The components of edible films are mainly based on natural biopolymers, protein, polysaccharide, and lipid compounds, which create a thin layer on the fruit surface and have been shown to extend the shelf-lives of early apple cultivars as well as those of citrus, European pears, pineapple, papaya, grapes, strawberry, and stone fruit. The natural coatings limit moisture and solute migration into the fruit tissue but do not consistently regulate diffusion of CO2gas across various fruit species, with no data available for the the post-harvest behavior of coated plumcots. A sucrose monoester coating mixed with palmitate and stearate has been observed to form a semi-permeable modified atmosphere, successfully reducing fruit quality loss in early apple cultivars for up to 28 days, mitigating anaerobic conditions and off-flavors.

- anthocyanin

- coating

- flavonoid

- plumcot

- respiration

1. Introduction

Plumcot ( Prunus salicina Lindl. × P. armeniaca L.) trees are likely a naturally interspecific hybrid originating between Japanese plum ( Prunus salicina Lindl.) and apricot ( P. armeniaca L.) trees a long time ago [1][2][3][4][5][6]. There has been an increasing consumer demand for plumcot fruit due to their high bioactive compound content, total flavonoid content, total phenol content, abundance of vitamins A and C, and abundance of mineral nutrients considered important to human health and prevention of disease [5][7]. New plumcot cultivars have been actively selected, from ‘Harmony’ varieties in 2007, ‘Tiffany’ in 2010, and ‘Symphony’ in 2011, by The National Horticultural Research Institute of South Korea. However, the post-harvest handling and storage of plumcot fruit has proven difficult for farmers due to its typical climacteric type as a prunus fruit species [2][3][5].

‘Harmony’ plumcots are widely cultivated in S. Korea and typically harvested at 30–50% red skin coloration in July [3][8]. The fruits soften and decay rapidly at room temperature within two to five days due to accelerating internal concentrations of ethylene and CO 2 [3][4][8][9][10][11][12][13][14][15]; however, 1-methylcyclopropene has been effective in controlling fruit ripening and the resulting softening, skin color change, and acidity in ‘Harmony’ fruits [8], but is not seen as a desirable additive by consumers, with additive-free food in increasing global demand [12]. Cold storage for several days at temperatures lower than 8 °C has been seen to increase the risk of chilling injury in stone fruits, resulting in internal browning, breakdown, and discoloration of the flesh [16], with fruits requiring novel post-harvest care at room temperature to prevent post-harvest loss.

The components of edible films are mainly based on natural biopolymers, protein, polysaccharide, and lipid compounds, which create a thin layer on the fruit surface and have been shown to extend the shelf-lives of early apple cultivars as well as those of citrus, European pears, pineapple, papaya, grapes, strawberry, and stone fruit [10][11][12][13][14][15][17][18][19][20][21][22][23][24][25][26][27][28][29][30][31][32]. The natural coatings limit moisture and solute migration into the fruit tissue but do not consistently regulate diffusion of CO 2 gas across various fruit species [10][11][12][13][14][15][17][18][19][20][21][22][23][24][25][26][27][28][29][30][31][32], with no data available for the the post-harvest behavior of coated plumcots. A sucrose monoester coating mixed with palmitate and stearate has been observed to form a semi-permeable modified atmosphere, successfully reducing fruit quality loss in early apple cultivars for up to 28 days, mitigating anaerobic conditions and off-flavors [22][25].

This study was carried out to investigate fruit quality in coated ‘Harmony’ plumcots by examining the plants’ morphological characteristics, antioxidant levels, and susceptibility to physiological disorders, as well as examining sucrose ester application during storage to effectively slow the fruit ripening process.

2. RMatesearchrials and Methods

Approximately 500 ‘Harmony’ plumcot samples were collected at harvest with a 30% to 50% red skin coloration from a packing house in a commercial orchard located in Yeongcheon, South Korea, on 30 June 2021 ( Figure 1 A,B). The fruit samples were immediately transferred to a laboratory at an agricultural experiment station at Daegu Catholic University in Gyeongsan, South Korea. Two methods of applying coating were adopted and evaluated for their effectiveness in prolonging post-harvest fruit quality after room temperature (25.0 ± 0.5 °C/60 ± 5% relative humidity (RH)) storage for 12 days, using two fruit sample groups; one group was from fruit immediately transferred from the packing house (after 0 d CS), while the other was kept for seven days in commercial cold storage (5.0 ± 0.5 °C/80 ± 5% RH; after 7 d CS) and then coated.

An analysis of all quality parameters was conducted using five fruits from the control and coated groups at each sampling time at three-day intervals throughout 12 days of room temperature storage (12 DAS) typical of when fruit is exhibited to consumers in supermarkets. This was done for both groups, those treated with coating after 0 d CS, and for those coated after 7 d CS, using 300 fruit samples from each group. All fruits were kept without packaging during the storage.

Each fruit was kept in a 3000-mL plastic film bag containing a digital CO 2 electronic sensor capable of measuring between 0–1000 mL −1 kg −1 h −1 (XE-2000 Multi-function, XEAST Co., Ltd., Shenzhen, China) that was placed inside for one hour to monitor concentrations of CO 2 inside the fruit tissue [25].

The sensory quality of each fruit was evaluated by four semi-trained persons on a hedonic scale (1–5 scale from worst to best) for sweetness, sourness, and fruit overall acceptability according to Novianti et al. [29].

3. Results and Discussion

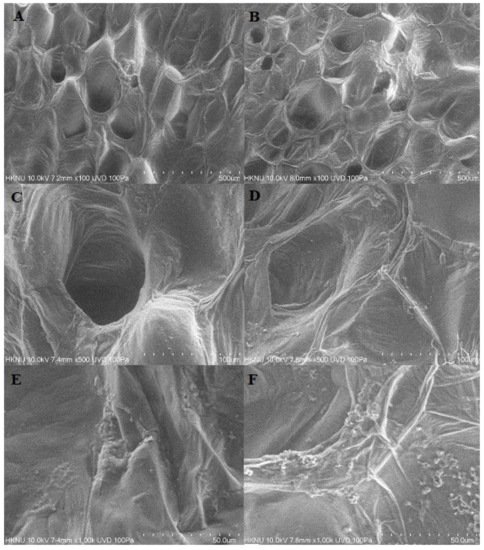

A porous surface was observed in the microstructure of the control fruits at 14 DAS via SEM ( Figure 2 A,C,E). The coated fragments of sucrose monoester did not completely retain cohesive films for lenticel and stomata on the epidermal cells ( Figure 2 B,D,F). This lack of adhesion was most likely due to an uneven application of the coating due to the hairy skin of the fruit, along with strong climacteric behavior, and substantial physical changes from fruit shrivel, which consequently reduced adhesion of the fragments at 14 days after storage [18][19][20]. The sucrose monoester with palmitate had previously been observed to be effective in studies on the smooth peel of bananas and apples over 30 days, as it uniformly covered the surface with small fragments [19][25][27].

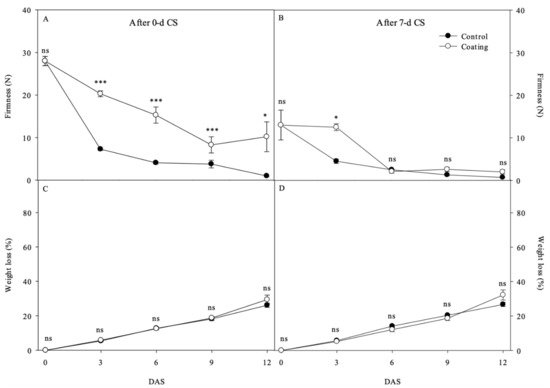

Flesh firmness is the prime factor in determining consumer acceptance and freshness of stone fruits [12][33]. The coated fruits retained significantly higher flesh firmness than those of control fruits from 3 DAS to 12 DAS after 0 d CS ( Figure 34 A) by limiting oxygen levels that degrade enzymes in cell walls of the stone fruits [12][34], previously reported for studies with apple, banana, and pear fruits coated with sucrose esters [19][20][21][22][25][27]. However, the coating did not maintain the fruit firmness after 7 d CS from 6 DAS to 12 DAS ( Figure 34 B), mostly due to the elevated respiration rate at 0 DAS and the delayed treatment of the coating. Flesh weight loss did not significantly differ between the treated fruits during storage either after 0 d CS ( Figure 34 C) or after 7 d CS ( Figure 34 D), although the edible coating has typically reduced weight loss in many other stone fruits through blocking fruit surface pores and reducing transpiration [10][11][12][13][14][15]. Flesh weight loss in all fruits rapidly increased between 26 and 32% at 12 DAS and promoted active respiration and transpiration, consequently reducing the treatment’s effect during storage time, previously addressed in the literature [10][11][12][13][14][15].

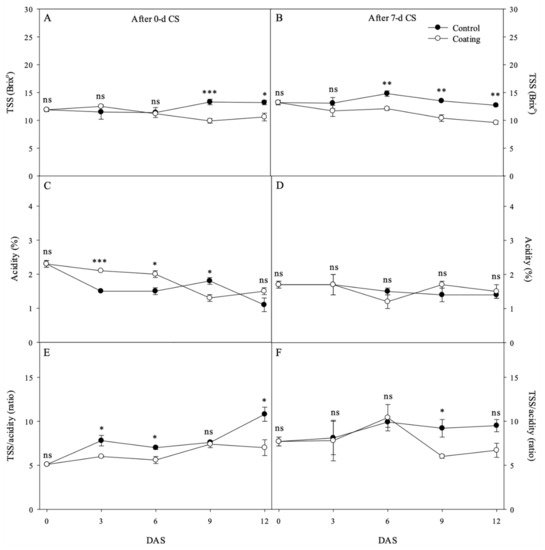

TSS, the components of soluble sugars and organic acids in the fruit juice, was generally higher in the control fruits at later storage periods after 0 d CS ( Figure 45 A) and after 7 d CS ( Figure 45 B) than in coated fruits. Low oxygen concentrations in coated fruits delayed starch degradation into TSS and inhibited Krebs cycle activity related to titratable acidity [17][18] which was observed as higher acidity in coated fruits at 3 DAS and 6 DAS after 0 d CS ( Figure 45 C) but were not confirmed in after 7 d CS samples ( Figure 45 D). TSS: acidity ratio increased in the control fruits at 3, 6, and 12 DAS in after 0 d CS samples ( Figure 45 E) and at 9 DAS in after 7 d CS ( Figure 45 F) with higher values more likely to decrease shelf-life of the different plum cultivars on the previously published research [12][15][33].

4. Conclusions

Immediately following harvest, plumcot fruits are susceptible to spoiling quickly during storage and distribution, significantly affecting fruit distribution to distant markets, and which is exacerbated by the lack of cold storage facilities in many developing countries [22][25][35]. Our research showed that a mixture of sucrose monoesters and volatile compounds could extend fruit shelf-life up to 9 days after 0 d CS by limiting the oxygen absorbed by the climacteric fruits compared with the control group, and could be easily used as a post-harvest treatment in plumcot fruits and other prunus fruit species during hot and humid weather. However, further research is needed to investigate the potential post-harvest effects of the coating application at different concentrations, and to acquire more detailed information on why delayed application did little to influence the post-harvest performance of fruits affected by cold stress and internal ethylene biosynthesis.

References

- Jun, J.H.; Kwon, J.H.; Chung, K.H. ‘Harmony’ plumcot. J. Am. Pomol. Soc. 2011, 65, 47–51.

- Kwon, J.H.; Nam, E.Y.; Jun, J.H.; Chung, K.H.; Yun, S.K.; Kim, S.J.; Do, Y.S. Asian plum diversity based on phenotypic traits in republic of Korea. Korean J. Plant Res. 2018, 31, 254–267.

- Kwon, J.H.; Choi, H.J.; Nam, E.Y.; Yun, S.K.; Kim, S.J.; Lee, J.S. Postharvest characteristics of plumcot cultivars bred in Republic of Korea. Acta Hortic. 2020, 1290, 191–195.

- Ledbetter, C.A.; Peterson, S.J.; Burgos, L. Variability of horticultural characteristics among plumcot progenies. J. Genet. Breed. 1994, 48, 117–124.

- Nam, E.Y.; Jun, J.H.; Chung, K.H.; Kwon, J.H.; Yun, S.K.; Yun, I.K.; Cho, K.H. ‘Tiffany’ red-fleshed plumcot. HortScience 2016, 51, 1304–1307.

- Okie, W.R. Spring Satin plumcot. J. Am. Pomol. Soc. 2005, 59, 119–124.

- Gómez, E.; Ledbetter, C.A. Development of volatile compounds during fruit maturation: Characterization of apricot and plum × apricot hybrids. J. Sci. Food Agric. 1997, 74, 541–546.

- Lim, B.S.; Yun, S.K.; Nam, E.Y.; Chun, J.P.; Cho, M.A.; Chung, D.S. Effects of storage temperature and 1-MCP treatment on postharvest quality in plumcot hybrid cv. Harmony. Hortic. Sci. Technol. 2013, 31, 203–210.

- Martínez-Romero, D.; Bailén, G.; Serrano, M.; Guillén, F.; Valverde, J.M.; Zapata, P.; Castillo, S.; Valero, D. Tools to maintain postharvest fruit and vegetable quality through the inhibition of ethylene action: A Review. Crit. Rev. Food Sci. Nutr. 2007, 47, 543–560.

- Bai, E. Physicochemical changes in ‘Santa Rosa’ plum fruit treated with melatonin during cold storage. J. Food Meas. Charact. 2019, 13, 1713–1720.

- Eum, H.L.; Hwang, D.K.; Linke, M.; Lee, S.K.; Zude, M. Influence of edible coating on quality of plum (Prunus salicina Lindl. cv. ‘Sapphire’). Eur. Food Res. Technol. 2009, 229, 427–434.

- Riva, S.C.; Opara, U.O.; Fawole, O.A. Recent developments on postharvest application of edible coatings on stone fruit: A review. Sci. Hortic. 2020, 262, 1–10.

- Thakur, R.; Pristijono, P.; Golding, J.B.; Stathopoulos, C.E.; Scarlett, C.J.; Bowyer, M.; Singh, S.P.; Vuong, Q.V. Development and application of rice starch based edible coating to improve the postharvest storage potential and quality of plum fruit (Prunus salicina). Sci. Hortic. 2018, 237, 59–66.

- Valero, D.; Díaz-Mula, H.M.; Zapata, P.J.; Guilléna, F.; Martínez-Romero, D.; Castillo, S.; Serrano, M. Effects of alginate edible coating on preserving fruit quality in four plum cultivars during postharvest storage. Postharvest Biol. Technol. 2013, 77, 1–6.

- Zhang, L.; Chen, F.; Lai, S.; Wang, H.; Yang, H. Impact of soybean protein isolatechitosan edible coating on the softening of apricot fruit during storage. LWT Food Sci. Technol. 2018, 96, 604–611.

- Lee, E.J. Chilling injury and phytochemical composition of peach fruits as affected by high carbon dioxide treatment before cold storage. Hortic. Environ. Biotechnol. 2014, 55, 190–195.

- Ali, A.; Muhammad, M.T.M.; Sijam, K.; Siddiqui, Y. Effect of chitosan coatings on the physicochemical characteristics of Eksotika II papaya (Carica papaya L.) fruit during cold storage. Food Chem. 2011, 124, 620–626.

- Bai, J.; Baldwin, E.A.; Hagenmaier, R.D. Coating selection for apples other than ‘Delicious’. Postharvest Biol. Technol. 2003, 28, 381–390.

- Bhardwaj, C.L.; Jones, H.F.; Smith, L.H. A study of the migration of externally applied sucrose esters of fatty acids through the skin of banana, apple and pear fruits. J. Sci. Food Agric. 1984, 35, 322–331.

- Dhall, R.K. Advances in edible coatings for fresh fruits and vegetables: A review. Crit. Rev. Food Sci. Nutr. 2013, 53, 435–450.

- Drake, S.R.; Fellman, J.K.; Nelson, J.W. Postharvest use of sucrose polyesters for extending the shelf-life of stored ‘Golden Delicious’ apples. J. Food Sci. 1987, 52, 1283–1285.

- Flores-López, M.L.; Cerqueira, M.A.; de Rodríguez, D.J.; Vicente, A.A. Perspectives on utilization of edible coatings and nano-laminate coatings for extension of postharvest storage of fruits and vegetables. Food Eng. Rev. 2016, 8, 292–305.

- Hasan, S.M.K.; Nicolai, B. Quality of pears with permeability of bio-freshTM edible coatings. Afr. J. Food Sci. 2014, 8, 410–418.

- Hwang, Y.S.; Lee, J.C.; Chun, J.P. Effect of fruit coatings on the marketable quality in ‘Tsugaru’ apples during storage and simulated marketing. J. Agric. Sci. 1992, 19, 136–144.

- Jung, S.K.; Choi, H.S. Fruit quality and antioxidant activities of yellow-skinned apple cultivars coated with natural sucrose monoesters. Sustainability 2021, 13, 2423.

- Lee, J.H.; Min, S.C.; Song, K.B. Effects of edible coating on the quality change in ‘Hongro’ apples during storage. J. Appl. Biol. Chem. 2015, 58, 61–64.

- Momen, M.N.; Tatsumi, Y.; Shimokawa, K. Effects of coating treatment with sucrose fatty acid esters on the ripening of Cavendish banana. Food Preserv. Sci. 1997, 6, 315–320.

- Nimitkeatkai, H.; Srilaong, V.; Kanlayanarat, S. Effect of edible coating on pineapple fruit quality during cold storage. Acta Hortic. 2006, 712, 643–648.

- Novianti, C.; Dwivany, F.M. Chitosan-based edible coating prolongs Musa troglodytarum L. (‘Pisang Tongkat Langit’) fruit shelf-life and changes the ACS1 and ACO1 gene expression profile. Pertanika J. Trop. Agric. Sci. 2020, 43, 563–581.

- Tharanathan, R.N. Biodegradable films and composite coatings: Past, present and future. Trends Food Sci. Technol. 2003, 14, 71–78.

- Wang, S.Y.; Gao, H. Effect of chitosan-based edible coating on antioxidants, antioxidant enzyme system, and postharvest fruit quality of strawberries (Fragaria x aranassa Duch.). LWT Food Sci. Technol. 2013, 52, 71–79.

- Xuan, H.; Streif, J. Effect of pre- and postharvest application of ‘Biofresh’ coating on the keepability of apple fruits. Acta Hortic. 1987, 513, 483–492.

- Crisosto, C.H.; Crisosto, G.; Neri, F. Understanding Tree fruit quality based on consumer acceptance. Acta Hortic. 2006, 712, 183–189.

- Zhang, S.; Li, Y.; Pei, F. Carbon monoxide fumigation improved the quality, nutrients, and antioxidant activities of postharvest peach. Int. J. Food Sci. 2014, 2014, 834150.

- Chen, H.Y.; Jiang, L.F.; Zeng, J.H.; Huo, Y.R.; Li, Y.X. Combination of carnauba wax-based coating and 1-methylcyclopropene (1-MCP) maintains better ‘‘Fuji’’ apple qualities during storage at low temperature. J. Food Process. Preserv. 2020, 44, 921–925.