case of tailor-made solutions, but this could evolve in the long term depending on future progress in the development of these technologies and the level of integration of the principles of Industry 4.0 within companies. The contribution of augmented reality is less generalizable and seems to be reserved for specific application cases, especially in addition to other technologies for the enhancement of the steps “Recognition of a problem or an opportunity”, “Diagnosis”, “Design”, and “Evaluation”. While the potential for cybersecurity to enhance the last “Authorization” step seems to be established, there is some dissensus on the enhancement of the other steps with two positions displayed:

- Cybersecurity must act primarily at the beginning of the decision-making process on capture/measurement to avoid working with corrupted data; and

- This technology group must make all the steps of the decision-making process reliable because if the slightest link is corrupted, the entire decision-making process is corrupted.

These different points of view call attention to the need to clarify and communicate widely on the exact scope covered by cybersecurity, particularly on the role played by this technological group concerning the corruption of data used in the decision-making process. The same applies to the field covered by cyber-physical systems, which is often perceived as very vague and associated with implementations of very different levels of aggregation.