Three-dimensional printing (3DP), also known as additive manufacturing (AM), has rapidly evolved over the past few decades. Researchers around the globe have been putting their efforts into AM processes improvement and materials development. One of the most widely used extrusion-based technology under AM processes is Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF). Numerical simulation tools are being employed to predict the FFF process complexities and material behavior. These tools allow exploring candidate materials for their potential use in the FFF process and process improvements. The prime objective of this study is to provide a comprehensive review of state-of-the-art scientific achievements in numerical simulations of the FFF process for polymers and their composites. The first section presents an in-depth discussion of the FFF process’s physical phenomena and highlights the multi-level complexity. The subsequent section discusses the research efforts, specifically on numerical simulation techniques reported in the literature for simulation of the FFF process. Finally, conclusions are drawn based on the reviewed literature, and future research directions are identified.

- Fused Filament Fabrication

- simulation

1. Introduction

2. Physics Involved in Fused Filament Fabrication Process

3. Future Outlook

-

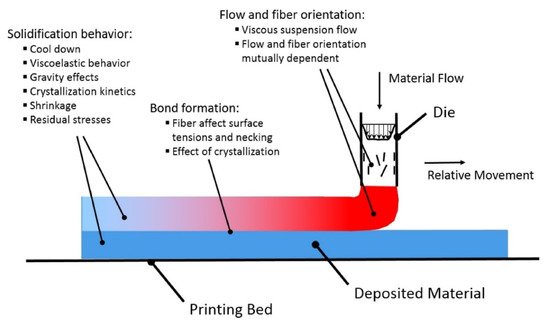

Fiber Orientation: The fiber orientation in deposited beads depends upon the material flow through the nozzle and deposition process. Most of the literature reports the use of Newtonian isotropic fluid properties; however, these materials should be modeled under anisotropic viscous flow conditions. Current modeling software cannot solve fourth or higher-order orientation tensors and cannot consider anisotropic flow characteristics (which is the case with fiber-reinforced composites). Therefore, there is a need for better numerical simulation tools to consider realistic fiber orientation during material flow.

-

Beads Deposition: Several heat transfer models have been reported in the literature to predict the cooling process of the deposited beads. However, due to the anisotropy involved in the 3DP process, interlayer conduction phenomena need to be considered as thermal conductivities of deposited beads change with the fiber orientation.

-

Interface and Bonding: Bonding between the subsequent layers is highly correlated with the interface; therefore, the presence of fibers on the bead surface can affect this process. In addition, the necking phenomenon is derived by the gradients of surface tension is also influenced by the bead surface morphology. Finally, the material behavior (crystalline or amorphous) will reflect its viscosity, which ultimately affects the bonding process; therefore, it must be accounted for accurate process modeling.

-

Integrated Simulation Models: The FFF process is a complex multi-stage process as described in this paper. However, most reported computational work either focused on the material flow inside the liquefier or material behavior after deposition and is not as mature as the experimental literature. Therefore, there is a need for integrated studies considering all these phases of the FFF process (i.e., melt flow behavior inside/outside the nozzle, material deposition, solidification behavior, bond formation, and warpage and residual stresses).

-

Model Validation: The validation of numerical and analytical models is vital through experimental studies. Limited studies compared the numerical simulation results with experimental work, which is essential for validating and broader application of these models.

-

Materials Portfolio: Materials portfolio for the FFF process is rapidly growing. However, few materials (such as PLA and ABS) are considered for numerical and analytical modeling of process or material behavior. The researchers should focus on implementing existing models to a broader range of materials or develop models for materials not yet considered in the literature.

-

Polymer Composites: Two-phase materials (composites) are also barely considered for the numerical modeling of material or the FFF process. The most reported models address linear amorphous polymers. Different polymers exhibit different characteristics, such as bare PLA and ABS act as amorphous materials; however, PBT, PA12, and PEEK exhibit a semi-crystalline nature [29][30][31]. Moreover, the addition of the reinforcing phase can alter the nature of the resulting composite material, e.g., PLA acts as semi-crystalline material with tricalcium phosphate (TCP) [32]. The effect of reinforcement type and process parameters on polymer nature (amorphous or crystalline) will be worth addressing.

References

- González-Henríquez, C.M.; Sarabia-Vallejos, M.A.; Rodriguez-Hernandez, J. Polymers for additive manufacturing and 4D-printing: Materials, methodologies, and biomedical applications. Prog. Polym. Sci. 2019, 94, 57–116.

- Al Rashid, A.; Ahmed, W.; Khalid, M.Y.; Koç, M. Vat Photopolymerization of Polymer and Polymer Composites: Processes and Applications. Addit. Manuf. 2021, 47, 102279.

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive manufacturing: Technology, applications, markets, and opportunities for the built environment. Autom. Constr. 2020, 118, 103268.

- Yilmaz, B.; Al Rashid, A.; Ait, Y.; Evis, Z.; Koç, M. Bioprinting: A review of processes, materials and applications. Bioprinting 2021, 23, e00148.

- Ahangar, P.; Cooke, M.E.; Weber, M.H. Rosenzweig, D.H. Current biomedical applications of 3D printing and additive manufacturing. Appl. Sci. 2019, 9, 1713.

- Rane, K.; Strano, M. A comprehensive review of extrusion-based additive manufacturing processes for rapid production of metallic and ceramic parts. Adv. Manuf. 2019, 7, 155–173.

- Nachal, N.; Moses, J.A.; Karthik, P.; Anandharamakrishnan, C. Applications of 3D Printing in Food Processing. Food Eng. Rev. 2019, 11, 123–141.

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196.

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Critical Review on 3DP Concrete trends, needs and research recommendations. In Proceedings of the International Conference of Materials and Engineering Technology (TICMET’20), Gaziantep, Turkey, 5–7 November 2020; p. 553.

- Crump, S.S. Apparatus and Method for Creating Three-Dimensional Objects. U.S. Patent 5,121,329A, 9 June 1992.

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies; Springer: Berlin/Heidelber, Gemany, 2015.

- Diegel, O.; Nordin, A.; Motte, D. Additive Manufacturing Technologies. In A Practical Guide to Design for Additive Manufacturing; Springer: Singapore, 2019; pp. 19–39.

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive Manufacturing of Polymer Nanocomposites: Needs and Challenges in Materials, Processes, and Applications. J. Mater. Res. Technol. 2021, 14, 910–941.

- Al Rashid, A.; Khalid, M.Y.; Imran, R.; Ali, U.; Koç, M. Utilization of Banana Fiber-Reinforced Hybrid Composites in the Sports Industry. Materials 2020, 13, 3167.

- Shaqour, B.; Abuabiah, M.; Abdel-Fattah, S.; Juaidi, A.; Abdullah, R.; Abuzaina, W.; Qarout, M.; Verleije, B.; Cos, P. Gaining a better understanding of the extrusion process in fused filament fabrication 3D printing: A review. Int. J. Adv. Manuf. Technol. 2021, 114, 1279–1291.

- Bhandari, S.; Lopez-Anido, R.A.; Gardner, D.J. Enhancing the interlayer tensile strength of 3D printed short carbon fiber reinforced PETG and PLA composites via annealing. Addit. Manuf. 2019, 30, 100922.

- Nawafleh, N.; Celik, E. Additive manufacturing of short fiber reinforced thermoset composites with unprecedented mechanical performance. Addit. Manuf. 2020, 33, 101109.

- Al Rashid, A.; Koc, M. Creep and Recovery Behavior of Continuous Fiber-Reinforced 3DP Composites. Polymers 2021, 13, 1644.

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused filament fabrication of fiber-reinforced polymers: A review. Addit. Manuf. 2018, 21, 1–16.

- Duty, C.; Ajinjeru, C.; Kishore, V.; Compton, B.; Hmeidat, N.; Chen, X.; Liu, P.; Hassen, A.A.; Lindahl, J.; Kunc, V. What makes a material printable? A viscoelastic model for extrusion-based 3D printing of polymers. J. Manuf. Process. 2018, 35, 526–537.

- Seppala, J.E.; Migler, K.D. Infrared thermography of welding zones produced by polymer extrusion additive manufacturing. Addit. Manuf. 2016, 12, 71–76.

- Jiang, Z.; Diggle, B.; Tan, M.L.; Viktorova, J.; Bennett, C.W.; Connal, L.A. Extrusion 3D Printing of Polymeric Materials with Advanced Properties. Adv. Sci. 2020, 7, 2001379.

- Pocius, A.V.; Dillard, D.A. (Eds.) Adhesion Science and Engineering: Surfaces, Chemistry and Applications; Elsevier Science: Amsterdam, The Netherlands, 2002.

- Stansbury, J.W.; Idacavage, M.J. 3D printing with polymers: Challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 54–64.

- McIlroy, C.; Graham, R.S. Modelling flow-enhanced crystallisation during fused filament fabrication of semi-crystalline polymer melts. Addit. Manuf. 2018, 24, 323–340.

- Shaqour, B.; Samaro, A.; Verleije, B.; Beyers, K.; Vervaet, C.; Cos, P. Production of drug delivery systems using fused filament fabrication: A systematic review. Pharmaceutics 2020, 12, 517.

- Kim, J.Y.; Kim, S.Y.; Song, Y.S.; Youn, J.R. Relationship between the Crystallization Behavior and the Warpage of Film-Insert-Molded Parts. J. Appl. Polym. Sci. 2010, 116, 2658–2667.

- Fitzharris, E.R.; Watanabe, N.; Rosen, D.W.; Shofner, M.L. Effects of material properties on warpage in fused deposition modeling parts. Int. J. Adv. Manuf. Technol. 2018, 95, 2059–2070.

- Gnanasekaran, K.; Heijmans, T.; van Bennekom, S.; Woldhuis, H.; Wijnia, S.; de With, G.; Friedrich, H. 3D printing of CNT-and graphene-based conductive polymer nanocomposites by fused deposition modeling. Appl. Mater. Today 2017, 9, 21–28.

- Li, H.; Zhang, S.; Yi, Z.; Li, J.; Sun, A.; Guo, J.; Xu, G. Bonding quality and fracture analysis of polyamide 12 parts fabricated by fused deposition modeling. Rapid Prototyp. J. 2017, 23, 973–982.

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of Layer Thickness and Raster Angle on the Mechanical Properties of 3D-Printed PEEK and a Comparative Mechanical Study between PEEK and ABS. Materials 2015, 8, 5834–5846.

- Drummer, D.; Cifuentes-Cuéllar, S.; Rietzel, D. Suitability of PLA/TCP for fused deposition modeling. Rapid Prototyp. J. 2012, 18, 500–507.