You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 2 by Conner Chen and Version 1 by Panagiotis Kapsalis.

Embedding reinforcing textiles into inorganic matrices is an innovative technique which offers the possibility to manufacture thin, slender, and lightweight but robust structural elements. Textile-reinforced concrete (TRC) is a promising composite material with enormous potential in structural applications because it offers the possibility to construct slender, lightweight, and robust elements.

- textile-reinforced concrete

1. Introduction

Embedding reinforcing textiles into inorganic matrices is an innovative technique which offers the possibility to manufacture thin, slender, and lightweight but robust structural elements. This cementitious composite material is known by several names in the literature and in practice. Textile-reinforced concrete (TRC), textile-reinforced mortar (TRM), or fabric-reinforced cementitious matrix (FRCM) are the most common. Since its first applications in the early 2000s, TRC has found its way into practice in a wide range of applications, either as a standalone material or as a component in composite members/structures, as it can exhibit high load-bearing capacity and ductility [1]. Several examples of TRM/TRC applications have been presented in various manuscripts, such as [2]. Some of the most interesting examples are related to the construction of pedestrian bridges, shell structures with various shapes and curvatures, load-bearing and non-bearing wall elements (either single panels or sandwich-type elements), roof elements, pipes, and several sorts of strengthening schemes of existing elements (structural strengthening of concrete columns and beams, load-bearing masonry elements, and infill walls). Hence, its mechanical performance has been widely investigated in the past decades and this research is still ongoing [2].

Despite the years of continuous investigations of the mechanical performance of TRC, there is some difficulty in compiling the obtained knowledge as there is no standard testing method yet [3]. The situation is even worse when it comes to thermal loading of TRC. Apart from variations in the specimen geometry, the clamping method, the loading rate, etc., the performed tests found in the literature also vary in the heating rate, the method and the position of the temperature measurements, and the exposure time. However, most importantly, they vary in the combination of the heating and mechanical loading conditions. The performance of the matrix and the bond may differ dramatically, depending on whether the mechanically loaded specimen is in a hot or a cooled down state. Additionally, the load level at which the heating is applied also affects the specimens’ response severely. The effects of these variations of the testing conditions are shown later on in the Discussion section of this paper. Therefore, the experimentations are categorized into three cases:

-

Heating at constant load, where the specimens are pre-loaded to a constant stress level before the heating initiates. In this case, the influence of the load level is the decisive parameter.

-

Load while heated, where the specimens are first subjected to an increased temperature which remains constant after reaching a target value and then, while being in hot conditions, the mechanical loading initiates. The dominant parameter, in this case, is the target temperature.

-

Residual capacity after heating, where the specimens are first exposed to high temperatures and then, after a cooling down phase, they are tested mechanically. The maximum reached temperature and the heating/cooling rates are the dominant parameters in this case.

The physical response of cement composites during exposure to high temperatures is not expected to differ significantly from the response of the unreinforced matrix. Due to the low fiber volume fraction that is commonly used in TRC, the thermal properties (thermal conductivity, specific heat capacity, etc.) are not strongly influenced by the fibers [4]. Additionally, TRC is characterized by its non-combustibility and no smoke/gas emissions [5]. However, the presence of the fibers (especially when they are polymer coated) might cause a stochastic spalling behavior, i.e., either triggering or preventing spalling [4].

Several studies have been conducted on structural elements with TRC parts. For example, fire tests on sandwich panels with TRC faces have been conducted [6,7,8][6][7][8]. The fire performance of TRC strengthened elements (of concrete or masonry) has been widely tested too [9,10,11,12,13,14,15,16,17,18,19][9][10][11][12][13][14][15][16][17][18][19]. However, in all these studies, the performance of the element does not depend solely on the thermal response and the thermomechanical performance of TRC, but also on the substrate and their interaction (i.e., bond strength). The effect of increased temperatures on the bond strength between the substrate (concrete or masonry) and the TRC strengthening layer has been studied by [20,21,22,23,24,25,26,27][20][21][22][23][24][25][26][27]. The performance of TRM/TRC systems under elevated temperatures and fire conditions has been discussed in the review study of [28], which emphasized the behavior of strengthening schemes.

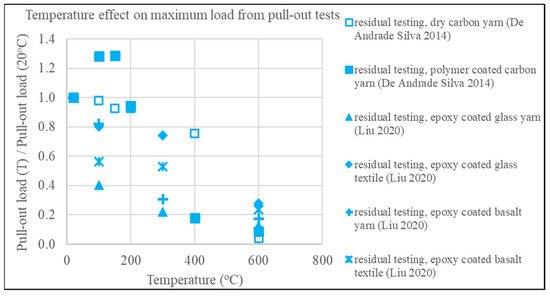

2. Performance of the Textile-to-Matrix Bond

The performance of TRC under thermal loads does not only depend on the performance of the constituent materials, that is the reinforcing fibers and the matrix, but also on their interaction, thus, on the matrix-to-fibers bond. Since the coating of the textiles is a common practice for several reasons (improvement of the textile-to-matrix bond, activation of the inner filaments, protection of the reinforcement from chemically aggressive matrices [2]), the bond strength depends on the coating nature. Therefore, the bond strength deterioration due to high temperatures depends a lot on the presence and the thermal behavior of the coatings. The study of De Andrade Silva et al. [29] investigated the residual bond behavior of coated versus uncoated carbon fiber-reinforced concrete specimens exposed to temperatures up to 600 °C, by double-sided pull-out tests. Liu et al. [30] tested the effect of temperature on epoxy-impregnated, single and double yarn specimens, of glass and basalt fibers, embedded into a cementitious matrix. The exposure temperatures were up to 600 °C and the specimens were tested after cooling down (residual capacity). The effect of temperature on the maximum load recorded at the pull-out tests is shown in Figure 1.

Figure 1. Influence of exposure temperature on the maximum pull-out load on TRC specimens.

References

- Hegger, J.; Will, N.; Bentur, A.; Curbach, M.; Jesse, F.; Mobasher, B.; Peled, A.; Wastiels, J. Composite materials—6.2 Mechanical behaviour of textile reinforced concrete in Textile Reinforced Concrete. In Textile Reinforced Concrete—State-of-the-Art Report of RILEM TC 201-TRC; Brameshuber, W., Ed.; RILEM Publications SARL: Bagneux, France, 2006; pp. 133–186. ISBN 2-912143-99-3.

- Papanicolaou, C.G. Applications of textile-reinforced concrete in the precast industry. In Textile Fibre Composites in Civil Engineering; Triantafillou, T.C., Ed.; Woodhead Publishing: Duxford, UK, 2016; pp. 227–244.

- D’Antino, T.; Papanicolaou, C. Mechanical characterization of textile reinforced inorganic-matrix composites. Compos. B Eng. 2017, 127, 78–91.

- Hulin, T.; Lauridsen, D.H.; Hodicky, K.; Schmidt, J.W.; Stang, H. Influence of basalt FRP mesh reinforcement on high-performance concrete thin plates at high temperatures. J. Compos. Constr. 2016, 20, 04015034.

- Bisby, L. Fire resistance of textile fiber composites used in civil engineering. In Textile Fibre Composites in Civil Engineering; Triantafillou, T.C., Ed.; Woodhead Publishing: Duxford, UK, 2016; pp. 169–186.

- Hegger, J.; Zell, M.; Horstmann, M. Textile reinforced concrete–realization in applications. In Proceedings of the International Fib Symposium: Tailor Made Concrete Structures: New Solutions for Our Society, Amsterdam, The Netherlands, 19–22 May 2008; pp. 357–362.

- Zani, G.; Rampini, M.C.; Colombo, M.; di Prisco, M. Fire behavior of sandwich panels for roofing applications. Key Eng. Mater. 2016, 711, 775–782.

- Shen, L.; Wang, J.; Xu, S.; Amoako-Atta, G. Fire Resistance Behavior of Full-scale Self-thermal Insulation Sandwich Walls Made of Textile-reinforced Concrete. Int. J. Heat Technol. 2019, 37, 239–248.

- Bisby, L.; Stratford, T.; Smith, J.; Halpin, S. Comparative performance of fibre reinforced polymer and fibre reinforced cementitious mortar strengthening systems in elevated temperature service environments. In Proceedings of the Structural Faults and Repair 2010 Conference, Edingbrugh, UK, 15–17 June 2010; Engineering Technics Press.

- Ehlig, D.; Hothan, S. Reinforced concrete slabs strengthened with textile reinforced concrete subjected to fire. In Proceedings of the 2nd International RILEM Workshop on Concrete Spalling due to Fire Exposure, Delft, The Netherlands, 5–7 October 2011; pp. 419–426.

- Bisby, L.; Stratford, T.; Hart, C.; Farren, S. Fire performance of well-anchored TRM, FRCM and FRP flexural strengthening systems. In Proceedings of the 6th International Conference on Advanced Composites in Construction, Belfast, UK, 10–12 September 2013; Network Group for Composites in Construction.

- Trapko, T. The effect of high temperature on the performance of CFRP and FRCM confined concrete elements. Comp. B Eng. 2013, 54, 138–145.

- Michels, J.; Zwicky, D.; Scherer, J.; Harmanci, Y.E.; Motavalli, M. Structural strengthening of concrete with fiber reinforced cementitious matrix (FRCM) at ambient and elevated temperature—Recent investigations in Switzerland. Adv. Struct. Eng. 2014, 17, 1785–1799.

- Al-Salloum, Y.A.; Almusallam, T.H.; Elsanadedy, H.M.; Iqbal, R.A. Effect of elevated temperature environments on the residual axial capacity of RC columns strengthened with different techniques. Constr. Build. Mater. 2016, 115, 345–361.

- Tetta, Z.C.; Bournas, D.A. TRM vs. FRP jacketing in shear strengthening of concrete members subjected to high temperatures. Compos. B Eng. 2016, 106, 190–205.

- Ombres, L. Structural performances of thermally conditioned PBO FRCM confined concrete cylinders. Compos. Struct. 2017, 176, 1096–1106.

- Triantafillou, T.C.; Karlos, K.; Kefalou, K.; Argyropoulou, E. An innovative structural and energy retrofitting system for URM walls using textile reinforced mortars combined with thermal insulation: Mechanical and fire behavior. Constr. Build. Mater. 2017, 133, 1–13.

- Zhang, J.; Ma, H.; Li, C.; Xu, Q.; Li, W. Experimental study on seismic performance of fire-exposed perforated brick masonry wall. Constr. Build. Mater. 2018, 180, 77–91.

- Cerniauskas, G.; Tetta, Z.; Bournas, D.A.; Bisby, L.A. Concrete confinement with TRM versus FRP jackets at elevated temperatures. Mater. Struct. 2020, 53, 58.

- Ombres, L. Analysis of the bond between fabric reinforced cementitious mortar (FRCM) strengthening systems and concrete. Compos. B Eng. 2015, 69, 418–426.

- Donnini, J.; y Basalo, F.D.C.; Corinaldesi, V.; Lancioni, G.; Nanni, A. Fabric-reinforced cementitious matrix behavior at high-temperature: Experimental and numerical results. Compos. B Eng. 2017, 108, 108–121.

- Maroudas, S.R.; Papanicolaou, C.G. Effect of high temperatures on the TRM-to-masonry bond. Key Eng. Mater. 2017, 747, 533–541.

- Raoof, S.M.; Bournas, D.A. Bond between TRM versus FRP composites and concrete at high temperatures. Compos. B Eng. 2017, 127, 150–165.

- Ombres, L.; Iorfida, A.; Mazzuca, S.; Verre, S. Bond analysis of thermally conditioned FRCM-masonry joints. Measurement 2018, 125, 509–515.

- Al-Jaberi, Z.; Myers, J.J.; Chandrashekhara, K. Effect of direct service temperature exposure on the bond behavior between advanced composites and CMU using NSM and EB techniques. Compos. Struct. 2019, 211, 63–75.

- Askouni, P.D.; Papanicolaou, C.G.; Kaffetzakis, M.I. The effect of elevated temperatures on the TRM-to-masonry bond: Comparison of normal weight and lightweight matrices. Appl Sci. 2019, 9, 2156.

- Gao, S.; Zhao, X.; Qiao, J.; Guo, Y.; Hu, G. Study on the bonding properties of Engineered Cementitious Composites (ECC) and existing concrete exposed to high temperature. Constr. Build. Mater. 2019, 196, 330–344.

- Papanicolaou, C.G.; Triantafillou, T. Performance of TRM/TRC systems under elevated temperatures and fire conditions. ACI Spec. Publ. 2021, 345, 32–46.

- De Andrade, S.F.; Butler, M.; Hempel, S.; Toledo, F.R.D.; Mechtcherine, V. Effects of elevated temperatures on the interface properties of carbon textile-reinforced concrete. Cem. Concr. Compos. 2014, 48, 26–34.

- Liu, S.; Rawat, P.; Chen, Z.; Guo, S.; Shi, C.; Zhu, D. Pullout behaviors of single yarn and textile in cement matrix at elevated temperatures with varying loading speeds. Compos. B Eng. 2020, 199, 108251.

- Rambo, D.A.S.; De Andrade, S.F.; Toledo, F.R.D.; da Fonseca, M.G.O. Effect of elevated temperatures on the mechanical behavior of basalt textile reinforced refractory concrete. Mater. Des. 2015, 65, 24–33.

- Rambo, D.A.S.; De Andrade, S.F.; Toledo, F.R.D.; Ukrainczyk, N.; Koenders, E. Tensile strength of a calcium-aluminate cementitious composite reinforced with basalt textile in a high-temperature environment. Cem. Concr. Compos. 2016, 70, 183–193.

More