An agrivoltaic system is a complex system, being, at least, a spatial, an energy and an agronomic system. Its design and assessment must adhere to requirements set depending on the project’s needs in order to meet desired performance quality objectives. Different dimensions of performance need to be taken into account.

- agrivoltaics

- land use

- photovoltaic design assessment

- landscape

- PV greenhouse

- PV pattern

- integrated photovoltaics

1. Introduction

In recent years, agrivoltaic (APV) systems have been the subject of numerous studies due to their potential in the food–energy nexus. Demonstrative projects with new conceptual designs based on photovoltaic (PV) modules for covering open fields have shown promising results through optimizing light availability while reducing the need for irrigation and protecting from extreme weather phenomena. APV denotes sharing the sunlight for co-production of food and energy on the same piece of land; therefore, designs must overcome, as far as possible, physical constrains of covering crops with photovoltaic modules in order to alleviate the reduction in crop profitability. Some examples of the main issues related to the use of co-located PV on cropland and the solutions commonly proposed to solve them are shown in Table 1.

| Topic | Design Related Solution | Technology Related Solution |

|---|---|---|

| Minimizing shadows on crops (biomass yield) | Optimal design: Distance between the arrays of modules (the stripes). Distance of the modules from the ground |

Sun-tracking systems Semi-transparent PV modules (by spacing PV cells) Light-selective PV devices |

| Maximizing electric energy generation | Optimal planning: Avoiding sharing losses from surrounding elements (structures, buildings, trees, inter-row shading of the PV modules should be minimized) |

Highly efficient systems (e.g., sun-tracking systems) Highly efficiency modules or technologies (e.g., bifacial module technology) |

| Optimal design: Azimuth facing equator and tilt close to latitude |

||

| Social acceptance (landscape dimension) | Optimal landscape design: Pattern of PV arrays aligned to the parcel Natural fences and low height structures to minimize visual disturbance Use of marginal areas Removable systems |

New materials for structure |

| Optimal design: Different tilt, azimuth and height to reproduces the orography of the land |

||

| New business models: Higher economic efficiency per land unit (farmer perspective) Benefits for local economy and employment (tourism, local recreation, etc.) |

2. State of Art

The concept of a dual-use approach for both solar photovoltaic power as well as agricultural production was theoretically conceived by Goetzberger and Zastrow at the Fraunhofer Institute (Germany) in 1981 [1]. They proposed to elevate the structure (by about 2 m) and the distance between rows (about 3 times the height of the modules) to achieve uniform radiation on the ground while at the same time that allow the moving of mechanized agricultural equipment. In 2004, Japanese engineer Akira Nagashima developed the first agrivoltaic system (here referred to as “solar sharing”) using a structure similar to a garden pergola [2]. Nagashima designed diverse test fields with different shadowing rates based on the concept of the light saturation point of each crop with the idea of sharing the excess of solar radiation with PV systems to generate electricity (plants only employ a small percentage of incident sunlight, between 3% and 6% of total solar radiation, to accomplish their maximum rate of photosynthesis).

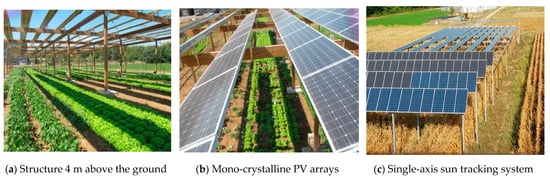

The first experimental pilot project, however, was installed in France, close to the southern city of Montpellier in the spring of 2010. The prototype has mono-crystalline PV modules mounted at a height of 4 m above the ground (Figure 1 a,b). In order to evaluate the effect of the shadow by the PV, the prototype was split into different parts with two densities of solar modules: one called “full density”, with optimal spacing between rows for electricity production and which transmitted on average 50% of the incident radiation to the crop, and the second called “half density”, obtained by removing one PV strip out of two and which left on average 70% of incident radiation available to the crop, so that the effect of the shadow by the PV can be compared to each density, and to control plants under full sun conditions [3]. Additionally, to evaluate the advantages of solar-tracking technology, which allows the adjustment of the radiation level on crops, two independent single-axis tracking PV systems were added in 2014 (Figure 1 c) [4]. The experimental farm led to the exploration of the potential of the open-field agrivoltaic systems, giving rise to many scientific publications, from the effect of the rain distribution (PV–water nexus) [5][6] to the impact on microclimatic condition together with growth, morphology and yield in crops such as lettuce, cucumber and durum wheat [7][8][9].

Figure 1.

Experimental agrivoltaic system in Montpellier, France. © C. Dupraz.

In recent years, several research groups have implemented agrivoltaics demonstration projects around the world. In Germany, the Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE) is at the forefront of APV research. A research pilot plant was installed in 2016 near Lake Constance in southern Germany (Figure 2 a,b). This pilot research plant is used to examine the impacts of the technology with regard to aspects such as energy production, economic feasibility, crop production, social acceptance and technological design. Moreover, in cooperation with their Chilean subsidiary Fraunhofer Center for Solar Energy Technologies (Fraunhofer CSET), three further pilot plants have been realized near Santiago de Chile to investigate the implementation of APV systems and its impact on field crops in regions with arid areas and high solar radiation (Figure 2 c).

The performance of the agrivoltaic systems in drylands is also under investigation by the Barron-Gafford research group in the USA. A small-scale research plant was installed in Arizona at the Biosphere 2 Lab in August 2016. The research group focuses on common agricultural species for drylands such as peppers, jalapeños and cherry tomatoes [10]. The APV system is 3.3 m off the ground with a tilt of 32° and 1 m of spacing between each row of PV modules.

Research in the field continues to progress at a furious pace. Aside from these pilot projects, agrivoltaics have triggered much interest in the research community that explores the potential from different disciplinary perspectives and practical issues, such as the solar power potential by land cover type (croplands, grasslands and wetlands) [11] (PV–water nexus), the economic value of energy production coupled with shade tolerant crop production [12], the implementation in peri-urban agriculture areas [13] or the viability over shade-intolerant crops in specific geographical locations [14][15].

Although research in the field continues to progress, excitement around agrivoltaics remains high enough that commercialization is well underway. Globally, the installed capacity of the APV continues to climb. It is estimated that 2200 systems have been installed worldwide since 2014 (Japan is probably the country where the most agrivoltaic farms were installed, with over 1992 APV farms which produced about 0.8% of total PV energy in 2019), leading to a capacity of about 2.8 GWp as of January 2020 [16]. From the results of the experimental farm in Montpellier, Sun’Agri (FR) was founded in cooperation with Sun’R group. In 2018, the first agrivoltaic field was built in the east Pyrenean region (France). This field has a capacity of 2.2 MWp installed on 4.5 ha of vineyards (Figure 3 a). Today, the company focuses on the development of large-scale demonstrator systems of dynamic agrivoltaic technology in orchards, grapes and market gardening. In Italy, together with the University of Piacenza, REM Tec patented an agrivoltaic solar tracking system named Agrovoltaico®. It was examined for maize crop production by Amaducci et al. [17] while Agostini et al. [18] assessed economic and environmental performance . The first two Agrovoltaico systems were installed in 2012 in Castelvetro Piacentino (1.3 MWp, Figure 3 b) and Monticelli d’Ongina (3.2 MWp) in the North of Italy covering an area of 7 ha and 20 ha, respectively. In the Dutch town of Babberich, BayWa r.e. company has installed a 2.7 MWp raspberry agri-PV farm, being the largest agrivoltaic system for fruit production in Europe (Figure 3 c). Semi-transparent PV modules without frames are mounted above the crop with a semi-enclosed single-row system, protecting from weather phenomena, whilst providing better ventilation and reducing the use of pesticides, thereby improving biodiversity in the fields.

Figure 3. First demonstrator projects developed by the following companies: Sun’agri in France (a), REM Tec in Italy (b) and BayWa r.e. in the Netherlands (c). © Sun’agri (a), REM Tec (b), BayWa r.e. (c).

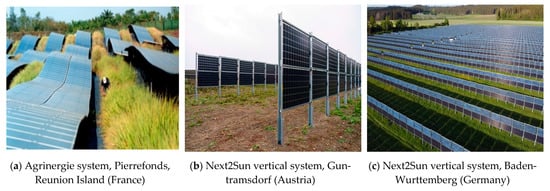

However, concepts that combine farming and energy production on the same site are not limited to stilted solar arrays (stripes) above crops. There are more design criteria with PV modules mounted on the ground (less than 2 m of clearance height). Low height mounting structures are then preferred because of their lower structure-related cost than stilted agrivoltaics and the microclimate, which is generated underneath the solar modules so that crops grow in between the rows of PV arrays or underneath the modules depending on the height of the plants and light requirements. Some studies in this regard have already been carried out in India [19][20] and Malaysia [21][22][23][24] for testing species such as java tea, aloe vera or spinach, achieving higher crop yields for herbal plants while at the same time reducing the module temperature by 0.85%, which may increase the annual energy production up to 2.8% [25], although with a potential risk of pest due the high moisture [23]. Some projects have also reached the market. Agrinergie® is the name of the systems created by Akou Energy group to combine energy generation from PV and crop production, while considering landscape preservation issues. The first project which incorporates this concept was installed in the French tropical island of La Reunion. Two modules’ stripes are deliberately spaced to allow cultivation of lemongrass between them. The ground has not been graded with the natural topography, as this helps to blend harmoniously into the landscape (Figure 4 a). More ground-based projects are being developed with innovative design concepts. Thus, vertical installations with bifacial PV modules facing east and west and leaving the areas between the rows (about 10 m) for agriculture is the idea behind the Next2Sun company (GE). Projects with an installed capacity from 22 kWp (Figure 4 b) to 4.1 MWp (Figure 4 c) have already been developed in Austria and Germany for the cultivation of potatoes and hay and silage, respectively.

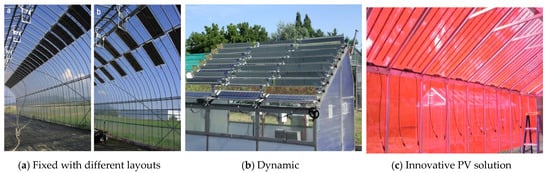

To further control the light delivered to the crops according to their needs, shading levels can be regulated dynamically. PV modules can rotate around fixed axes to adjust the degree of shading inside the greenhouse (Figure 5 b). Sun-tracking mechanisms are then installed in the roof with PV rows used as slats of venetian blinds. The PV blind, oriented parallel to the roof, partially blocks intense sunlight penetration into the greenhouse and generates electricity, and perpendicular to the roof, the sunlight passes through the roof to crops below the PV modules. Already, some researchers have investigated the feasibility of using dynamic systems in greenhouses under different configurations:

- Opaque PV modules mounted above the greenhouse roof at different PV densities and layouts [41][42][43];

- Opaque PV modules integrated into the roof coupling with high reflective mirrors in order to allow for a better collection of reflective light (Figure 5b) [44][45][46][47][48];

- PV blinds installed underneath the greenhouse glass roof using semi-transparent PV technology [49][50][51].

- Opaque PV modules mounted above the greenhouse roof at different PV densities and layouts [41][42][43];

- Opaque PV modules integrated into the roof coupling with high reflective mirrors in order to allow for a better collection of reflective light (Figure 5 b) [44][45][46][47][48];

- PV blinds installed underneath the greenhouse glass roof using semi-transparent PV technology [49][50][51].

Researchers also propose additional strategies for the application of dynamic mechanisms which allow control of the shading in an active way. Colantoni et al. [52] set up a rail system inside a PV greenhouse prototype, where two rows of semi-transparent glass-glass PV modules are installed. The modules translate over the fixed ones, and in combination with the others, enable a variation from 33% to 66% of light transmission by overlapping the transparent part of PV modules located above with PV cells from the PV module placed below (and therefore configuration a dense or porous layout). In all these cases, the shading level is regulated by a threshold parameter, commonly the irradiance level, for the blind rotation or rail movement to adjust the ratio for electricity production and for plant cultivation.

Progress in PV technology has also provided additional possibilities for application in greenhouses. PV modules are not then conceived as partial shading systems where the spacing or coverage must be optimized since the annual solar radiation available inside a greenhouse may decrease with a ratio of 0.8% for each 1% of additional PV cover ratio [37]. The sunlight quality (direct vs. diffuse; availability of PAR) management inside the greenhouse is addressed by different innovative approaches: from using semi-transparent films [53][54], the use of new materials or techniques to transmit to the plant the diffuse component of the light [55] and devices based on spherical silicon micro-cells (1.2 mm of diameter) where the overlapping of the PV cells over the sun barely eclipses the plants [56][57] to sharing the solar spectrum through PV devices which generate electricity outside the PAR regions [58][59][60].

Recently, studies of combining concentrated photovoltaic (CPV) technology with special bended glass modules (an optimized dichroitic polymer film which allows the transmission of the blue light and red light for photosynthesis) has been reported with an efficiency of 6.8% [61][62][63]. CPV technology also allows the possibility to separate direct and diffuse light. Thus, systems that focus direct radiation through Fresnel lenses, transmitting the diffuse sunlight to the crops, have been analyzed to optimize their performance in recent years [64]. In fact, commercial production under this concept is already under way. Swiss startup Insolight patented a system where optical lenses concentrate the direct sunlight onto tiny cells, which cover only 0.5% of the module surface [65].

Along the development of CPV technology, wavelength-selective PV systems which combine luminescent solar concentrator technology (LSC) with PV have also attracted great interest from the scientific community. Luminescent dyes are embedded into a transparent matrix, trapping and guiding some of the incoming solar radiation at certain wavelengths and delivering to PV cells that are integrated into the module (Figure 5 c). Designs to optimize this technology for APV applications have been developed by Corrado et al. [66] to field-test studies to explore its performance and reliability [67]. Additional research shows the potential of this technology over species such basil [68], tomato [58] and microalgae [69].

Customized PV modules to harness specific portions of the solar spectrum are also possible by using thin film semi-transparent devices. Emmott et al. [70] demonstrated the potential of OPV devices in greenhouses modeling the impact on crop growth for a wide range of commercially available organic semiconductor materials. Intensive research on OPV greenhouses currently focuses on developing new optimized devices that minimize the impact on crop yield [71][72][73][74][75], to evaluate performance in real operational conditions [76][77][78][79] and to study of the environmental impacts through the life cycle assessment (LCA) methodology [80][81][82]. Variation in color and transparency are characteristics that can be also achieved by DSSC technology being a potential candidate to be considered as a photo-selective covering for a greenhouse [83][84][85][86][87][88]. Despite the specific features of third-generation PV devices (flexibility, light weight, diverse colors and transparency degree, lower fabrication costs and environmental impact in comparison to silicon-based PV) and the new developments in the field, stability and efficiency are still critical factors which must be improved to promote them as an alternative to PV technologies consolidated at market levels.

2.1. Relevant Design Parameters and Performance Metrics

2.1.1. Height of the Modules from the Ground

The height of the systems from the ground (space in between the modules and the ground surface) is an important design parameter since the use of higher structures, commonly associated with APV, can determine the homogeneity of the radiation availability under the PV modules, improve the connectivity and allow the use of high plants. The closer to the ground the modules are, the higher the heterogeneity of radiation over the crops in the same land unit is (without considering the effects on the surrounding areas).

However, there are also other implications when the modules are installed high on the ground. For instance, taller configurations may result in several public concerns or even rejection due to the negative impact (visibility is acknowledged as one of the complex objective factors that contribute to the visual impact of PV [89]) on areas such as recreation and tourism [90][91][92]. The use of higher mounting structures not only have influence on social acceptance but would also significantly affect the cost of installation and the environmental impact. Higher emissions are related to larger size of the structure for elevating the modules. Serrano et al. [93] shows, an integrated PV parking lot (222 kWp) needs 72 t of steel, accounting for 82 t of CO2 emissions, that, in comparison to the galvanized steel structure of a conventional PV mounted system, generates eight times more CO2 emissions. In the case of PVG, the gutter height also is an important design parameter since it positively affects the cumulated global radiation inside the greenhouse; each additional 1 m of gutter height may increase by 3.8% the yearly global radiation on the PV greenhouse compared to the conventional one [37].

Thus, high APV systems can be beneficial for the plants, as they allow for better solar energy collection; nevertheless, literature also presents some concerns related to possible detrimental effects on the ecological performance of the system.

2.1.2. Spatial Configuration of PV and Type of Crops

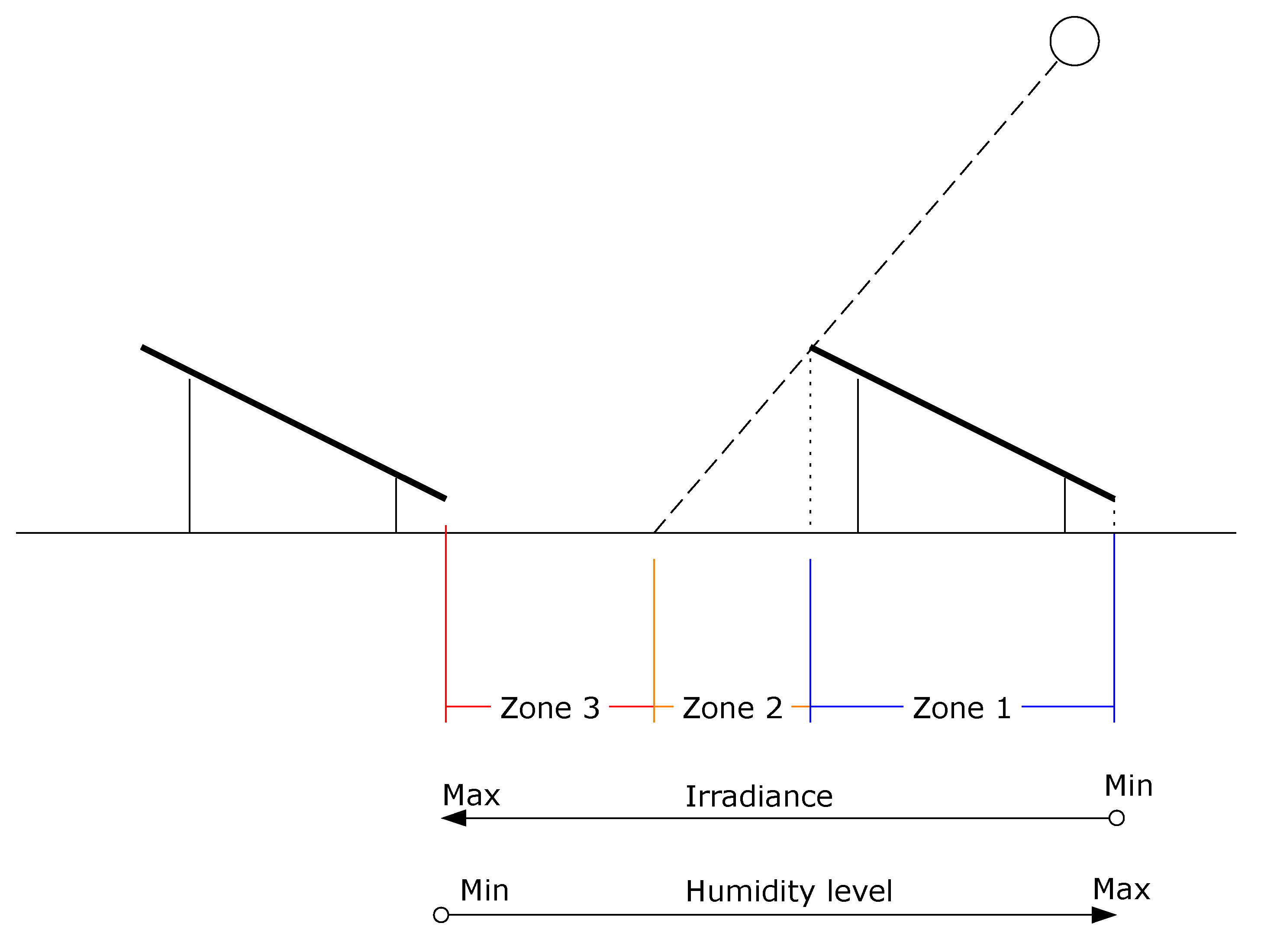

A module’s height and spacing may be adjusted to grow different types of crops depending on plant light, humidity, temperature and space requirements. Thus, for ground-mounted PV installations combined with low-height crops, three different areas are detected (Figure 6): zone 1 with a low irradiance and high humidity level, zone 2 with regular light exposure and enough soil moisture and zone 3, which shows the highest irradiation and lowest humidity [94]. In the same way, APV for orchards or grapevines will need designs with tilt-mounted structures and PV modules placed at higher heights to allow tree growth and farm machinery to pass underneath.

Figure 6. Ground-mounted PV and crop zones (adapted from [94])

Quality aspects (size, fruit coloration, sugar content, etc.) can be affected by the passive influence of the PV modules even though there are no significant yield losses. Ureña et al. [95] shows that tomato cultivated under a PVG with 9.8% of PV covering area is affected negatively in terms of fruit size and color although there is not a significant impact on its yield and price. Bulgari et al. [96] also found a lower content of quality parameters for tomatoes with a configuration of 50% PV coverage besides lower yield by the high PV percentage coverage. Cho et al. [97] detected lower weight and sugar content in grapes cultivated in Korea than those of the control group, delaying the harvest time about 10 days, and the sugar-content level present almost the same level as that of the control site. Conversely, some species including strawberry show good response in terms of quality (with higher chlorophyll content) and yield in comparison to unshaded treatment [98]. Despite the studies mentioned above, there is a little information on the effects on quality parameters of the APV systems since they strongly depend on the season, crop type (with its own adapted strategy in terms of morphology, yield or quality parameters) and microclimatic conditions given by the technical implementation of PV.

PV greenhouses are closed systems and should not be compared to open-field APV, where the effect of shading has no significant effect on air temperature or relative humidity. As covering ratio increases, the microclimate can play a negative role in the PV greenhouse yield production or quality of the plant, reducing the amount of solar radiation and thereby decreasing the air temperature and increasing the humidity. On the contrary, for open-field crops and open-field PV, soil temperature can significantly decrease, affecting the early phase of the plant growth [7].

Currently, the effectiveness of agrivoltaic systems, in terms of crop suitability, is analyzed based on the priority of the biomass yield, which is directly related to the potential benefit in terms of market value.

2.1.3. Performance Metrics

Since the APV system is composed of PV modules and farmland, the impact of land use intensity on the energy performance of the system will determine an important part of the feasibility of the whole system’s solution. In this sense, the land use energy intensity can be quantified by metrics which express the land area use per unit of energy generation (ha/kWh) and/or land area use per unit of capacity (ha/kWp), whereas the performance can be expressed as unit of energy per unit of capacity over the course of a typical or actual year (kWh/kWp/y), as commonly used for solar systems.In order to assess the performance of the APV system, authors suggest using the indicator land equivalent ratio (LER) that leads to comparing the conventional approach (PV and farm set up separately) with the integrated solution on the same land area [3].

The impact of the PV design on agricultural production also can be quantified through the water usage efficiency (WUE) as proposed by [99] and [8]. WUE is then calculated as unit of biomass per unit of water used (commonly kg/m3) against the biomass produced in a control zone without the influence of PV.

The technical feasibility is strongly influenced by the design parameters of the PV system. Design criteria that consider a variation in azimuth and tilt angles of the modules to meet the light requirements for an optimal crop growth affect other parameters such as the land area occupation ratio (LAOR, the ratio between the area of the modules and the area of land that they occupy, expressed in percentage) [100].

High LAOR values provide a high energy yield due to the amount of solar radiation that reaches solar modules, whereas the crop yield will be low. LER is a combination of PV and agriculture efficiency and comprises energy yield (unit of energy per unit of area on a yearly basis, or by time parameters that farmers can set according to the growing season) and agricultural yields, so the value also depends on local factors such as climate and crop under test. LER should only be used as reference for similar climatic conditions, PV system configuration and technology and crop. WUE is a useful parameter to assess the benefits of the food–energy–water nexus in drylands.

References

- A. Goetzberger; A. Zastrow; On the Coexistence of Solar-Energy Conversion and Plant Cultivation. International Journal of Solar Energy 1982, 1, 55-69, 10.1080/01425918208909875.

- Nagashima, Akira. Solar Sharing. Changing the World and Life; Access International Ltd., Eds.; Amazon: Online, 2020; pp. 208.

- C. Dupraz; H. Marrou; G. Talbot; L. Dufour; A. Nogier; Y. Ferard; Combining solar photovoltaic panels and food crops for optimising land use: Towards new agrivoltaic schemes. Renewable Energy 2011, 36, 2725-2732, 10.1016/j.renene.2011.03.005.

- B. Valle; T. Simonneau; F. Sourd; P. Pechier; P. Hamard; T. Frisson; M. Ryckewaert; A. Christophe; Increasing the total productivity of a land by combining mobile photovoltaic panels and food crops. Applied Energy 2017, 206, 1495-1507, 10.1016/j.apenergy.2017.09.113.

- Yassin Elamri; Bruno Cheviron; Annabelle Mange; Cyril Dejean; François Liron; Gilles Belaud; Rain concentration and sheltering effect of solar panels on cultivated plots. Hydrology and Earth System Sciences 2018, 22, 1285-1298, 10.5194/hess-22-1285-2018.

- Y. Elamri; B. Cheviron; J.-M. Lopez; C. Dejean; G. Belaud; Water budget and crop modelling for agrivoltaic systems: Application to irrigated lettuces. Agricultural Water Management 2018, 208, 440-453, 10.1016/j.agwat.2018.07.001.

- H. Marrou; L. Guilioni; L. Dufour; C. Dupraz; J. Wery; Microclimate under agrivoltaic systems: Is crop growth rate affected in the partial shade of solar panels?. Agricultural and Forest Meteorology 2013, 177, 117-132, 10.1016/j.agrformet.2013.04.012.

- H. Marrou; L. Dufour; J. Wery; How does a shelter of solar panels influence water flows in a soil–crop system?. European Journal of Agronomy 2013, 50, 38-51, 10.1016/j.eja.2013.05.004.

- H. Marrou; J. Wery; L. Dufour; C. Dupraz; Productivity and radiation use efficiency of lettuces grown in the partial shade of photovoltaic panels. European Journal of Agronomy 2013, 44, 54-66, 10.1016/j.eja.2012.08.003.

- Greg A. Barron-Gafford; Mitchell A. Pavao-Zuckerman; Rebecca L. Minor; Leland F. Sutter; Isaiah Barnett-Moreno; Daniel T. Blackett; Moses Thompson; Kirk Dimond; Andrea K. Gerlak; Gary P. Nabhan; et al.Jordan E. Macknick Agrivoltaics provide mutual benefits across the food–energy–water nexus in drylands. Nature Sustainability 2019, 2, 848-855, 10.1038/s41893-019-0364-5.

- Elnaz H. Adeh; Stephen P. Good; M. Calaf; Chad W. Higgins; Solar PV Power Potential is Greatest Over Croplands. Scientific Reports 2019, 9, 1-6, 10.1038/s41598-019-47803-3.

- Harshavardhan Dinesh; Joshua M. Pearce; The potential of agrivoltaic systems. Renewable and Sustainable Energy Reviews 2015, 54, 299-308, 10.1016/j.rser.2015.10.024.

- Debaleena Majumdar; Martin J. Pasqualetti; Dual use of agricultural land: Introducing ‘agrivoltaics’ in Phoenix Metropolitan Statistical Area, USA. Landscape and Urban Planning 2018, 170, 150-168, 10.1016/j.landurbplan.2017.10.011.

- Prannay R. Malu; Utkarsh S. Sharma; Joshua Pearce; Agrivoltaic potential on grape farms in India. Sustainable Energy Technologies and Assessments 2017, 23, 104-110, 10.1016/j.seta.2017.08.004.

- Takashi Sekiyama; Akira Nagashima; Solar Sharing for Both Food and Clean Energy Production: Performance of Agrivoltaic Systems for Corn, A Typical Shade-Intolerant Crop. Environments 2019, 6, 65, 10.3390/environments6060065.

- Stephan Schindele; Maximilian Trommsdorff; Albert Schlaak; Tabea Obergfell; Georg Bopp; Christian Reise; Christian Braun; Axel Weselek; Andrea Bauerle; Petra Högy; et al.Adolf GoetzbergerEicke Weber Implementation of agrophotovoltaics: Techno-economic analysis of the price-performance ratio and its policy implications. Applied Energy 2020, 265, 114737, 10.1016/j.apenergy.2020.114737.

- Stefano Amaducci; Xinyou Yin; Michele Colauzzi; Agrivoltaic systems to optimise land use for electric energy production. Applied Energy 2018, 220, 545-561, 10.1016/j.apenergy.2018.03.081.

- A. Agostini; M. Colauzzi; S. Amaducci; Innovative agrivoltaic systems to produce sustainable energy: An economic and environmental assessment. Applied Energy 2020, 281, 116102, 10.1016/j.apenergy.2020.116102.

- Santra, P.; Pande, P.C.; Kumar, S.; Mishra, D.; Singh, R.K.; Agri-Voltaics or Solar Farming: The Concept of Integrating Solar PV Based Electricity Generation and Crop Production in a Single Land Use System. Int. J. Renew. Energy Res 2017, 7, 694-699.

- Beena Patel; Bharat Gami; Vipul Baria; Akash Patel; Pankaj Patel; Co-Generation of Solar Electricity and Agriculture Produce by Photovoltaic and Photosynthesis—Dual Model by Abellon, India. Journal of Solar Energy Engineering 2018, 141, 031014, 10.1115/1.4041899.

- Noor Fadzlinda Othman; Mohammad Effendy Yaacob; Ahmad Suhaizi Mat Su; Juju Nakasha Jaafar; Hashim Hizam; Mohd Fairuz Shahidan; Ahmad Hakiim Jamaluddin; Guangnan Chen; Adam Jalaludin; Modeling of Stochastic Temperature and Heat Stress Directly Underneath Agrivoltaic Conditions with Orthosiphon Stamineus Crop Cultivation. Agronomy 2020, 10, 1472, 10.3390/agronomy10101472.

- N.F. Othman; M.E. Ya'Acob; A.S. Abdul-Rahim; Mohd Shahwahid Othman; Mohd Amran Mohd Radzi; H. Hizam; Yaodong Wang; A.M. Ya'Acob; H.Z.E. Jaafar; Embracing new agriculture commodity through integration of Java Tea as high Value Herbal crops in solar PV farms. Journal of Cleaner Production 2014, 91, 71-77, 10.1016/j.jclepro.2014.12.044.

- N. Fadzlinda Othman; S. Jamian; A. S. Mat Su; M. E. Ya’Acob; Tropical field assessment on pests for Misai Kucing cultivation under agrivoltaics farming system. APPLIED PHYSICS OF CONDENSED MATTER (APCOM 2019) 2019, 2129, 020002, 10.1063/1.5118010.

- N F Othman; A S Mat Su; M E Ya’Acob; Promising Potentials of Agrivoltaic Systems for the Development of Malaysia Green Economy. IOP Conference Series: Earth and Environmental Science 2018, 146, 012002, 10.1088/1755-1315/146/1/012002.

- N.F. Othman; M. Effendy Yaacob; A.S. Abdul-Rahim; H. Hizam; M.M. Farid; Samsuzana Abd Aziz; Inculcating herbal plots as effective cooling mechanism in urban planning. Acta Horticulturae 2017, 1152, 235-242, 10.17660/ActaHortic.2017.1152.32.

- Erdem Cuce; Dewanto Harjunowibowo; Pinar Mert Cuce; Renewable and sustainable energy saving strategies for greenhouse systems: A comprehensive review. Renewable and Sustainable Energy Reviews 2016, 64, 34-59, 10.1016/j.rser.2016.05.077.

- Reda Hassanien Emam Hassanien; Ming Li; Wei Dong Lin; Advanced applications of solar energy in agricultural greenhouses. Renewable and Sustainable Energy Reviews 2015, 54, 989-1001, 10.1016/j.rser.2015.10.095.

- Raúl Aroca-Delgado; José Pérez-Alonso; Ángel Callejón-Ferre; Borja Velázquez-Martí; Compatibility between Crops and Solar Panels: An Overview from Shading Systems. Sustainability 2018, 10, 743, 10.3390/su10030743.

- Akira Yano; Marco Cossu; Energy sustainable greenhouse crop cultivation using photovoltaic technologies. Renewable and Sustainable Energy Reviews 2019, 109, 116-137, 10.1016/j.rser.2019.04.026.

- Marco Cossu; Lelia Murgia; Luigi Ledda; Paola A. Deligios; Antonella Sirigu; Francesco Chessa; Antonio Pazzona; Solar radiation distribution inside a greenhouse with south-oriented photovoltaic roofs and effects on crop productivity. Applied Energy 2014, 133, 89-100, 10.1016/j.apenergy.2014.07.070.

- Wael El Kolaly; Wenhui Ma; Ming Li; Mohammed Darwesh; The investigation of energy production and mushroom yield in greenhouse production based on mono photovoltaic cells effect. Renewable Energy 2020, 159, 506-518, 10.1016/j.renene.2020.05.144.

- K. Ezzaeri; H. Fatnassi; A. Wifaya; A. Bazgaou; A. Aharoune; C. Poncet; A. Bekkaoui; L. Bouirden; Performance of photovoltaic canarian greenhouse: A comparison study between summer and winter seasons. Solar Energy 2020, 198, 275-282, 10.1016/j.solener.2020.01.057.

- H. Fatnassi; C. Poncet; R. Brun; M.M. Müller; N. Bertin; CFD STUDY OF CLIMATE CONDITIONS UNDER GREENHOUSES EQUIPPED WITH PHOTOVOLTAIC PANELS. Acta Horticulturae 2014, 1054, 63-72, 10.17660/actahortic.2014.1054.6.

- A. Yano; M. Kadowaki; A. Furue; N. Tamaki; T. Tanaka; E. Hiraki; Y. Kato; F. Ishizu; S. Noda; Shading and electrical features of a photovoltaic array mounted inside the roof of an east–west oriented greenhouse. Biosystems Engineering 2010, 106, 367-377, 10.1016/j.biosystemseng.2010.04.007.

- Masayuki Kadowaki; Akira Yano; Fumito Ishizu; Toshihiko Tanaka; Shuji Noda; Effects of greenhouse photovoltaic array shading on Welsh onion growth. Biosystems Engineering 2012, 111, 290-297, 10.1016/j.biosystemseng.2011.12.006.

- José Pérez-Alonso; Manuel Pérez-García; M. Pasamontes-Romera; A.J. Callejón-Ferre; Performance analysis and neural modelling of a greenhouse integrated photovoltaic system. Renewable and Sustainable Energy Reviews 2012, 16, 4675-4685, 10.1016/j.rser.2012.04.002.

- Marco Cossu; Andrea Cossu; Paola A. Deligios; Luigi Ledda; Zhi Li; Hicham Fatnassi; Christine Poncet; Akira Yano; Assessment and comparison of the solar radiation distribution inside the main commercial photovoltaic greenhouse types in Europe. Renewable and Sustainable Energy Reviews 2018, 94, 822-834, 10.1016/j.rser.2018.06.001.

- Alvaro Marucci; Ilaria Zambon; Andrea Colantoni; Danilo Monarca; A combination of agricultural and energy purposes: Evaluation of a prototype of photovoltaic greenhouse tunnel. Renewable and Sustainable Energy Reviews 2018, 82, 1178-1186, 10.1016/j.rser.2017.09.029.

- Jiaoliao Chen; Fang Xu; Binjie Ding; Nanye Wu; Zheng Shen; Libin Zhang; Performance analysis of radiation and electricity yield in a photovoltaic panel integrated greenhouse using the radiation and thermal models. Computers and Electronics in Agriculture 2019, 164, 1-13, 10.1016/j.compag.2019.104904.

- Marco Cossu; Akira Yano; Stefania Solinas; Paola A. Deligios; Maria Teresa Tiloca; Andrea Cossu; Luigi Ledda; Agricultural sustainability estimation of the European photovoltaic greenhouses. European Journal of Agronomy 2020, 118, 126074, 10.1016/j.eja.2020.126074.

- Amir Vadiee; Mahmoud Yaghoubi; Viktoria Martin; Yousef Bazargan-Lari; Energy analysis of solar blind system concept using energy system modelling. Solar Energy 2016, 139, 297-308, 10.1016/j.solener.2016.09.039.

- Yuan Gao; Jianfei Dong; Olindo Isabella; Rudi Santbergen; Hairen Tan; Miro Zeman; Guoqi Zhang; Modeling and analyses of energy performances of photovoltaic greenhouses with sun-tracking functionality. Applied Energy 2018, 233-234, 424-442, 10.1016/j.apenergy.2018.10.019.

- T. Alinejad; M. Yaghoubi; A. Vadiee; Thermo-environomic assessment of an integrated greenhouse with an adjustable solar photovoltaic blind system. Renewable Energy 2020, 156, 1-13, 10.1016/j.renene.2020.04.070.

- Alvaro Marucci; Danilo Monarca; Massimo Cecchini; Andrea Colantoni; Andrea Cappuccini; Analysis of internal shading degree to a prototype of dynamics photovoltaic greenhouse through simulation software. Journal of Agricultural Engineering 2015, 46, 144-150, 10.4081/jae.2015.483.

- Alvaro Marucci; Andrea Cappuccini; Dynamic photovoltaic greenhouse: Energy balance in completely clear sky condition during the hot period. Energy 2016, 102, 302-312, 10.1016/j.energy.2016.02.053.

- Alvaro Marucci; Andrea Cappuccini; Dynamic photovoltaic greenhouse: Energy efficiency in clear sky conditions. Applied Energy 2016, 170, 362-376, 10.1016/j.apenergy.2016.02.138.

- Simona Moretti; Alvaro Marucci; A Photovoltaic Greenhouse with Variable Shading for the Optimization of Agricultural and Energy Production. Energies 2019, 12, 2589, 10.3390/en12132589.

- Simona Moretti; Alvaro Marucci; A Photovoltaic Greenhouse with Passive Variation in Shading by Fixed Horizontal PV Panels. Energies 2019, 12, 3269, 10.3390/en12173269.

- Zhi Li; Akira Yano; Marco Cossu; Hidekazu Yoshioka; Ichiro Kita; Yasuomi Ibaraki; Electrical Energy Producing Greenhouse Shading System with a Semi-Transparent Photovoltaic Blind Based on Micro-Spherical Solar Cells. Energies 2018, 11, 1681, 10.3390/en11071681.

- Zhi Li; Akira Yano; Marco Cossu; Hidekazu Yoshioka; Ichiro Kita; Yasuomi Ibaraki; Shading and electric performance of a prototype greenhouse blind system based on semi-transparent photovoltaic technology. Journal of Agricultural Meteorology 2018, 74, 114-122, 10.2480/agrmet.d-17-00047.

- Zhi Li; Akira Yano; Hidekazu Yoshioka; Feasibility study of a blind-type photovoltaic roof-shade system designed for simultaneous production of crops and electricity in a greenhouse. Applied Energy 2020, 279, 115853, 10.1016/j.apenergy.2020.115853.

- Andrea Colantoni; Danilo Monarca; Alvaro Marucci; Massimo Cecchini; Ilaria Zambon; Federico Di Battista; Diego Maccario; Maria Grazia Saporito; Margherita Beruto; Solar Radiation Distribution inside a Greenhouse Prototypal with Photovoltaic Mobile Plant and Effects on Flower Growth. Sustainability 2018, 10, 855, 10.3390/su10030855.

- Alvaro Marucci; Danilo Monarca; Massimo Cecchini; Andrea Colantoni; Alberto Manzo; Andrea Cappuccini; The Semitransparent Photovoltaic Films for Mediterranean Greenhouse: A New Sustainable Technology. Mathematical Problems in Engineering 2012, 2012, 1-14, 10.1155/2012/451934.

- Alvaro Marucci; Adolfo Gusman; Barbara Pagniello; Andrea Cappuccini; Solar radiation inside greenhouses covered with semitransparent photovoltaic film: first experimental results. Journal of Agricultural Engineering 2013, 44, 247-252, 10.4081/jae.2013.291.

- Akira Tani; Suguru Shiina; Kazuki Nakashima; Makio Hayashi; Improvement in lettuce growth by light diffusion under solar panels. Journal of Agricultural Meteorology 2014, 70, 139-149, 10.2480/agrmet.d-14-00005.

- Akira Yano; Mahiro Onoe; Josuke Nakata; Prototype semi-transparent photovoltaic modules for greenhouse roof applications. Biosystems Engineering 2014, 122, 62-73, 10.1016/j.biosystemseng.2014.04.003.

- Marco Cossu; Akira Yano; Zhi Li; Mahiro Onoe; Hidetoshi Nakamura; Toshinori Matsumoto; Josuke Nakata; Advances on the semi-transparent modules based on micro solar cells: First integration in a greenhouse system. Applied Energy 2016, 162, 1042-1051, 10.1016/j.apenergy.2015.11.002.

- Michael E. Loik; Sue A. Carter; Glenn Alers; Catherine E. Wade; David Shugar; Carley Corrado; Devin Jokerst; Carol Kitayama; Wavelength-Selective Solar Photovoltaic Systems: Powering Greenhouses for Plant Growth at the Food-Energy-Water Nexus. Earth's Future 2017, 5, 1044-1053, 10.1002/2016ef000531.

- Changsoon Cho; Kibok Nam; Ga-Yeong Kim; Yeong Hwan Seo; Tae Gyu Hwang; Ji-Won Seo; Jae Pil Kim; Jong-In Han; Jung-Yong Lee; Multi-bandgap Solar Energy Conversion via Combination of Microalgal Photosynthesis and Spectrally Selective Photovoltaic Cell. Scientific Reports 2019, 9, 1-10, 10.1038/s41598-019-55358-6.

- Norbert Osterthun; Nils Neugebohrn; Kai Gehrke; Martin Vehse; Carsten Agert; Spectral engineering of ultrathin germanium solar cells for combined photovoltaic and photosynthesis. Optics Express 2021, 29, 938-950, 10.1364/oe.412101.

- Luqing Liu; Chenggang Guan; Fangxin Zhang; Ming Li; Hui Lv; Yang Liu; Peijun Yao; Jan Ingenhoff; Wen Liu; A novel application for concentrator photovoltaic in the field of agriculture photovoltaics. 13TH INTERNATIONAL CONFERENCE ON CONCENTRATOR PHOTOVOLTAIC SYSTEMS (CPV-13) 2017, 1881, 80008, 10.1063/1.5001446.

- Wen Liu; Luqing Liu; Chenggang Guan; Fangxin Zhang; Ming Li; Hui Lv; Peijun Yao; Jan Ingenhoff; A novel agricultural photovoltaic system based on solar spectrum separation. Solar Energy 2018, 162, 84-94, 10.1016/j.solener.2017.12.053.

- Zhisen Zhang; Fangxin Zhang; Ming Li; Luqing Liu; Hui Lv; Yang Liu; Peijun Yao; Wenjun Liu; Quninglan Ou; Wen Liu; et al.Jan Ingenhoff Progress in agriculture photovoltaic leveraging CPV. AIP Conference Proceedings 2018, 2012, 110006, 10.1063/1.5053554.

- P.J. Sonneveld; G.L.A.M. Swinkels; B.A.J. van Tuijl; H.J.J. Janssen; J. Campen; G.P.A. Bot; Performance of a concentrated photovoltaic energy system with static linear Fresnel lenses. Solar Energy 2011, 85, 432-442, 10.1016/j.solener.2010.12.001.

- Gaël Nardin; César Domínguez; Álvaro Fernando Aguilar; Laetitia Anglade; Mathilde Duchemin; David Schuppisser; Florian Gerlich; Mathieu Ackermann; Laurent Coulot; Blaise Cuénod; et al.Delphine PetriXavier NiquilleNicolas BadelAgata LachowiczMatthieu DespeisseJacques LevratChristophe BallifStephen AskinsRubén NúñezNorman JostGuido VallerottoIgnacio Antón Industrialization of hybrid Si/III–V and translucent planar micro‐tracking modules. Progress in Photovoltaics: Research and Applications 2020, 29, 819-834, 10.1002/pip.3387.

- Carley Corrado; Shin Woei Leow; Melissa Osborn; Emory Chan; Benjamin Balaban; Sue A. Carter; Optimization of gain and energy conversion efficiency using front-facing photovoltaic cell luminescent solar concentratordesign. Solar Energy Materials and Solar Cells 2013, 111, 74-81, 10.1016/j.solmat.2012.12.030.

- Carley Corrado; Shin Woei Leow; Melissa Osborn; Ian Carbone; Kaitlin Hellier; Markus Short; Glenn Alers; Sue A. Carter; Power generation study of luminescent solar concentrator greenhouse. Journal of Renewable and Sustainable Energy 2016, 8, 043502, 10.1063/1.4958735.

- Bernardoni,P.;Vincenzi,D.;Mangherini,G.;Boschetti,M.;Andreoli,A.;Gjestila,M.;Samà,C.;Gila,L.;Palmery,S.;Tonezzer, M.; et al. Improved Healthy Growth of Basil Seedlings under LSC Filtered Illumination. In Proceedings of the 37th European Photovoltaic Solar Energy Conference and Exhibition, Lisbon, Portugal, 7–11 September 2020; pp. 1767–1771.

- Angela M. Detweiler; Cécile E. Mioni; Katie L. Hellier; Jordan J. Allen; Sue A. Carter; Brad M. Bebout; Erich E. Fleming; Carley Corrado; Leslie E. Prufert-Bebout; Evaluation of wavelength selective photovoltaic panels on microalgae growth and photosynthetic efficiency. Algal Research 2015, 9, 170-177, 10.1016/j.algal.2015.03.003.

- Christopher J. M. Emmott; Jason Rohr; Mariano Campoy-Quiles; Thomas Kirchartz; Antonio Urbina; Nicholas Ekins-Daukes; Jenny Nelson; Organic photovoltaic greenhouses: a unique application for semi-transparent PV?. Energy & Environmental Science 2015, 8, 1317-1328, 10.1039/c4ee03132f.

- Fan Yang; Ye Zhang; Yuying Hao; Yanxia Cui; Wenyan Wang; Ting Ji; Fang Shi; Bin Wei; Visibly transparent organic photovoltaic with improved transparency and absorption based on tandem photonic crystal for greenhouse application. Applied Optics 2015, 54, 10232-10239, 10.1364/ao.54.010232.

- Sheng-Yung Chang; Pei Cheng; Gang Li; Yang Yang; Transparent Polymer Photovoltaics for Solar Energy Harvesting and Beyond. Joule 2018, 2, 1039-1054, 10.1016/j.joule.2018.04.005.

- Yuqiang Liu; Pei Cheng; Tengfei Li; Rui Wang; Yaowen Li; Sheng-Yung Chang; Yuan Zhu; Hao-Wen Cheng; Kung-Hwa Wei; Xiaowei Zhan; et al.Baoquan SunYang Yang Unraveling Sunlight by Transparent Organic Semiconductors toward Photovoltaic and Photosynthesis. ACS Nano 2019, 13, 1071-1077, 10.1021/acsnano.8b08577.

- Hui Shi; Ruoxi Xia; Guichuan Zhang; Hin-Lap Yip; Yong Cao; Spectral Engineering of Semitransparent Polymer Solar Cells for Greenhouse Applications. Advanced Energy Materials 2018, 9, 1803438, 10.1002/aenm.201803438.

- Wei Song; Billy Fanady; Ruixiang Peng; Ling Hong; Lirong Wu; Wenxia Zhang; Tingting Yan; Tao Wu; Sanhui Chen; Ziyi Ge; et al. Foldable Semitransparent Organic Solar Cells for Photovoltaic and Photosynthesis. Advanced Energy Materials 2020, 10, 2000136, 10.1002/aenm.202000136.

- Gisele Alves Dos Reis Benatto; Michael Corazza; Bérenger Roth; Franz Schütte; Markus Rengenstein; Suren A. Gevorgyan; Frederik C Krebs; Inside or Outside? Linking Outdoor and Indoor Lifetime Tests of ITO-Free Organic Photovoltaic Devices for Greenhouse Applications. Energy Technology 2016, 5, 338-344, 10.1002/ente.201600335.

- Maayan Friman Peretz; Farhad Geoola; Ibrahim Yehia; Shay Ozer; Asher Levi; Esther Magadley; Roman Brikman; Lavi Rosenfeld; Avi Levy; Murat Kacira; et al.Meir Teitel Testing organic photovoltaic modules for application as greenhouse cover or shading element. Biosystems Engineering 2019, 184, 24-36, 10.1016/j.biosystemseng.2019.05.003.

- Maayan Friman-Peretz; Shay Ozer; Farhad Geoola; Esther Magadley; Ibrahim Yehia; Asher Levi; Roman Brikman; Shelly Gantz; Avi Levy; Murat Kacira; et al.Meir Teitel Microclimate and crop performance in a tunnel greenhouse shaded by organic photovoltaic modules – Comparison with conventional shaded and unshaded tunnels. Biosystems Engineering 2020, 197, 12-31, 10.1016/j.biosystemseng.2020.06.007.

- Esther Magadley; Meir Teitel; Maayan Friman Peretz; Murat Kacira; Ibrahim Yehia; Outdoor behaviour of organic photovoltaics on a greenhouse roof. Sustainable Energy Technologies and Assessments 2020, 37, 100641, 10.1016/j.seta.2020.100641.

- Ai Leon; Keiichi N. Ishihara; Assessment of new functional units for agrivoltaic systems. Journal of Environmental Management 2018, 226, 493-498, 10.1016/j.jenvman.2018.08.013.

- Ai Leon; Keiichi N. Ishihara; Influence of allocation methods on the LC-CO2 emission of an agrivoltaic system. Resources, Conservation and Recycling 2018, 138, 110-117, 10.1016/j.resconrec.2018.06.017.

- Joseph A. Hollingsworth; Eshwar Ravishankar; Brendan O'Connor; Jeremiah Johnson; Joseph F. DeCarolis; Environmental and economic impacts of solar‐powered integrated greenhouses. Journal of Industrial Ecology 2019, 24, 234-247, 10.1111/jiec.12934.

- Jeum-Jong Kim; Mangu Kang; Ock Keum Kwak; Yong-Jin Yoon; Kil Sik Min; Moo-Jung Chu; Fabrication and Characterization of Dye-Sensitized Solar Cells for Greenhouse Application. International Journal of Photoenergy 2014, 2014, 1-7, 10.1155/2014/376315.

- Claire S. Allardyce; Christian Fankhauser; Shaik M. Zakeeruddin; Michael Grätzel; Paul Dyson; The influence of greenhouse-integrated photovoltaics on crop production. Solar Energy 2017, 155, 517-522, 10.1016/j.solener.2017.06.044.

- Elena Barbera; Eleonora Sforza; Andrea Guidobaldi; Aldo Di Carlo; Alberto Bertucco; Integration of dye-sensitized solar cells (DSC) on photobioreactors for improved photoconversion efficiency in microalgal cultivation. Renewable Energy 2017, 109, 13-21, 10.1016/j.renene.2017.03.013.

- N. Roslan; M.E. Ya'Acob; Mohd Amran Mohd Radzi; Y. Hashimoto; D. Jamaludin; G. Chen; Dye Sensitized Solar Cell (DSSC) greenhouse shading: New insights for solar radiation manipulation. Renewable and Sustainable Energy Reviews 2018, 92, 171-186, 10.1016/j.rser.2018.04.095.

- Georgios K. Ntinas; Kalliopi Kadoglidou; Nektaria Tsivelika; Konstantinos Krommydas; Apostolos Kalivas; Parthenopi Ralli; Maria Irakli; Performance and Hydroponic Tomato Crop Quality Characteristics in a Novel Greenhouse Using Dye-Sensitized Solar Cell Technology for Covering Material. Horticulturae 2019, 5, 42, 10.3390/horticulturae5020042.

- Dimitris Chalkias; Christos Charalampopoulos; Stefania Aivali; Aikaterini Andreopoulou; Aggeliki Karavioti; Elias Stathatos; A Di-Carbazole-Based Dye as a Potential Sensitizer for Greenhouse-Integrated Dye-Sensitized Solar Cells. Energies 2021, 14, 1159, 10.3390/en14041159.

- Núria Sánchez-Pantoja; Rosario Vidal; M. Carmen Pastor; Aesthetic impact of solar energy systems. Renewable and Sustainable Energy Reviews 2018, 98, 227-238, 10.1016/j.rser.2018.09.021.

- Noriko Irie; Naoko Kawahara; Ana Maria Esteves; Sector-wide social impact scoping of agrivoltaic systems: A case study in Japan. Renewable Energy 2019, 139, 1463-1476, 10.1016/j.renene.2019.02.048.

- Daniel Ketzer; Nora Weinberger; Christine Rösch; Stefanie B. Seitz; Land use conflicts between biomass and power production – citizens’ participation in the technology development of Agrophotovoltaics. Journal of Responsible Innovation 2019, 7, 193-216, 10.1080/23299460.2019.1647085.

- Daniel Ketzer; Peter Schlyter; Nora Weinberger; Christine Rösch; Driving and restraining forces for the implementation of the Agrophotovoltaics system technology – A system dynamics analysis. Journal of Environmental Management 2020, 270, 110864, 10.1016/j.jenvman.2020.110864.

- Lucía Serrano-Luján; Rafael Garcia-Valverde; Nieves Espinosa; M. Socorro García-Cascales; Juan M. Sánchez-Lozano; Antonio Urbina; Environmental benefits of parking-integrated photovoltaics: a 222 kWp experience. Progress in Photovoltaics: Research and Applications 2013, 23, 253-264, 10.1002/pip.2415.

- Beck,M.;Bopp,G.;Goetzberger,A.;Obergfell,T.;Reise,C.;Schindele,S.CombiningPVandFoodCropstoAgrophotovoltaic– Optimization of Orientation and Harvest. In Proceedings of the 27th European Photovoltaic Solar Energy Conference and Exhibition, Frankfurt (GE), Germany, 24–28 September 2012; pp. 4096–4100.

- Raúl Ureña-Sánchez; Angel Jesus Callejon-Ferre; José Pérez-Alonso; Angel Carreño Ortega; Greenhouse tomato production with electricity generation by roof-mounted flexible solar panels. Scientia Agricola 2012, 69, 233-239, 10.1590/s0103-90162012000400001.

- Bulgari,R.;Cola,G.;Ferrante,A.;Franzoni,G.;Mariani,L.;Martinetti,L.MicrometeorologicalEnvironmentinTraditionaland Photovoltaic Greenhouses and Effects on Growth and Quality of Tomato (Solanum Lycopersicum L.). Ital. J. Agrometeorol. 2015, 20, 27–38.

- Jaiyoung Cho; Sung Min Park; A Reum Park; On Chan Lee; Geemoon Nam; In-Ho Ra; Application of Photovoltaic Systems for Agriculture: A Study on the Relationship between Power Generation and Farming for the Improvement of Photovoltaic Applications in Agriculture. Energies 2020, 13, 4815, 10.3390/en13184815.

- Yilian Tang; Xun Ma; Ming Li; Yunfeng Wang; The effect of temperature and light on strawberry production in a solar greenhouse. Solar Energy 2019, 195, 318-328, 10.1016/j.solener.2019.11.070.

- Elnaz Hassanpour Adeh; John S. Selker; Chad W. Higgins; Remarkable agrivoltaic influence on soil moisture, micrometeorology and water-use efficiency. PLOS ONE 2018, 13, e0203256, 10.1371/journal.pone.0203256.

- Alessandra Scognamiglio; ‘Photovoltaic landscapes’: Design and assessment. A critical review for a new transdisciplinary design vision. Renewable and Sustainable Energy Reviews 2015, 55, 629-661, 10.1016/j.rser.2015.10.072.