High pressure processing (HPP) is a novel technology that involves subjecting foods to high hydrostatic pressures of the order of 100–600 MPa. This technology has been proven successful for inactivation of numerous microorganisms, spores and enzymes in foods, leading to increased shelf life. HPP is not limited to cold pasteurization but has many other applications. The focus of this aentrticley is to explore other applications of HPP, such as gelatinization, forced water absorption and infusion of nutrients. The use of high pressure in producing cold gelatinizing effects, imparting unique properties to food and improving food quality has also been discussed, highlighting the latest published studies and the innovative methods adopted.

- high pressure processing (HPP)

- gelatinization

- infusion

- quality improvement

1. Introduction

2. High Pressure Gelatinization

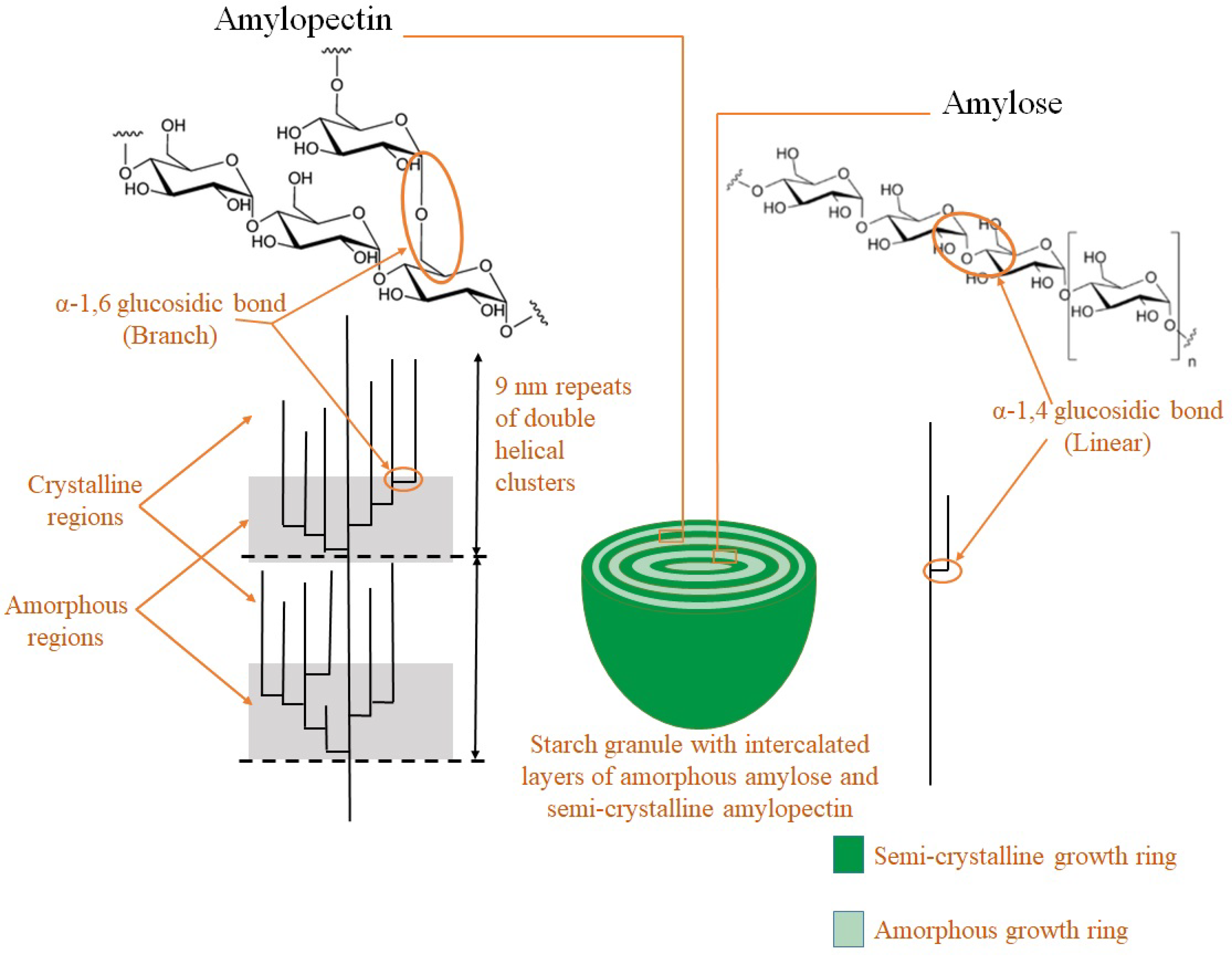

2.1. Starch Gelatinization

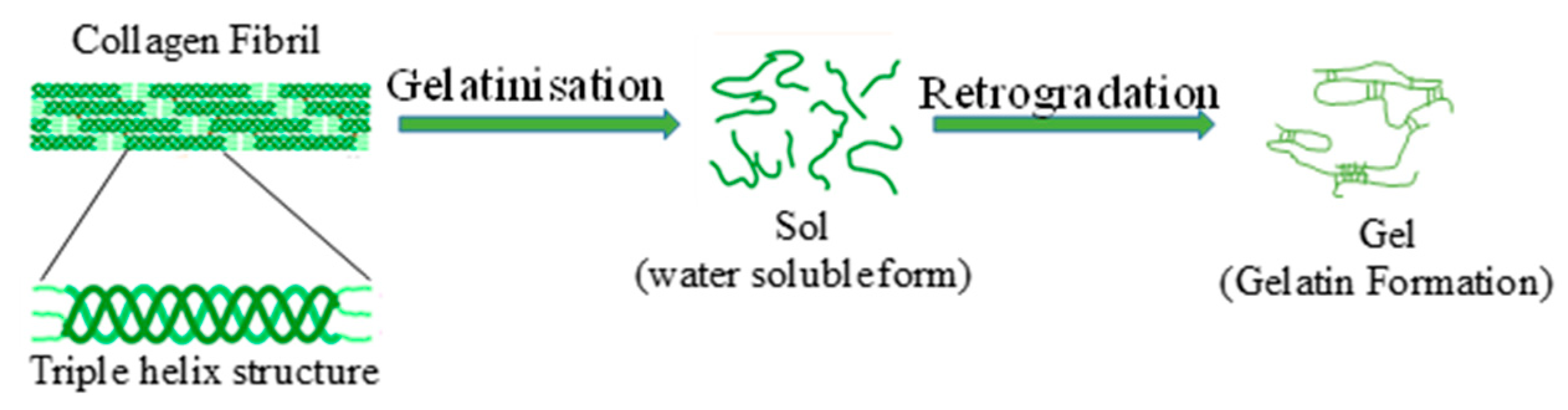

2.2. Gelatinization of Collagen

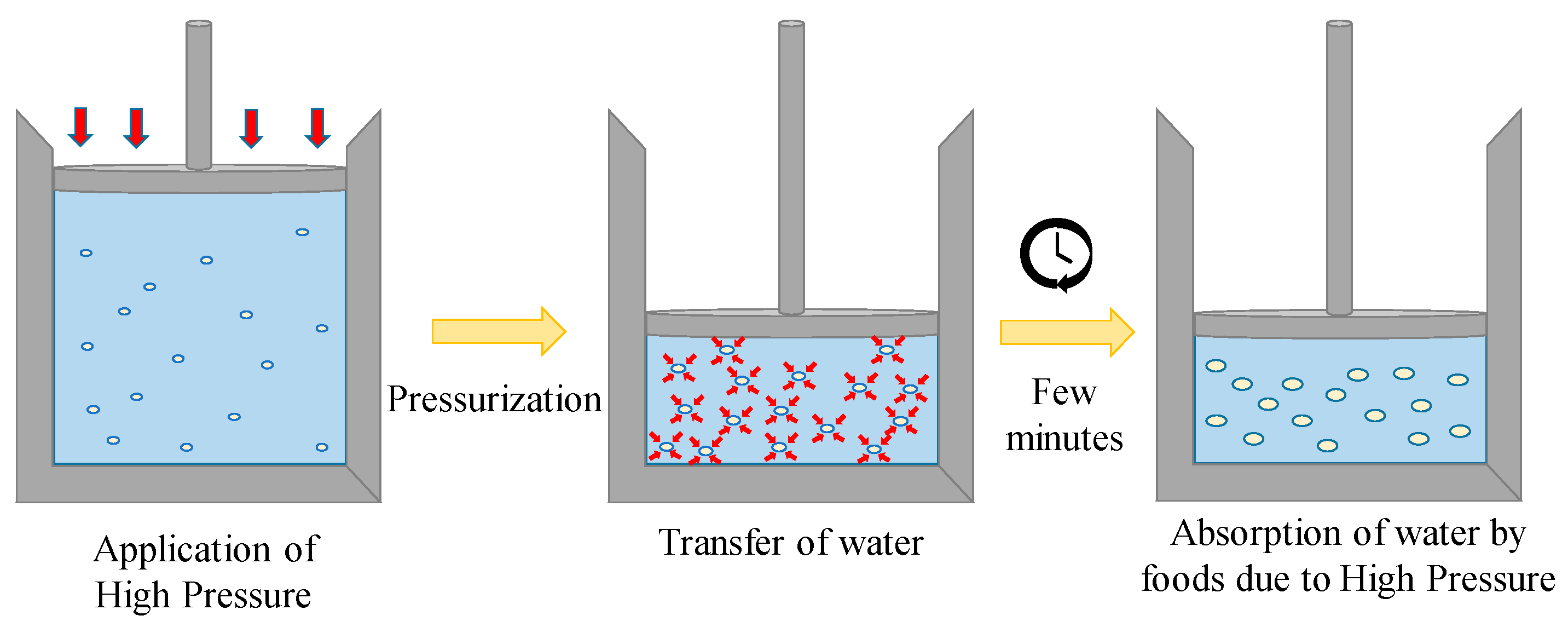

3. Forced Water Absorption in Foods Using HPP

4. Pressure Assisted Infusion in Foods

4.1. Aroma Infusion

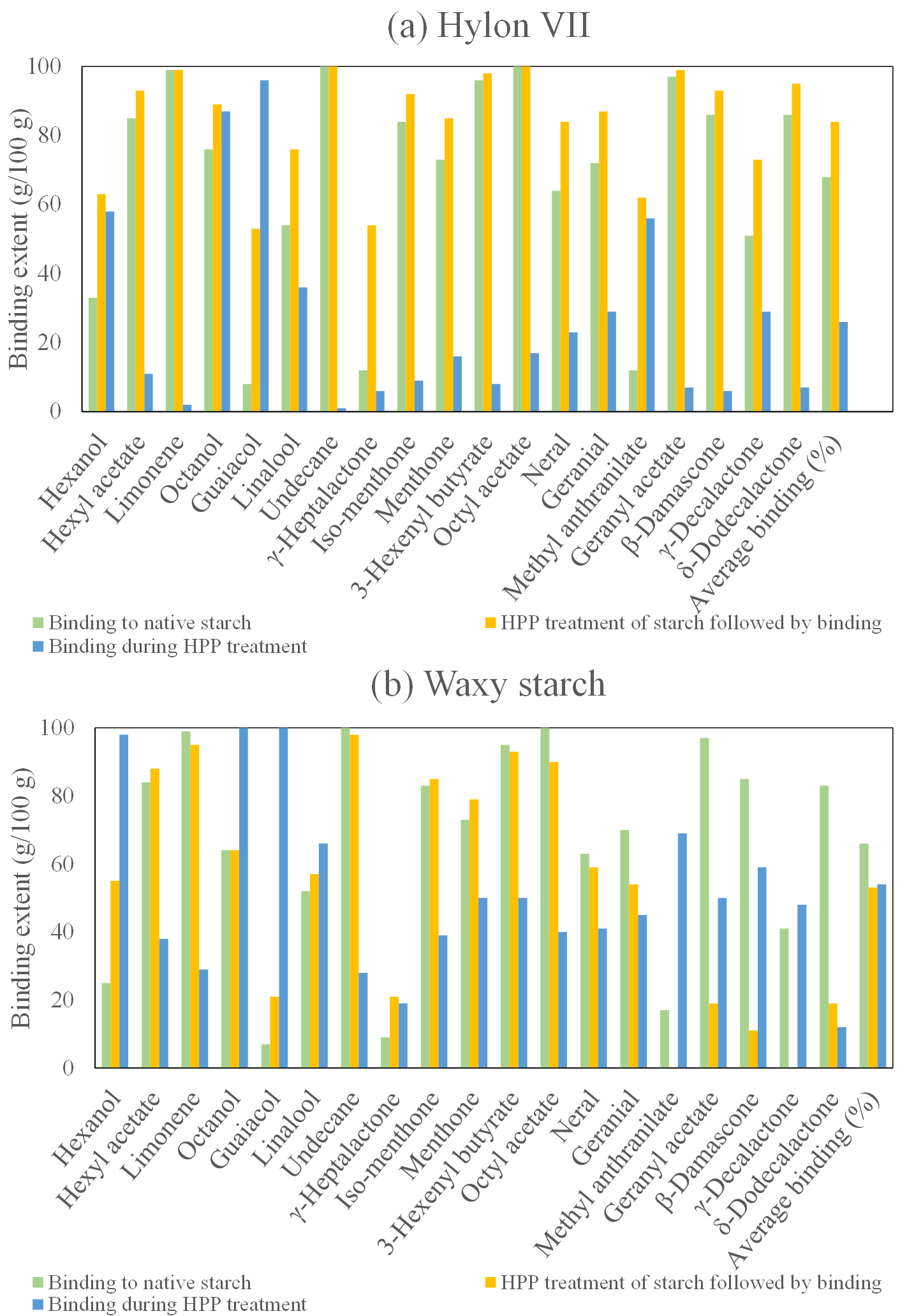

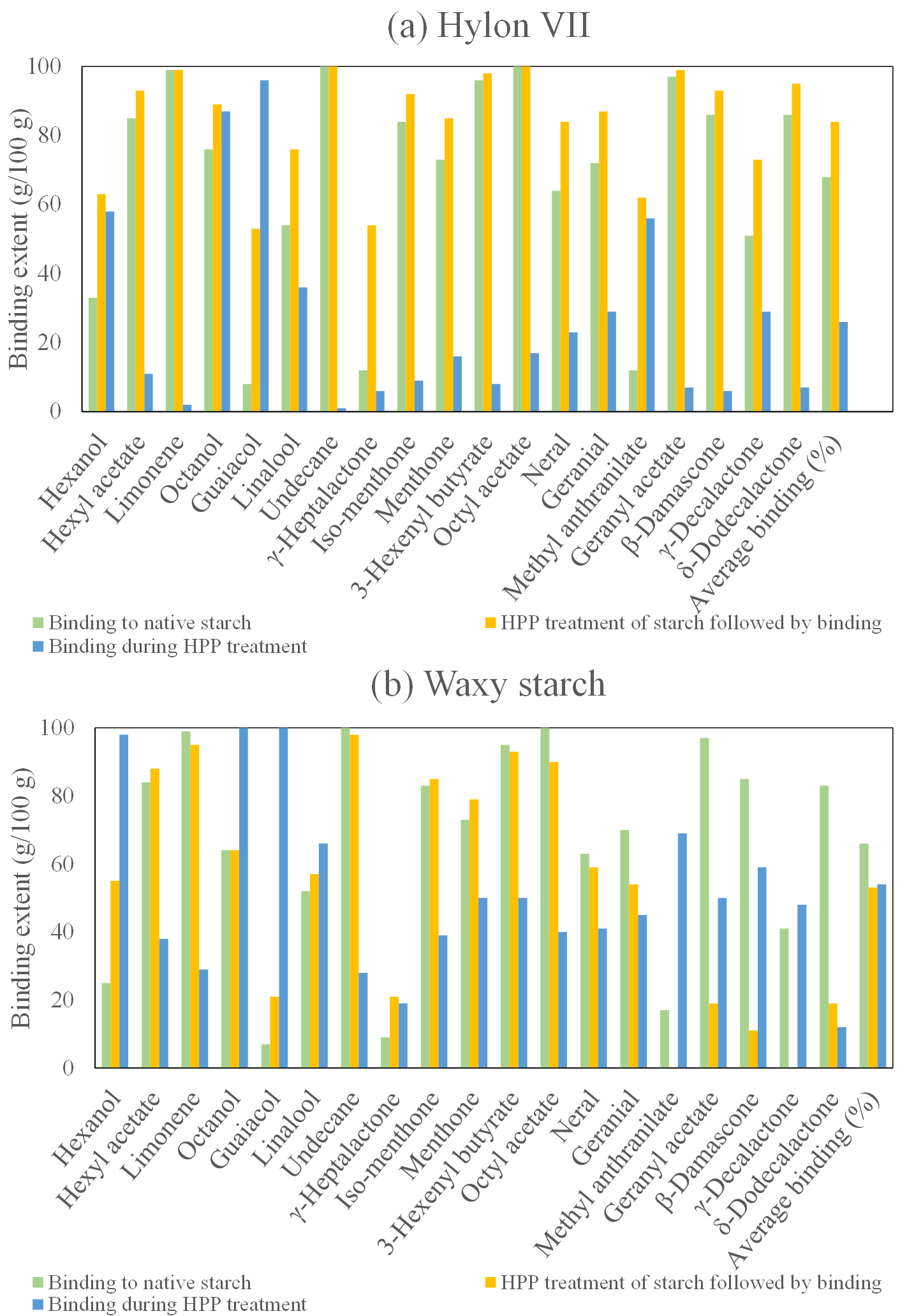

HPP has had some application in binding different aromas to foods. Some common odorants were mixed with maize starch in native form, with HPP treated maize starch and with maize starch during HPP treatment at 650 MPa for 9 min [29]. Different maize starches with varying amylose content were studied for comparison. The binding extent of these different methods was then analyzed. Hylon VII, a high amylose maize starch, showed similar or slightly enhanced binding characteristics after it was treated with HPP (Figure 7a). However, when it was mixed with odorants during HPP, the binding was poorer for most varieties of the odorants excepting hexanol, guaiacol, methyl anthranilate, and octanol. Guaiacol and methyl anthranilate had very poor binding characteristics for native starch. In waxy maize starch with no amylose, there were a few compounds whose sorption reduced in the HPP treated starch. Although the overall average sorption of odorants reduced for both types of HPP treatments, hexanol, guaiacol, methyl anthranilate, and octanol, along with a few more compounds, showed enhanced sorption characteristics during HPP treatment (Figure 7b). The process of HPP also led to gelatinization of starch and was inversely related to the amylose content.

Figure 7. Comparison of binding properties of different odorants to (a) high amylose maize starch (Hylon VII), (b) no amylose maize starch (waxy starch) treated in various ways (plotted using the data from Błaszczak, Misharina, Yuryev, and Fornal, 2007 [30]).

Figure 7. Comparison of binding properties of different odorants to (a) high amylose maize starch (Hylon VII), (b) no amylose maize starch (waxy starch) treated in various ways (plotted using the data from Błaszczak, Misharina, Yuryev, and Fornal, 2007 [30]).4.2. High Pressure Impregnation (HPI)

When any compound is used in the liquid form or in a dissolved form for infusion by pressure into a solid food (generally a solid porous matrix), it has been referred to as high pressure impregnation or HPI. Vatankhah and Ramaswamy [30] used HPI for the impregnation of ascorbic acid in apple cubes. They found the ascorbic acid content in the apple pieces increased with pressure. They also checked the effect of viscosity in HPI by making use of different concentrations of chitosan. The result showed a decrease in the level of mass intake of chitosan with an increase in its concentration. The impregnation of chitosan also increased the pressure stability of the apple, which would otherwise collapse under high pressure due to the presence of small air pockets. Osmotic dehydration (OD) was compared with vacuum impregnation (VI) and high pressure impregnation by adding sucrose and calcium lactate in unripened and ripened mango chunks [31]. All samples after OD, VI or HPI were subjected to further OD for up to 4 h before the examination. The effect of the presence of pectin methylesterase (PME), which is generally used for improving food firmness, was also evaluated. It was found that both VI and HPI led to an increase in the soluble solids gain and lower water loss in comparison to OD alone. HPI, however, had lesser pronounced effects than VI. The presence of PME for all cases led to a slight increase in firmness and work of shear. The soluble solids gain, with or without the presence of PME, increased in the unripened mango but decreased in ripened mangoes. This was because of two reasons; the sturdy cellular structure of unripened mangoes and the lower sugar content in them. When water leaves the fruit tissue, the susceptibility of the tissues structure to collapse in unripened mangoes is much lower than ripened ones. The collapse of tissue structure can lead to physical hindrance of the osmotic solution from entering the fruit. In addition, lower sugar content in unripened mangoes results in a greater concentration gradient with the osmotic solution, thereby promoting a higher soluble solids gain. PME-pretreated baby carrots with HPP treatment with calcium lactate gluconate (CLG) showed that the high pressures increased their calcium content by almost seven times [32]. The HPP-treated baby carrots had calcium contents of more than three times that obtained by soaking at atmospheric pressure or with vacuum infusion techniques. Experiments using Box-Behnken design showed that the pressure level, processing time and CLG concentration are directly related to the increase in the calcium content and hardness of the carrots. The application of cyclic pressures also causes a significant increase in calcium. The follow-up study using SEM imaging showed that HPP caused cell damage in the carrots [33]. The extraction of beta carotene from the carrots increased by three to five times in comparison to the untreated variety. The effects of individual processing variables, i.e., pressure, processing time, CLG concentration and PME pretreatment on the amount of beta carotene extracted were not significant. HPP also led to a mild to moderate darkening of the carrots after infusion.

Another study using HPI was done to impregnate oil into selected fruits through water-based emulsions [34]. Oil and Tween 80, an edible emulsifier, were used in different ratios to form different emulsified oil mixtures. Twenty per cent of these emulsified oil mixtures were homogenized along with 80% water to form the infusate. It was found that the presence of hydrophilic emulsifiers in the solutions facilitated the transport of oil into the inner layers. Without the presence of emulsifiers, oil transfer in fruits was not very efficient. In addition, the higher the concentration of the emulsifier, the lower the transport, whereas higher oil concentration gave higher transfer. This method could prove to be a very efficient method for the fortification of foods with lipid-soluble vitamins, such as vitamin A, vitamin K, etc. in foods [34].

A unique study involving a combination of high pressure gelatinization and high pressure infusion was carried out with paddy rice [35]. Rice loses most of its thiamine, present in the bran and germ layers, during its processing from brown rice to white rice. Parboiled rice, however, has much of the thiamine retained in it. Rice undergoes gelatinization during parboiling and gelatinization facilitates the process of thiamine transfer. Since high pressure environments have shown to cause gelatinization, paddy rice was subjected to pressures of 450 MPa and 600 MPa at the temperatures of 50 °C and 70 °C for 15 min and 30 min. The results showed that HPP caused a higher transfer of thiamine as the pressure and temperature increased. Long processing times, however, led to its degradation. The HPP treated rice maintained the grain dimensions whilst parboiling rendered the rice shorter and broader.

4.3. Flavour Infusion

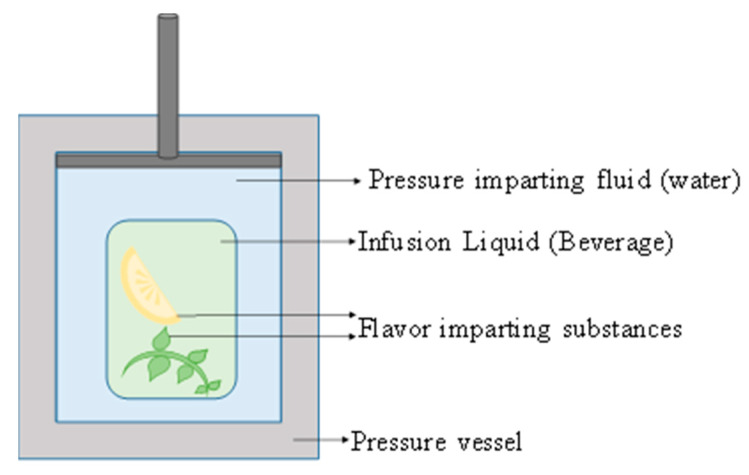

HPP has been used to impart flavours to foods. Villacís, Rastogi, and Balasubramaniam [36] demonstrated the use of HPP for adding salt and moisture to turkey breast while improving its textural properties. Lemus-Mondaca et al. [37] also used HPP to impregnate salt and water into jumbo squid to enhance sensory characteristics. The Weibull model was reported as the best fit for the mass transfer of compounds into the jumbo squid. When the flavour from solid foods like lemon needs to be infused into any drink, the flavour imparting substance must be placed in the target liquid. On the application of high pressure, the flavour components will be transferred to the drink. The brewing of coffee or tea needs to be done at high temperatures. Cold brewed beverages take considerably longer times to reach similar infusion levels. If a pot of hot brewed coffee takes five to ten minutes for preparation, the cold brewed variety can take several hours [38]. Thus, HPP can make the infusion process faster and much more effective. Hence, a design for the infusion of alcoholic beverages with at least 20% alcohol content was carried out with the HPP technology, as shown in (Figure 8) [38]. This technology can be effectively applied in the near future for the enhancement of flavours in the beverage industry.

5. Conclusions

High pressure processing has many unexplored possibilities for food quality improvements. A significant amount of work has been done in the area of high pressure gelatinization but with limited industrial-scale applications. The niche market for high pressure infusions and high pressure impregnations is an upcoming method, leading to a high potential for food quality enhancements. The ability to make use of the three parameters of pressure, temperature and time can be optimized for the design of food products with specific properties. Since HPP also inactivates most pathogens, it can be very useful for the production of final packaged ready-to-consume foods that undergo gelatinization and/or infusion during pressure treatment. The impregnation of vital nutrients such as vitamins, flavours and stabilizers into foods are other beneficial applications of this method. Although aroma binding to foods is an innovative idea for augmenting the sensory attributes of foods, the application of HPP in this field has not been extensively studied yet. The simultaneous quality enrichment, along with microbial inactivation, would be very useful in developing processed foods and making the overall expensive process of HPP viable.

References

- Martínez-Monteagudo S.I., Balasubramaniam V.M. Fundamentals and applications of high-pressure processing technology. In: Balasubramaniam V.M., Barbosa-Cánovas G.V., Lelieveld H.L.M., editors. High Pressure Processing of Food: Principles, Technology and Applications. Springer; New York, NY, USA: 2016. pp. 3–17. [CrossRef] [Google Scholar]

- Fauzi N.A., Farid M.M. High-pressure processing of Manuka honey: Brown pigment formation, improvement of antibacterial activity and hydroxymethylfurfural content. Int. J. Food Sci. Technol. 2015;50:178–185. doi: 10.1111/ijfs.12630. [CrossRef] [Google Scholar]

- Silva F.V.M., Tan E.K., Farid M. Bacterial spore inactivation at 45–65 °C using high pressure processing: Study of Alicyclobacillus acidoterrestris in orange juice. Food Microbiol. 2012;32:206–211. doi: 10.1016/j.fm.2012.04.019. [PubMed] [CrossRef] [Google Scholar]

- Sulaiman A., Farid M., Silva F.V. Strawberry puree processed by thermal, high pressure, or power ultrasound: Process energy requirements and quality modeling during storage. Food Sci. Technol. Int. 2017;23:293–309. doi: 10.1177/1082013216685485. [PubMed] [CrossRef] [Google Scholar]

- Ghani A.A.G., Farid M.M. Computational fluid dynamics analysis of high pressure processing of food. In: Farid M.M., editor. Mathematical Modeling of Food Processing. CRC Press; Boca Raton, FL, USA: 2010. pp. 537–557. [Google Scholar]

- Wazed M.A., Farid M. Hypoallergenic and Low-Protein Ready-to-Feed (RTF) Infant Formula by High Pressure Pasteurization: A Novel Product. Foods. 2019;8:408. doi: 10.3390/foods8090408. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

- Liu P.L., Hu X.S., Shen Q. Effect of high hydrostatic pressure on starches: A review. Starke. 2010;62:615–628. doi: 10.1002/star.201000001. [CrossRef] [Google Scholar]

- Vallons K.J.R., Ryan L.A.M., Arendt E.K. Pressure-Induced Gelatinization of Starch in Excess Water. Crit. Rev. Food Sci. Nutr. 2014;54:399–409. doi: 10.1080/10408398.2011.587037. [PubMed] [CrossRef] [Google Scholar]

- Karwe M.V., Salvi D., Gosavi N.S. High Pressure-Assisted Infusion in Foods. Ref. Modul. Food Sci. 2016 doi: 10.1016/B978-0-08-100596-5.21042-1. [CrossRef] [Google Scholar]

- Leite T.S., de Jesus A.L.T., Schmiele M., Tribst A.A.L., Cristianini M. High pressure processing (HPP) of pea starch: Effect on the gelatinization properties. LWT. 2017;76:361–369. doi: 10.1016/j.lwt.2016.07.036. [CrossRef] [Google Scholar]

- O’Neill E.C., Field R.A. Underpinning Starch Biology with in vitro Studies on Carbohydrate-Active Enzymes and Biosynthetic Glycomaterials. Front. Bioeng. Biotechnol. 2015;3 doi: 10.3389/fbioe.2015.00136. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

- Raguin A., Ebenhöh O. Design starch: Stochastic modeling of starch granule biogenesis. Biochem. Soc. Trans. 2017;45:885–893. doi: 10.1042/BST20160407. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

- Chen L., Ma L., Zhou M., Liu Y., Zhang Y. Effects of pressure on gelatinization of collagen and properties of extracted gelatins. Food Hydrocoll. 2014;36:316–322. doi: 10.1016/j.foodhyd.2013.10.012. [CrossRef] [Google Scholar]

- Yusof N., Jaswir I., Jamal P., Jami M.S. Texture Profile Analysis (TPA) of the jelly dessert prepared from halal gelatin extracted using High Pressure Processing (HPP) Malays. J. Fundam. Appl. Sci. 2019;15:604–608. doi: 10.11113/mjfas.v15n4.1583. [CrossRef] [Google Scholar]

- Zhang Y., Ma L., Cai L., Zhou M., Li J. Effects of acid concentration and the UHP pretreatment on the gelatinisation of collagen and the properties of extracted gelatins. Int. J. Food Sci. Technol. 2016;51:1228–1235. doi: 10.1111/ijfs.13089. [CrossRef] [Google Scholar]

- von Endt D.W., Baker M.T. The Chemistry of Filled Animal Glue Systems. [(accessed on 20 March 2020)]; Available online: https://cool.culturalheritage.org/albumen/library/c20/vonendt1991.html.

- Ahromrit A., Ledward D.A., Niranjan K. High pressure induced water uptake characteristics of Thai glutinous rice. J. Food Eng. 2006;72:225–233. doi: 10.1016/j.jfoodeng.2004.11.013. [CrossRef] [Google Scholar]

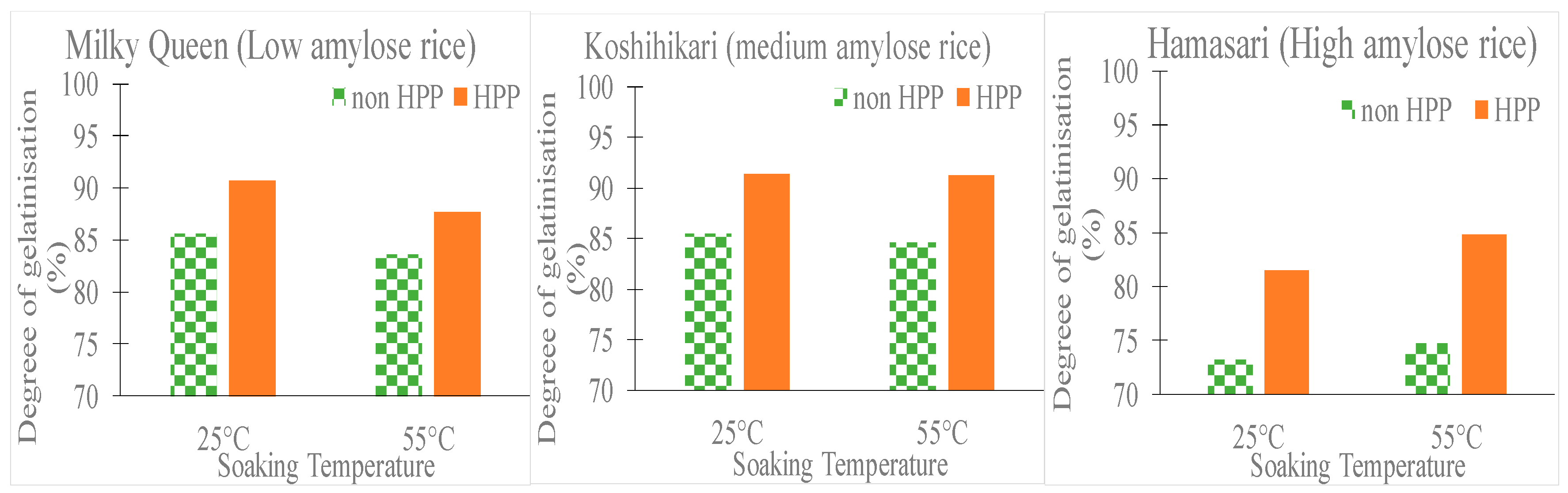

- Yamakura M., Haraguchi K., Okadome H., Suzuki K., Tran U.T., Horigane A.K., Yoshida M., Homma S., Sasagawa A., Yamazaki A., et al. Effects of Soaking and High-Pressure Treatment on the Qualities of Cooked Rice. J. Appl. Glycosci. 2005;52:85–93. doi: 10.5458/jag.52.85. [CrossRef] [Google Scholar]

- Zhu S.M., Hu F.F., Ramaswamy H.S., Yu Y., Yu L., Zhang Q.T. Effect of High Pressure Treatment and Degree of Milling on Gelatinization and Structural Properties of Brown Rice. Food Bioprocess. Technol. 2016;9:1844–1853. doi: 10.1007/s11947-016-1770-6. [CrossRef] [Google Scholar]

- Sharma N., Goyal S.K., Alam T., Fatma S., Chaoruangrit A., Niranjan K. Effect of high pressure soaking on water absorption, gelatinization, and biochemical properties of germinated and non-germinated foxtail millet grains. J. Cereal Sci. 2018;83:162–170. doi: 10.1016/j.jcs.2018.08.013. [CrossRef] [Google Scholar]

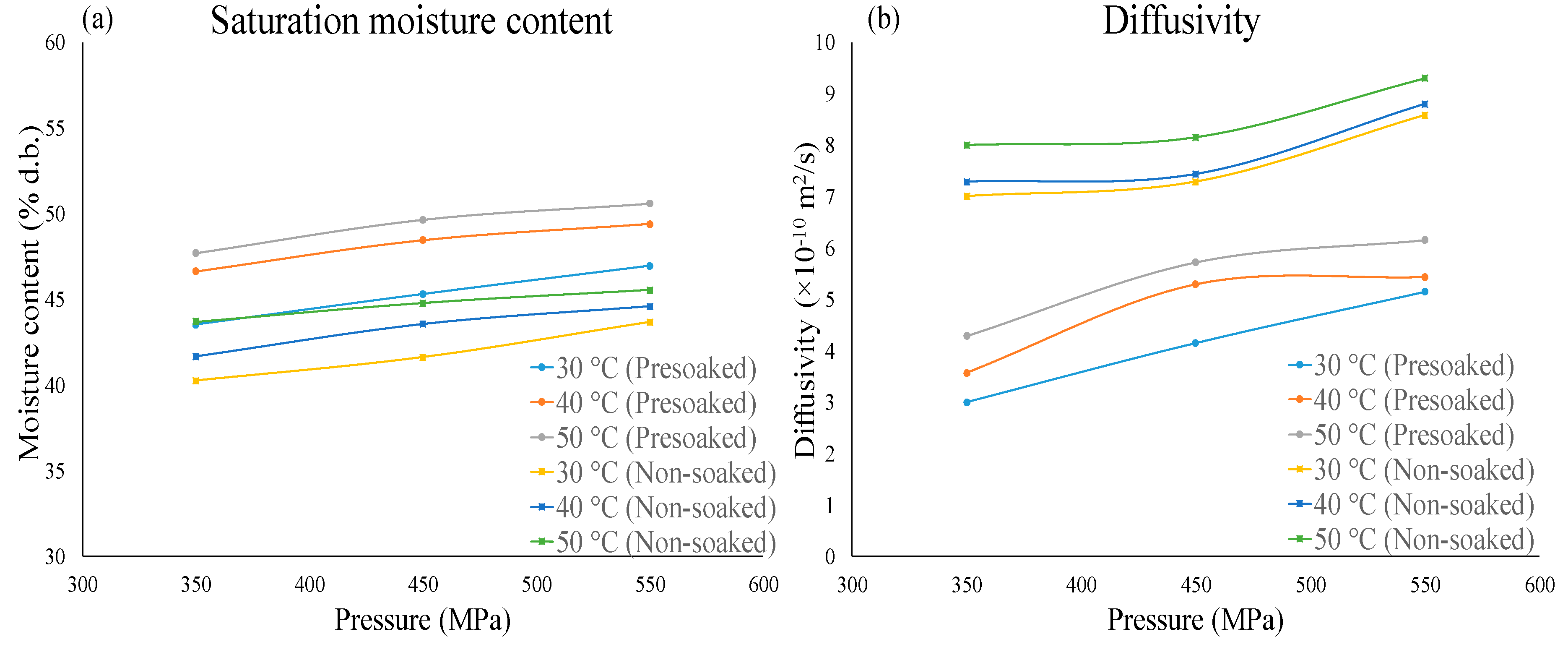

- Ravichandran C., Purohit S.R., Rao P.S. High pressure induced water absorption and gelatinization kinetics of paddy. Innov. Food Sci. Emerg. Technol. 2018;47:146–152. doi: 10.1016/j.ifset.2018.02.012. [CrossRef] [Google Scholar]

- Pallares A., Rousseau S., Chigwedere C.M., Kyomugasho C., Hendrickx M., Grauwet T. Temperature-pressure-time combinations for the generation of common bean microstructures with different starch susceptibilities to hydrolysis. Food Res. Int. 2018;106:105–115. doi: 10.1016/j.foodres.2017.12.046. [PubMed] [CrossRef] [Google Scholar]

- Islam M.S., Igura N., Shimoda M., Hayakawa I. The synergistic effect of moderate heat and pressure on the physical properties and pectic substances of potato tissue. Int. J. Food Sci. Technol. 2007;42:434–440. doi: 10.1111/j.1365-2621.2006.01251.x. [CrossRef] [Google Scholar]

- Shigematsu T., Furukawa N., Takaoka R., Hayashi M., Sasao S., Ueno S., Nakajima K., Kido M., Nomura K., Iguchi A. Effect of high pressure on the saccharification of starch in the tuberous root of sweet potato (Ipomoea batatas) Biophys. Chem. 2017;231:105–110. doi: 10.1016/j.bpc.2017.04.012. [PubMed] [CrossRef] [Google Scholar]

- Yu Y., Ge L., Zhu S., Zhan Y., Zhang Q. Effect of presoaking high hydrostatic pressure on the cooking properties of brown rice. J. Food Sci. Technol. 2015;52:7904–7913. doi: 10.1007/s13197-015-1901-5. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

- George J.M., Senthamizh Selvan T., Rastogi N.K. High-pressure-assisted infusion of bioactive compounds in apple slices. Innov. Food Sci. Emerg. Technol. 2016;33:100–107. doi: 10.1016/j.ifset.2015.11.010. [CrossRef] [Google Scholar]

- Préstamo G., Arroyo G. High Hydrostatic Pressure Effects on Vegetable Structure. J. Food Sci. 1998;63:878–881. doi: 10.1111/j.1365-2621.1998.tb17918.x. [CrossRef] [Google Scholar]

- Mahadevan S., Nitin N., Salvi D., Karwe M.V. High-Pressure Enhanced Infusion: Influence of Process Parameters. J. Food Process. Eng. 2015;38:601–612. doi: 10.1111/jfpe.12190. [CrossRef] [Google Scholar]

- Błaszczak W., Misharina T.A., Yuryev V.P., Fornal J. Effect of high pressure on binding aroma compounds by maize starches with different amylose content. LWT. 2007;40:1841–1848. doi: 10.1016/j.lwt.2006.11.002. [CrossRef] [Google Scholar]

- Vatankhah H., Ramaswamy H.S. High pressure impregnation (HPI) of apple cubes: Effect of pressure variables and carrier medium. Food Res. Int. 2019;116:320–328. doi: 10.1016/j.foodres.2018.08.042. [PubMed] [CrossRef] [Google Scholar]

- Sulistyawati I., Dekker M., Fogliano V., Verkerk R. Osmotic dehydration of mango: Effect of vacuum impregnation, high pressure, pectin methylesterase and ripeness on quality. LWT. 2018;98:179–186. doi: 10.1016/j.lwt.2018.08.032. [CrossRef] [Google Scholar]

- Gosavi N.S., Salvi D., Karwe M.V. High Pressure-Assisted Infusion of Calcium into Baby Carrots Part I: Influence of Process Variables on Calcium Infusion and Hardness of the Baby Carrots. Food Bioprocess Technol. 2019;12:255–266. doi: 10.1007/s11947-018-2203-5. [CrossRef] [Google Scholar]

- Gosavi N.S., Salvi D., Karwe M.V. High Pressure-Assisted Infusion of Calcium into Baby Carrots Part II: Influence of Process Variables on β-carotene Extraction and Color of the Baby Carrots. Food Bioprocess Technol. 2019;12:613–624. doi: 10.1007/s11947-019-2236-4. [CrossRef] [Google Scholar]

- Vatankhah H., Ramaswamy H.S. High pressure impregnation of oil in water emulsions into selected fruits: A novel approach to fortify plant-based biomaterials by lipophilic compounds. LWT. 2019;101:506–512. doi: 10.1016/j.lwt.2018.11.080. [CrossRef] [Google Scholar]

- Balakrishna A.K., Farid M. Enrichment of rice with natural thiamine using high-pressure processing (HPP) J. Food Eng. 2020:110040. doi: 10.1016/j.jfoodeng.2020.110040. [CrossRef] [Google Scholar]

- Villacís M.F., Rastogi N.K., Balasubramaniam V.M. Effect of high pressure on moisture and NaCl diffusion into turkey breast. LWT. 2008;41:836–844. doi: 10.1016/j.lwt.2007.05.018. [CrossRef] [Google Scholar]

- Lemus-Mondaca R., Zambra C., Marín F., Pérez-Won M., Tabilo-Munizaga G. Mass Transfer Kinetic and Quality Changes During High-Pressure Impregnation (HPI) of Jumbo Squid (Dosidicus gigas) Slices. Food Bioprocess. Technol. 2018;11:1516–1526. doi: 10.1007/s11947-018-2122-5. [CrossRef] [Google Scholar]

- Resch G., Maglio S.J. High Pressure Processing (HPP) for Infusing Flavor into Liquids Containing Alcohol. 2,018,037,138,6A1. U.S. Patent. 2018 Dec 27;