The exposure to extreme temperatures in workplaces involves physical hazards for workers. A poorly acclimated worker may have lower performance and vigilance and therefore may be more exposed to accidents and injuries. Due to the incompatibility of the existing standards implemented in some workplaces and the lack of thermoregulation in many types of protective equipment, thermal stress remains one of the most frequent physical hazards in many work sectors. In order to provide a better protection of individuals against thermal aggressors, the scientific community has been interested in the development of the textile-xtile based or flexible temperature sensors that can be integrated into personal protective equipment. These sensors can measure the skin temperature and monitor the microclimate temperature between the body and the clothing or the outside temperature during exposure to thermal aggressors.

- thermoregulation

- personal protective equipment

- smart textiles

- flexible electronics

- performance

1. Thermal Stress in the Workplace

2. Personal Protective Equipment Design Challenges

3. Temperature Sensor

3.1. Methods to Measure Body Temperature

3.2. Flexible Temperature Sensors

3.3. Radio-Frequency Identification (RFID)

3.4. Textile Prototypes with Flexible Temperature Sensors

3.5. Commercial Textile with Temperature Sensors

3.6. Apparels Measuring Thermal Stress

| Technology Used | Integration Method | Operating Temperature Range | Reference | ||||||

|---|---|---|---|---|---|---|---|---|---|

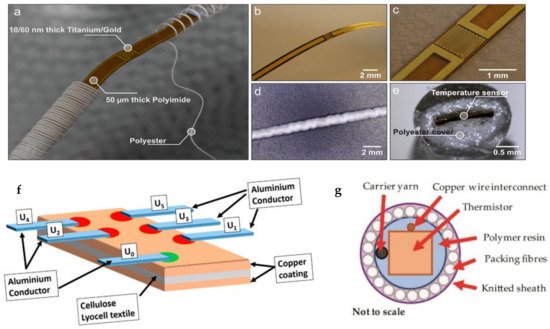

| Temperature-sensing yarns incorporated in a knitted fabric | An off-the-shelf thermistor encapsulated into a polymer resin Multi-Cure | ® | 9-20801 (Dymax Inc.) micro-pod embedded within the fibers of a polyester yarn | Physiologically relevant temperature range of 25–38 °C | [78] | ||||

| Electronic temperature sensing yarn | Knitted polyester-based armband demonstrator using a polyester yarn with embedded thermistor encapsulated into a polymer resin Multi-Cure | ® | 9-20801 (Dymax Inc.) and connected to an Arduino Pro Min Hardware | Tested to measure the temperature of a hot object of 65 °C | [83] | ||||

| Yarn with embedded thermistor | NTC thermistor soldered to copper interconnects and encapsulated with a cylindrical micro-pod made of conductive resin (Multi-Cure | ® | 9-20801 by Dymax Inc.), then embedded in a polyester yarn | Tested in a range of 0 to 40 °C | [82] | ||||

| Yarn with embedded thermistor | A commercial temperature-sensing element within a polymeric resin micro-pod embedded in the fibers of a polyester yarn | Tested in a range of heating-cooling cycle of 25–38 °C | [81] | ||||||

| Yarn with embedded thermistor | Commercially available NTC thermistor encapsulated in a polymer micro-pod made of UV curable resin (Multi-Cure | ® | 9001-E-V-3.5 by Dymax Inc.) embedded into the fibers of a thermoplastic monofilament yarn spun from liquid crystal polymer (Vectran | TM | ) | NTC sensitive to 25–38 °C | [80] | ||

| Thermistor integrated into textiles | Embedded NTC thermistor and conductive textile yarns (Shieldex | ® | silver plated polyamide) in a belt made of soft bamboo yarns | 25 to 43 °C | [79] | ||||

| Embroidered hybrid resistive thread (RTD) | (1) Hybrid thread composed of three strands. Each strand contains 33 polyester fibers; only one includes one resistive stainless steel microwire, (2) The surface of the hybrid thread is covered by a silicone lubricant, (3) The sensor is embroidered in a helical meander-shaped structure into the carrier fabric made of KERMEL | ® | , Lenzing | TM | FR, Technora, and antistatic fibers | Temperature calibration (40 to 120 °C); rapid temperature cycling (−40 to 125 °C) | [92] | ||

| Embroidered resistance temperature detector (RTD) | Conductive silver R.STAT | ® | yarn as humidity and chromium–nickel austenitic stainless steel yarn as thermal sensors embroidered on a cotton substrate | Validated for 20 °C to 100 °C and 50 to 98% of RH | [90] | ||||

| Temperature-sensing knitted resistance temperature detector (RTD) | Metal wire inlaid in the middle of a rib knitted structure of polyester fabric | Validated at 20–50 °C | [87] | ||||||

| Dip dyed yarn by PEDOT-PSS as RTD |

RTD yarns fabricated by: (1) Dip dyeing cotton yarns in PEDOT-PSS solution, (2) Applying a silver paste applied at the two ends of the dyed threads to form electrical pads, (3) Creating encapsulation layer by dip dyeing the yarns in polystyrene to better protect against dust and moisture | Validated for −50 to 80 °C | [89] | ||||||

| Metal wires incorporated in a knitted fabric (RTD) | Knitted temperature-sensing fabric developed with two different wire inlay densities and a fine metallic filament embedded within the courses of a double-layer knitted structure made of poly acrylic/wool yarns |

Validated at 20–60 °C | [88] | ||||||

| Flexible platinum-based resistance temperature detector (RTD) integrated into textile | Sensors manufactured by electron beam evaporation followed by photolithography on Kapton | ® | polyimide foils, then cutting the foil into stripes each containing an individual sensor and connecting lines, which are then inserted into a fabric during the weaving process | Validated for 25 to 90 °C | [142] | ||||

| Optical fiber Bragg grating (FBG) based sensor integrated into textile | Encapsulating the optical fiber with polymeric (copolymerization of unsaturated methyl ethyl ketone peroxide (MEKP) and cobalt naphthenate) filled strips, then embedding it into the fabric by combining large and small pipes together in fabrication | Validated for body temperature ranging from 33 to 42 °C | [95] | ||||||

| Optical fiber Bragg grating (FBG)-based sensor integrated into textile | A textile structure of hollow double-wall fabric was adopted as a base, and quasi-distributed FBG sensors were embedded by the methods of cross-walls and between-walls for smart fabric sensor development | Validated in a T | env | range of 20 to 130 °C with 10 °C steps and then decrease back to 20 °C with the same procedure | [96] | ||||

| Textile thermocouple | Four different textile thermocouples: (1) Flat textile composed of pairs of textile electrodes: graphite non-woven—woven fabric with nirtil static fibers, (2) Linear textiles composed of pairs of textile electrodes: thread of Nitinol—static fibers—thread of steel fibers, (3) Flat linear thermocouple manufactured from pairs of electrodes: graphite nonwoven—silver-covered polyamide yarn, (4) Hybrid thermocouple composed of pairs of electrodes: steel knitted fabric—constantan wire |

Validated for temperatures up to 70 °C and 90 °C | [86] | ||||||

| Thermocouple | (1) T | s | measured by a thermocouple placed at the armpit with an elastic belt made of spandex, (2) T | env | and the heat flux through the garment measured by modified platinum sensor array integrated into the outer garment of firefighters, (3) Sensors associated to a planar textile-based antenna made of conductive yarns | Heat flux sensor is able to operate in the range of −70 to +500 °C | [62] | ||

| Textile heat flow sensor | Insertion of a constantan wire within three different textile structures (polyamide-based knit, aramid non-woven, woven aramid-based), followed by a local treatment with polymeric resin to allow the partial copper deposition, then an electrochemical deposition of copper on the constantan wire to obtain a thermo-electrical wire and finally a post-treatment for polymer removal | Tested in a range of 30 and 80 °C and 0 to 150% moisture content | [97] | ||||||

| Sensorized glove/upper-arm strap | (1) A glove with two textile electrodes integrated inside in the proximal phalanx of the index and middle fingers on the inside of the glove and a temperature sensor placed in the tip of the ring finger of the glove, (2) Upper arm strap confectioned with two integrated textile electrodes and a temperature sensor placed in the inner lining of the strap | Validated for T | s | measurements averaging 34 °C | [137] | ||||

| Platinum sensor integrated into a jacket | Modified platinum sensor array (welded on Kapton | ® | polyimide foil) integrated into the outer firefighting garment (composed of external impermeable, thermal insulation Gore-Tex | ® | PTFE membrane, and internal comfort layers) to measure T | env | and the heat flux through the jacket | Able to operate in the range of −70 to +500 °C | [134] |

| Working jacket with integrated sensors | Sensors and wireless communication integrated into a commercialized Wenaas | ® | working jacket, while packing sensors on the textile by vacuum molding using biocompatible silicon, and wiring external sensors to the main sensor module by conductive yarns also coated with silicon after vacuum molding | Verified in a climatic chamber −20 to 25 °C with RH 0% to 50% | [136] | ||||

| Working jacket with integrated sensors | Infrared temperature sensor and two combined humidity–temperature sensors integrated into the jacket in three different areas, using two different packages: (1) sensor enclosed into a pouch made from Gore-Tex Paclite | ® | PTFE membrane, and (2) only the opening of the sensor covered with membrane made form Gore-Tex Paclite | ® | Validated at 22 °C and −5 °C | [135] | |||

| Firefighting clothing with integrated sensors | A firefighting garment with three main integrated components: physiological sensors (including the body temperature), fire-related sensors (including field temperature), and the computing node | N/A | [63] | ||||||

| Sailing garment with integrated sensors | The electronic system is consisted of a master system and a slave system placed inside a waterproof pocket above the cuff of a waterproof sailing top garment made of coated and laminated woven fabrics | N/A | [143] | ||||||

| Thermosensing armband, glove, and sock based on yarn with embedded thermistor | Temperature-sensing garments (armband and glove made of polyamide/spandex, sock made of cotton) containing thermistor soldered to copper interconnects and encapsulated with a cylindrical micro-pod made of conductive resin (Multi-Cure | ® | 9-20801 by Dymax Inc.) | Tested at 23 °C and validated for T | s | ranging from 28 to 33 °C | [138] | ||

| Printed polymeric PTC and NTC thermistors | Carbon-based paste screen printed on Kapton | ® | polyimide foil | Validated at a range of 30 to 42 °C | [43] | ||||

| Printed polymeric PTC and NTC thermistors | Resistive inks screen printed on polyethylene naphthalate and protected by a dielectric ink (CYTOP-like fluro-polymer) as a passivation layer, followed by a plasma post-treatment | Validated at a range of 20 to 90 °C | [116] | ||||||

| Printed polymeric NiO based NTC thermistor | Stable NiO ink (suspended in ethylene glycol aqueous solution) inkjet-printed in between two silver conductive electrodes on a polyimide substrate, then thermally cured at 200 °C for an hour | Validated at a range of 25 to 250 °C | [117] | ||||||

| Printed resistance temperature detector (RTD) | Silver complex ink inkjet printed on Kapton | ® | polyimide foil | Validated at a range of 20 to 60 °C | [119] | ||||

| Printed smart bandage | Temperature sensor fabricated by PEDOT-PSS/CNT paste screen-printed on a nm-thick-SiO 2-coated Kapton | ® | polyimide, then cured at 100 °C for 10 min | Validated for 22 to 48 °C (normal T | s | ≈ 29 to 31 °C) | [121] | ||

| Printed wearable resistance temperature detector (RTD) | Shadow mask printing of PEDOT-PSS/CNT suspension on SiO | 2 | -coated Kapton | ® | polyimide substrate and silver electrodes by screen printing | Validated at a range of 22 to 50 °C | [120] | ||

| Printed paper-based thermal sensor | (1) Ionic liquid, 1-ethyl-3-methyl imidazolium bis (trifluoromethylsulfonyl) imide ([EMIm][Tf2N]), inkjet printed on a regular paper, (2) Two gold electrodes deposited on the paper substrate through magnetic sputtering evaporation setup | Thermal responses validated at 25 and 45 °C | [123] | ||||||

| Printed resistance temperature detector (RTD) on paper | Silver nanoparticle ink inkjet printed on specific coated paper substrate | Validated at a range of −20 to 60 °C | [103] | ||||||

| Stretchable graphene-based resistance temperature detector (RTD) | (1) Silver nanowire first filtered as electrodes using polycarbonate filter membranes, (2) Graphene/nanocellulose dispersion then filtered as the detection channel to connect electrodes, (3) PDMS base and curer poured on top of the filtered films, then degassed and cured, (4) Solidified PDMS with embedded silver electrodes and graphene detection channels peeled off from the polycarbonate membrane to obtain a stretchable device | Validated at a range of 30–100 °C | [111] | ||||||

| Graphene-based wearable resistance temperature detector (RTD) | Graphene nanowalls deposited on a polydimethylsiloxane substrate with plasma-enhanced chemical vapor deposition technique and polymer-assisted transfer method, associated to silver paste electrodes | Validated at 35 to 45 °C | [114] | ||||||

| Flexible graphene-based resistance temperature detector (RTD) | Graphene oxide-based formulation printed on Kapton | ® | polyimide and polyethylene terephthalate substrates reduced by infrared heat lamp and then annealed at 200 °C | Validated in a range of 30 to 180 °C | [113] | ||||

| Flexible composite-based resistance temperature detector (RTD) | Ni microparticle-filled binary polymer of polyethylene and polyethylene oxide composites with copper tape strips-based RFID antenna | Validated at a range of 35 to 42 °C | [85] | ||||||

| Flexible composite-based resistance temperature detector (RTD) | HCl doped poly-o-methyl aniline/Mn | 3 | O | 4 | nanocomposite spin coated on glass substrate | RT characteristics in the temperature range of 35–185 °C with repeatability in the range of 75–185 °C | [124] | ||

| Flexible composite-based resistance temperature detector (RTD) | Dispersions of multiwall CNT drop casted onto gold electrodes fabricated on a polyimide substrate | Validated in a range of 20 to 60 °C | [127] | ||||||

| Flexible composite-based resistance temperature detector (RTD) | Graphite/PDMS composite dispensed on flexible polyimide films, associated to copper electrodes | Validated at 30 to 110 °C | [126] | ||||||

| Flexible CNT-based composite | Multiwall CNT/polyvinyl benzyl chloride derivative with trimethylamine (PVBC_Et3N) dispersions drop casted onto a gold electrode pair supported on a polyimide film | Validated for 20–40 °C | [128] | ||||||

| Flexible composite-based thermoelectric nanogenerator | A composite of the tellurium nanowires/poly (3-hexylthiophene) (P3HT) dropped onto a Kapton | ® | polyimide flexible substrate associated to two silver electrodes | A heat source of 24.8 °C | [125] | ||||

| E-patch | A modular patch with electronics elements: (1) The thermometer prototyped by attaching a flexible adhesive-backed copper foil on a polyethylene terephthalate substrate, (2) The loop enclosed between two layers of a medical-grade adhesive dressings to attach the tag over the skin | Validated for T | s | ranging from 32.7 to 34.7 °C | [132] | ||||

| E-skin sensor | Two main technologies compared: (1) Arrays of 16 temperature sensors relying on thin serpentine traces of gold, fabricated using microlithographic techniques with thin layers of polyimide, (2) Multiplexed arrays of 64 sensors based on PIN diodes formed by patterned doping of nanoscale membranes of silicon | T ranging from 27 to 31 °C and 30.7 to 32 °C (during mental and physical stimulus tests) | [129] | ||||||

| Dual-heat-flux associated with two double-sensors | Two double-sensors with dual-heat-flux embedded in the neck pillow, while using rubber sheets to simulate the subcutaneous tissue layer of the neck during experiments | Tested at 32–38 °C | [144] | ||||||

| Heater-less deep body temperature probe | Dual-heat-flux method wired sensors placed on the skin, each probe containing the two insulators on a rubber sheet | Validated at 36.5–37.5 °C | [145] | ||||||

| Double-sensor thermometer | The sensor consists of two temperature probes on each side of a standardized insulator placed in a plastic shell | Validated at 36–37.8 °C | [146] | ||||||

| Double-sensor thermometer | Combined heat and skin sensors specially sealed in a polycaprolactone-based enclosing cover | Validated at 10, 25 and 40 °C | [147] | ||||||

| Double-sensor thermometer | Combined skin and heat flux sensors specially sealed in a polycaprolactone-based enclosing cover | Validated for a body temperature of 36–38 °C | [148] | ||||||

| Wearable thermistor | T | s | measured by a textile strip wristband containing a NTC thermistor | 16–42 °C | [149] | ||||

| Wearable thermometer | Array of 4 × 4 Silicon Kelvin precise sensor thermometers integrated into a textile-based affixation aid to the arm, associated with a signal processing chain |

25–41 °C | [150] | ||||||

| Wireless connected temperature sensor | T | s | of the hand measured by a connected temperature sensor | 0–100 °C | [151] | ||||

| Wireless connected temperature sensor | The system consists of a transceiver, a microcontroller, and a digital temperature sensor enclosed in a polycarbonate covering to be placed under the subject’s arm | Validated for T | s | (36.7 to 37.3 °C) in an ambient environment | [152] | ||||

| Long-range RFID tag | RFID rigid tag based on temperature dependence of the frequency of the ring oscillator integrated in a ceramic package and assembled to a matched impedance dipole antenna designed on high-dielectric constant ceramic substrates | 35 to 45 °C | [130] | ||||||

| Epidermal RFID-UHF tag | Tag and antenna layout with adhesive copper transferred on a polycaprolactone membrane attached on a skin with a hypoallergenic cosmetic glue | Validated at 30 to 42.5 °C | [131] | ||||||

| Remote HR and body temperature monitoring | A temperature sensor integrated into a polyurethane flexible substrate wearied on the left thumb, while being connected to a programmed microcontroller | Validated for body temperature range of 36.6 to 37.2 °C | [153] | ||||||

| Remote HR and body temperature monitoring | A portable temperature sensor connected to an analogue microcontroller measuring the body temperature, with the final product being packaged in a small lightweight polymeric package | Validated for body temperature range of 36.6 to 39.4 °C | [154] | ||||||

| Wireless humidity and temperature sensor | A semiconductor temperature and RH sensor affixed to the internal surface of an N95 filtering face-piece respirator made of highly hydrophobic nature of polypropylene | Validated for 30–36 °C and 60–89% RH | [155] | ||||||

| Wearable in-ear thermometer | (1) Thermal sensors integrated into a textile based earbag in order to measure the tympanic temperature inside the ear, T | s | , and T | env | , (2) The earbag added to a resizable headset shielding the outer ear | Validated for the body temperature range of 34.5 and 37 °C | [156] | ||

| Graphene-coated lens of IR thermopile sensors for an ear-based device | (1) Graphene/isopropyl solution drop casted over the silicon substrate of the lens of commercial IR thermopile being associated to a microcontroller collecting the temperature measured, (2) The ear hook-type enclosure 3D printed using Accura Xtreme polymeric resin, while covering the thermopile with a silicone cushion |

Validated at T env of 21 °C and a body temperature range of 36.5 to 37.5 °C | [133] |

3.7. Temperature Sensors Challenges

References

- Lucas, R.A.I.; Epstein, Y.; Kjellstrom, T. Excessive occupational heat exposure: A significant ergonomic challenge and health risk for current and future workers. Extrem. Physiol. Med. 2014, 3, 14.

- Cheung, S.S.; Lee, J.K.W.; Oksa, J. Thermal stress, human performance, and physical employment standards. Appl. Physiol. Nutr. Metab. 2016, 41, S148–S164.

- Jacklitsch, B. Criteria for a Recommended Standard: Occupational Exposure to Heat and Hot Environments; Centers for Disease Control and Prevention: Atlanta, GA, USA, 2016.

- Rowlinson, S.; Yunyanjia, A.; Li, B.; Ju, C. Management of climatic heat stress risk in construction: A review of practices, methodologies, and future research. Accid. Anal. Prev. 2014, 66, 187–198.

- Kovats, R.S.; Hajat, S. Heat Stress and Public Health: A Critical Review. Annu. Rev. Public Health 2008, 29, 41–55.

- Carlsson, I.K.; Dahlin, L.B. Self-reported cold sensitivity in patients with traumatic hand injuries or hand-arm vibration syndrome—An eight year follow up. BMC Musculoskelet. Disord 2014, 15, 83.

- Daanen, H.A.M.; van de Vliert, E.; Huang, X. Driving performance in cold, warm, and thermoneutral environments. Appl. Ergon. 2003, 34, 597–602.

- Pienimäki, T. Cold exposure and musculoskeletal disorders and diseases. A review. Int. J. Circumpolar Health 2002, 61, 173–182.

- Heus, R.; Daanen, H.A.M.; Havenith, G. Physiological criteria for functioning of hands in the cold. Appl. Ergon. 1995, 26, 5–13.

- Tochihara, Y.; Ohkubo, C.; Uchiyama, L.; Komine, H. Physiological Reaction and Manual Performance during Work in Cold Storages. Appl. Human Sci. J. Physiol. Anthropol. 1995, 14, 73–77.

- Flouris, A.D.; Westwood, D.A.; Cheung, S.S. Thermal balance effects on vigilance during 2-h exposures to −20 degrees C. Aviat. Space Environ. Med. 2007, 78, 673–679.

- Annaheim, S.; Saiani, F.; Grütter, M.; Fontana, P.; Camenzind, M.; Rossi, R. Internal and external heat load with fire fighter protective clothing: Data from the lab and the field. Extrem. Physiol. Med. 2015, 4, A100.

- Smith, D.L.; Barr, D.A.; Kales, S.N. Extreme sacrifice: Sudden cardiac death in the US Fire Service. Extrem. Physiol. Med. 2013, 2, 6.

- Truchon, G.; Zayed, J.; Bourbonnais, R.; Lévesque, M.; Deland, M.; Busque, M.-A.; Duguay, P. Thermal Stress and Chemicals: Knowledge Review and the Highest Risk Occupations in Québec; (Report R-834); IRSST: Montréal, QC, Canada, 2014.

- Adam-Poupart, A.; Smargiassi, A.; Busque, M.-A.; Duguay, P.; Fournier, M.; Zayed, J.; Labrèche, F. Summer Temperatures, Ozone Concentrations and Occupational Injuries Accepted for Compensation in Quebec; (Report R-953); IRSST: Montréal, QC, Canada, 2017.

- Kjellstrom, T.; Weaver, H. Climate change and health: Impacts, vulnerability, adaptation and mitigation. NSW Public Health Bull. 2009, 20, 5–9.

- Schulte, P.A.; Chun, H. Climate Change and Occupational Safety and Health: Establishing a Preliminary Framework. J. Occup. Environ. Hyg. 2009, 6, 542–554.

- Dessureault, P.C.; Tellier, A. L’Autosurveillance de l’Astreinte Thermique des Jeunes Travailleurs Affectés à l’Engrangement du Foin; (Report R-580); IRSST: Montréal, QC, Canada, 2008.

- Farooq, A.S.; Zhang, P. Fundamentals, materials and strategies for personal thermal management by next-generation textiles. Compos. Part A Appl. Sci. Manuf. 2021, 142, 106249.

- Dessureault, P.C.; Gressard, B. Cueillette de Données et Vérification de la Concordance Entre la Température de l’Air Corrigée et l’Indice WBGT sous des Ambiances Thermiques Extérieures; (Report R-476); IRSST: Montréal, QC, Canada, 2006.

- Dessureault, P.C.; Oupin, P.; Bourassa, M. Pertinence et Conditions D’utilisation des Indices Thermiques Dans le Contexte Québécois; (Report R-824); IRSST: Montréal, QC, Canada, 2014.

- Dolez, P.I.; Mlynarek, J. Smart materials for personal protective equipment. In Smart Textiles and their Applications; Elsevier: Amsterdam, The Netherlands, 2016; pp. 497–517.

- Shishoo, R. Recent developments in materials for use in protective clothing. Int. J. Cloth. Sci. Technol. 2002, 14, 201–215.

- Jan, E.; Wahlberg, A.B.; Estlander, T.; Maibach, H.I. Protective Gloves for Occupational Use, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2004.

- Bhuiyan, M.A.R.; Shaid, L.W.A.; Shanks, R.A.; Ding, J. Advances and applications of chemical protective clothing system. J. Ind. Text. 2018, 49, 97–138.

- Dolez, P.; Vu-Khanh, T. Recent Developments and Needs in Materials Used for Personal Protective Equipment and Their Testing. Int. J. Occup. Saf. Ergon. JOSE 2009, 15, 347–362.

- Arvinte, C.; Sandu, A.V.; Burduhos-Nergis, D.D.; Sava, M.A.B.; Bejinariu, C. Technical requirements and materials used in firefighters gloves manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2019, 572, 012070.

- Wang, F.; Gao, C. Protective Clothing: Managing Thermal Stress, 1st ed.; Woodhead Publishing: Sawston, UK, August 2014.

- .Truong, Q.T.; Wilusz, E. Chemical and biological protection. Eng. Agric. Environ. Food 2005, 557–594.

- Khalil, E. A Technical Overview on Protective Clothing against Chemical Hazards. AATCC J. Res. 2015, 2, 67–76.

- Dolez, P.I. 5-Smart barrier membranes for protective clothing. Smart Text. Prot. 2013, 148–189.

- Pan, N.; Sun, G. (Eds.) Functional Textiles for Improved Performance, Protection and Health; Woodhead Publishing Series in Textiles; Elsevier: Amsterdam, The Netherlands, 2011.

- Erdem, Ö.; İşmal, R.P. 17—Composite textiles in high-performance apparel. High-Perform. Appar. Mater. Dev. Appl. 2018, 377–420.

- Ravindra, V.; Gadhave, S.K.V.; Pradeep, T.G. Polymers and Polymeric Materials in COVID-19 Pandemic: A Review. J. Polym. Chem. 2020, 10, 66–75.

- Kośla, K.; Olejnik, M.; Olszewska, K. Preparation and properties of composite materials containing graphene structures and their applicability in personal protective equipment: A Review. Rev. Adv. Mater. Sci. 2020, 59, 215–242.

- Williams-Bell, F.M.; Boisseau, G.; McGill, J.; Kostiuk, A.; Hughsona, R.L. Air management and physiological responses during simulated firefighting tasks in a high-rise structure. Appl. Ergon. 2010, 41, 251–259.

- Marchand, D.; Gauvin, C.; Brien-Breton, A.; Aubertin-Leheudre, M.; Tessier, D.; Sadier, Y. Évaluation de Nouvelles Technologies Visant à Réduire le Stress Thermophysiologique Associé au port de Vêtements Individuels de Protection pour les Pompiers; (Report R-891); IRSST: Montréal, QC, Canada, 2015.

- Dolez, P.; Decaens, J.; Buns, T.; Lachapelle, D.; Vermeersch, O.; Mlynarek, J. Analyse du Potentiel d’Application des Textiles Intelligents en Santé et en Sécurité au Travail; (Report R-1029); IRSST: Montreal, QC, Canada, 2018.

- Cao, H. Smart technology for personal protective equipment and clothing. In Smart Textiles for Protection; Elsevier: Amsterdam, The Netherlands, 2013; pp. 229–243.

- Decaens, J.; Vermeersch, O. Wearable technologies for personal protective equipment. In Smart Textiles and their Applications; Elsevier: Amsterdam, The Netherlands, 2016; pp. 519–537.

- Ehrman, A.; Nguyen, T.; Tri, P.N. (Eds.) Nanosensors and Nanodevices for Smart Multifunctional Textiles, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2020.

- Golebiowski, J.; Walczak, S.; Milcarz, S. Design and Simulation of the Comb MWCNT Temperature Sensor for Textronics. Procedia Eng. 2014, 87, 428–431.

- Bielska, S.; Sibinski, M.; Lukasik, A. Polymer temperature sensor for textronic applications. Mater. Sci. Eng. B 2009, 165, 50–52.

- Stoppa, M.; Chiolerio, A. Wearable electronics and smart textiles: A critical review. Sensors 2014, 14, 11957–11992.

- Shi, J.; Liu, S.; Zhang, L.; Yang, B.; Shu, L.; Yang, Y.; Ren, M.; Wang, Y.; Chen, J.; Chen, W.; et al. Smart Textile-Integrated Microelectronic Systems for Wearable Applications. Adv. Mater. 2019, 32, 1901958.

- Ehrmann, A.; Nguyen, T.A.; Nguyen-Tri, P. (Eds.) Chapter 1—Smart Nanotextiles: An Introduction; O’Reilly Media, Inc.: Sevastopol, CA, USA, 2021.

- Arindam Basu, S.J.; Khoiwal, V.S. Development of Smart Textiles for Medical Care. In Functional Textiles and Clothing; Springer: Cham, Switzerland, 2019.

- Yang, L.; Lu, K.; Diaz-Olivares, J.A.; Seoane, F.; Lindecrantz, K.; Forsman, M.; Abtahi, F.; Eklund, J.A.E. Towards Smart Work Clothing for Automatic Risk Assessment of Physical Workload. IEEE Access 2018, 6, 40059–40072.

- Crown, E.M.; Batcheller, J.C. Technical Textiles for Personal Thermal Protection; Elsevier: Amsterdam, The Netherlands, 2016; Volume 2.

- Holmér, I. Protective clothing and heat stress. Ergonomics 1995, 38, 166–182.

- Rezazadeh, M.; Torvi, D.A. Assessment of Factors Affecting the Continuing Performance of Firefighters’ Protective Clothing: A Literature Review. Fire Technol. 2011, 47, 565–599.

- Singha, K.; Kumar, J.; Pandit, P. Recent Advancements in Wearable & Smart Textiles: An Overview. Mater. Today Proc. 2019, 16, 1518–1523.

- Hurford, R.D. 2—Types of smart clothes and wearable technology. In Smart Clothes and Wearable Technology; McCann, J., Bryson, D., Eds.; Woodhead Publishing: Sawston, UK, 2009; pp. 25–44.

- Foo, E.; Gagliardi, N.R.; Schleif, N.; Dunne, L.E. Toward the Development of Customizable Textile-Integrated Thermal Actuators. In Proceedings of the UbiComp ‘17: The 2017 ACM International Joint Conference on Pervasive and Ubiquitous Computing, Maui, HI, USA, 11 September 2017; pp. 29–32.

- Wang, F.; Gao, C.; Kuklane, K.; Holmér, I. A Review of Technology of Personal Heating Garments. Int. J. Occup. Saf. Ergon. 2010, 16, 387–404.

- Roh, J.-S.; Kim, S. All-fabric intelligent temperature regulation system for smart clothing applications. J. Intell. Mater. Syst. Struct. 2016, 27, 1165–1175.

- Donelan, C.; Park, H. Evaluation of Passive Cooling Garments for Thermal Comfort Based on Thermal Manikin Tests. AATCC J. Res. 2016, 3, 1–11.

- Mokhtari Yazdi, M.; Sheikhzadeh, M. Personal cooling garments: A review. J. Text. Inst. 2014, 105, 1231–1250.

- Babu, V.; Ramesh, A.A. Thermo regulated clothing with phase change materials. J. Text. Eng. Fash. Technol. 2018, 4, 344–347.

- Salaün, F. Phase Change Materials for Textile Application, Textile Industry and Environment; Körlü, A., Ed.; IntechOpen: London, UK, 2019.

- Zarma, I. Thermal Energy Storage in Phase Change Materials: Applications, Advantages and Disadvantages. In Proceedings of the 1st International Cnferecne of Chemical, Energy and Environmental Engineering, Alexandria, Egpyt, 28 November 2017.

- Hertleer, C.; Odhiambo, S.; Van Langenhove, L. Protective clothing for firefighters and rescue workers. In Smart Textiles for Protection; Elsevier; Woodhead Publishing: Amsterdam, The Netherlands; Sawston, UK, 2013; pp. 338–363.

- Bu, Y.; Wu, W.; Zeng, X.; Koehl, L.; Tartare, G. A Wearable Intelligent System for Real Time Monitoring Firefighter’s Physiological State and Predicting Dangers. In Proceedings of the 2015 IEEE 16th International Conference on Communication Technology (ICCT), Hangzhou, China, 18–21 October 2015; pp. 429–432.

- Dias, D.; Paulo Silva Cunha, J. Wearable Health Devices—Vital Sign Monitoring, Systems and Technologies. Sensors 2018, 18, 2414.

- Majumder, S.; Mondal, T.; Deen, M. Wearable Sensors for Remote Health Monitoring. Sensors 2017, 17, 130.

- Kang, L.; Shi, Y.; Zhang, J.; Huang, C.; Zhang, N.; He, Y.; Li, W.; Wang, C.; Wu, X.; Zhou, X.; et al. A flexible resistive temperature detector (RTD) based on in-situ growth of patterned Ag film on polyimide without lithography. Microelectron. Eng. 2019, 216, 111052.

- Butts, C.L.; Smith, C.R.; Ganio, M.S.; McDermott, B.P. Physiological and perceptual effects of a cooling garment during simulated industrial work in the heat. Appl. Ergon. 2017, 59, 442–448.

- Moran, D.S.; Shitzer, A.; Pandolf, K.B. A physiological strain index to evaluate heat stress. Am. J. Physiol.-Regul. Integr. Comp. Physiol. 1998, 275, R129–R134.

- Petruzzello, S.J.; Gapin, J.I.; Snook, E.; Smith, D.L. Perceptual and physiological heat strain: Examination in firefighters in laboratory- and field-based studies. Ergonomics 2009, 52, 747–754.

- Tikuisis, P.; McLellan, T.M.; Selkirk, G. Perceptual versus physiological heat strain during exercise-heat stress. Med. Sci. Sports Exerc. 2002, 34, 1454–1461.

- Buller, M.J.; Tharion, W.J.; Cheuvront, S.N.; Montain, S.J.; Kenefick, R.W.; Castellani, J.; Latzka, W.A.; Roberts, W.S.; Richter, M.; Jenkins, O.C.; et al. Estimation of human core temperature from sequential heart rate observations. Physiol. Meas. 2013, 34, 781–798.

- Buller, M.J.; Tharion, W.J.; Duhamel, C.M.; Yokota, M. Real-time core body temperature estimation from heart rate for first responders wearing different levels of personal protective equipment. Ergonomics 2015, 58, 1830–1841.

- Xu, X.; Karis, A.J.; Buller, M.J.; Santee, W.R. Relationship between core temperature, skin temperature, and heat flux during exercise in heat. Eur. J. Appl. Physiol. 2013, 113, 2381–2389.

- Richmond, V.L.; Davey, S.; Griggs, K.; Havenith, G. Prediction of core body temperature from multiple variables. Ann. Occup. Hyg. 2015, 59.

- Hatamie, A.; Angizi, S.; Saurabh, K.; Mouli, P.C.; Abdolreza, S.; Magnus, W.; Malhotra Bansi, D. Review—Textile Based Chemical and Physical Sensors for Healthcare Monitoring. J. Electrochem. Soc. 2020, 167, 037546.

- Khan, Y.; Ostfeld, A.E.; Lochner, C.M.; Pierre, A.; Arias, A.C. Monitoring of Vital Signs with Flexible and Wearable Medical Devices. Adv. Mater. 2016, 28, 4373–4395.

- Honarvar, M.G.; Latifi, M. Overview of wearable electronics and smart textiles. J. Text. Inst. 2017, 108, 631–652.

- Lugoda, P.; Hughes-Riley, T.; Morris, R.; Dias, T. A Wearable Textile Thermograph. Sensors 2018, 18, 2369.

- Chen, W.; Dols, S.; Bambang, O.S.; Loe, F. Monitoring Body Temperature of Newborn Infants at Neonatal Intensive Care Units Using Wearable Sensors. In Proceedings of the Fifth International Conference, Corfu, Greece, 10–12 September 2010; p. 188.

- Theodore, H.-R.; Lugoda, P.; Dias, T.; Trabi, C.L.; Morris, R.H. A Study of Thermistor Performance within a Textile Structure. Sensors 2017, 17, 1804.

- Hughes-Riley, T.; Dias, T.; Cork, C. A Historical Review of the Development of Electronic Textiles. Fibers 2018, 6, 34.

- Pasindu, L.; Dias, T.; Hughes-Riley, T.; Morris, R. Refinement of Temperature Sensing Yarns. Proceedings 2017, 2, 123.

- Lugoda, P.; Dias, T.; Morris, R. Electronic Temperature Sensing Yarn. J. Multidiscip. Eng. Sci. Stud. 2015, 1, 100–103.

- Tao, X.; Koncar, V. 25—Textile electronic circuits based on organic fibrous transistors. In Smart Textiles and their Applications; Woodhead Publishing: Oxford, UK, 2016; pp. 569–598.

- Jeon, J.; Lee, H.-B.-R.; Bao, Z. Flexible Wireless Temperature Sensors Based on Ni Microparticle-Filled Binary Polymer Composites. Adv. Mater. 2013, 25, 850–855.

- Ziegler, S.; Frydrysiak, M. Initial Research into the Structure and Working Conditions of Textile Thermocouples. Fibres Text. East. Eur. 2008, 17, 84–88.

- Husain, M.D.; Kennon, R.; Dias, T. Design and fabrication of Temperature Sensing Fabric. J. Ind. Text. 2014, 44, 398–417.

- Husain, M.; Kennon, R. Preliminary Investigations into the Development of Textile Based Temperature Sensor for Healthcare Applications. Fibers 2013, 10, 2–10.

- Lee, J.-W.; Han, D.-C.; Shin, H.-J.; Yeom, S.-H.; Ju, B.-K.; Lee, W. PEDOT:PSS-Based Temperature-Detection Thread for Wearable Devices. Sensors 2018, 18, 2996.

- Soukup Radek, H.A.; Lukas, M.; Jan, R. Textile Based Temperature and Humidity Sensor Elements for Healthcare Applications. In Proceedings of the 2014 37th ISSE International Spring Seminar in Electronics Technology (ISSE), Dresden, Germany, 7–11 May 2014; pp. 407–411.

- Tyler, D.J. 17—Joining of wearable electronic components. In Joining Textiles; Jones, I., Stylios, G.K., Eds.; Woodhead Publishing: Sawston, UK, 2013; pp. 507–535.

- Polanský, R.; Soukup, R.; Řeboun, J.; Kalčík, J.; Moravcová, D.; Kupka, L.; Švantner, M.; Honnerová, P.; Hamáček, A. A novel large-area embroidered temperature sensor based on an innovative hybrid resistive thread. Sens. Actuators A Phys. 2017, 265, 111–119.

- Guo, L.; Bashir, T.; Bresky, E.; Persson, N.K. 28—Electroconductive textiles and textile-based electromechanical sensors—integration in as an approach for smart textiles. In Smart Textiles and their Applications; Koncar, V., Ed.; Woodhead Publishing: Oxford, UK, 2016; pp. 657–693.

- Ivanov, I.I.; Skryshevsky, V.A.; Belarouci, A. Porous Bragg reflector based sensors: Ways to increase sensitivity. Sens. Actuators A Phys. 2020, 315, 112234.

- Li, H.; Yang, H.; Li, E.; Liu, Z.; Wei, K. Wearable sensors in intelligent clothing for measuring human body temperature based on optical fiber Bragg grating. Opt. Express 2012, 20, 11740.

- Xiang, Z.; Wan, L.; Gong, Z.; Zhou, Z.; Ma, Z.; OuYang, X.; He, Z.; Chan, C.C. Multifunctional Textile Platform for Fiber Optic Wearable Temperature-Monitoring Application. Micromachines 2019, 10, 866.

- Codau, T.-C.; Onofrei, E.; Bedek, G.; Dupont, D.; Cochrane, C. Embedded textile heat flow sensor characterization and application. Sens. Actuators A Phys. 2015, 235, 131–139.

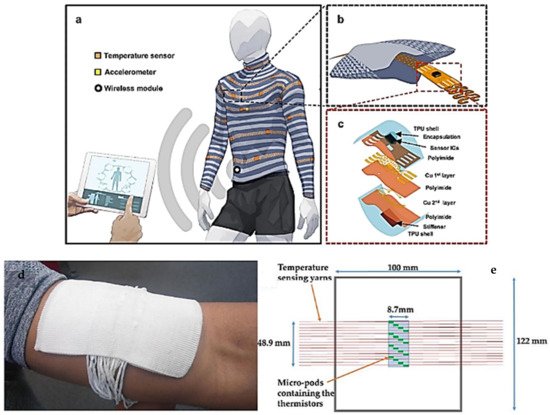

- Wicaksono, I.; Tucker, C.; Sun, T.; Guerrero, C.; Liu, C.; Woo, W.; Pence, E.; Dagdeviren, C. A tailored, electronic textile conformable suit for large-scale spatiotemporal physiological sensing in vivo. NPJ Flex. Electron. 2020, 4, 5.

- Xu, K.; Timothy, Y.C.; Okhai, A.; Snyman, L.W. Micro optical sensors based on avalanching silicon light-emitting devices monolithically integrated on chips. Opt. Mater. Express 2019, 9, 3985–3997.

- Castano, L.M.; Flatau, A.B. Smart fabric sensors and e-textile technologies: A review. Smart Mater. Struct. 2014, 23, 053001.

- du Plessis, M.; Wen, H.; Bellotti, E. Temperature characteristics of hot electron electroluminescence in silicon. Opt. Express 2015, 23, 12605–12612.

- Hu, J.; Meng, H.; Li, G.; Ibekwe, S.I. A review of stimuli-responsive polymers for smart textile applications. Smart Mater. Struct. 2012, 21, 053001.

- Xu, B.; Tang, G.; He, C.Q.; Yan, X.X. Flexible Temperature Microsensor for Application of High-Intensity Focused Ultrasound. Sens. Mater. 2017, 29, 1713–1722.

- Vuorinen, T.; Niittynen, J.; Kankkunen, T.; Kraft, T.M.; Mäntysalo, M. Inkjet-Printed Graphene/PEDOT:PSS Temperature Sensors on a Skin-Conformable Polyurethane Substrate. Sci. Rep. 2016, 6, 35289.

- Li, H.; Ding, J.; Yuan, N.; Xu, J.; Zhou, X.; Dai, S.; Chen, B. Visual and flexible temperature sensor based on a pectin-xanthan gum blend film. Org. Electron. 2018, 59, 243–246.

- You, X.; Pak, J.J. Graphene-based field effect transistor enzymatic glucose biosensor using silk protein for enzyme immobilization and device substrate. Sens. Actuators B Chem. 2014, 202, 1357–1365.

- Mahadeva, S.K.; Yun, S.; Kim, J. Flexible humidity and temperature sensor based on cellulose–polypyrrole nanocomposite. Sens. Actuators A Phys. 2011, 165, 194–199.

- Peng, B.; Ren, X.; Wang, Z.; Wang, X.; Roberts, R.C.; Chan, P.K.L. High performance organic transistor active-matrix driver developed on paper substrate. Sci. Rep. 2014, 4, 6430.

- Hong, S.Y.; Lee, Y.H.; Park, H.; Jin, S.W.; Jeong, Y.R.; Yun, J.; You, I.; Zi, G.; Ha, J.S. Stretchable Active Matrix Temperature Sensor Array of Polyaniline Nanofibers for Electronic Skin. Adv. Mater. 2016, 28, 930–935.

- Moser, Y.; Gijs, M.A.M. Miniaturized Flexible Temperature Sensor. J. Microelectromech. Syst. 2007, 16, 1349–1354.

- Yan, C.; Wang, J.; Lee, P.S. Stretchable Graphene Thermistor with Tunable Thermal Index. ACS Nano 2015, 9, 2130–2137.

- Fan, Y.; Zhao, H.; Wei, F.; Yang Yi Ren, T.; Tu, H. A facile and cost-effective approach to fabrication of high performance pressure sensor based on graphene-textile network structure. Prog. Nat. Sci. Mater. Int. 2020, 30, 437–442.

- Kong, D.; Le, L.T.; Li, Y.; Zunino, J.L.; Lee, W. Temperature-Dependent Electrical Properties of Graphene Inkjet-Printed on Flexible Materials. Langmuir 2012, 28, 13467–13472.

- Yang, J.; Wei, D.; Tang, L.; Song, X.; Luo, W.; Chu, J.; Gao, T.; Shi, H.; Du, C. Wearable temperature sensor based on graphene nanowalls. RSC Adv. 2015, 5, 25609–25615.

- Arman Kuzubasoglu, B.; Kursun Bahadir, S. Flexible temperature sensors: A review. Sens. Actuators A Phys. 2020, 315, 112282.

- Aliane, A.; Fischer, V.; Galliari, M.; Tournon, L.; Gwoziecki, R.; Serbutoviez, C.; Chartier, I.; Coppard, R. Enhanced printed temperature sensors on flexible substrate. Microelectron. J. 2014, 45, 1621–1626.

- Huang, C.-C.; Kao, Z.-K.; Liao, Y.-C. Flexible Miniaturized Nickel Oxide Thermistor Arrays via Inkjet Printing Technology. ACS Appl. Mater. Interfaces 2013, 5, 12954–12959.

- Wu, K.; Zhang, H.; Chen, Y.; Luo, Q.; Xu, K. All-Silicon Microdisplay Using Efficient Hot-Carrier Electroluminescence in Standard 0.18μm CMOS Technology. IEEE Electron Device Lett. 2021, 42, 541–544.

- Dankoco, M.D.; Tesfay, G.Y.; Benevent, E.; Bendahan, M. Temperature sensor realized by inkjet printing process on flexible substrate. Mater. Sci. Eng. B 2016, 205, 1–5.

- Honda, W.; Harada, S.; Arie, T.; Akita, S.; Takei, K. Printed Wearable Temperature Sensor for Health Monitoring. In Proceedings of the 2014 IEEE Sensors, Valencia, Spain, 2–5 November 2014; pp. 2227–2229.

- Honda, W.; Harada, S.; Arie, T.; Akita, S.; Takei, K. Wearable, Human-Interactive, Health-Monitoring, Wireless Devices Fabricated by Macroscale Printing Techniques. Adv. Funct. Mater. 2014, 24, 3299–3304.

- Courbat, J.; Kim, Y.B.; Briand, D.; Rooij, N.F. Inkjet Printing on Paper for the Realization of Humidity and Temperature Sensors. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011; pp. 1356–1359.

- Tao, X.; Jia, H.; He, Y.; Liao, S.; Wang, Y. Ultrafast Paper Thermometers Based on a Green Sensing Ink. ACS Sens. 2017, 2, 449–454.

- Kumar Arvind, S.M.L.; Kumar, A.; Rajput, J.K. POMANI-Mn3O4 based thin film NTC thermistor and its linearization for overheating protection sensor. Mater. Chem. Phys. 2015, 156, 150–162.

- Yang, Y.; Lin, Z.H.; Hou, T.; Zhang, F.; Wang, Z.L. Nanowire-composite based flexible thermoelectric nanogenerators and self-powered temperature sensors. Nano Res. 2012, 5, 888–895.

- Shih, W.-P.; Tsao, L.C.; Lee, C.-W.; Cheng, M.-Y.; Chang, C.; Yang, Y.-J.; Fan, K.-C. Flexible Temperature Sensor Array Based on a Graphite-Polydimethylsiloxane Composite. Sensors 2010, 10, 3597–3610.

- Matzeu, G.; Pucci, A.; Savi, S.; Romanelli, M.; Di Francesco, F. A temperature sensor based on a MWCNT/SEBS nanocomposite. Sens. Actuators A Phys. 2012, 178, 94–99.

- Giuliani Alessio, P.M.; Di Francesco, F.; Pucci, A. A new polystyrene-based ionomer/MWCNT nanocomposite for wearable skin temperature sensors. React. Funct. Polym. 2014, 76, 57–62.

- Webb, R.; Chad, B.A.P.; Alex, B.; Yihui, Z.; Jun, Y.K.; Huanyu, C.; Mingxing, S.; Zuguang, B.; Zhuangjian, L.; Yun-Soung, K.; et al. Erratum: Ultrathin conformal devices for precise and continuous thermal characterization of human skin. Nat. Mater 2013, 12, 1078.

- Vaz, A.; Ubarretxena, A.; Zalbide, I.; Pardo, D.; Solar, H.; Garcia-Alonso, A.; Berenguer, R. Full Passive UHF Tag With a Temperature Sensor Suitable for Human Body Temperature Monitoring. IEEE Trans. Circuits Syst. II Express Briefs 2010, 57, 95–99.

- Milici, S.; Amendola, S.; Bianco, A.; Marrocco, G. Epidermal RFID Passive Sensor for Body Temperature Measurements. In Proceedings of the 2014 IEEE International Conference on RFID-Technologies and Applications (RFID-TA), Tampere, Finland, 8–9 September 2014; pp. 140–144.

- Miozzi, C.; Amendola, S.; Bergamini, A.; Marrocco, G. Reliability of a Re-Usable Wireless Epidermal Temperature Sensor in Real Conditions. In Proceedings of the 2017 IEEE 14th International Conference on Wearable and Implantable Body Sensor Networks (BSN), Eindhoven, The Netherlands, 9–12 May 2017; pp. 95–98.

- Chaglla, E.J.; Celik, N.; Balachandran, W. Measurement of Core Body Temperature Using Graphene-Inked Infrared Thermopile Sensor. Sensors 2018, 18, 3315.

- Oliveira, A.; Gehin, C.; Massot, B.; Ramon, C.; Dittmar, A.; McAdams, E. Thermal Parameters Measurement on Fire Fighter: Improvement of the Monitoring System. In Proceedings of the 2010 32nd Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC 2010), Buenos Aires, Argentina, 31 August–4 September 2010; pp. 6453–6456.

- Seeberg, T.M.; Hjelstuen, M.; Austad, H.O.; Larsson, A.; Færevik, H.; Tjønnås, M.S.; Storholmen, T.C.B. Smart Textiles-Safety for Workers in Cold Climate. November 2011. Available online: https://www.sintef.no/projectweb/coldwear/Coldwear (accessed on 30 September 2021).

- Seeberg, T.M.; Vardøy, A.-S.B.; Austad Hanne, O.; Wiggen, O.; Stenersen, H.S.; Liverud, A.E.; Storholmen, T.C.B.; Faerevik, H. Protective Jacket Enabling Decision Support for Workers in Cold Climate. In Proceedings of the 2013 35th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Osaka, Japan, 3–7 July 2013; pp. 6498–6501.

- Fernando, S.; Mohino-Herranz, I.; Javier, F.; Lorena, A.; Ruben, B.; David, A.; Cosme, L.; Roberto, G.-P. Wearable Biomedical Measurement Systems for Assessment of Mental Stress of Combatants in Real Time. Sensors 2014, 14, 7120–7141.

- Lugoda, P.; Hughes Riley, T.; Oliveira, C.; Morris, R.; Dias, T. Developing Novel Temperature Sensing Garments for Health Monitoring Applications. Fibers 2018, 6, 46.

- Liu, Y.; Wang, H.; Zhao, W.; Zhang, M.; Qin, H.; Xie, Y. Flexible, Stretchable Sensors for Wearable Health Monitoring: Sensing Mechanisms, Materials, Fabrication Strategies and Features. Sensors 2018, 18, 645.

- Wang, S. 3D Printing clothing design based on wireless sensors and FPGA. Microprocess. Microsyst. 2020, 103407.

- Duval, C. Quand l’EPI Devient Intelligent; Travail & Sécurité (768); Perspectives, Institut National de Recherche et de Sécurité (INRS): Paris, France, January 2016.

- Kinkeldei, T.; Zysset, C.; Cherenack, K.; Troester, G. Development and Evaluation of Temperature Sensors for Textile Integration. In Proceedings of the 2009 IEEE Sensors, Christchurch, New Zealand, 25–28 October 2009; pp. 1580–1583.

- Kara, S.; Yesilpinar, S.; Yavuz, S.; Taner, A. Design of an electronically equipped sailing garment for improved safety. Ind. Text. 2017, 68, 23–30.

- Sim, S.Y.; Lee, W.K.; Baek, H.J.; Park, K.S.A. A Nonintrusive Temperature Measuring System for Estimating Deep Body Temperature in Bed. In Proceedings of the 2012 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, San Diego, CA, USA, 28 August–1 September 2012.

- Kitamura, K.-I.; Zhu, X.; Chen, W.; Nemoto, T. Development of a new method for the noninvasive measurement of deep body temperature without a heater. Med. Eng. Phys. 2010, 32, 1–6.

- Kimberger, O.; Thell, R.; Schuh, M.; Koch, J.; Sessler, D.I.; Kurz, A. Accuracy and precision of a novel non-invasive core thermometer. Br. J. Anaesth. 2009, 103, 226–231.

- Botonis Petros, C.E.; Kounalakis, S.; Maria, K.; Nickos, G. The Effect of Skin Surface Menthol Application on Rectal Temperature During Prolonged Immersion in Cool and Cold Water. In Proceedings of the 13th International Conference on Environmental Ergonomics, Boston, MA, USA, 2–7 August 2009.

- Gunga, H.-C.; Werner, A.; Stahn, A.; Steinach, M.; Schlabs, T.; Koralewski, E.; Kunz, D.; Belavý, D.L.; Felsenberg, D.; Sattler, F.; et al. The Double Sensor-A non-invasive device to continuously monitor core temperature in humans on earth and in space. Respir. Physiol. Neurobiol. 2009, 169, S63–S68.

- Boano, C.; Lasagni, M.; Römer, K.; Lange, T. Accurate Temperature Measurements for Medical Research Using Body Sensor Networks. In Proceedings of the 14th IEEE International Symposium on Object/Component/Service-Oriented Real-Time Distributed Computing Workshops, Newport Beach, CA, USA, 28–31 March 2011; pp. 189–198.

- Daniele Giansanti, G.M.; Bernhardt, P. Toward the design of a wearable system for contact thermography in telemedicine. Telemed. E-Health 2009, 15.

- Mansor, H.; Shukor, M.H.A.; Meskam, S.S.; Rusli, N.Q.A.M.; Zamery, N.S. Body Temperature Measurement for Remote Health Monitoring System. In Proceedings of the 2013 IEEE International Conference on Smart Instrumentation, Measurement and Applications (ICSIMA), Kuala Lumpur, Malaysia, 25–27 November 2013.

- Javadpour, A.; Memarzadeh-Tehran, H.; Saghafi, F. A Temperature Monitoring System Incorporating an Array of Precision Wireless Thermometers. In Proceedings of the International Conference on Smart Sensors and Application (ICSSA), Kuala Lumpur, Malaysia, 26–28 May 2015; pp. 155–160.

- Miah, M.A.; Kabir, M.H.; Tanveer, M.S.R.; Akhand, M.A.H. Continuous Heart Rate and Body Temperature Monitoring System Using Arduino UNO and Android Device. In Proceedings of the 2015 2nd International Conference on Electrical Information and Communication Technologies (EICT), Khulna, Bangladesh, 10–12 December 2015; pp. 183–188.

- Rahman, M.A.; Barai, A.; Islam, M.A.; Hashem, M.M.A. Development of a Device for Remote Monitoring of Heart Rate and Body Temperature. In Proceedings of the 15th International Conference on Computer and Information Technology (ICCIT), Chittagong, Bangladesh, 22–24 December 2012; pp. 411–416.

- Roberge, R.; Kim, J.-H.; Benson, S. N95 Filtering Facepiece Respirator Deadspace Temperature and Humidity. J. Occup. Environ. Hyg. 2012, 9, 166–171.

- Boano, C.A.; Römer, K. Non-Invasive Measurement of Core Body Temperature in Marathon Runners. In Proceedings of the 10th European Conference on Wireless Sensor Networks (EWSN), Ghent, Belgium, 13 February 2013.

- Cochrane, C.; Hertleer, C.; Schwarz-Pfeiffer, A. 2—Smart textiles in health: An overview. In Smart Textiles and Their Applications; Koncar, V., Ed.; Woodhead Publishing: Oxford, UK, 2016; pp. 9–32.