The Sustainability Green Industry (SGI) 4.0 framework captures the relations of Industry 4.0, green processes and sustainability in manufacturing. The framework is structured into three vertical levels: technological, process and development, integrated through the circular economy. The SGI 4.0 framework’s purpose is to explain how Industry 4.0 technologies create sustainability outcomes through green processes. The facilitating, enabling and supporting functions of green processes allow to understand how modern technologies can be linked to the concept of sustainability. In the literature we can find various concepts connecting Industry 4.0 and sustainability, however, the key role of green processes is not mentioned.

- Keywords: green processes

- green technologies

- green manufacturing

- sustainability

- Industry 4.0

- SGI 4.0

1. IDefintroductition

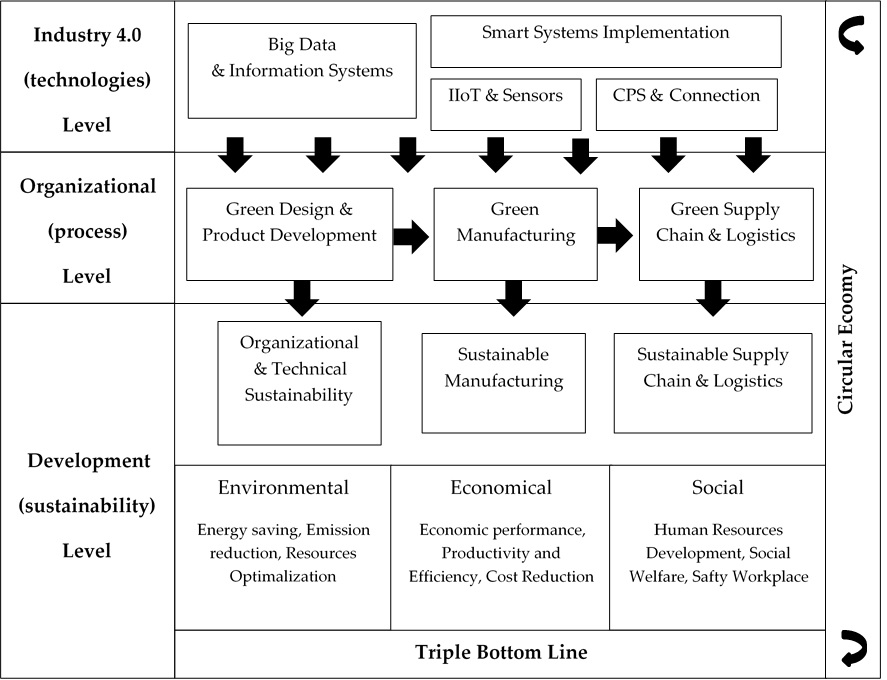

Based on the relationship of sustainability, green processes and Industry 4.0, the SGI 4.0 conceptual framework (Sustainability Green Industry 4.0) is developed by the authors’ team, as shown in Figure 1. The framework captures the relations of Industry 4.0, green processes and sustainability in manufacturing. The framework is structured into three vertical levels: technological, process and development, integrated through the circular economy [1]. The horizontal axis consists of three main processes (design, manufacturing, supply chain and logistics), integrated through the life cycle and the value chain. Their implementation is ensured at a higher level by Industry 4.0 technologies [2] and green technologies. The development level follows them in terms of sub-goals of sustainability (organizational and technical sustainability, sustainable manufacturing, sustainable supply chain and logistics) and the main outcomes of sustainability (environmental, economical and social) through the triple bottom line [3].

The SGI 4.0 framework can explain how Industry 4.0 technologies create sustainability outcomes through green processes. Green processes are an important part of the relationship between Industry 4.0 and sustainability outcomes. The core of green processes is based on green technologies. Industry 4.0 technologies enable full use of green processes to achieve sustainability objectives. The importance of green processes lies in functions they can perform to create sustainability outcomes:

-

The supporting function of green processes connects organizational and technical sustainability with technologies. Green processes use current technologies to create an environment for innovations, working, social and technical conditions at the workplace. This includes processes of eco-design, innovation, maintenance and desirable recovery.

-

The facilitating function of green processes refers to technologies and systems that ensure a continuous and uninterrupted material and information flow from suppliers to end customers. These processes also include reverse flow based on reverse logistics of packaging, recycling, reuse and dismantling of products.

-

Activation function of green processes means the creation of sustainable production system via green value creation, appropriate lean practices, monitoring and the possibility of reprocessing products. Finished manufactured products through these processes minimize negative environmental impacts by conserving energy and natural resources.

2. History

The concept of green technologies and processes was started in the 1960s, as a part of the environmental movement in the industrialized countries. The use of such technologies and processes is seen by researchers in homes, industry, energy and products. The use of green technologies allows enterprises and factories to introduce the green processes into production that reduce impact of the production processes on the environment. The scope of the green processes (operations) ranges from product development to product lifecycle management, including the environmental practices such as ecodesign, clean production, recycling and reuse, with a focus on minimizing costs associated with production, distribution, use and disposal of products [4]. Green technology generally refers to the terms of technology, industrial processes, steps and products that are able to reduce environmental pollution and the use of raw materials, as the natural energy sources [5]. By Chen [6], “green” and “green image” represent a set of brand perception in the mind of the consumer, which is associated with environmental commitments and environmental concerns. In this way, it refers to the corporate social responsibility. For reasons of environmental responsibility, enterprises try to reuse, refurbish and recycle used products to reduce the negative impact on the environment [7].

The green processes are currently a great challenge and an opportunity for new industries, bringing a competitive advantage in the field of the environment [8]. The enterprises should use ecological and technological innovation of the processes, products and image to improve their financial performance [9].

3. Model Description

3.1. Technological level:

-

Big data and information systems—in the context of using information systems for big data analytics. This part of the framework allows using information systems for the processing of large volumes of data (big data are quantified in petabytes 1015) stored on the servers and on the Internet in the Cloud through real-time information systems. The information systems and data are the backbone of smart factories, integrated into ERP and visualized through business intelligence technologies. The users access the data using a web browser and a software client for the application virtually from anywhere.

-

IIoT and sensors—includes the technologies (sensors, switches), which are a source of information for a control system (computer, brain), and technical devices (robot, machine), which measure certain physical and technical quantities (temperature, pressure, speed, humidity, movement, position, sound, power, time, etc.) and convert them into a signal that is transmitted and further processed remotely. The IIoT devices are useful because they are able to communicate with each other thanks to the CPS systems (i.e., they can receive and send information).

3.2. Organizational (process) level:

-

Green Design and Product Development—eco-design of the product means the use of recyclable and recycled materials, recovery parts, reductions in chemicals, energy saving in products, the possibility of further use (re-use), long product life cycle (LCA), possibility of product sharing, durability, disclosure of environmental information, low carbon footprint measure, using standards, renewable resources.

-

Green Manufacturing—it is basically the production of the products used in less energy-intensive equipment and the products that minimize the impact on the environment. At the same time, it is a method of production that reduces the occurrence of harmful emissions and waste of natural resources, using the renewable resources and “clean” technologies.

Sustainable Manufacturing—it includes the sustainability of production processes in the production of environmentally friendly products in accordance with the conditions arising from the requirements of environmental protection and optimization of the production costs.

-

CPS and Connection—The basis is the cooperation of independent control (computer) units, which are able to make autonomous decisions, manage the technological unit and especially to become an independent and full member of complex production units. This intelligent connection (Bluetooth, RFID, Z-Wave, Zigbee, WiFi, etc.) of various products and devices brings new functions to each other and connects the virtual world with people. Their goal is to connect the real and digital world in production through MES and Digital Twin technologies, in the field of development using CAD tools, augmented (AR) and virtual reality (VR) and in logistics in various CRM (customer relationship management) and SCM (supply chain managmeent) applications.

-

Green Supply Chain and Logistics—includes the introduction of systemic measures and the implementation of logistics activities enabling recycling and reusing the waste and reducing emissions. It involves the use of renewable and recyclable packaging, environmentally friendly fuels, means of transport (meeting emission standards), etc.

-

Sustainable Supply Chain and Logistics—the sustainability of the supply chain and logistics networks is based on the requirements for continuous security of supply, with careful waste management at the same time. The key in terms of the management and optimization of supplier networks is the cooperation between enterprises in the distribution, warehousing, transport and implementation of other logistics functions. In the area of logistics, it is mainly about sustainability resulting from the negative impact of transport on the environment.

-

Smart Systems Implementation—the area includes the integration of the above-mentioned technologies into a fully functional system. The implementation is associated with digitization, development of robotics and processes based on automation and artificial intelligence. The smart systems are based on technologies that allow sensors, databases, and wireless to work together, adapt, and modify their behaviour to adapt to the environment and their users. They are able to learn, use experience, anticipate future behaviour and use the skills of self-management and self-regulation. This area also includes other Industry 4.0 technologies such as 3D printing used in additive manufacturing.

3.3. Development (sustainability) level:

-

Organizational and Technical Sustainability—such type of sustainability is focused on the inside of the enterprise. It deals with the optimal use of the resources. It involves the use of human labour, maintenance of technical equipment and machinery and IT infrastructure.

-

Triple Bottom Line—a basic concept of sustainability based on the concept of 3P (People, Planet and Profit). The triple bottom line includes meeting human needs and achieving a satisfactory quality of life while allocating resources efficiently (economically), conserving natural resources, including ecosystems and their biodiversity (ecologically), and social resources accessible to all while preserving cultural diversity (socially).

-

Circular Economy (circularity)—an economic system aimed at reducing waste through the unlimited use of resources. In the SGI 4.0 framework, it consolidates the use of technologies and resources through the green processes enabling long-term sustainability.

-

Sustainability Outcomes—these outcomes are divided into three groups (economic, environmental, social) and are characterized by the most frequently found benefits for each dimension.

New research seeking to use our SGI 4.0 framework should attempt to show empirical results of sustainability outcomes of green processes in relation to Industry 4.0. The SGI 4.0 framework allows to develop assessment tools for evaluationg the sustainability of green processes in the context of Industry 4.0. The framework highlights which sustainability outcomes should be included in these methodologies. This study develops a framework for adopting and facilitating sustainability via green processes across enterprises that use Industry 4.0 technologies. It is conceptual and theoretical preparation for the empirical verification of the interconnection between these various [10].

References

- Martin Geissdoerfer; Paulo Savaget; Nancy M.P. Bocken; Erik Jan Hultink; The Circular Economy – A new sustainability paradigm?. Journal of Cleaner Production 2017, 143, 757-768, 10.1016/j.jclepro.2016.12.048.

- Jaroslav Vrchota; Martin Pech; Readiness of Enterprises in Czech Republic to Implement Industry 4.0: Index of Industry 4.0. Applied Sciences 2019, 9, 5405, 10.3390/app9245405.

- Kerry Maree Lee; So What is the 'Triple Bottom Line'?. The International Journal of Diversity in Organizations, Communities, and Nations: Annual Review 2007, 6, 67-72, 10.18848/1447-9532/cgp/v06i06/39283.

- Kee-Hung Lai; Christina W.Y. Wong; Green logistics management and performance: Some empirical evidence from Chinese manufacturing exporters. Omega 2012, 40, 267-282, 10.1016/j.omega.2011.07.002.

- Xiaoqing Heng; Chengxiao Zou; How Can Green Technology Be Possible. Asian Social Science 2010, 6, 110-114, 10.5539/ass.v6n5p110.

- Yu-Shan Chen; The Drivers of Green Brand Equity: Green Brand Image, Green Satisfaction, and Green Trust. Journal of Business Ethics 2009, 93, 307-319, 10.1007/s10551-009-0223-9.

- I.D. Paul; G.P. Bhole; J.R. Chaudhari; A Review on Green Manufacturing: It's Important, Methodology and its Application. Procedia Materials Science 2014, 6, 1644-1649, 10.1016/j.mspro.2014.07.149.

- Amandeep Singh; Deepu Philip; J. Ramkumar; Quantifying Green Manufacturability of a Unit Production Process Using Simulation. Procedia CIRP 2015, 29, 257-262, 10.1016/j.procir.2015.01.034.

- Xuemei Xie; Jiage Huo; Hailiang Zou; Green process innovation, green product innovation, and corporate financial performance: A content analysis method. Journal of Business Research 2019, 101, 697-706, 10.1016/j.jbusres.2019.01.010.

- Jaroslav Vrchota; Martin Pech; Ladislav Rolínek; Jiří Bednář; Sustainability Outcomes of Green Processes in Relation to Industry 4.0 in Manufacturing: Systematic Review. Sustainability 2020, 12, 5968, 10.3390/su12155968.