Absorption Refrigeration Systems (ARS) are potential alternatives to direct expansion (DX) refrigeration systems. This review focuses on the incorporation of an ejector into absorption refrigeration cycles to constitute Hybrid Ejector-Absorption Refrigeration Systems (HEARS). The ejector adds several advantages to the absorption refrigeration systems depending on its location in the cycle. The two prevalent configurations of HEARS are Triple pressure level (TPL-HEARS), and Low Pressure Condenser (LPC-HEARS). Previous studies revealed the preference of the later configuration as it allows lower circulation ratios, enhances the refrigeration effect, and could achieve a COP up to 1. Moreover, LPC configuration is suitable with single, double, and variable effect absorption systems with a COP of above unity. In turn, the TPL-HEARS notably enhances the absorption process particularly when a variable geometry ejector is utilized. This configuration could obtain a COP around 1.1, but only with high-density refrigerant vapor. Lately, to attain the advantages of both configurations; some studies investigated the viability of adding two ejectors to the cycle. This paper meticulously reviews investigations conducted on the emerging dual ejectors-absorption refrigeration technology. This paper reveals the general performance trend and the maximum attainable COP by each type of hybrid ejector-absorption refrigeration system. DEARS and Ejector-driven absorption refrigeration systems (ED-ARS) could achieve COP that ranges between 1.2 and 1.46. The use of a flash tank and a RHE is essential in NH3/H2O HEARS. At high generator temperatures of (120 – 170 °C), DEARS was found to be the system with the less complexity and best performance. Nevertheless, the performance of the DEARS might drop significantly if the heat source temperature is fluctuating. Thence, the variable effect HEARS is considered the best alternative. The capability of HEARS to be integrated with different power generation cycles is also highlighted. Finally, the review presents possible future research opportunities to improve the absorption refrigeration technology.

- absorption refrigeration

- cooling system

- hybrid refrigeration system

- combined ejector absorption system

- dual ejectors

1. Introduction

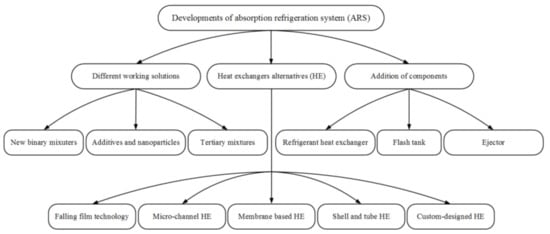

The most commonly used thermally driven refrigeration systems are ejector refrigeration system, adsorption refrigeration system, and absorption refrigeration system. The absorption refrigeration system (ARS) is comprised of absorber, generator (desorber), evaporator, condenser, two throttling (expansion) valves, and solution heat exchanger. ARS could produce large refrigeration power in comparison to the other two thermally driven systems. However, it has low COPs, high maintenance costs, and a large size of the system [4][1]. Therefore, many developments were carried out on the basic cycle to enhance its performance. Predominantly, developments on the ARS’ performance targets enhancing heat and mass transfer, absorption, and desorption processes, and/or miniaturize the size of the system. The developments are usually accomplished by employing different working solution, using more effective heat exchangers’ alternatives, and/or adding components to the basic cycle. Figure 1 illustrates some of the prevalent developments in absorption refrigeration systems.

The first method to improve the absorption refrigeration system is substituting the conventional mixtures (such as NH 3/H 2O and H 2O/LiBr) with other working fluids that have better thermodynamic and thermos-physical properties for higher efficiency and better heat and mass transfer processes. Several binary and tertiary mixtures, as well as mixtures with additives and nanoparticles, were proposed. Sun et al. [5][2] presented a thorough review on working fluids used in absorption cycles, including absorption chillers, heat pumps, and absorption transformers. The authors classified the working fluids into five categories according to prevalent absorbents, while Boman et al. [6][3] developed a thermodynamics and heat transfer screening method for comparison of working pairs used in absorption heat pumps. The authors applied the method to over 40 potential working fluids and, thence, recommended the best alternatives for cooling and heating modes.

Absorption refrigeration systems could also be developed by adding sub-components such as a refrigerant heat exchanger (RHE), flash tank, and ejector. After conducting a thorough review on the use of RHE in an absorption system, Abed et al. [21][4] concluded that adding RHE had slight influence in increasing the COP of ARS (4–8%). Additionally, to increase the thermal load of the evaporator and, consequently, the COP, the effectiveness of the RHE must be high. Moreover, other studies contained reviews of different improvements in absorption refrigeration systems. Besides the aforementioned enhancement aspects, the authors stated some conclusions: For instance, multi-effect cycles are more promising than single-effect ones [2,22][5][6] , combined vapor compression–absorption refrigeration systems outperform the conventional ARS [23][7], and the need for improving the design of the distillation column, rectifying column, and most importantly the stripping section within the generator [21][4]. The authors also recommended to apply the above modifications on domestic refrigerators and air conditioners, increase the stripping stages of the desorber, and using working solutions that prevent corrosion and utilize nanoparticles. In turn, incorporating a flash tank in the ARS increases the COP of the system by means of increasing the quality of refrigerant exiting from the evaporator [24][8]. Moreover, one of the effective utilization and improvement approaches of the ejector is to integrate it with absorption refrigeration systems [25][9]. Research trials carried out on improving the performance of absorption system by utilizing an ejector will be elaborated on in the following sections. Several scholars claimed that it is realizable and economically viable to drive the various configurations of ARS by means of solar thermal systems [26,27][10][11] and photovoltaics [28][12]. Although the claim was proven via several experimental investigations [29][13], the efficient and economic system operation was limited to specific working solutions, most probably NH 3-H 2O [30][14] and water-based solutions [31][15]. Moreover, in solar-driven ARS, H. Sheikhani et al. [32][16] insisted on the importance of using auxiliary devices such as backup heating units and storage tanks.

Regarding review studies done on ejectors and their use in cooling and refrigeration systems, Tashtoush et al. [33][17] carried out a thorough review on ejector design, performance, and applications, whereas Aidoun et al. [34][18] reviewed the present developments in experimentation, modeling, and applications of ejectors for refrigeration and heat pumps. Milazzo and Mazzelli summarized the potential prospective on ejector refrigeration in the future [35][19], while Besagni et al. [36][20] presented a comprehensive review on ejector refrigeration technologies and evaluated the working fluid that suits such technologies, but the hybrid ejector-absorption technology was merely discussed briefly.

2. Ejectors and Hybrid Ejector-Absorption Refrigeration System (HEARS)

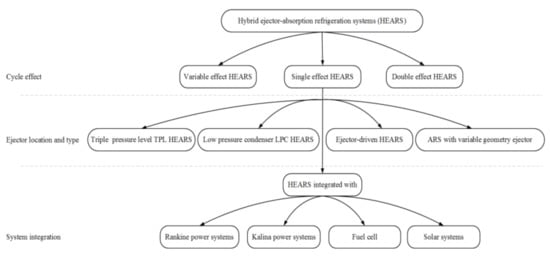

The function produced by ejectors could be utilized in an absorption refrigeration cycle in several ways. The high-pressure energy in the vapor produced in the desorber could be utilized to entrain the vapor exiting from the evaporator. Consequently, the amount of the refrigerant that flows into the condenser and the evaporator increases; thus, the refrigeration power increases. Correspondingly, according to other studies, adding an ejector before the absorber enhances the absorption process [39][21]. These improvements are applicable to various cycle configurations such as single effect, variable effect, and double-effect absorption cycles. Moreover, some studies demonstrated the feasibility of utilizing variable geometry ejector in achieving optimum system performance [40,41][22][23]. Figure 2 shows different categories of hybrid ejector-absorption refrigeration systems that have been investigated in the literature.

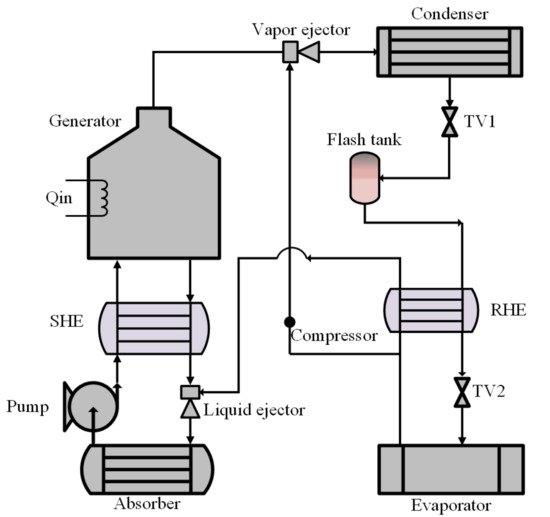

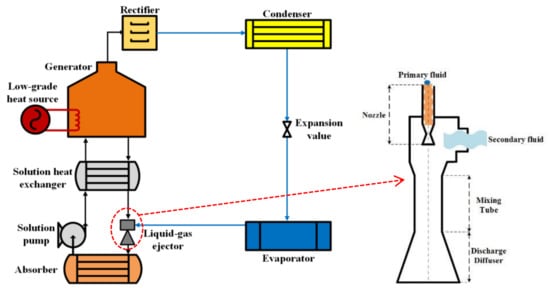

One of the earliest studies about incorporating ejectors into absorption refrigeration systems was done by Kuhlenschmidt in 1973 [42][24]. The author patented a cycle configuration similar to that of double-effect absorption system. The cycle involved an ejector incorporated between the evaporator and the absorber with a secondary flow from a second generator. In the case of single-effect systems, the triple pressure level (TPL) configuration ( Figure 3 ) uses a liquid–gas ejector to entrain refrigerant vapor from the evaporator, and it preserves the absorber at higher pressure than that of the evaporator without any additional energy consumption. Thus, the hybrid ejector-absorption cycle operates at three pressure levels [39,43][21][25]. Moreover, due to the generation of liquid spray, in addition to the considerable sub-cooling of the weak (in-refrigerant) solution in the heat exchanger, the mixing “or absorption” process in the ejector is intensified [39][21]. However, such systems are only operable under high-density refrigerant vapor because liquid-driven ejectors are not suitable for low-density vapor (for example, water vapor, which is used in H 2O/LiBr absorption refrigeration systems) [21][4].

Recently, Sioud and Bellagi [60][26] developed a mathematical model of a hybrid system in which an external steam ejector loop was used to activate an H 2O/liBr single-effect absorption refrigeration system. Numerical results revealed that the entrainment ratio of the ejector was directly proportional to the steam pressure and condenser temperature, while it was inversely proportional to the generator temperature and a negligible effect was recorded for the evaporator temperature. Additionally, at T e = 4 °C, T c = 37 °C, and within a narrow certain range of activation temperature (75 °C < T g < 85 °C) the system achieved high values of COP that were comparable to that of a conventional double-effect configuration. Nevertheless, outside this range the proposed system behaved almost similarly to the conventional single-effect absorption cycle. The authors also investigated a double-effect configuration in which the ejector was used to recompress part of the vapor exiting from the high pressure generator to reheat the solution. Regarding ejector design and performance in such a cycle where the ejector is used in external loop to drive the cycle, the major conclusion of this theoretical study was the relation “ratio” between the high pressure generator and the primary steam pressure that should be kept as low as possible in order to achieve the maximum performance with a driving temperature that is about 20–25 °C less than in the conventional double-effect cycles [61][27].

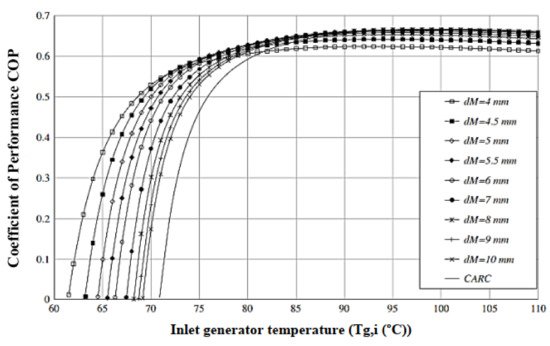

Incorporating an ejector into an absorption cycle driven by a low-grade heat source such as solar energy offers a simple and low-cost solution for the operation within a range of set temperatures [62][28]. Nevertheless, the ejector’s operation mechanism is complicated due to the interactions occur during the mixing of two streams in supersonic and subsonic flow conditions [63][29]. Under variable operating conditions, the geometrical design of the ejector should be carefully carried out to maximize the COP [51][30] or variable geometry ejectors could be utilized, as they were theoretically investigated by Vereda et al. [40][22] where the solution expansion valve was replaced with an ejector whose dimensions were fixed except the nozzle area, which was adjustable. The authors aimed to investigate the effect of ejector geometry on the system performance and to set the optimal range of heat source temperature within which the use of a practical ejector becomes beneficial. The developed simulation used a NH 3-LINO 3 solution, which was based on novel models for detached heat transfer regions in plate heat exchangers. The results were exhibited as a function of external temperatures and the cycle performance was recorded for various ejector mixing tubes with fixed diameters. The results demonstrated that the use of an ejector allows operating with a generator activation temperature of 9 °C less in comparison to the conventional cycle and achieved higher COPs at temperate source temperatures. This adjustable ejector develops three functions: expansion control valve of variable geometry, booster of the absorption process using no external energy, and jet bubble ejector [48][31]. It was observed that the ejector mixing tube had a significant effect on the COP ( Figure 64 ). However, at a fixed diameter of the mixing tube, the max COP of the cycle was less than the COP of the conventional cycle, particularly at smaller diameters. In smaller diameters, there is much reduction in the activation temperature, yet the peak value of the COP was less than that of the conventional cycle. Despite this, and relying on the ejector geometry, the ejector-absorption cycle exhibited a higher COP when the heat source inlet temperature ranged between 81–92 °C. Otherwise, under the considered hypothesis and high source inlet temperature, modifying the ejector-absorption cycle to a conventional cycle, via bypassing the ejector, was more suitable.

3. Dual Ejector-Absorption Refrigeration Systems (DEARS)

In the absorption refrigeration cycle, condensation, evaporation, and absorption processes could be improved by utilizing an ejector in various locations in the cycle, which eventually leads to higher COPs [25][9]. This section pertains to the incorporation of two ejectors in the absorption refrigeration cycle and their effect on the cycle performance.

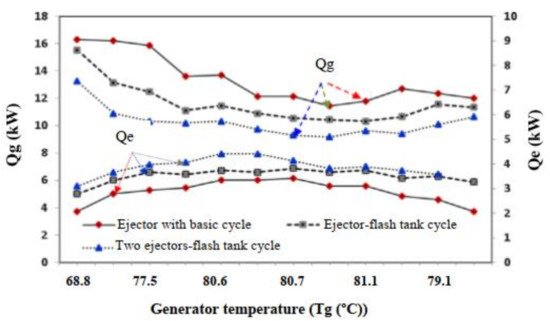

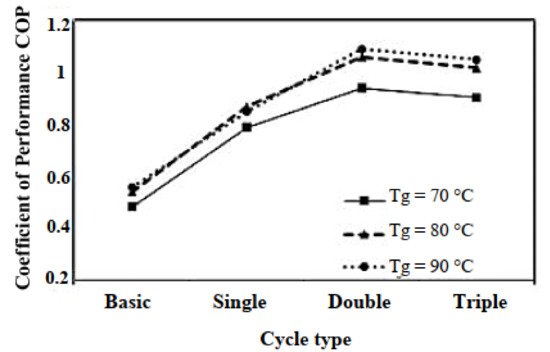

Following the experimental setup of Abed et al. [51][30], Al-Shamani [74][32] proposed the use of the three ejectors ( Figure 115 ) to enhance the system performance. A theoretical study was carried out in which the performance of the NH 3-H 2O absorption refrigeration cycle was investigated for the case of single, double, and triple ejectors. In order to compare the system performances in each case, the simulation was executed under T c = T a = 20–50 °C, T g = 65–100 °C, and T e = −10 to 15 °C to estimate the thermal loads of the main components. The results indicated that the cycle with triple ejectors realized the lowest thermal loads in the evaporator and the generator, whereas the dual-ejector configuration resulted in the highest generator thermal load, with the evaporator thermal load always less than the basic and single-ejector cycles and slightly higher than triple-ejector cycle. Since the use of ejectors enables the exploitation of the high pressure in the flash tank and the low pressure in the evaporator, in addition to the effective utilization of low-grade heat sources with an unpretentious absorption system structure, a trade-off was made between the multi-ejector absorption cycles to determine the best configuration under various operating conditions. Consistently, the dual ejector absorption cycle achieved the greatest COP ( Figure 146 ). This was attributed to fact that the second ejector tolerates higher condenser temperature as it develops the refrigerant quality at the evaporator inlet, whereas the booster in the triple-ejector cycle pushes the flow toward the constant section of the third ejector and, hence, decreases the flow and entrainment ratio of the third ejector [74][32].

Khalili and Farshi [76][33] presented an ARS that involved liquid and vapor ejectors besides RHS. A small compressor was used to compress the amount of vapor exiting from the evaporator and supplied to the vapor ejector as a secondary flow ( Figure 157 ). The simulation results showed that the DEARS exhibited the best performance (highest COP and second law efficiency) in comparison with CARS and TRL-HEARS with activation energy 36 to 55 °C lower than TPL cycle and refrigeration temperature down to −24 °C. In spite of the low evaporator temperatures that indicate great refrigeration capability, attention should be paid to the performance of the vapor ejector as it slightly deteriorates at such low temperatures. The study also pointed out the essentiality of designing the mixing chamber in the liquid ejector with a suitable diameter as it significantly affects the pressure recovery.

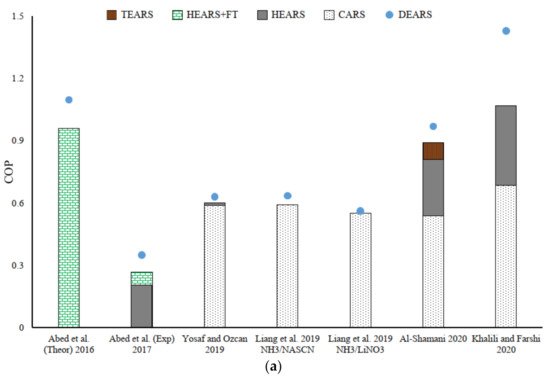

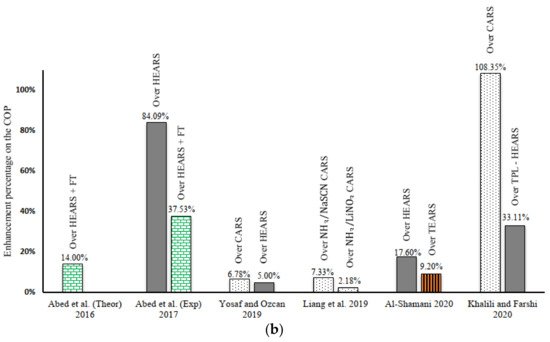

Thus, the incorporation of dual ejectors into the absorption system was proposed in different locations to form different configurations of DEARS. Five different configurations were identified from the literature. The performance of each DEARS was compared to its corresponding CARS and/or HEARS and/or TEARS ( Figure 168 ). In all investigated configurations, the DEARS always revealed a higher performance with respect to the other corresponding systems. as shown in Figure 168 a. The percentages of the COP improvement due to the use of dual ejectors over the other types of absorption refrigeration systems are presented in Figure 168 b. The highest COP of a DEARS was achieved by the multi-pressure levels’ configuration proposed by Khalili and Farshi [76][33]. This configuration could achieve a COP of 1.43 compared to the 1.07 that was obtained by the TPL configuration.

4. Coefficient of Performance of Hybrid Ejector-Absorption Refrigeration Systems (COPHEARS)

A typical single-effect ARS requires a driving temperature in the range of 70–95 °C and achieves a COP between 0.5 and 0.7, whereas a typical double-effect ARS has a COP between 0.8 and 1.2, but it needs a driving temperature that ranges between 120 and 150 °C [77][34]. Those values of COP are too small in comparison to the COPs of vapor compression refrigeration systems. Several studies claimed that single-effect ARS is capable to achieve a COP greater than unity when an ejector is added to the basic absorption cycle [57,78][35][36]. The vast majority of the studies reviewed in this paper calculated the COP as the ratio between the useful thermal energy output in the evaporator ( Qe ) and the heat input ( Qg ) plus the pumping work ( Wp ). Some studies included additional power consumed by components in their design such as booster [73][37] and small compressor [76][33]. Thus, the input power of these miscellaneous components ( Wm ) was added to the denominator in the below equation of COP. It is worth mentioning that none of the reviewed studies considered the energy consumed by the fans used in the heat exchangers. However, for absorption systems that utilize air-cooled heat exchangers, it is important to take into consideration the energy consumed by the fans when evaluating the overall system performance. Ignoring the power consumed by fans can lead to inaccurate calculation of the COPs. COP = Q e Q g + W p + W m

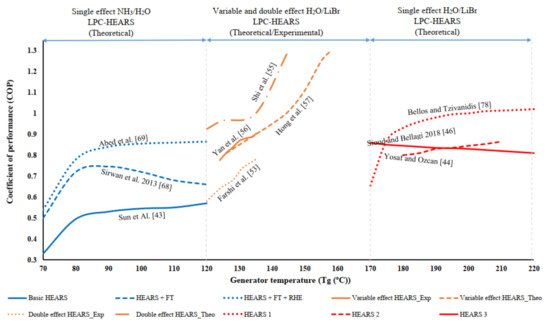

However, the majority of the available HEARS studies were theoretical studies carried out through mathematical modeling by applying thermodynamics laws and the use of computer software. In addition, those high values of the COP were obtained at particular or narrow ranges of operating conditions. The highest COP HEARS values were obtained at high evaporator temperatures and low condenser temperatures. However, some operating conditions were impractical. For instance, R. Sirwan et al. [68][38] obtained a COP HEARS of 1.14 but at evaporation temperature equal to 14 °C, which seems inappropriate for either refrigeration or cooling applications. Similarly, Bellos and Tzivanidis [78][36] claimed that a COP HEARS up to 1.65 is achievable at evaporation temperature of 12.5 °C, but at high generator temperature (T g = 246 °C). This driving temperature is extremely high and unfeasible for single-effect ARS. The experimental studies of the HEARS revealed lower values of maximum COP HEARS . At the same generator temperature, Abed et al. [51][30] increased the COP HEARS from 0.29 to 0.46 by adding a flash tank. Y. Shi et al. [55][39] achieved a COP HEARS of 0.87 but for double-effect configuration at a generator temperature of 200 °C. A higher value could be obtained at a lower generator temperature (T g = 135.5 °C) when Yan et al. [56][40] built and operated a variable effect HEARS that achieved a COP of 0.905. The theoretical COP HEARS of this system was 0.98.

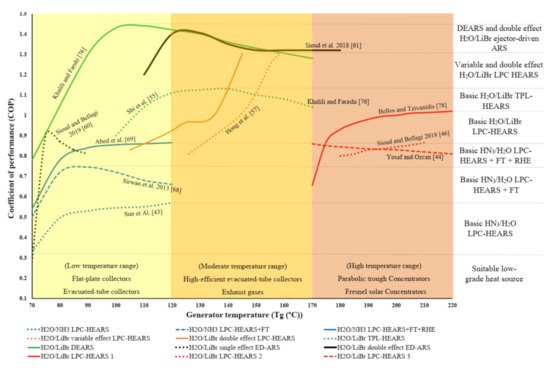

For a generator temperature in the range of 120–170 °C, variable- and double-effect configurations were investigated. The experimental and theoretical studies of the variable-effect HEARS revealed an identical, incremental trend with the generator temperature, whereas the double-effect HEARS showed a similar trend but with some divergence between the theoretical and experimental studies. To the best of the authors’ knowledge, no study addressed triple-effect HEARS. In addition to its complex design, it requires generator temperatures over 180 °C. Additionally, for single-effect H 2O/LiBr LPC-HEARS, S. Yosaf and H. Ozcan [44][41] claimed that the circulation ratio increased considerably if the system was operated at the typical generator temperatures of 70–100 °C. Correspondingly, the system performed better at higher generator temperatures of 170–220 °C. A similar claim was also stated by Jelinek and Borde [48][31]. However, such high operating temperatures in the generator should be avoided, as serious corrosion and thermal decomposition issues may arise when using the conventional H 2O/LiBr solution [61][27]. This issue explains why the performance of variable- and double-effect HEARS was only examined up to 170 °C, as shown in Figure 179 .

Thus, adding an ejector to ARS improved the COP of the system. To obtain further improvement of the system performance, a flash tank and/or RHE could also be utilized. However, regardless of the added components or the type of the working solution, the COP of single-effect HEARS merely exceeded 1 unless upgrading the system configuration. According to the theoretical studies that are indicated in Figure 180 , the COPs of variable- and double-effect HEARS range between 0.82 and 1.3 at the moderate range of the generator temperature of 120–170 °C. Yet, such upgraded configurations were only studied in the LPC design and solely for H 2O/LiBr solution. Thence, to obtain higher COPs, it is recommended to conduct investigations on variable- and double-effect TPL-HEARS with other alternatives of working fluids such as NH 3/H 2O and H 2O/LiCl. Among the different types of the hybrid systems, the best performance was achieved by the single-effect NH 3/H 2O DEARS and double-effect ejector-driven H 2O/LiBr ARS. The COPs of the two systems ranged between 1.2 and 1.46 under a generator temperature between 90–170 °C.

References

- Shovon, M.K.B.; Raman, S.K.; Suryan, A.; Kim, T.H.; Kim, H.D. Performance of ejector refrigeration cycle based on solar energy working with various refrigerants. J. Therm. Anal. Calorim. 2020, 141, 301–312.

- Sun, J.; Fu, L.; Zhang, S. A review of working fluids of absorption cycles. Renew. Sustain. Energy Rev. 2012, 16, 1899–1906.

- Boman, D.B.; Hoysall, D.C.; Staedter, M.A.; Goyal, A.; Ponkala, M.J.; Garimella, S. A Method for Comparison of Absorption Heat Pump Working Pairs. Int. J. Refrig. 2017, 77, 149–175.

- Abed, A.M.; Alghoul, M.A.; Sopian, K.; Majdi, H.S.; Al-Shamani, A.N.; Muftah, A.F. Enhancement aspects of single stage absorption cooling cycle: A detailed review. Renew. Sustain. Energy Rev. 2017, 77, 1010–1045.

- Srikhirin, P.; Aphornratana, S.; Chungpaibulpatana, S. A review of absorption refrigeration technologies. Renew. Sustain. Energy Rev. 2000, 5, 343–372.

- Nikbakhti, R.; Wang, X.; Hussein, A.K.; Iranmanesh, A. Absorption cooling systems—Review of various techniques for energy performance enhancement. Alex. Eng. J. 2020, 59, 707–738.

- Talpada, J.S.; Ramana, P.V. A review on performance improvement of an absorption refrigeration system by modification of basic cycle. Int. J. Ambient Energy 2019, 40, 661–673.

- Sirwan, R.; Alghoul, M.A.; Sopian, K.; Ali, Y.; Abdulateef, J. Evaluation of adding flash tank to solar combined ejector-absorption refrigeration system. Sol. Energy 2013, 91, 283–296.

- Sleiti, A.K.; Al-Ammari, W.A.; Al-Khawaja, M. Review of innovative approaches of thermo-mechanical refrigeration systems using low grade heat. Int. J. Energy Res. 2020, 44, 9808–9838.

- Zhai, X.Q.; Qu, M.; Li, Y.; Wang, R.Z. A review for research and new design options of solar absorption cooling systems. Renew. Sustain. Energy Rev. 2011, 15, 4416–4423.

- Majdi, H.S. Performance evaluation of combined ejector LiBr/H2O absorption cooling cycle. Case Stud. Therm. Eng. 2016, 7, 25–35.

- Alobaid, M.; Hughes, B.; Calautit, J.K.; O’Connor, D.; Heyes, A. A review of solar driven absorption cooling with photovoltaic thermal systems. Renew. Sustain. Energy Rev. 2017, 76, 728–742.

- Aliane, A.; Abboudi, S.; Seladji, C.; Guendouz, B. An illustrated review on solar absorption cooling experimental studies. Renew. Sustain. Energy Rev. 2016, 65, 443–458.

- Sarbu, I.; Sebarchievici, C. Review of solar refrigeration and cooling systems. Energy Build. 2013, 67, 286–297.

- Arshi Banu, P.S.; Sudharsan, N.M. Review of water based vapour absorption cooling systems using thermodynamic analysis. Renew. Sustain. Energy Rev. 2018, 82, 3750–3761.

- Sheikhani, H.; Barzegarian, R.; Heydari, A.; Kianifar, A.; Kasaeian, A.; Gróf, G.; Mahian, O. A review of solar absorption cooling systems combined with various auxiliary energy devices. J. Therm. Anal. Calorim. 2018, 134, 2197–2212.

- Tashtoush, B.M.; Al-Nimr, M.A.; Khasawneh, M.A. A comprehensive review of ejector design, performance, and applications. Appl. Energy 2019, 240, 138–172.

- Aidoun, Z.; Ameur, K.; Falsafioon, M.; Badache, M. Current advances in ejector modeling, experimentation and applications for refrigeration and heat pumps. Part 1: Single-phase ejectors. Inventions 2019, 4, 15.

- Milazzo, A.; Mazzelli, F. Future perspectives in ejector refrigeration. Appl. Therm. Eng. 2017, 121, 344–350.

- Besagni, G.; Mereu, R.; Inzoli, F. Ejector refrigeration: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 53, 373–407.

- Sözen, A.; Özalp, M. Performance improvement of absorption refrigeration system using triple-pressure-level. Appl. Therm. Eng. 2003, 23, 1577–1593.

- Vereda, C.; Ventas, R.; Lecuona, A.; Venegas, M. Study of an ejector-absorption refrigeration cycle with an adaptable ejector nozzle for different working conditions. Appl. Energy 2012, 97, 305–312.

- Ma, X.; Zhang, W.; Omer, S.A.; Riffat, S.B. Experimental investigation of a novel steam ejector refrigerator suitable for solar energy applications. Appl. Therm. Eng. 2010, 30, 1320–1325.

- Kuhlenschmidt, D. Cooling of Absorption Refrigeration System. U.S. Patent 3750416, 7 August 1973.

- Sun, D.W.; Eames, I.W.; Aphornratana, S. Evaluation of a novel combined ejector—Absorption refrigeration cycle—I: Computer simulation. Int. J. Refrig. 1996, 19, 172–180.

- Sioud, D.; Bellagi, A. Analysis of Hybrid Ejector Absorption Cooling System. J. Eng. 2019, 2019, 1862917.

- Sioud, D.; Bourouis, M.; Bellagi, A. Investigation of an ejector powered double-effect absorption/recompression refrigeration cycle. Int. J. Refrig. 2019, 99, 453–468.

- Boyaghchi, F.A.; Taheri, R. Hourly performance prediction of solar ejector-absorption refrigeration based on exergy and exergoeconomic concept. Int. J. Renew. Energy Res. 2014, 4, 901–910.

- Jiang, L.; Gu, Z.; Feng, X.; Li, Y. Thermo-economical analysis between new absorption—Ejector hybrid refrigeration system and small double-effect absorption system. Appl. Therm. Eng. 2002, 22, 1027–1036.

- Abed, A.M.; Sopian, K.; Alghoul, M.A.; Majadi, H.S.; Al-Shamani, A.N. Experimental evaluation of single stage ejector-absorption cooling cycle under different design configurations. Sol. Energy 2017, 155, 130–141.

- Jelinek, M.; Levy, A.; Borde, I. Performance of a triple-pressure-level absorption cycle with R125-N, N1-dimethylethylurea. Appl. Energy 2002, 71, 171–189.

- Al-Shamani, A.N. Evaluation of solar-assisted absorption refrigeration cycle by using a multi-ejector. J. Therm. Anal. Calorim. 2020, 142, 1477–1481.

- Khalili, S.; Garousi Farshi, L. Design and performance evaluation of a double ejector boosted multi-pressure level absorption cycle for refrigeration. Sustain. Energy Technol. Assess. 2020, 42, 100836.

- Sehgal, S.; Alvarado, J.L.; Hassan, I.G.; Kadam, S.T. A comprehensive review of recent developments in falling-film, spray, bubble and microchannel absorbers for absorption systems. Renew. Sustain. Energy Rev. 2021, 142, 110807.

- Hong, D.; Chen, G.; Tang, L.; He, Y. A novel ejector-absorption combined refrigeration cycle. Int. J. Refrig. 2011, 34, 1596–1603.

- Bellos, E.; Tzivanidis, C. Parametric analysis and optimization of a cooling system with ejector—Absorption chiller powered by solar parabolic trough collectors. Energy Convers. Manag. 2018, 168, 329–342.

- Abed, A.M.; Alghoul, M.A.; Sopian, K. Performance evaluation of flash tank-absorption cooling cycle using two ejectors. Appl. Therm. Eng. 2016, 101, 47–60.

- Sirwan, R.; Alghoul, M.A.; Sopian, K.; Ali, Y. Thermodynamic analysis of an ejector-flash tank-absorption cooling system. Appl. Therm. Eng. 2013, 58, 85–97.

- Shi, Y.; Li, F.; Hong, D.; Wang, Q.; Chen, G. Experimental study of a new ejector-absorption refrigeration cycle driven by multi-heat sources. Appl. Therm. Eng. 2018, 133, 604–612.

- Yan, X.; Shi, Y.; Wang, L.; Hong, D.; Chen, G. Experimental evaluation of a 1.x-effect ejector-absorption refrigeration system. Appl. Therm. Eng. 2019, 157, 113738.

- Yosaf, S.; Ozcan, H. Effect of ejector location in absorption refrigeration cycles using different binary working fluids. Int. J. Air-Cond. Refrig. 2019, 27, 1950003.