With the swift global development of tunnels, mines, subways, water conservancy and hydropower projects, and so on, shotcrete, as an advanced support method, is widely applied to surrounding rock control and roadway closure. Shotcrete is a kind of concrete formed by mixing concrete materials, such as gel material, aggregate, and so on, into the ejection equipment, by means of compressed air or other power transmission, and sprayed onto the spray surface at high speed. Shotcrete technology was first used in mining and civil engineering by the United States in 1914. It has a history of more than 100 years.

- high temperature

- shotcrete

- mechanical properties

- microscopic properties

1. Introduction

Shotcrete is used in underground and tunnel support, infrastructure repair and rehabilitation, slope stabilization, and in areas difficult to reach with conventional concrete, such as bridge piers and beam soffits [2][1]. Shotcrete has the characteristics of high compressive strength, good durability, and wide range of strength grades [3,4,5][2][3][4]. As a supporting material of roadway, shotcrete can not only prevent the oxidation of surrounding rock, but also plays a supporting role for the roadway. With the development of deep mines and deep tunnels, shotcrete is facing great challenges. Especially deep underground, high temperature accelerates the deterioration of shotcrete [6,7,8,9][5][6][7][8]. According to relevant reports, the rock wall temperature of Sangzhuling Tunnel in the Yarlung Zangbo River Canyon in China reached 89 °C, and it was identified as a class I risk tunnel. The high temperature of 75 °C and the extreme temperature of 170 °C were encountered in the construction of Anfang tunnel and the third hydropower station of Heibu in Japan. The highest original rock temperature is 46.8 °C, at −980 m level in Sanhejian coal mine. The underground rock temperature of the Mbonig gold mine in South Africa reaches 65.6 °C.

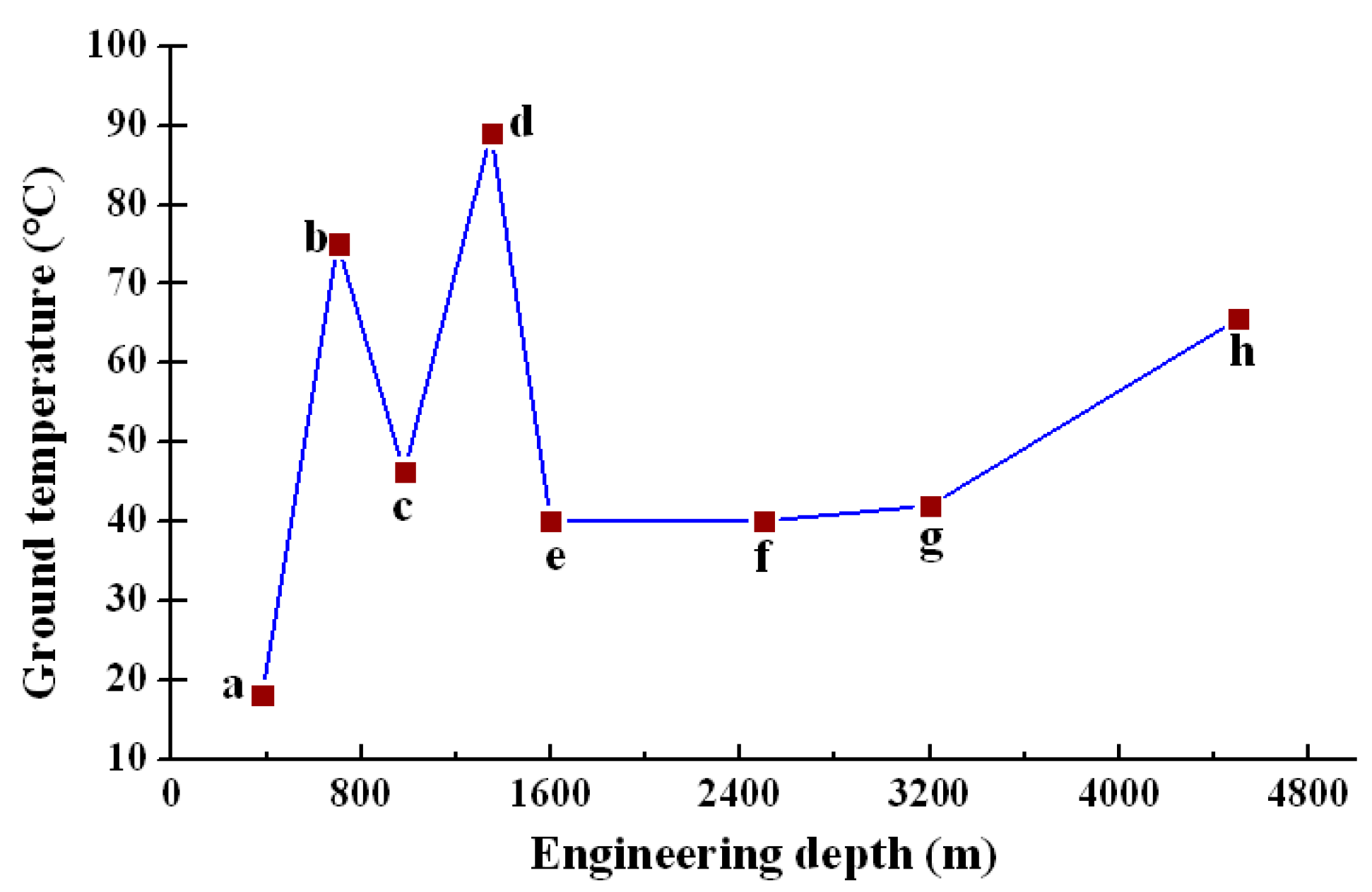

Many scholars have shown that there is a certain relationship between temperature and depth, and the rock temperature gradient is about 3–4 °C/100 m [10,11,12][9][10][11]. However, in a deep environment, due to the different rock properties and the possible existence of large fault zones, the change of temperature with temperature gradient is not obvious. Figure 1 shows the distribution of temperature with depth in deep tunnels and deep mines in some projects. From the figure, it could be concluded that the variation between temperature and depth in underground projects was a nonlinear relationship, that is, the ground temperature in deep environments shows an abnormal pattern [13,14][12][13].

2. Challenges

| Challenges | Current Technologies | Future Challenges |

|---|---|---|

| High temperature detection technology research | Thermocouple temperature measurement, infrared temperature measurement, and other technologies. However, the temperature can change in the hot and humid environment of the roadway, and a complete test system has not been formed. | Develop a new temperature measurement method, establish a temperature measurement system, predict and forecast the high temperature area of the roadway, ensure that the construction environment is in a balanced state, and reinforce the area where the roadway sprayed concrete may be damaged in advance. |

| Experimental device for performance of shotcrete | Shotcrete is made by pouring or spraying. Then, constant temperature and a humidity curing box or high-temperature drying box are used to simulate high-temperature environment curing. There will be a gap in the simulation of the high-temperature environment, which will affect the experimental results. | Research and development of shotcreting equipment and performance testing system in high temperature. Accurately simulate high-temperature environment to improve the authenticity of research results. Provide reliable results for improving the development of infrastructure under high temperature. |

| Shotcrete spray layer structure | The existing research is based on the study of the adhesion of shotcrete under the action of temperature, but it has not involved research on the shotcrete spraying layer in the process of roadway reinforcement under high temperature. | Study the performance change trend of high-temperature roadway shotcrete with the thickness of shotcrete layer. Get the optimal spray layer thickness under high temperature. Study the adhesion between spray layers. Research and develop high-efficiency, environmentally friendly, and low-cost adhesives |

| Performance of shotcrete in special environments | Existing research is based on the permeability of shotcrete, and there is basically no relevant literature on the high-temperature conditions of the construction roadway in a high-water-spray environment. | Study the mechanical properties of shotcrete in high-temperature acid and alkaline environments. Investigate the non-linear relationship between the compatibility of the sprayed concrete and the cemented surface of the high-water-spray area and the interface’s mechanical properties. |

| Microscopic properties of shotcrete | The existing research has explained the deterioration performance of shotcrete at high temperature from the micro level, but it is still not perfect. There is no detailed study on the crack development process and deterioration mechanism of concrete in a high temperature environment. | Study the microscopic changes of shotcrete under high temperature. Establish a damage model of shotcrete under high temperature. Study the impact properties of shotcrete layers under high temperature. Establish a damage prediction model for shotcrete layer structure under high temperature, using acoustic emission technology to predict the development trend of shotcrete deterioration in advance. |

| Optimization of shotcrete | Existing research is mainly based on studies of thermal insulation sprayed concrete, which is mainly improved from the material ratio by adding inorganic materials. Although it has a certain thermal insulation effect, its thermal insulation performance is insignificant for the ultra-high temperature construction environment. | Study the modification of shotcrete. Choose low-quality, low-thermal-conductivity materials to reduce the potential energy of concrete. Preliminary research on the high temperature resistance between silica aerogel and shotcrete. |

3. Conclusions

- (2) Results concluded that the mechanical properties (including compressive strength, tensile strength, bond strength, shear strength) of shotcrete were affected by the critical temperature: before the critical temperature, the mechanical properties of shotcrete showed an increasing trend with the increase of temperature; after the critical temperature, the mechanical properties of shotcrete appeared to show the phenomenon of shrinkage. Through microscopic analysis, multiple studies have shown that when the temperature exceeds the critical temperature, the internal molecules of the shotcrete move violently and the molecules overlap in a disorderly way, the hydration reaction of shotcrete cement is terminated prematurely, and the brittle de-formation is enhanced, which leads to the weakening of shotcrete strength.

- (3) It is concluded that taking cooling measures for a high-temperature construction environment will increase the recoverability of concrete after deterioration and reduce the deterioration degree of shotcrete. In terms of optimizing the performance of shotcrete, adding inorganic materials, such as vitrified microbeads, foam fibers, expanded perlite, and silica fume, will improve the heat insulation and heat resistance of shotcrete.

- (4) It was found that the current temperature measurement system, high-temperature simulation equipment, and material ratio had limitations. At the same time, the challenges that high-temperature shotcrete faces in terms of the process structure, performance optimization, and its application in special engineering fields were summarized.

References

- Burns, B.D. Characterization of Wet-Mix Shotcrete for Small Line Pumping; Laval University: Québec, QC, Canada, 2008.

- Brooks, J.W. Shotcrete and its application. In Shotcreting Proceedings; South African Institute of Mining and Metallurgy School: Johannesburg, South Africa, 1998.

- Chen, L.; Li, P.; Liu, G.; Cheng, W.; Liu, Z. Development of cement dust suppression technology during shotcrete in mine of China-A review. J. Loss Prev. Process. Ind. 2018, 55, 232–242.

- Liu, G.; Chen, L.; Cheng, W.; Huang, Y. Research on pump primers for friction reduction of wet-mix shotcrete based on pre-creating lubricating layer. Adv. Mater. Sci. Eng. 2017, 2017, 1–12.

- Zhu, K.; Zhou, Y.; Wang, P.; Liu, J.; Shi, C. Study on monitoring technique and distribution regularity of geothermal field in deep mining. Nonferrous Met. 2016, 68, 90–94.

- Chen, X. Prediction and analysis of ground temperature in deep mining of metal mine. Sci. Technol. Inf. 2017, 15, 94–111.

- Zhang, C.; Zhao, L.; Wu, Z. Depth characteristics of Curie surface in the Eastern seas of China. J. Shandong Univ. Sci. Technol. 2019, 38, 10–17.

- Wang, X.; Li, X.; Kong, F.M. Metamorphism and tectonic evolution of the sedimentary-matrix mélange in the central Yarlung Zangbo Suture Zone, Southern Tibet. J. Shandong Univ. Sci. Technol. 2020, 39, 16–27.

- Yao, H.; Xu, C.; Wu, H.; Zheng, Z.; Sun, X.; Wang, H.; Chai, J.; Li, Y. Study on geothermal parameters of mid-deep and deep mines in Inner Mongolia and Shaanxi mining area. China Coal 2017, 43, 91–96.

- Wang, C. Analysis of thermal damage factors in deep mine. Zhongzhou Coal. 2013, 40, 42–105.

- Guo, Z. Current situation and technical problems of deep mining in China’s coal mines. Coal 2017, 26, 58.

- He, M.; Guo, P. Deep rock mass thermodynamic effect and temperature control measuresd. Chin. J. Rock Mech. Eng. 2013, 32, 2377–2393.

- Shengai, C.; Pin, L.; Jiao, S.; Enqi, C.; Chen, G.; Bing, Z. Experimental study on mechanical and microstructural properties of cement-based paste for shotcrete use in high-temperature geothermal environment. Constr. Build. Mater. 2018, 174, 603–612.

- Lee, C.-H.; Wang, T.-T.; Chen, H.-J. Experimental study of shotcrete and concrete strength development in a hot spring environment. Tunn. Undergr. Space Technol. 2013, 38, 390–397.

- Yang, H. Performance Research and Structural Behavior Analysis of Shotcrete in Thermal Damage Tunnel; Southwest Jiaotong University: Chengdu, China, 2013.

- Wang, J.; Niu, D.; Wang, Y.; He, H.; Liang, X. Chloride diffusion of shotcrete lining structure subjected to nitric acid, salt–frost degradation, and bending stress in marine environment. Cem. Concr. Compos. 2019, 104, 103396.

- Wang, J.; Niu, D.; Ding, S.; Mi, Z.; Luo, D. Microstructure, permeability and mechanical properties of accelerated shotcrete at different curing age. Constr. Build. Mater. 2015, 78, 203–216.

- Cui, S.A.; Li, J.W.; Ye, Y.Z.; Yang, H.Y. Bond Strength of shotcrete with rock in dry and hot environment of high ground temperature tunnel. J. Build. Mater. 2013, 4, 663–666.

- Dong, W.; Yang, D.; Zhou, X.; Kastiukas, G.; Zhang, B. Rimental and numerical investigations on fracture process zone of rock–concrete interface. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 820–835.

- Yang, C.; Chen, J. Fully noncontact nonlinear ultrasonic characterization of thermal damage in concrete and correlation with microscopic evidence of material cracking. Cem. Concr. Res. 2019, 123, 105797.

- Lu, T.; Zhao, G.; Lin, Z. Experimental study on mechanical properties of long standing concrete after exposure to high temperature. J. Build. Struct. 2004, 25, 63–70.

- Lu, T.; Zhao, G.; Lin, Z.; Yue, Q.R. Microscopic analysis of long standing concrete after high temperature. J. Build. Mater. 2003, 6, 135–141.

- Kjellsen, K.O. Heat curing and post-heat curing regimes of higher-performance concrete: Inflfluence on microstructure and C–S–H composition. Cem. Concr. Res. 1996, 26, 295–307.

- Akca, A.H.; Zihnioğlu, N.Ö. High performance concrete under elevated temperatures. Constr. Build. Mater 2013, 44, 317–328.