The charging station is useful in this interest to make the EVs functional. It is up to the general customer to adopt EVs and the utility grid to inject more renewables into grid so that the energy EV draws is clean. But fast charging stations are rarely found at home.

1. Introduction

Worldwide awareness on climate related challenges and sustainable mobility, motivated to control the emissions from the gasoline-powered internal combustion engine vehicles (ICEVs), which constitutes to 16.2% of the total emission worldwide [1]. Apart from ground transportation via passenger cars, the heavy-duty commercial vehicles constitute a major number of electric vehicles in usage today. Lightweight Battery electric vehicles represent only 2.5% of total vehicle sales [2]. The same can be said for the aviation and marine industry where they have the potential to be electric or, as in the case of ships, are already electric but use fossil fuels to generate power on-board. Replacing these vehicles with battery vehicles for all three modes of transportation can bring a sharp reduction in carbon emissions. Several applications in aviation and ground transportation have been advancing at a remarkable pace due to the progress of electric motors, power electronics, and batteries etc. This has contributed to the commercial take-off of fully electric transportation.

2. Current Insights

Early history of electrical grid saw a battle over AC and DC in which, despite Thomas Edison’s best efforts, AC won. AC had the ease of changing voltage levels with transformers and the transmission of electricity seemed easier. But after almost hundred and fifty years later AC power is still predominantly used in grid despite having huge power losses and higher cost.

DC power is energy efficient, reliable, and has a better quality of power. The power density of DC machines is way higher than AC machines. DC also is inherently compatible with free fuel energy (solar and wind) systems generating intermittent DC power stored in batteries to have a reliable power supply. Solar PV is inherently a DC energy supply, as are batteries, making DC a more naturally compatible interface. Any energy storage technology is DC based, creating opportunities for improved integration efficiencies, and reduced operating losses.

Most of the modern electronic equipment like cell phones, laptops, and household appliances are DC. If the requirement for converting energy could be eliminated, then efficiency will increase. Reduced loss will also reduce the dissipated heat in electronic circuitry so that the electronic equipment lasts longer. The technology of DC power in data centers, homes, and communities is making significant advances.

Moreover, different countries operate in different power frequencies and qualities. Due to this, different countries need different conversion equipment which is an additional hassle. If universal DC is accepted, then one single equipment can travel the world. In places like Alaska where human population is scarce, power is generated in a nano grid system and DC is prevalent as it is convenient. In the rural areas of low GDP countries or the war ridden countries which have their power grid destroyed, DC is used. While charging from AC power, whether be it from household 120 V or 240 V outlet or use J1772 charging equipment, the car’s rectifier converts that power to DC. Therefore, there are multiple levels of conversion and associated losses before the power can reach the battery.

From safety and carbon emission point of view, PV generation of electric power is the best technology

[91][3]. The cost of photovoltaics generated electric power is lower than any other energy source

[92][4]. At utility scale, the cost of PV generated electric power has reached as low as 0.0104 USD/kWh

[92][4]. Due to advancement in technology and volume manufacturing, the cost of lithium ion batteries is falling constantly

[93][5]. For four hours of power storage currently the cost of stored electric power is 0.8 cents/kWh to 1.4 cents/kWh and has the potential to reach to 0.4 cents/kWh to 0.9 cents/kWh by 2022

[94][6]. For longer hours of battery use the cost is significantly reduced. For a standalone photovoltaics and lithium-ion battery power network, ad stowing PV generated power in batteries for 16–18 h, the cost of electric power is roughly half than the cost current AC grid

[94][6].

As mentioned in the introduction, reference

[8][7] has an extensive review of power electronics topologies but other aspects remain untouched. Every aspect of the shortcomings in engineering for charging station has been thoroughly analyzed in this paper. The authors of reference

[8][7] don’t delve into the subject of DC grid or silicon carbide power electronics for fast charging. This paper addresses that as well. In reference

[9][8] emphasis is placed on the charging equipment and inductive charging. The scopes of inductive charging remain doubtful economically for heavy duty vehicles because of their high losses. Therefore, this paper recommends the reduction of losses in power systems by adopting SiC power electronics. In reference

[10][9], the authors discuss all levels of charging, but no special emphasis is given on fast charging, so this paper focuses solely on the XFC architecture. The charging standards are mentioned in

[11][10] but technical aspects are not as deeply investigated as this paper. The energy storage design for DCFC is mentioned in

[12][11] but the important aspects of power electronics, security which are valuable for a good energy storage are not paid attention to, this paper addresses those issues. The emphasis of this review paper is on relevant power electronics technologies of DC fast charging and other aspects such as cyber security, protection, impact of DC power clean electrical power networks and the role of silicon carbide power electronics in fast deployment of XFC on a large-scale basis.

To advance the technology of XFC, advancements must be made both in the power network as well as the XFC.

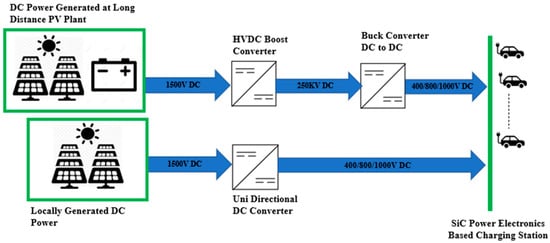

Figure 13 shows our proposed system. If the DC power generated by PV and battery-based power network can be used locally, there is no need of transmission of power. This concept is exactly what Thomas Edison proposed and involve minimum distance between power source and load as well as minimum power conversions

[95][12]. In case of long-haul transmission, HVDC is used and there is opportunity to design and fabricate high voltage solid state silicon carbide converters. The use of larger silicon carbide wafers and the use of single wafer manufacturing has the potential of bringing cost of SiC power electronics at par or lower than silicon power electronics

[95][12]. Based on the isolation techniques it is far more viable to isolate a DC charging station in case of a cyber-attack. Judging by all these advantages of DC over AC, it is safe to presume that extremely fast charging technology will be far more efficient and cheaper if DC grid was adopted.

Figure 13. Fully Renewable and DC XFC Charging Infrastructure

[14][13].

3. Conclusions

Thorough research and planning are required to make a charging infrastructure that will encourage the consumers to opt for EVs for not only daily usage but also for long distance travel and totally forego the ICEV. The power electronics topologies are the cornerstone for charging stations and improving on the current topologies discussed here will make charging stations less expensive, thus more acceptable. The effect of Silicon Carbide in performance improvement of power electronics is discussed. How it effects the environment and what are the cyber threat in the station are also discussed. In tThis article we have aentry addressed the gaps in research which are hindering the widespread usage of EV in today’s scenario. The technology gaps range from power electronics, protection, DC vs. AC to cyber security. Implementing the suggestions proposed here will help reduce power electronics losses, make the protection architecture stronger and secure the network apart from many other aspects. Use of DC power network over AC power can cut down the capital cost of the entire system and provide low-cost charging solution to customers. The acceptance of electric vehicles is not only the individual’s responsibility, but it is a responsibility that lies on government and big corporations alike. This articlefinding helps the academia by directing the research initiatives and the industry to develop the necessary architecture to implement the XFC. Modeling a free fuel based fully DC network powered by SiC electronics will form the nucleus of the next step of this research. Although we have emphasized the advantages of DC input power for various loads, practical implementation of DC power as input for XFC as well as for other applications depends on the energy policy of individual country.