The potential of H2 as a fuel with the highest energy density per unit mass makes it great for application in all sectors that require energy. H2 is produced from a wide range of resources using different raw materials, pathways, and technologies, including fossil fuels and renewable energy. The classical method consists of breaking or reforming fossil fuels as a profitable H2 production pathway for industrial use, which was estimated (globally) at 85 million tons in 2016 (more than 600 billion Nm3/year). Therefore, the energy value of H2 and the clean energy index were not the main factors to consider in its use at an industrial level. Industrial H2 was used for the production of fertilizers, petrochemical refining, metalworking, food processing, cooling of generators of power plant energy and semiconductor manufacturing.

1. Introduction

The decarbonization of the energy sector requires urgent action on a global scale while a global energy transition is taking place

[1]. Therefore, it is crucial to take more actions to reduce carbon emissions and mitigate the effects of climate change. Based on this, renewable energy and energy efficiency measures can potentially achieve 90% of the required carbon reductions

[2][3][2,3].

One of the global players, the International Renewable Energy Agency (IRENA), has evaluated the decarbonization pathways through REmap

[4]. This plan is to determine the potential of countries, regions and the world to expand renewable energy. In addition, it supports and accelerates the energy transition by providing the necessary knowledge, tools and support to member countries as they increase the share of renewables in their energy sectors.

In the specific case of Chile, during the last decade, the energy system has undergone a profound transformation due to the impact of two factors: the increase in energy demand due to rapid economic growth and changes in climatic conditions. It was reflected during 2020 through the gross electricity generation of the National Electric System (SEN), where approximately 35% was produced from coal plants, which, since the 2000s, have substantially increased their participation in the electricity production of Chile

[5]. In addition, the irruption of Renewable Energy Systems (RES), mainly solar and wind, which began to be exploited in the 2010s, in 2020 represented more than 20% of the total energy generation of the SEN

[6]. Thus, an upward trend that promises to reduce the emission of Greenhouse Gases (GHG) in the energy sector, the emission factor of the SEN was 0.3905 tCO

2eq/MWh for the year 2020.

According to the last available energy balance

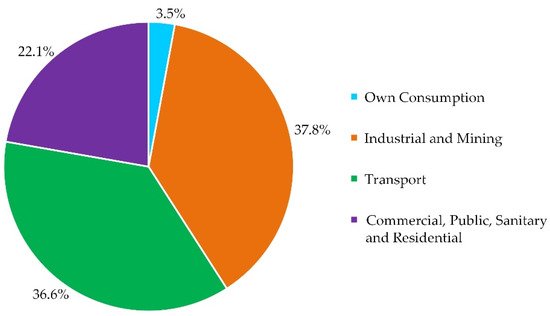

[7], primary and secondary energy carriers consumptions were distributed according to the graph shown in

Figure 1. In this, it was observed that the transportation sector and the industrial and mining sector represent 75% of the total energy consumed in the country. In addition, the transportation sector has large consumptions for ground and maritime transport, representing 85% of all consumption. Meanwhile, in the industry and mining sector, more than 50% of the energy consumed in this sector corresponds to copper and pulp-paper. It should be noted that Chile imports almost all of the energy it consumes, where oil accounts for 98%, coal for 91% and natural gas for 81%. These numbers show that Chile is an energy-dependent country and, during the current COVID-19 pandemic, this was reflected more strongly. Therefore, this has prompted the government and business sector of the country to search for new strategies for development and energy future. At that point, the “National Green Hydrogen Strategy in Chile”

[8] has come to play a fundamental role.

Figure 1. Representation of energy consumption by economic sector in Chile, created from data of the energy balance of 2019

[7].

In this sense, for hydrogen (H

2) development as an energy vector, RES resources play a crucial role in the transition towards a clean and sustainable energy system

[9][10][11][9,10,11]. The main challenge in the transition to 100% RES is a variable and intermittent nature

[12][13][14][12,13,14]. It requires technical adaptation, particularly balancing variable supply and variable demand for energy

[15]. The increased penetration of renewable energies in current energy systems raises the need for large-scale energy storage systems to cope with the variability and intermittency of renewable energy sources

[16][17][16,17].

Based on this, H

2 plays an essential role in the future of the energy system worldwide, constituting a pillar of the path towards energy transformation and the decarbonization objectives

[18]. The conversion of electricity to H

2 represents a viable way to reduce the impacts of so-called renewable electricity in electricity grids

[19]. H

2 allows the integration of renewable electricity in sectors difficult to electrify, such as heat and industry

[20][21][22][20,21,22]. In addition, it provides energy storage capacity, showing competitiveness for other technologies for reliability reasons or large storage volumes

[23][24][23,24]. It is worth mentioning that this H

2 produced from renewable energy sources is called green hydrogen (green H

2)

[25].

To a large extent, the techno-economic viability of green H

2 production depends on the country’s specific resources and the characteristics of the energy market, which play a fundamental role in determining cost competitiveness

[26][27][26,27]. Therefore, the estimation and projection of costs for the green H

2 must be carried out with care to obtain precise values

[28][29][28,29]. Furthermore, the transport route, mode and carrier significantly affect the overall structure of the supply chain and the levelized cost of hydrogen (

LCOH). Each step for the development and future of this technology in the country is highly complex to model

[30][31][30,31], hence the care that must be taken when offering certain costs and energy indicators associated with green H

2 [32][33][32,33].

2. H2 as an Energy Vector

The potential of H

2 as a fuel with the highest energy density per unit mass makes it great for application in all sectors that require energy

[25]. H

2 is produced from a wide range of resources using different raw materials, pathways, and technologies, including fossil fuels and renewable energy

[34][35][36][37][38][61,62,63,64,65]. The classical method consists of breaking or reforming fossil fuels as a profitable H

2 production pathway for industrial use, which was estimated (globally) at 85 million tons in 2016 (more than 600 billion Nm

3/year)

[39][66]. Therefore, the energy value of H

2 and the clean energy index were not the main factors to consider in its use at an industrial level

[40][41][67,68]. Industrial H

2 was used for the production of fertilizers

[42][43][69,70], petrochemical refining

[44][45][71,72], metalworking

[46][73], food processing

[47][48][49][74,75,76], cooling of generators of power plant energy and semiconductor manufacturing

[40][67].

Meanwhile, with increasing attention to reducing GHG emissions, renewable energy resources are rapidly beginning to gain potential as a clean source to produce green H

2 as a carbon-free energy vector

[42][69]. Green H

2 creates the link between RES resources and the modernization of energy supply, transport, industry, and renewable energy export

[44][50][71,77]. Moreover, a H

2-based power system is no less resilient than a conventional fossil fuel-based system, as H

2 can be used as a direct fuel (pure H

2 or in a mixture of fuels) or converted into other liquid/gaseous fuels

[51][52][78,79].

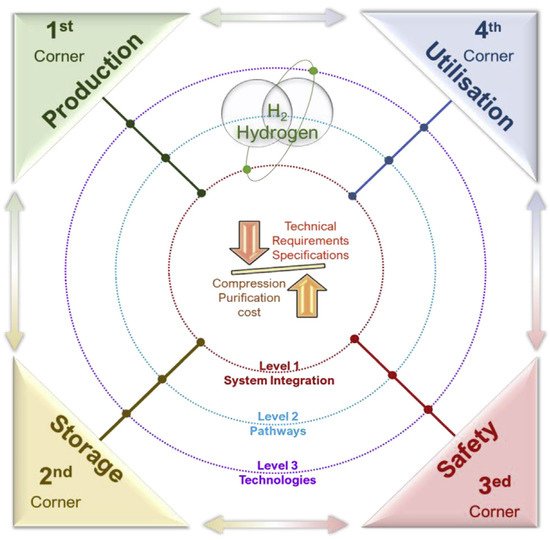

The literature review identified that the H

2-based energy system mainly comprises four main stages, which are interconnected and interdependent

[30][53][54][30,80,81]. These four stages are the production, storage, safety and use of H

2, which is seen graphically in the recently presented study

[25], which proposed a four-corner model, called H

2 Square (HydS), as shown in

Figure 2. The proposed innovative HydS model illustrates the interdependence of each stage on the other stages, and was considered in any selection of a pathway or value chain for green H

2.

Figure 2. Four-stage model for green H

2. Reproduced with permission from

[25], International Journal of Hydrogen Energy, published by Elsevier, 2020.

Considering the above, green H

2 can play a fundamental role in port operations, not only because of its potential to reduce GHG emissions. Studies in Japan, the United States and Germany

[55][56][57][48,82,83] have shown that the adoption of H

2 eliminates the need to designate a significant interior space for battery charging and storage rooms, which allows efficient use of space, higher performance and higher productivity. Similarly, H

2 fuel cells have been observed to supply constant voltage until the fuel tanks are depleted. It means that fuel cell-driven devices do not experience performance degradation during the shift under normal operating conditions, operate at full speed, and reduce wear on some parts and pieces.