Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Jessie Wu and Version 1 by Antonio Bevilacqua.

A low value fish is a product which addresses one or more points of the following:

a) a fish discarded because of unwanted traits (weight, dimension etc...)

b) an accidental catch

c) a species of moderate value.

There are several possibilities to valorize low-value fish material and this entry offers an overview of the most useful ways.

- Low-Value Fish

- food waste

1. Background

Fish is a perishable raw material and, more than other matrices, generally experiences the challenges of food waste and food loss (up to 40% as physical loss in some middle-low income countries), although this is a paradox because the consumption of fish is below the recommended levels worldwide [3][1]. FAO estimated that of the 178.5 million tons (MT) of seafood, mainly (at least 88%) intended for human use, of the total amount of seafood, 96.4 MT were from fish capture (mainly anchoveta, Alaska pollock, skipjack tuna, herring, and blue whiting) and 67.1 MT from farmed species (shrimp, prawns, salmon, molluscs, tilapia, catfish, sea bass, and sea bream) [4,5][2][3]. The projection for fishery development predicts a further increase up to 200 MT in ten years, while the amount of sustainable fishery is significantly decreasing (ca. 66% in 2017 versus 90% in 1990) [4][2].

An important initiative is Food Lost and Waste in Fish Value Chains [6][4]. It is an important tool because it focuses on both scenarios (causes and economic value) and on solutions (both from the side of consumers and producers).

A global challenge requires holistic and global solutions, as this threat was studied in the past from different point of views (biorefinery, designing new foods, and aquaculture feeding).

2. Low Value Fish or Unwanted Catches: Criteria and Idea to Design New Products

Apart from food waste and loss and the possible utilization of by-products, as described in the previous sections, there are two challenges in fishery that require appropriate decisions and solutions from stakeholders, policy makers, and consumers: bycatch/unwanted catches and low value fish species.

Although different, these challenges could have common solutions, as briefly reported in this section. In 2013, the European Commission introduced the Landing Obligation (LO) or “discard ban,” which stated that all catches of species subject to catch quotas and/or minimum conservation reference size (MCRS) must be landed and will be counted against the quota [45][5]. Although this measure has been implemented, there is still a significant quota of unwanted catches or by-products, which requires alternative solutions. Connected to this threat, there is a need for decisions to made with respect to low-value fish.

The category of low-value fish is complex and is composed of at least three different groups of products/species [46][6]: (i) catches discarded for their morphological characteristics (low body growth and edible part not attractive for consumers); (ii) accidental catches, which are generally refused for consumer habits and ancient tradition; and (iii) fishes of moderate value in which its sale could be not profitable.

The University of Wageningen has developed an online dossier to address the challenge of discards and unwanted catches with regulatory framework, definition, new research topics, and possible solutions [47][7]. This dossier is currently updated and improved with the most recent advances in research and technological transfer.

The Waste Framework Directive of EU in 2008 established a hierarchy of solutions, also shared by the US Environmental Protection Agency [45][5]. The most important solutions in this list include prevention and reduction and then use of loss/waste for new products intended for human consumption.

This second choice is very important in fishery, considering that fish proteins generally covers 17% of protein intake [48][8], and there is an increasing demand of fish due to healthy, social, and economic reasons.

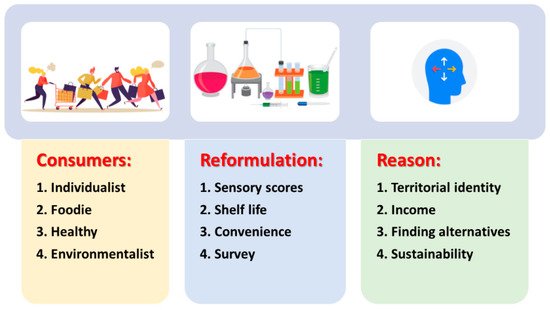

When designing new food, the first challenge is to point out the target: the consumers for which the product is intended to. In the field of fishery, Silva et al. [49][9] and Corallo et al. [50][10] reported four possible targets of consumers: (a) Individualist—food trends depend on personal reason (mainly economic considerations, habits, and mood); (b) Foodie—food choice relies upon sensory and organoleptic properties (flavour, texture, general appearance, freshness, etc.); (c) Health enthusiast—food choices depending on label, claims, and nutritional or functional properties; (d) Environmentalist—food choices based on sustainability.

The use of discards and low-value fish could catch the attention of environmentalist consumers, but if some factors/variables are stressed in a good manner (for example, by using interesting technological formulations or by pointing out positive health effects), foodie and health consumers could be caught too.

The second challenge is the technological goal; for the purpose of low-value fish and by-products/discards, a possible goal could be referred to as reformulation [49][9] because raw materials generally require some approaches intended to improve sensory scores, to prolong the shelf life through preserving treatments, and to increase the economic value by other factors (for example by adding a convenience value). Reformulation is generally the result of a combined action of designers/innovators in the lab and experts in economy and food choices who try to know consumer habits and preferences in order to develop or to reformulate a product able to satisfy their needs [51][11]. This process generally starts with a survey about consumers’ diet and choices and aims to gain knowledge on consumer profiles (gender, age, and occupation) in order to identify a potential target market segment [52][12].

Finally, the last challenge is to elucidate the reason beyond all these processes, as pointing out the reason is a key factor for the promotion of the product and for a correct definition of price, targets, places, and supply chain. Figure 21 shows a graphical overview of the factors to address when designing new food.

Figure 21. The design of new foods from discards or loss in fishery should rely on three main variables: the target (consumers), the technological aim (reformulation), and the reasons beyond the entire process; this scheme can be regarded as the “virtuous cycle” for new product design from low-value or discards of fishery.

This approach or the design of new products from low-value or discards has been tested since the mid 1900s in the categories of processed and ready-to-eat food; for example, fish pulp was the basis to produce surimi or other restructured products or derivatives [52][12].

After the lab phase and the optimization of the formulation, before effective scaling up, there is an economic matrix to fill in, and there are decisions made on the opportunity of industrial validation.

The approach was developed as a deliverable in project H2020 DiscardLess [53][13]; it is based on some criteria and scores, and a summary is provided in Table 31; some products fail because they do not meet the criteria for TRL (technology readiness level), costs (production process has costs that are not compatible with economic valorisation), or availability of facilities.

Table 31. Criteria and scores for the evaluation of economic and technical feasibility of a new product from by-products/discards or low-value fish (modified from Iñarra et al. [45][5]). Each criterion has 4 possible scores (high, medium, low, and null) reported in descending order in the table.

| Macrocategory | Criterion | Scores |

|---|

There are thousands of solutions and possible approaches depending also on the habits and tradition of different countries; hereby, we focus only on some examples that could be regarded as best practices, as reported in Table 42.

Table 42. Examples of new products from low-value or discard fish.

| Product | Species | Process | Product Description | Reference | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Case-dependent study | Available raw materials | High | ||||||||||||||||

| Fermented surimi | Anchovy ( | Engraulis | spp.), roundscad ( | Decapterus | spp.), and other small pelagic and demersal species | Fermentation | Surimi blocks were prepared as mix of the reported fish species and supplemented with 2% glucose, 5% corn starch, and 1% isolated soy protein. The product was fermented by Actinomucor elegans for 36 h. | [54] | [14] | |||||||||

| Medium | ||||||||||||||||||

| Fermentation increased the content of histidine, phenylalanine, and glutamic acid. | Low | |||||||||||||||||

| Surimi | Ungutted myctophid ( | Benthosema pterotum | ) | Mixing and food formulation with other ingredients | Ungutted fish was deboned, minced, and used to give structure to surimi and then mixed with onion, breadcrumbs, wheat flour, skim milk powder, sunflower oil, fresh grated garlic, and salt. | [55] | [15] | Very low | ||||||||||

| The product had lower fish odour and flavour and better sensory scores for texture attributes than silver carp mince. | Available facilities | Many and/or nearby | ||||||||||||||||

| Fish burgers fortified with algae | Common barbel ( | Barbus barbus | ) | Fortification | Fish mince was thawed overnight in the refrigerator and mixed thoroughly with salt (2% W/V), cornstarch (1% W/V), and different concentrations (0.5, 1, and 1.5%) of microalgae powders (Chlorella minutissima, Isochrysis galbana, Picochlorum sp.). | [56] | [16] | Far away | ||||||||||

| The presence of microalgae gave better swelling ability and higher antioxidant levels. | Pilot plant | |||||||||||||||||

| Paste and burgers made form waste or low-value fish | Red porgy ( | Pagrus pagrus | ), Argentine croaker ( | Umbrina | sp.), Atlantic bigeye ( | Priacanthus arenatus | ), Black cusk-eel ( | Conger | sp.), Cusk-eel ( | Genypterus brasiliensis | ), and Blackfin goosefish ( | Lophius gastrophysus | ) | Mixing | Mincing, mixing, and product designing. | [57] | [17] | Experimental |

| Black seabream ceviche, smoked blue jack mackerel pâté, dehydrated piper gurnard, fried boarfish, and comber pastries | Blue jack mackerel ( | Trachurus picturatus | ), black seabream ( | Spondyliosoma cantharus | ), piper gurnard ( | Trigla lyra | ), and two unexploited species (comber, | Serranus cabrilla | and boarfish, | Capros aper | ) | Mixing | Mincing, mixing, and product designing. | [49] | Technical | Yield of the process | High (>50%) | |

| [ | 9 | ] | ||||||||||||||||

| Packed fillet | Sea bass ( | Dicentrarchus labrax | ) | Biopreservation and addition of essential oils | Fillets of sea bass were inoculated with a mixture of lactic acid bacteria (Lactococcus lactis, Lactiplantibacillus plantarum, and Carnobacterium piscicola) and added with citrus essential oil and then vacuum packed. | [58] | [18] | Medium (10–50%) | ||||||||||

| Costs for the production | ||||||||||||||||||

| The product exhibited prolonged shelf-life and ameliorated muscle liquid-holding capacity. | Low (<10%) | |||||||||||||||||

| Thai snacks (Jeep Thai, Shor Moung, and Pun Khlip) | Nile tilapia ( | Oreochromis niloticus | Very low (0.05%) | |||||||||||||||

| ) | Reformulation (substitution of an ingredient) | Addition of tilapia instead of some other ingredients. | [ | Technology readiness level (TRL) | High | |||||||||||||

| Medium | ||||||||||||||||||

| Low | ||||||||||||||||||

| Experimental | ||||||||||||||||||

| Very low | ||||||||||||||||||

| 59 | ] | [ | 19 | ] | ||||||||||||||

| Probiotic fillets | Sea bream of the Adriatic Sea ( | Sparus aurata | ) | Probiotication | Marinated sea bream fillets enriched with | Lactiplantibacillus plantarum | and | Bifidobacterium animalis | subsp. | lactis | , then packed in oil or in a diluted brine. | [60] | [20] | Economic | Product (value) | High | ||

| Medium | ||||||||||||||||||

| Low | ||||||||||||||||||

| Null | ||||||||||||||||||

| Market | Big (international) | |||||||||||||||||

| Medium (national or transnational) | ||||||||||||||||||

| Low (Regional or local) | ||||||||||||||||||

| Low | ||||||||||||||||||

| None | ||||||||||||||||||

| Medium | ||||||||||||||||||

| High | ||||||||||||||||||

| Competitors | None/few | |||||||||||||||||

| Some | ||||||||||||||||||

| Many | ||||||||||||||||||

| Saturated market |

References

- Kruijssen, F.; Tedesco, I.; Ward, A.; Pincus, L.; Love, D.; Thorne-Lyman, A.L. Loss and waste in fish value chains: A review of the evidence from low and middle-income countries. Glob. Food Secur. 2020, 26, 100434.

- FAO. The State of World Fisheries and Aquaculture 2020—Sustainability in Action; FAO: Rome, Italy, 2020.

- Venugopal, V. Valorization of seafood processing discards: Bioconversion and bio-refinery approaches. Front. Sustain. Food Syst. 2021, 5, 611835.

- FAO. Food Loss and Waste in Fish Value Chains. 2021. Available online: http://www.fao.org/flw-in-fish-value-chains/value-chain/en/ (accessed on 4 October 2021).

- Iñarra, B.; Bald, C.; Cebrián, M.; Antelo, L.T.; Franco-Uría, A.; Vázquez, J.A.; Pérez-Martín, R.I.; Zufía, J. What to do with unwanted catches: Valorisation options and selection strategies. In The European Landing Obligation; Uhlmann, S.S., Ulrich, C., Kennelly, S.J., Eds.; Springer: Cham, Switzerland, 2019; pp. 333–362.

- Simeone, M.; Scarpato, D. The low commercial value fish. How can we increase its consumption? Agric. Econ. Rev. 2014, 15, 43–59.

- Wageningen University and Research. Discards-Unwanted catch. Available online: https://www.wur.nl/en/Dossiers/file/Discards-Unwanted-catch.htm (accessed on 4 October 2021).

- FAO. FAO Yearbook. Fishery and Aquaculture Statistics. 2015/FAO annuaire. Statistiques des pêches et de l’aquaculture. 2015/FAO anuario. Estadísticas de pesca y acuicultura. 2015; FAO: Rome, Italy, 2017.

- Silva, F.; Duarte, A.M.; Mendes, S.; Borges, P.; Magalhães, E.; Pinto, F.R.; Barroso, S.; Neves, A.; Sequeira, V.; Vieira, A.R.; et al. Adding Value to Bycatch Fish Species Captured in the Portuguese Coast—Development of New Food Products. Foods 2021, 10, 68.

- Corallo, A.; Latino, M.E.; Menegoli, M.; Spennato, A. A survey to discover current food choice behaviors. Sustainability 2019, 11, 5041.

- Horvat, A.; Granato, G.; Fogliano, V.; Luning, P.A. Understanding consumer data use in new product development and the product life cycle in European food firms—An empirical study. Food Qual. Prefer. 2019, 76, 20–32.

- Silva, F.; Duarte, A.M.; Mendes, S.; Pinto, F.R.; Barroso, S.; Ganhão, R.; Gil, M.M. CATA vs. FCP for a rapid descriptive analysis in sensory characterization of fish. J. Sens. Stud. 2020, 35, e12605.

- DiscardLess. Available online: http://www.discardless.eu/ (accessed on 4 October 2021).

- Zhou, X.-X.; Zhao, D.-D.; Liu, J.-H.; Lu, F.; Ding, Y.-T. Physical, chemical and microbiological characteristics of fermented surimi with Actinomucor elegans. LWT-Food Sci. Technol. 2014, 59, 335–341.

- Shaviklo, A.R.; Rafipour, F. Surimi and surimi seafood from whole ungutted myctophid mince. LWT-Food Sci. Technol. 2013, 54, 463–468.

- Atitallah, A.B.; Barkallah, M.; Hentati, F.; Dammak, M.; Hlim, M.B.; Fendri, I.; Attia, H.; Michaud, P.; Abdelkafi, S. Physicochemical, textural, antioxidant and sensory characteristics of microalgae-fortified canned fish burgers prepared from minced flesh of common barbel (Barbus barbus). Food Biosci. 2019, 30, 100417.

- Ribeiro, D.S.; Calixto, F.A.A.; Guimarães, J.L.B.; Aronovich, M.; Keller, L.A.M.; Mesquita, E.F.M. Fish products made from trawl fishery waste: Physical, chemical, microbiological, and toxicological analysis. Arq. Bras. Med. Vet. Zootec. 2018, 70, 238–246.

- Boulares, M.; Moussa, O.B.; Mankai, M.; Sadok, S.; Hassouna, M. Effects of Lactic Acid Bacteria and Citrus Essential Oil on the Quality of Vacuum-Packed Sea Bass (Dicentrarchus labrax) Fillets During Refrigerated Storage. J. Aquat. Food Prod. Technol. 2018, 27, 698–711.

- Pianjing, P.; Vites, J.; Santijanyabhorn, J. Utilization of Nile Tilapia (Oreochromis niloticus) in development of fish based Thai snacks. Int. Food Res. J. 2016, 23, 2564–2570.

- Speranza, B.; Bevilacqua, A.; Racioppo, A.; Campaniello, D.; Sinigaglia, M.; Corbo, M.R. Marinated sea bream fillets enriched with Lactiplantibacillus plantarum and Bifidobacterium animalis subsp. lactis: Brine optimization and product design. Foods 2021, 10, 661.

More