Non-destructive testing (NDT) is a broad group of testing and analysis techniques used in science and industry to evaluate the properties of a material, structure, or system for characteristic defects and discontinuities without causing damage. Recently, infrared thermography is one of the most promising technologies as it can inspect a large area quickly using a non-contact and non-destructive method. Moreover, thermography testing has proved to be a valuable approach for non-destructive testing and evaluation of structural stability of materials. Pulsed thermography is one of the active thermography technologies that utilizes external energy heating. However, due to the non-uniform heating, lateral heat diffusion, environmental noise, and limited parameters of the thermal imaging system, there are some difficulties in detecting and characterizing defects.

1. Introduction

Non-destructive testing (NDT) is helpful for manufacturing defect-free products, but it is also used for maintenance and condition inspection of industrial structures and facilities

[1]. There are many NDT techniques, each based on different theoretical principles and producing different results concerning the physical properties of an object. The solutions provided through each non-destructive testing technology must be further analyzed to interpret the object’s physical properties or structure. However, this interpretation inevitably involves several assumptions

[2][3][4][2,3,4].

Infrared thermography (IRT), also known as thermal imaging, is a rapidly developing field in science and industry due to the tremendous advances made over the past few decades in microsystem technology in the design of infrared detectors consisting of electronics and computer science

[5]. In addition, IRT is an optical measurement technique, evolving rapidly with the development of high spatial resolution and sensitivity detectors and improved computation power. Today, IRT technology is being applied in research and development in various industries

[6][7][6,7], including non-destructive testing, detailed structural condition monitoring, predictive maintenance, manufacturing quality assurance, energy cost reduction, metal and composite material evaluation, gas leak detection, and more. Meanwhile, researchers worldwide are working to develop infrared thermography technology to improve the reliability and ability to detect failures such as defects. Every technique has its own limitations, and no technique can be considered good, effective, or perfect. In this context, there is a growing trend to integrate thermography technology into other conventional NDT technologies to compensate for each other’s limitations. It will result in better inspection capability and the possibility that more information can be acquired in a single test than a particular technique. Furthermore, it can solve the limitations posed by one NDT technique to obtain the intended information and achieve the required inspection efficiencies.

IRT has gained increased recognition in recent years because it has good benefits over its counterparts. The benefits include high-speed contactless functioning, a higher level of safety, and portability with the potential to encompass a large inspection area. IRT is generally divided into two approaches: passive thermography and active thermography. Passive thermography measures thermal variations of a material using an infrared vision device without external thermal sources

[8]. Contrary to passive thermography, active thermography requires an external heat source to stimulate the materials under tests. Commonly, halogen lamps, high-power photographic flash, and laser beams are widely used, and other high-power cinematographic lamps and quartz line IR lamps are used

[9][10][9,10]. In addition, active thermography is subdivided into lock-in thermography (LIT), pulsed thermography (PT), step-heated thermography (SHT), and vibration thermography (VT) according to external heating methods

[11][12][13][11,12,13], and PT and LIT are the most utilized. The pulsed thermography (PT) idea was first proposed by Parker et al.

[14]. However, other researchers integrated this technique into various NDT applications. The concept of a PT system for defect detection consists of applying a very short time and powerful energy pulse to an object and then recording the temperature rise, decay, or both curves in transient mode. The thermal energy propagates under the surface by thermal diffusion. The presence of subsurface defects interrupts the diffusion rate of the energy pulse.

Pulsed thermography is one of the active infrared techniques, which uses an optical device as an external heat source. Among the active thermography techniques described above, it is the easiest to apply and widely used. However, regardless of being one of the most promising techniques for NDT&E of materials, IRT still presents significant challenges due to non-uniform surface heating, lateral heat diffusion, environmental noise, and limited parameters of the thermal imaging device as image acquisition frequency and spatial resolution. In order to improve this problem, various IRT signal processing techniques were developed, such as the Fourier transforms

[15], Principal Component Thermography

[16], Thermography Signal Reconstruction

[17], PCA data fusion

[18], Wavelet transforms

[19], etc., and used to expand IRT. Thus, a profound work review is required, including the principle, developments, strengths and limitations, signal processing, and research trends for thermography NDT with optical excitation sources.

2. Basic Concepts of Optical Thermography NDT

IRT deals with the acquisition and analysis of thermal pattern from a non-contact thermal imaging device based upon the fact that all objects above absolute zero (−273.15 °C) emit infrared energy

[20]. Infrared thermography (IRT) is an emerging NDT technique developed rapidly in recent years with many advantages such as high speed, large area of observation, wide area coverage and non-contact

[2][5][2,5]. IRT is a thermal radiation measurement technique that is used to detect spatial variations in the measured surface temperature pattern. From an experimental approach aspect, infrared thermography techniques are classified into two major categories: passive and active. The passive approach is generally used in the research on materials that are at different temperature compared with the ambient, while in the case of active approach, an external excitation source, such as optical flash lamps, halogen heat lamps, mechanical ultrasonic vibration, or hot and cold air gun is employed with the intention of inducing thermal contrast. In the active approach of the infrared thermographic non-destructive testing and evaluation (NDT&E), pulsed transient thermography and lock-in thermography are the most commonly used approaches.

2.1. Passive Thermography

In passive thermography, no external energy is used to excite thermal gradients on the surface of the structural component under investigation. The features of interest are naturally at a lower or higher temperature than the background. In general, it is a qualitative approach, since the main objective is to pinpoint discontinuities

[21]. This approach operates well in the SWIR range of 3–5 μm and LWIR range of 8–12 μm and has many applications such as process monitoring, condition monitoring, predictive maintenance, medical imaging, building thermal efficiency, forest fire detection, monitoring of road traffic, monitoring of power stations, night vision and surveillance, agriculture, and biology

[2][22][2,22]. Unfortunately, this technique is limited in NDT applications as a sufficient, natural thermal contrast should be present.

2.2. Active or Dynamic Thermography

In active thermography, a certain amount of energy is introduced to the object, which is initially in thermal equilibrium, and thermal contrast is produced to highlight the features of interest. The energy transfer to the object can be pulses or either in a modulated continuous form. A halogen lamp, optical flash lamp, and cold or hot air guns can be used as an energy source.

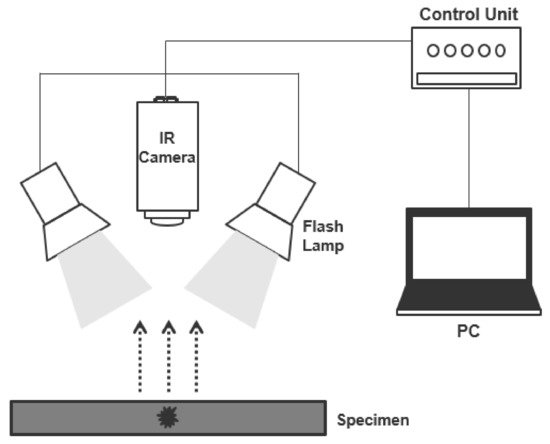

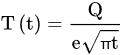

Figure 1 shows the experimental setup of typical active thermography

[23][24][23,24].

Figure 1. General schematic diagram of active thermography testing.

The controlled experimentation condition, such as the amount and form of stimulation, allows not only identification of defect but also quantitative analysis of anomalies

[6][25][6,25]. In NDT application, active thermography can be used to detect the layers structures such as delamination and inserts in the automotive and aerospace industry, investigate the interior structures such as lightweight honeycomb structures, and recognize deeper material deficiencies

[26].

The inspection can be conducted either in transmission or reflection mode. In transmission mode, the heating source and thermal imaging device are positioned on opposite sides of the object being inspected, whereas in reflection mode, both the heating source and the thermal imaging device are positioned on the same side of the object.

The two primary classical or conventional practices are pulsed thermography (PT) and lock-in thermography (LIT). In both techniques, thermal energy is delivered into the object in which the heat propagates by diffusion through the material. Then, the thermal response recorded by the infrared imaging device is observed to reveal the presence of the defect. In PT, a short- and high-power thermal energy is applied to the object’s surface being inspected, and the thermal response of the stimulated surface is observed in a transient state. It is a fast and popular thermal imaging technique in NDT&E, whereas in the LIT, the object’s surface being inspected is stimulated by a periodically modulated thermal wave, and the thermal response of the surface is observed in steady state.

To access the defect information, efficient signal processing and filtering is very important. With the help of adapted image and signal processing algorithms, it is possible to detect small discontinuities inside structures or extract material characteristic information. By reducing the amount of acquired data, the process is accelerated, but a certain decrease in accuracy has to be kept in mind

[27].

Results obtained in active thermography are often damaged by different noise sources such as moisture, external reflections, variations in the specimen’s emissivity, and non-uniform heating. In thermal images, these noise effects create unusual thermal patterns and complicate damage detection. To reduce noise in thermal images, several signal processing techniques have been developed to improve the defect detection and quantification evaluation of each active thermography method.

Table 1 compares representative optics utilized in active thermography methods, including flash lamps used in pulsed thermography for defect detection

[28][29][28,29]. The primary differences between stimulation mechanisms of these devices determine two essential methods of optical infrared thermography

[28]. We can submit a high-energy heat pulse in short (few milliseconds) time intervals using photographic flash. In contrast, halogen lamps provide a lower amount of energy submitted to the object in a relatively longtime frame (few seconds), usually in either continuous or modulated form.

Table 1. Summary of thermal heating devices most commonly used for active thermography for NDT application.

| Thermal Source |

IRT Terminology |

Acronym |

Major Advantages |

Major Limitations |

| Photographic Flashes |

Pulsed

Thermography |

PT |

|

- -

-

Very fast inspection time (few ms)

- -

-

Wide inspection area

- -

-

High power energy

- -

-

Beneficial for flat defects

|

|

|

- -

-

Non-uniform heating

- -

-

Relatively expensive

- -

-

Limited to some field applications

|

|

| Halogen Lamp |

Lock-in

Thermography |

LIT |

|

- -

-

Wide inspection area

- -

-

Beneficial for flat defects

- -

-

Less non-uniform heating and environmental factors Detecting defects located at various depths

|

|

|

- -

-

Considering the optimal modulation frequency according to material properties

- -

-

Long heating time

- -

-

Limited to some field applications

|

|

2.3. Pulsed Thermography (PT)

The concept of a PT system for defect detection consists of applying a very short time and powerful energy pulse to an object and then recording the temperature rise, decay, or both curves in transient mode According to the thermal diffusion effect, pulsed thermal energy incident on the surface propagates under the surface. If a defect exists below the surface, it interferes with the diffusion of the pulse energy

[6].

Consequently, each defect will appear differently from the other defects located at different depths. Dirac pulse is defined as an intense unit-area pulse of such a short duration that no measuring equipment can differentiate it from a shorter pulse. However, in practice, producing an ideal Dirac pulse is not possible

[22].

Pulsed thermography (PT) is among the most prevalent thermographic techniques in TNDT.

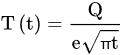

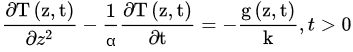

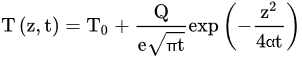

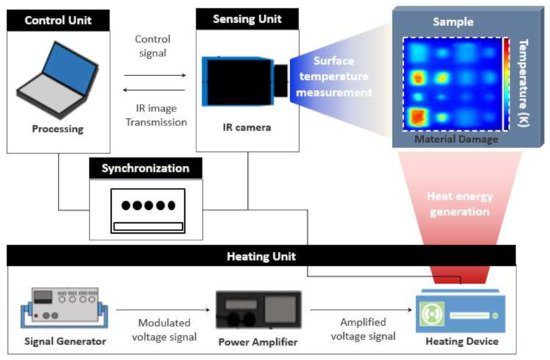

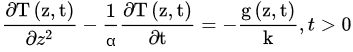

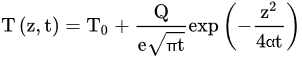

Figure 2 depicts the principle of PT where a high-power pulse heating is employed to the sample under inspection, and the response of the sample is recorded with an infrared camera. The continuance of the pulse depends on the sample’s thermal conductivity under inspection and runs between 2 to 15 ms, making PT well known for its quickness in testing. As soon as the sample becomes excited, the surface absorbs the light energy, and temperature increases instantly. Due to the propagation of thermal waves inside the sample, the surface temperature starts to decay. Imperfections could be seen if there is variance in the thermal decay rate across the sample surface. The transient temperature field T(z,t) of PT can be expressed by an in-homogeneous one-dimensional (1D) Equation (1).

(1)

(2)

where α is the material’s thermal diffusivity with k being the thermal conductivity, ρ is the density, and Cp is the specific heat capacity. The one-dimensional solution of the Fourier’s law for the propagation of a Dirac pulse in a semi-infinite isotropic solid by conduction can be expressed by Equation (3)[6][22][6,22].

(3)

(3)

(4)

(4)

where T is the temperature rise at the time after the flash heating, T0 is the initial temperature, Q is the energy density deposited on the surface, and e is the material’s thermal effusivity to exchange heat with its surrounding.

Figure 2. Configuration of a pulsed thermography inspection system.

At the surface (z = 0 mm), Equation (3) can be rewritten as Equation (5).

(1)

(1) (2)

(2) (3)

(3) (4)

(4)