Compared with the traditional vapor-compression cooling system, the solid desiccant evaporative cooling system consumes less electricity, has no harmful refrigerant, controls air humidity effectively and maintains a high level of air quality. The hybrid system usually includes two main processes: the dehumidification process and the evaporative cooling process. The function of the dehumidification process is to remove the moisture, and the evaporative cooling process is responsible for handling the sensible heat of the air.

- direct evaporative cooling

- indirect evaporative cooling

- solid desiccant

- air conditioning

- solar energy

1. Introduction

Evaporative cooling technology (ECT) is one of the most effective and sustainable alternatives to vapor-compressed cooling technology that could provide thermal comfort with less power consumption and installation cost [1][2]. In ECT, the refrigerant is water, which is environmentally benign, and there is no requirement for compressors, which consume a large amount of energy [2]. On the other hand, the demand for designing a more efficient and environmentally friendly cooling system has been increasing in recent years [3][4]. This is mainly because over 30% of the total energy usage in the world is consumed in buildings and mostly by air conditioning systems [5][6]. In addition, the global warming effect and high demands of cooling systems exacerbate energy consumption [7]. Among air conditioning systems, vapor-compressed cooling technology has dominated the market for more than 100 years [8]. This cooling approach has the two major drawbacks of high energy demand for operating mechanical compressors and global warming issues caused by typical refrigerants, such as R-134a and R-410a [3]. These factors have made ECT a hot topic for a long time. However, the humidity ratio of the inlet air significantly affects the system performance because ECT achieves cooling through water evaporation [9]. When the ambient air is humid, less water can be evaporated into the air, which means less cooling capacity is obtained. In this case, a dehumidification process is usually adopted to pre-dry the supply air before entering the evaporative cooling system [10]. In this hybrid system, the temperature and humidity ratio can be controlled separately, and the solid desiccant wheel is a typical dehumidification system that can be applied to remove the moisture, while the evaporative cooling unit is responsible for providing sensible cooling [11]. Therefore, the ECT integrated with a solid desiccant system attracts attention from engineers and researchers. Furthermore, low-grade heat, such as solar or waste heat, can be used to meet the regeneration temperature requirement of the desiccant unit, which makes such hybrid systems even more favorable [12].

Although some papers have conducted reviews for the evaporative cooling technology that could be found in the literature [1][8][13][14][15][16][17][18], there is still a lack of reviews specifically on the ECT integrated with a solid desiccant system. In this paper, recent technical developments and evaluation methods of ECT and solid desiccant-assisted evaporative cooling technologies (SDECT) were comprehensively reviewed. Firstly, the development of ECT was reviewed. In this section, the history of ECT development was briefly introduced. Then, these two types of ECT were reviewed separately, direct evaporative cooling (DEC) and indirect evaporative cooling (IEC). Later, the solid desiccant material used in recent studies was also reviewed. After that, the recent development of conventional solid desiccant-based ECT was evaluated. Afterward, the enhancement techniques were discussed with respect to configuration optimization, desiccant unit improvement and integration of novel IEC technologies. Furthermore, experimental and numerical methods were used to evaluate the SDECT and report its advantages and limitations. The current research gap, challenges, opportunities and future research recommendations were discussed. This review provides useful information for researchers and engineers in the development of effective ECT technologies for wide community applications under different climate conditions.

2. Overview of Solid Desiccant Dehumidification

Desiccant dehumidification has been widely studied and applied in air-conditioning systems to control the room humidity. The desiccant dryer could be classified into liquid desiccant and solid desiccant according to the desiccant material, and each has its own characteristics. The solid desiccant has a higher water adsorption rate, simpler structure and no carry-over risk compared to the liquid desiccant [19]. The dehumidification process is to remove the moisture of air through the strong water vapor attraction property of the desiccant material. The water vapor pressure difference between the desiccant surface and flowing air is the main driving force [19]. As the process air is continuously dehumidified, the desiccant materials become saturated, and sorption ability decreases, which requires a regeneration process [20]. Thermal energy is usually used to regenerate the desiccant unit, and this could be achieved using solar energy, electrical heater, electro-osmotic and waste heat [21][22][23]. To improve the desiccant system performance, many studies have been conducted from the aspects of improving water adsorption capacity and reducing regeneration temperature [24]. Zheng et al. [24] reviewed the recent developments of solid desiccant material by considering both adsorption isotherms and regeneration ability, which covered composite desiccants, nanoporous inorganic materials and polymetric desiccants. The results showed that the dehumidification and regeneration capacity of composite desiccant could be enhanced via host matrix and immersed salts selection. For nanoporous inorganic materials, a good balance between regeneration and adsorption could be identified by modifying the textural properties. However, further investigation into advanced materials is needed to fulfill all the demands of solid desiccant cooling systems.

3. Integrated Evaporative Cooling and Solid Desiccant System

The temperature difference between the ambient dry-bulb temperature and dew-point temperature is an important indicator to determine the application eligibility of evaporative cooling technology. According to this criterion, evaporative cooling technology is not suggested in hot and humid areas [25]. In order to extend the application of evaporative cooling, integrated evaporative cooling with a solid desiccant unit gained lots of attention, and it is believed that the desiccant-based evaporative cooling system is one of the best alternatives to the vapor-compression system under wet and hot climates [26]. Compared with the traditional vapor-compression cooling system, the solid desiccant evaporative cooling system consumes less electricity, has no harmful refrigerant, controls air humidity effectively and maintains a high level of air quality [27]. The hybrid system usually includes two main processes: the dehumidification process and the evaporative cooling process. The function of the dehumidification process is to remove the moisture, and the evaporative cooling process is responsible for handling the sensible heat of the air. Some commonly used desiccant materials are silica gel, zeolites, alumina, hydratable salts and mixtures [12].

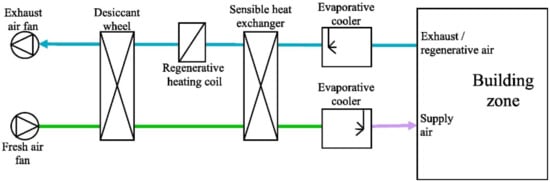

Figure 1 shows a typical solid desiccant-assisted evaporative cooling system configuration. From the configuration, the ambient air is dehumidified when flowing through the desiccant wheel. Then the dehumidified air flows through the sensible heat wheel, where it is cooled by the return air from the building zone. The cool, dry air then flows through the evaporative cooler and is further cooled and supplied to the building. The return air from the conditioned room flows through the evaporative cooler and is cooled. This cold air flows through the heat wheel, where it cools the supply air. Afterward, this return air is heated to the regenerative temperature in a heat exchanger by solar or electric energy. Then the high temperature returns airflow through the solid desiccant wheel, where the solid desiccant is regenerated. The exhaust air is discharged into the environment [28].

Solid desiccant-assisted evaporative cooling systems have been studied extensively from different aspects. Zadpoor and Golshan [29] investigated the performance enhancement of a gas turbine cycle with a desiccant-based evaporative cooling system; a comparative study was conducted between the proposed system and in combination with other types of evaporative cooling, such as direct evaporative and direct and indirect evaporative cooling. Numerical models were built based on the configuration and tested in three climatic conditions. The authors concluded that the performance enhancement obtained using this hybrid system was more obvious than the other evaporative cooling technologies for hot and humid climates. Khalid et al. [30] proposed four configurations of solar-assisted, pre-cooled hybrid desiccant cooling system and tested numerically and experimentally under Pakistan climates. The results showed that the fourth operation mode, which applied IEC for pre-cooling and DEC for post-cooling of the air, achieved the highest COP. However, none of these four operation modes could fully provide a cooling load without the assistance of the auxiliary cooling unit. For the city of Lahore’s climate, the hybrid system could only provide enough thermal comfort for three of the seven months of the cooling season. White et al. [31] used TRNSYS to study a solar-assisted desiccant two-stage evaporative cooling system without any backup heating equipment under Australian climates. The first stage of evaporative cooling was an IEC, and then the air passed into the second stage DEC for further cooling. The results revealed that the effectiveness of IEC, supply airflow rate and solar collector area were the main factors that would affect the thermal comfort of the building. The results also pointed out that the system was not suitable for tropical climates. Goldsworthy and White [32] numerically investigated the optimization of a desiccant cooling system design with IEC. The heat and mass transfer equations of the desiccant wheel and IEC were solved simultaneously. It was found that the hybrid system showed great potential to reduce energy consumption and greenhouse emission. The electrical COP could be greater than 20 when the regeneration temperature was 70 °C, supply and regeneration airflow ratio was 0.67 and the extraction air ratio of IEC was 0.3. Hatami et al. [33] conducted an optimization study of the solar collector surface requirement in a desiccant evaporative cooling cycle. They concluded that after considering the design parameters and operating conditions of the desiccant wheel, the compulsory solar collector areas could decrease by 45% compared to an empirical model. Parmar and Hindoliya [34] evaluated a desiccant cooling system performance under four types of climates in India (hot and dry, warm and humid, moderate and composite climates). From the research outcomes, the desiccant cooling system was suggested to use in warm and humid climates; the maximum system thermal COP achieved 4.98 when the flow rate ratio between the regeneration air and process air (R/P ratio) was 0.55. They also claimed that the increase of the R/P ratio led to an elevation of the regeneration heat load requirement and a reduction in system thermal COP. Angrisani et al. [35] compared three types of solar collectors applied in the solar desiccant cooling systems in terms of energy, environmental and economic performance with a reference system. A selection of 16 m 2 of the evacuated solar collectors was recommended to obtain a drop of 50.2% in energy consumption and 49.8% equivalent CO 2 emissions. But the economic payback period was over 20 years due to its high installation cost. Rafique et al. [27] developed a numerical model of desiccant evaporative cooling systems and conducted a feasibility analysis for a hot and humid city in Saudi Arabia. The results showed that this system was feasible to use in such weather conditions with optimum selection of the operating parameters. Ma and Guan [36] investigated the system performance of a solar desiccant evaporative cooling system for a commercial building under various climates in Australia. Performance parameters including thermal COP, annual primary energy consumption, annual energy saving and annual CO 2 emissions reduction were compared with a reference variable air volume system. The maximum energy saving and CO 2 emission reduction were obtained as 557 GJ and 121 tones per year, respectively, in Darwin. The highest values of 7 of thermal COP could be achieved during summertime in Darwin. They pointed out that the solar desiccant evaporative cooling technology was useful in Darwin, which has a tropical climate, while it was not a competitive approach for other climate regions. Ma et al. [37] evaluated several important performance parameters of a solar desiccant evaporative cooling system, which included solar fraction, electrical COP, electricity power consumption, CO 2 emissions reduction, payback period and net present value. A comparative study was also carried out between the proposed system and two other solar-assisted vapor-compression air cooling systems under Australian climates. The simulation results presented that the solar desiccant-evaporative cooling system is suitable for most Australian climates, especially for hot and humid places. A total of 82.1% of annual power saving, 178.45 tons of annual CO 2 emissions reduction, 3.9 years of payback period and AUD 466,199 net present value could be accomplished by applying this cooling system in Darwin. Ma et al. [38] conducted a parametric study on solar collector area, solar thermal storage tank volume and backup heater capacity for a cooling system under Australian climates. It was shown that both increasing solar collector areas or solar thermal storage tanks could lead to solar fraction and electrical COP increase, but the tank volume was more sensitive to affect the system. A humidity control set point was also given as 0.008 kg/kg by considering indoor design conditions and electricity usage of the backup heater. Narayanan et al. [39] evaluated a desiccant evaporative cooling system for a residential building in Brisbane by using TRNSYS software. They found that this type of system could provide thermal comfort for about 50% of the time required for cooling. They also concluded that the system performance was mainly affected by the evaporative cooling system, heat recovery system and desiccant regeneration process.

4. Evaluation Methods of the Solid Desiccant Evaporative Cooling System

The main experimental investigations on solid desiccant-based evaporative cooling systems are illustrated in Table 1. It is noted that only a few experimental studies existed in the literature based on the literature survey. This is mainly caused by high initial construction cost and large geometric size. As it can be seen from Table 1, previous experimental studies mainly explore the following considerations.

Table 1. Experimental study of solid desiccant evaporative cooling system.

| Experimental Studies | Year | Description |

| Uckan et al. [40] | 2013 | Analysis of novel configuration of solid desiccant-based evaporative cooling system |

| Hands et al. [41] | 2016 | Performance analysis of a solar-assisted two-stage desiccant evaporative cooling system in a building, which can produce heating, cooling and hot water simultaneously. |

| Lin et al. [42] | 2017 | Comparative study of a cross flow M-cycle IEC with and without dehumidification. |

| Qadar Chaudhary et al. [43] | 2018 | Combination of solar desiccant-based cooled and M-cycle IEC. |

| Pandelidis et al. [44] | 2020 | Comparative study of pre-cooled desiccant system with different dew point coolers. |

| Kashif et al. [45] | 2020 | Assessment of desiccant-based evaporative cooling system for animals. |

Although each experiment has a different arrangement of configurations, evaporative cooler and desiccant unit, the experimental results are similar. It proves that the hybrid system can provide thermal cooling in hot and humid areas without the need for the backup cooling equipment. Most efforts have been made to improve dehumidification performance at low regeneration temperatures, to use solar energy to reduce regeneration energy usage and to use advanced evaporative cooling technology.

In comparison with experimental approaches, numerical methods are more popular because they can provide accurate results within a short time and at a low cost. Among the numerical methods, the transient system simulation program (TRNSYS) was commonly adopted to simulate solid desiccant-based evaporative cooling systems [46]. TRNSYS is a flexible and component-based software package that mainly focuses on assessing the performance of thermal and electrical energy systems. Around 150 models are included in the TRNSYS library, which are written in Fortran, such as HVAC equipment, solar components and weather date processors. It is possible to easily connect and modify the existing components or even create your own models when necessary [47]. MATLAB, EnergyPlus and EES have also been used to simulate the hybrid system. ε -NTU and finite element/difference/volume methods are often applied to solve the heat and mass transfer equations of the system. For different numerical models, the major difference between each model is the assumptions adopted for building the models. The commonly used assumptions in the literature are listed below. In fact, most of the assumptions are made for simplification of the numerical model, which will result in sacrificing accuracy. When a system is working at a steady-state, most assumptions are suitable to use. However, when it comes to a dynamic situation, some assumptions are not appropriate anymore. For example, the cooling performance of the evaporative cooler relies on the inlet air condition heavily, if the cooling effectiveness of the evaporative cooler is still assumed as a constant when the inlet air condition varies, a huge error will be obtained in the result. Table 2 shows the assumptions that are commonly used in numerical simulations.

| Assumptions | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |

| White et al. | [31] | √ | √ | √ | √ | |||||||

| Parmar and Hindoliya | [34] | √ | √ | √ | √ | |||||||

| Rafique et al. | [27] | √ | √ | √ | √ | √ | √ | √ | ||||

| Elgendy et al. | [48] | √ | √ | √ | √ | √ | ||||||

| Heidari et al. | [49] | √ | √ | √ | √ | |||||||

| Arun and Mariappan | [50] | √ | √ | √ | √ | √ | ||||||

| Lee et al. | [51] | √ | √ | √ |

References

- Ala Hasan; Going below the wet-bulb temperature by indirect evaporative cooling: Analysis using a modified ε-NTU method. Applied Energy 2011, 89, 237-245, 10.1016/j.apenergy.2011.07.005.

- Glanville, Paul; Kozlov, Aleksandr; Maisotsenko, Valeriy; Dew point evaporative cooling: Technology review and fundamentals. ASHRAE Transactions 2011, 117, 111-118.

- Thibaut Vitte; Jean Brau; Nadège Chatagnon; Monika Woloszyn; Proposal for a new hybrid control strategy of a solar desiccant evaporative cooling air handling unit. Energy and Buildings 2008, 40, 896-905, 10.1016/j.enbuild.2007.07.004.

- Xiangjie Chen; Saffa Riffat; Hongyu Bai; Xiaofeng Zheng; David Reay; Recent progress in liquid desiccant dehumidification and air-conditioning: A review. Energy and Built Environment 2019, 1, 106-130, 10.1016/j.enbenv.2019.09.001.

- Luis Pérez-Lombard; José Ortiz; Christine Pout; A review on buildings energy consumption information. Energy and Buildings 2008, 40, 394-398, 10.1016/j.enbuild.2007.03.007.

- Hoy Yen Chan; Saffa B. Riffat; Jie Zhu; Review of passive solar heating and cooling technologies. Renewable and Sustainable Energy Reviews 2010, 14, 781-789, 10.1016/j.rser.2009.10.030.

- Ala Hasan; Indirect evaporative cooling of air to a sub-wet bulb temperature. Applied Thermal Engineering 2010, 30, 2460-2468, 10.1016/j.applthermaleng.2010.06.017.

- Zhiyin Duan; Changhong Zhan; Xingxing Zhang; Mahmud Mustafa; Xudong Zhao; Behrang Alimohammadisagvand; Ala Hasan; Indirect evaporative cooling: Past, present and future potentials. Renewable and Sustainable Energy Reviews 2012, 16, 6823-6850, 10.1016/j.rser.2012.07.007.

- Muhammad Mujahid Rafique; P. Gandhidasan; Shafiqur Rehman; Luai M. Al-Hadhrami; A review on desiccant based evaporative cooling systems. Renewable and Sustainable Energy Reviews 2015, 45, 145-159, 10.1016/j.rser.2015.01.051.

- B. Riangvilaikul; S. Kumar; An experimental study of a novel dew point evaporative cooling system. Energy and Buildings 2010, 42, 637-644, 10.1016/j.enbuild.2009.10.034.

- D.B. Jani; Manish Mishra; P.K. Sahoo; Performance analysis of a solid desiccant assisted hybrid space cooling system using TRNSYS. Journal of Building Engineering 2018, 19, 26-35, 10.1016/j.jobe.2018.04.016.

- Mahmut Sami Büker; Saffa B. Riffat; Recent developments in solar assisted liquid desiccant evaporative cooling technology—A review. Energy and Buildings 2015, 96, 95-108, 10.1016/j.enbuild.2015.03.020.

- Anna Pacak; William Worek; Review of Dew Point Evaporative Cooling Technology for Air Conditioning Applications. Applied Sciences 2021, 11, 934, 10.3390/app11030934.

- Bogdan Porumb; Paula Ungureşan; Lucian V. Fechete Tutunaru; Alexandru Şerban; Mugur Bălan; A Review of Indirect Evaporative Cooling Operating Conditions and Performances. Energy Procedia 2016, 85, 452-460, 10.1016/j.egypro.2015.12.226.

- Hamed Sadighi Dizaji; Eric Jing Hu; Lei Chen; A comprehensive review of the Maisotsenko-cycle based air conditioning systems. Energy 2018, 156, 725-749, 10.1016/j.energy.2018.05.086.

- Uzair Sajjad; Naseem Abbas; Khalid Hamid; Saleem Abbas; Imtiyaz Hussain; Syed Muhammad Ammar; Muhammad Sultan; Hafiz Muhammad Ali; Muzamil Hussain; Tauseef- Ur- Rehman; et al.Chi Chuan Wang A review of recent advances in indirect evaporative cooling technology. International Communications in Heat and Mass Transfer 2021, 122, 105140, 10.1016/j.icheatmasstransfer.2021.105140.

- Evi Sofia; Nandy Putra; Evaporative cooling innovations - A review. INTERNATIONAL CONFERENCE ON TRENDS IN MATERIAL SCIENCE AND INVENTIVE MATERIALS: ICTMIM 2020 2020, 2255, 020036, 10.1063/5.0020449.

- Yifan Yang; Gary Cui; Christopher Q. Lan; Developments in evaporative cooling and enhanced evaporative cooling - A review. Renewable and Sustainable Energy Reviews 2019, 113, 109230, 10.1016/j.rser.2019.06.037.

- A. Frein; M. Muscherà; Rossano Scoccia; M. Aprile; M. Motta; Field testing of a novel hybrid solar assisted desiccant evaporative cooling system coupled with a vapour compression heat pump. Applied Thermal Engineering 2018, 130, 830-846, 10.1016/j.applthermaleng.2017.10.168.

- Ali M. Baniyounes; Gang Liu; M.G. Rasul; M.M.K. Khan; Analysis of solar desiccant cooling system for an institutional building in subtropical Queensland, Australia. Renewable and Sustainable Energy Reviews 2012, 16, 6423-6431, 10.1016/j.rser.2012.07.021.

- Ismanizam Abd Manaf; Faisal Durrani; Mahroo Eftekhari; A review of desiccant evaporative cooling systems in hot and humid climates. Advances in Building Energy Research 2018, 15, 1-42, 10.1080/17512549.2018.1508364.

- Nidal H. Abu-Hamdeh; Khalid H. Almitani; Solar liquid desiccant regeneration and nanofluids in evaporative cooling for greenhouse food production in Saudi Arabia. Solar Energy 2016, 134, 202-210, 10.1016/j.solener.2016.04.048.

- Kishor S. Rambhad; Pramod V. Walke; D.J. Tidke; Solid desiccant dehumidification and regeneration methods—A review. Renewable and Sustainable Energy Reviews 2016, 59, 73-83, 10.1016/j.rser.2015.12.264.

- X. Zheng; T.S. Ge; R.Z. Wang; Recent progress on desiccant materials for solid desiccant cooling systems. Energy 2014, 74, 280-294, 10.1016/j.energy.2014.07.027.

- Ali Sohani; Hoseyn Sayyaadi; Sina Hoseinpoori; Modeling and multi-objective optimization of an M-cycle cross-flow indirect evaporative cooler using the GMDH type neural network. International Journal of Refrigeration 2016, 69, 186-204, 10.1016/j.ijrefrig.2016.05.011.

- Hamidreza Hasani Balyani; Ali Sohani; Hoseyn Sayyaadi; Ramin Karami; Acquiring the best cooling strategy based on thermal comfort and 3E analyses for small scale residential buildings at diverse climatic conditions. International Journal of Refrigeration 2015, 57, 112-137, 10.1016/j.ijrefrig.2015.04.008.

- M. Mujahid Rafique; P. Gandhidasan; Shafiqur Rehman; Luai M. Alhems; Performance analysis of a desiccant evaporative cooling system under hot and humid conditions. Environmental Progress & Sustainable Energy 2016, 35, 1476-1484, 10.1002/ep.12358.

- K.F. Fong; C.K. Lee; Solar desiccant cooling system for hot and humid region – A new perspective and investigation. Solar Energy 2019, 195, 677-684, 10.1016/j.solener.2019.12.009.

- Amir Abbas Zadpoor; A Golshan; Performance improvement of a gas turbine cycle by using a desiccant-based evaporative cooling system. Energy 2006, 31, 2652-2664, 10.1016/j.energy.2005.11.004.

- A. Khalid; M. Mahmood; M Asif; T. Muneer; Solar assisted, pre-cooled hybrid desiccant cooling system for Pakistan. Renewable Energy 2009, 34, 151-157, 10.1016/j.renene.2008.02.031.

- S.D. White; P. Kohlenbach; C. Bongs; Indoor temperature variations resulting from solar desiccant cooling in a building without thermal backup. International Journal of Refrigeration 2009, 32, 695-704, 10.1016/j.ijrefrig.2009.01.019.

- Mark Goldsworthy; Stephen White; Optimisation of a desiccant cooling system design with indirect evaporative cooler. International Journal of Refrigeration 2011, 34, 148-158, 10.1016/j.ijrefrig.2010.07.005.

- Zahra Hatami; Mohammad Hassan Saidi; Masoud Mohammadian; Cyrus Aghanajafi; Optimization of solar collector surface in solar desiccant wheel cycle. Energy and Buildings 2012, 45, 197-201, 10.1016/j.enbuild.2011.11.002.

- H. Parmar; D. A. Hindoliya; Performance of solid desiccant-based evaporative cooling system under the climatic zones of India. International Journal of Low-Carbon Technologies 2012, 8, 52-57, 10.1093/ijlct/ctr051.

- Giovanni Angrisani; Carlo Roselli; Maurizio Sasso; Francesco Tariello; Assessment of Energy, Environmental and Economic Performance of a Solar Desiccant Cooling System with Different Collector Types. Energies 2014, 7, 6741-6764, 10.3390/en7106741.

- Yunlong Ma; Lisa Guan; Performance Analysis of Solar Desiccant-Evaporative Cooling for a Commercial Building under Different Australian Climates. Procedia Engineering 2015, 121, 528-535, 10.1016/j.proeng.2015.08.1024.

- Yunlong Ma; Suvash C. Saha; Wendy Miller; Lisa Guan; Comparison of Different Solar-Assisted Air Conditioning Systems for Australian Office Buildings. Energies 2017, 10, 1463, 10.3390/en10101463.

- Yunlong Ma; Suvash C. Saha; Wendy Miller; Lisa Guan; Parametric Analysis of Design Parameter Effects on the Performance of a Solar Desiccant Evaporative Cooling System in Brisbane, Australia. Energies 2017, 10, 849, 10.3390/en10070849.

- Ramadas Narayanan; Edward Halawa; Sanjeev Jain; Performance Characteristics of Solid-Desiccant Evaporative Cooling Systems. Energies 2018, 11, 2574, 10.3390/en11102574.

- Irfan Uçkan; Tuncay Yılmaz; Ertaç Hürdoğan; Orhan Büyükalaca; Experimental investigation of a novel configuration of desiccant based evaporative air conditioning system. Energy Conversion and Management 2013, 65, 606-615, 10.1016/j.enconman.2012.09.014.

- Stuart Hands; Subbu Sethuvenkatraman; Mark Peristy; Daniel Rowe; Stephen White; Performance analysis & energy benefits of a desiccant based solar assisted trigeneration system in a building. Renewable Energy 2016, 85, 865-879, 10.1016/j.renene.2015.07.013.

- J. Lin; R.Z. Wang; M. Kumja; T.D. Bui; K.J. Chua; Modelling and experimental investigation of the cross-flow dew point evaporative cooler with and without dehumidification. Applied Thermal Engineering 2017, 121, 1-13, 10.1016/j.applthermaleng.2017.04.047.

- Ghulam Qadar Chaudhary; Muzaffar Ali; Nadeem Ahmed Sheikh; Syed Ihtsham Ul Haq Gilani; Shahab Khushnood; Integration of solar assisted solid desiccant cooling system with efficient evaporative cooling technique for separate load handling. Applied Thermal Engineering 2018, 140, 696-706, 10.1016/j.applthermaleng.2018.05.081.

- Demis Pandelidis; Anna Pacak; Aleksandra Cichoń; Paweł Drąg; William Worek; Sabri Cetin; Numerical and experimental analysis of precooled desiccant system. Applied Thermal Engineering 2020, 181, 115929, 10.1016/j.applthermaleng.2020.115929.

- Muhammad Usman; Hassan Niaz; Muhammad Sultan; Takahiko Miyazaki; Yongqiang Feng; Muhammad Wakil Shahzad; Yasir Niaz; Muhammad Mohsin Waqas; Imran Alic; Study on Desiccant and Evaporative Cooling Systems for Livestock Thermal Comfort: Theory and Experiments. Energies 2020, 13, 2675, 10.3390/en13112675.

- D. B. Jani; Kiran Bhabhor; Mohsin Dadi; Sachindra Doshi; P. V. Jotaniya; Harish Ravat; Kumar Bhatt; A review on use of TRNSYS as simulation tool in performance prediction of desiccant cooling cycle. Journal of Thermal Analysis and Calorimetry 2019, 140, 2011-2031, 10.1007/s10973-019-08968-1.

- RNSYS 18: A Transient System Simulation Program . TRNSYS official website. Retrieved 2021-10-13

- E. Elgendy; A. Mostafa; M. Fatouh; Performance enhancement of a desiccant evaporative cooling system using direct/indirect evaporative cooler. International Journal of Refrigeration 2014, 51, 77-87, 10.1016/j.ijrefrig.2014.12.009.

- Amirreza Heidari; Ramin Roshandel; Vahid Vakiloroaya; An innovative solar assisted desiccant-based evaporative cooling system for co-production of water and cooling in hot and humid climates. Energy Conversion and Management 2019, 185, 396-409, 10.1016/j.enconman.2019.02.015.

- Bs Arun; V Mariappan; Experimental study of an ultrasonic regenerative evaporative cooler for a desiccant cooling system. Building Services Engineering Research and Technology 2018, 40, 151-175, 10.1177/0143624418810934.

- Yulho Lee; Sungjin Park; Sanggyu Kang; Performance analysis of a solid desiccant cooling system for a residential air conditioning system. Applied Thermal Engineering 2020, 182, 116091, 10.1016/j.applthermaleng.2020.116091.