Infrared (IR) technology is highly energy-efficient, less water-consuming, and environmentally friendly compared to conventional heating. Further, it is also characterized by homogeneity of heating, high heat transfer rate, low heating time, low energy consumption, improved product quality, and food safety. Infrared technology is used in many food manufacturing processes, such as drying, boiling, heating, peeling, polyphenol recovery, freeze-drying, antioxidant recovery, microbiological inhibition, sterilization grains, bread, roasting of food, manufacture of juices, and cooking food.

- infrared

- heating

- microwave

- cooking

- conductive heating

1. Introduction

2. Infrared Radiation

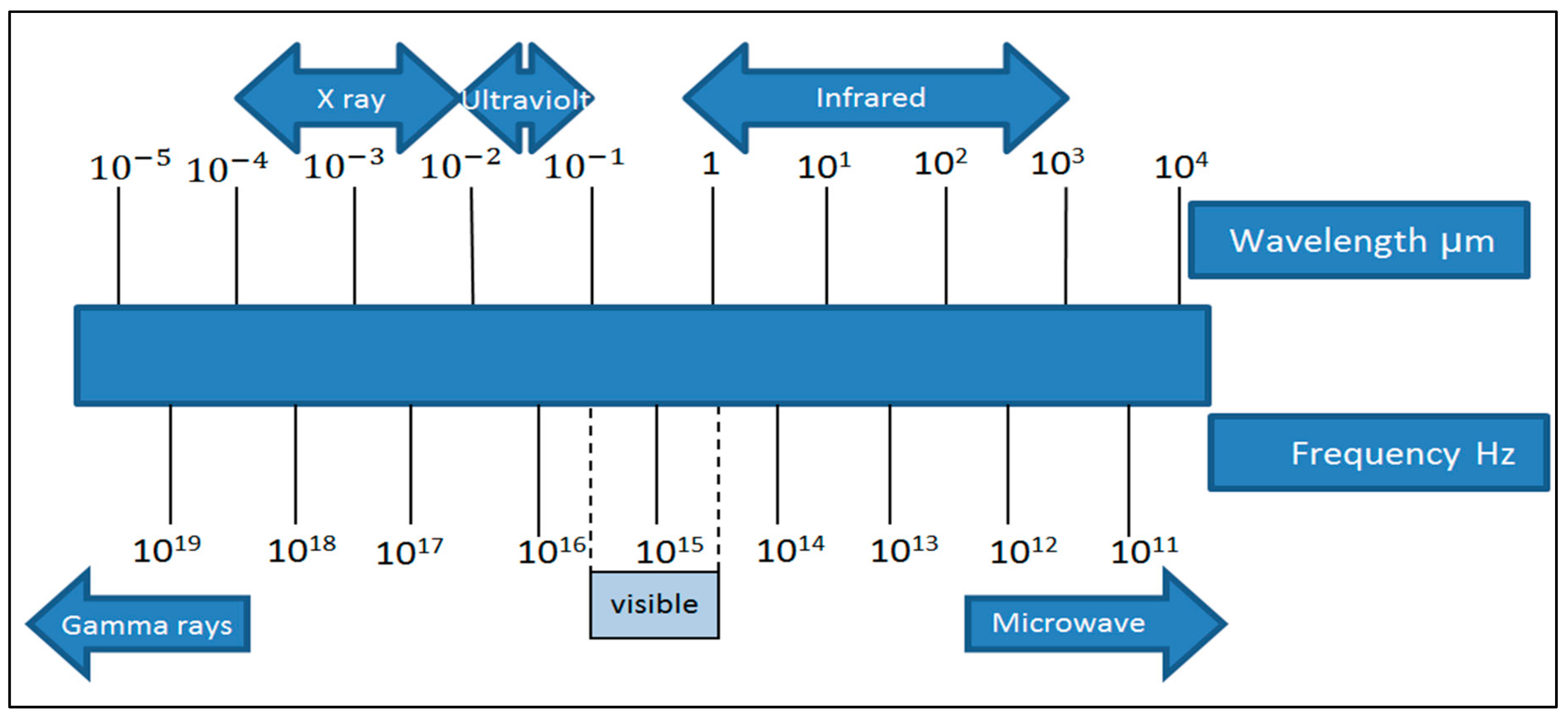

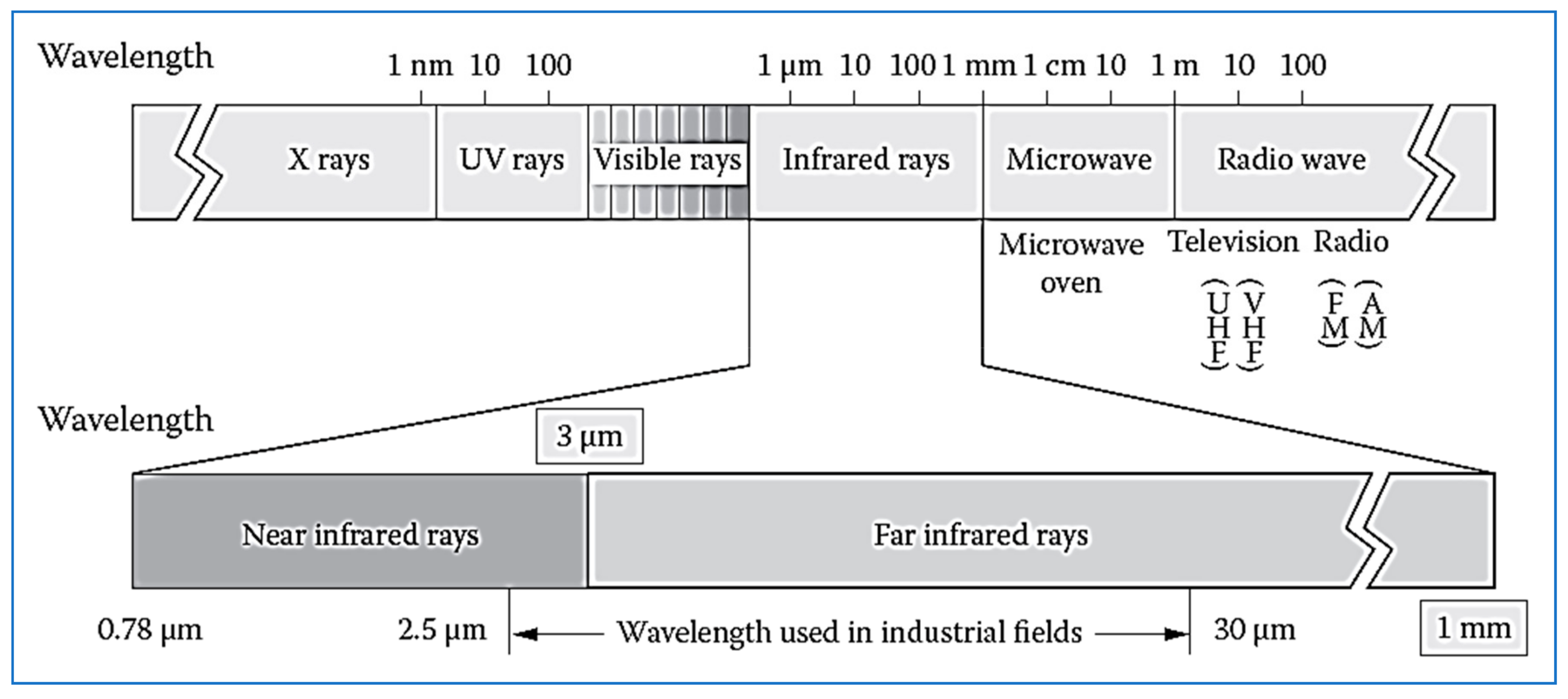

Infrared radiation is part of the electromagnetic spectrum that is located between the visible region and microwaves. Its wavelength ranges from 0.5 to 100 µm. In 1800, Herschel wrote the first scientific report on infrared heating. In his report, it was shown that when the lenses were exposed to the sun, the paper beneath was burned. In the study, a prism was used to separate the light into different colors and a thermometer was subsequently placed in the different colors of the solar energy spectrum. Researchers noticed that there was severe heating in the area beyond the red color, which began at the end of the visible spectrum. The invisible part of the spectrum is called infrared and it is in the wavelength range of 0.76–350 µm [3]. The heat from the sun’s rays is infrared and is part of the electromagnetic radiation [6]. Sixty-six percent of solar radiation is infrared. Figure 1 and Figure 2 illustrate the electromagnetic spectrum of different types of radiation, including infrared.

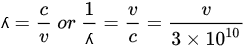

where c is the speed of electromagnetic radiation (cm/s).

The wave number can be calculated from the following equation and its units (1/cm)

where c is the speed of electromagnetic radiation (cm/s).

The wave number can be calculated from the following equation and its units (1/cm)

ΔE can be calculated from the following relationship:

ΔE can be calculated from the following relationship:

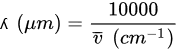

The conversion between wavelength and wavenumber is:

The conversion between wavelength and wavenumber is:

The maximum obtained power at a given wavelength µm and T divided by the unit area (cm2) of the black body is calculated as follows:

The maximum obtained power at a given wavelength µm and T divided by the unit area (cm2) of the black body is calculated as follows:

The Stefan–Boltzmann function shows the relationship between the intensity of the emitted radiation (I) and the absolute temperature (T) of the source as in the following equation:

The Stefan–Boltzmann function shows the relationship between the intensity of the emitted radiation (I) and the absolute temperature (T) of the source as in the following equation:

Infrared radiation is divided into three types [3]:

Infrared radiation is divided into three types [3]:

-

Near-IR (NIR) with wavelength ranging from 0.75 to 1.4 µm.

-

Mid-IR (MIR) with a wavelength between 1.4 and 3 µm.

-

Far-IR radiation (FIR) with wavelength between 3 and 1000 µm.

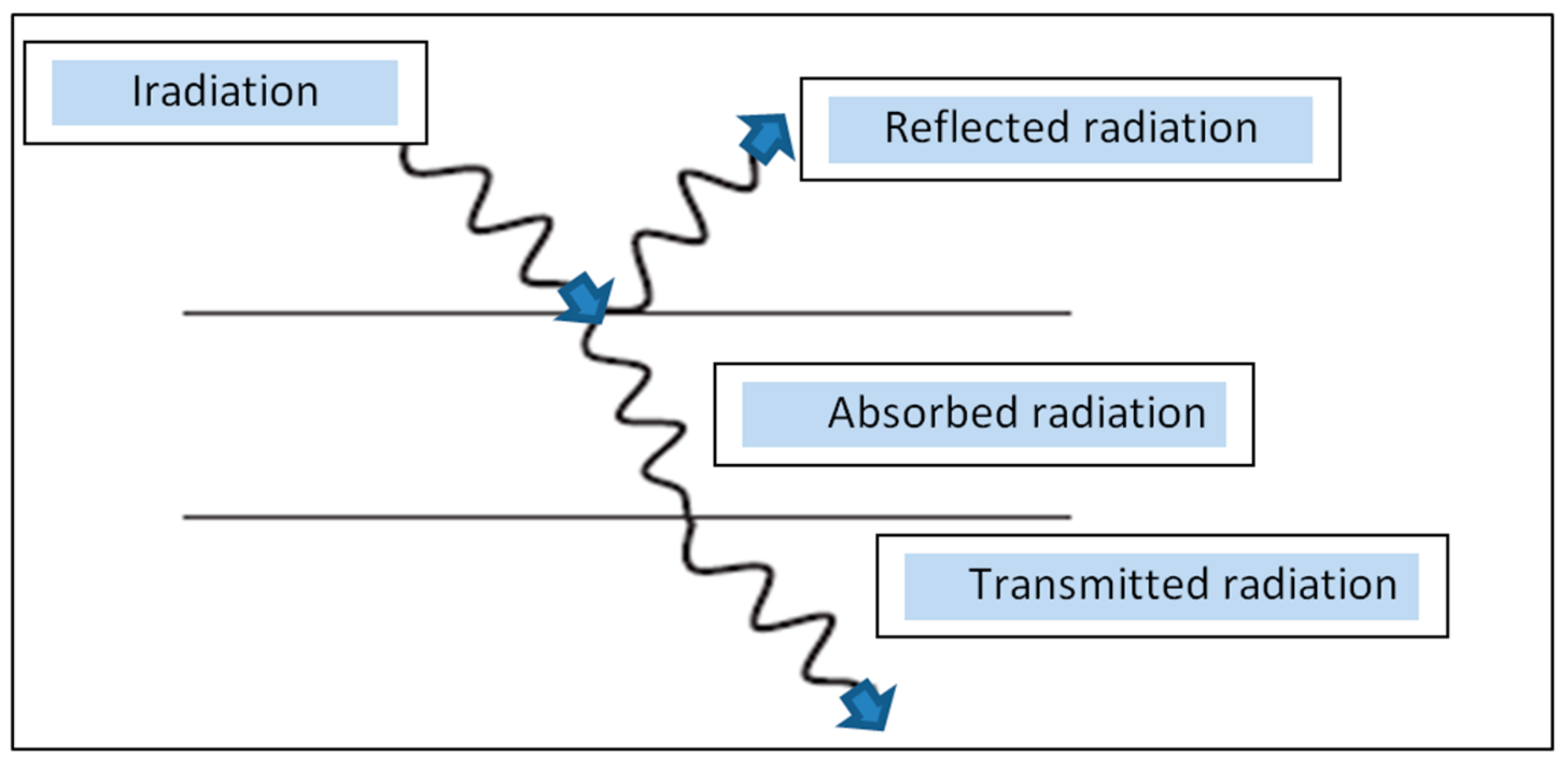

3. Infrared Food Heating Mechanism

|

Relevant Food Component |

Absorption Wavelength (μm) |

Chemical Group |

|---|---|---|

|

Water, sugars |

2.7–3.3 |

Hydroxyl group (O–H) |

|

Lipids, sugars, proteins |

3.25–3.7 |

Aliphatic carbon-hydrogen bond |

|

Lipids |

5.71–5.76 |

Carbonyl group (C=O) (ester) |

|

Proteins |

5.92 |

Carbonyl group (C=O) (amide) |

|

Proteins |

2.83–3.33 |

Nitrogen-hydrogen group (–NH–) |

|

Unsaturated lipids |

4.44–4.76 |

Carbon-carbon double bond (C=O) |

References

- Saravacos, G.; Kostaropoulos, A.E. Handbook of Food Processing Equipment; Springer: Berlin, Germany, 2016.

- Lee, S.C.; Jeong, S.M.; Kim, S.Y.; Park, H.R.; Nam, K.C.; Ahn, D.U. Effect of far-infrared radiation and heat treatment on the antioxidant activity of water extracts from peanut hulls. Food Chem. 2006, 94, 489–493.

- Rosenthal, I. Electromagnetic Radiations in Food Science; Springer-Verlag: Berlin, Germany, 1992.

- Sakai, N.; Hanazawa, T. Applications and advances in far-infrared heating in Japan. Trends Food Sci. Technol. 1994, 5, 357–362.

- Skjöldebrand, C. Infrared heating. In Thermal Technologies in Food Processing; Richardson, P., Ed.; CRC Press: New York, NY, USA, 2001.

- Pan, Z.; Atungulu, G.G. Infrared Heating for Food and Agricultural Processing; CRC Press: New York, NY, USA, 2010.

- Nowak, D.; Lewicki, P.P. Infrared drying of apple slices. Innov. Food Sci. Emerg. Technol. 2004, 5, 353–360.

- Mortensen, A.M. Is Infrared Cooking Healthy? Available online: https://www.livestrong.com/article/497296-is-infrared-cooking-healthy/ (accessed on 10 September 2019).

- Nindo, C.I.; Tang, J. Refractance Window Dehydration Technology: A Novel Contact Drying Method. Dry. Technol. 2007, 25, 37–48.

- Dagerskog, M.; Österström, L. Infrared radiation for food processing I: A study of the fundamental properties of infrared radiation. LWT Food Sci. Technol. 1979, 12, 237–242.

- Afzal, T.M.; Abe, T. Energy and quality aspects of combined FIR convection drying of barley. J. Food Eng. 1999, 42, 177–182.

- Anagnostopoulou, M.A.; Kefalas, P.; Papageorgiou, V.P.; Assimopoulou, A.N.; Boskou, D. Radical scavenging activity of various extracts and fractions of sweet orange peel (Citrus sinensis). Food Chem. 2006, 94, 19–25.

- Sandu, C. Infrared radiative drying in food engineering: A process analysis. Biotechnol. Progr. 1986, 2, 109–119.

- Ratti, C.; Majumdar, A.S. Infrared drying. In Handbook Industrial Drying; Majumdar, A.S., Ed.; Marcel Dekker: New York, NY, USA, 1995; pp. 567–588.

- Kouzeh, K.M.; Roozen, J.P.; Pilnik, W.A. Modified procedure for low temperature infrared radiation of soybeans.II. Inactivation of lipoxygenase and keeping quality of full fat flour. LWT- Food Sci. Technol. 1982, 15, 139–142.

- Rastogi, N.K. Recent Trends and Developments in Infrared Heating in Food Processing. Crit. Rev. Food Sci. Nutr. 2012, 52, 737–760.

- Uysal, N.; Sumnu, G.; Sahin, S. Optimization ofmicrowave infrared roasting of hazelnut. J. Food Eng. 2009, 90, 255–261.

- Aghajanzadeh, S.; Kashaninejad, M.; Ziaiifar, A.M. Effect of infrared heating on degradation kinetics of key lime juice physicochemical properties. Innov. Food Sci. Emerg. Technol. 2016, 38, 139–148.

- Yılmaz, F.; Tuncel, N.Y.; Tuncel, N.B. Stabilization of immature rice grain using infrared radiation. Food Chem. 2018, 253, 269–276.

- Lopes, J.A.; Tsochatzis, E.D.; Robouch, P.; Hoekstra, E. Influence of pre-heating of food contact polypropylene cups on its physical structure and on the migration of additives. Food Packaging Shelf 2019, 20, 100305.

- Ding, C.; Khir, R.; Pan, Z.; Wood, D.F.; Venkitasamy, C.; Tu, K.; El-Mashad, H.; Berrios, J. Influence of infrared drying on storage characteristics of brown rice. Food Chem. 2018, 264, 149–156.

- Cheng, W.; Sørensen, K.M.; Mongi, R.J.; Ndabikunze, B.K.; Chove, B.E.; Sun, D.W.; Engelsen, S.B. A comparative study of mango solar drying methods by visible and near-infrared spectroscopy coupled with ANOVA-simultaneous component analysis (ASCA). LWT Food Sci. Technol. 2019, 112.

- Mohammadi, Z.; Kashaninejad, M.; Ziaiifar, A.M.; Ghorbani, M. Peeling of kiwifruit using infrared heating technology: A feasibility and optimization study. LWT Food Sci. Technol. 2019, 99, 128–137.

- Rajha, H.N.; Mhanna, T.; El Kantar, S.; El Khoury, A.; Louka, N.; Maroun, R.G. Innovative process of polyphenol recovery from pomegranate peels by combining green deep eutectic solvents and a new infrared technology. LWT Food Sci. Technol. 2019, 111, 138–146.

- Wu, X.-F.; Zhang, M.; Bhandari, B. A novel infrared freeze drying (IRFD) technology to lower the energy consumption and keep the quality of Cordyceps militaris. Innov. Food Sci. Emerg. Technol. 2019, 54.

- Raghavi, L.M.; Moses, J.A.; Anandharamakrishnan, C. Refractance window drying of foods: A review. J. Food Eng. 2018, 222, 267–275.

- Bejar, A.K.; Ghanem, N.; Mihoubi, D.; Kechaou, N. Effect of infrared drying on drying kinetics, color, total phenols and water and oil holding capacities of orange (Citrus Sinensis) peel and leaves. Int. J. Food Eng. 2011, 7, 1–25.

- Hamanaka, D.; Uchino, T.; Furuse, N.; Han, W.; Tanaka, S. Effect of the wavelength of infrared heaters on the inactivation of bacterial spores at various water activities. Int. J. Food Microbiol. 2006, 108, 281–285.

- Hamanaka, D.; Uchino, T.; Inoue, A.; Kawasaki, K.; Hori, Y. Development of the rotating type grain sterilizer using infrared radiation heating. J. Fac. Agr. Kyushu U. 2007, 52, 107–110.

- Sato, H.; Hatae, K.; Shimada, A. Studies on radiative heating condition of foods. I. Effect of radiant characteristics of heaters on crust formation and coloring processes of food surfaces. J. Jpn. Soci. Food Sci. Technol. 2012, 39, 784–789.

- Poss, G.T. Roasting Coffee Beans. U.S. Patent 7 235 764 B2, 26 June 2007.

- Vikram, V.; Ramesh, M.; Prapulla, S. Thermal degradation kinetics of nutrients in orange juice heated by electromagnetic and conventional methods. J. Food Eng. 2005, 69, 31–40.

- Sheridan, P.; Shilton, N. Application of far-infrared radiation to cooking of meat products. J. Food Eng. 1999, 41, 203–208.

- Modest, M.F. Radiative Heat Transfer; McGraw-Hill International Edition: New York, NY, USA, 1993.