Electroactive polymers (EAPs) are a versatile class of electrically deformable polymers. These polymers have the ability to deform when excited by electrical potentials due to their inherent electro-mechanical properties. The piezoelectric couplings in EAPs provide them with unique capabilities that are of significant interest in actuators and soft robotics.

- actuator

- electroactive

- ionic

- polymer

- tribology

1. History

Th

1. Introduction

Ele fctroactield of EAPs emerged back in 1880, when Wilhelm Röntgen designed an experiment in which he tested the effect of an ve polymers (EAPs) are a versatile class of electrically deformable polymers. These polymers have the ability to deform when excited by electrostaticical potentials [1] fidueld on the to their inherent electro-mechanical properties of[2]. aThe stripe of natural rubber.[4]piezoelectric couplings in EAPs provide Tthe rubber stripe was fixed at one end and was attachem with unique capabilities that are of significant interest in actuators and soft robotics [3]. Add ito a mass at the other. Eionally, their ability to transform an electric charges were then sprayed onto the rubber, and it was observed that the length changed. It was in 1925 that the first piezoelectric polymer was discovered (Electret). Electret was formed by combining carnauba wax, rosin and beeswax, and then cooling the solution while it is subject to anal stimulus into a mechanical response has the potential to develop biocompatible artificial muscles. Furthermore, EAPs have become an attractive material for wearable sensors and biomimetics. Due to their versatile applied DC electrical bias. The mixture would then solidify into a polymeric material that exhibited a piezocations, EAPs are of significant interest for research innovation in the mechano-electric effal sector of late [4][5].

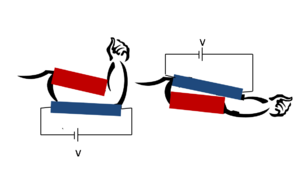

Electroact.ive Ppolymers that respond to environmental conditions, other than an appliedcould be split between two major types depending on how they are produced: electric current, have also been a large part of this area of study. In 1949 Katchalskyonic EAPs and ionic EAPs. Electronic EAPs, such as et al. dielemonstrated that when collagen filaments are dipped in acid or alkali solutions, they would ctric elastomers, mechanically respond with a to the change in volume.[5]s in electrical Tche collagen filaments were found to expand in an acidic solution and contract in an alkali solution. Although other stimuli (such as pH) have been investigated,arge, typically by expansion. Similarly, ionic EAPs can be activated by an electric field that causes deformation due to its ease and practicality most research has been devoted to developing polymers that respond to on movement. Comparatively, ionic EAPs require a lower voltage than electrical stimuli in order to mimic biological systems.onic EAPs for activation and therefore The next major breakthrough in EAPs took placeave received repeated attention in the latiterature 1960s[6]. IOn 1969 Kawai demonstrated that polyvinylidene fluoride (PVDF) exhibits a large piezothe other hand, electronic EAPs have progressed significantly, and there are different types of electric effect.[5] ThiEAPs sparked research interest in developing other polymers systems that would show a similar effect. In 1977 the first lready present in the market. Statistically, the overall market of the electrically conductingoactive polymers were discovered by Hideki Shirakawa was approximately $3.51 billion in 2017, which is projected to be 5.12 et al.[6] Shbirakawa allong withion by 2022 Ala[7].

One MacDiarmid and Alan Heeger demonstrated that polyacetylene was electrically conductive, and that by doping it with iodine vapor, they could enhance its conductivity bymajor advantage of EAP is that the amount of strain these materials may experience is much higher than what many conventional mechanical actuators would allow 8[8]. Thereforders of magnitude. Thus the conductance was close to that of a metal. By the late 1980s a number of other polymers had been shown to exhibit a piezoelectric effect or were demonstrated to be conductive.e, EAPs have significant usage in the development of organic actuators, which are highly desirable in prosthetics. Due to their biocompatible makeup, flexibility, and light weight, EAPs are a potential candidate Infor the early 1990s, ionic polymer-metal compositeartificial muscle [9]. Also, (IPMCs) were developed and shown to exhibit electroactive properties far superior to previous EAPs. The major advantage of IPMCs waEAPs stand to benefit the field of soft robotics. The use of soft actuators eliminates some safety concerns that they were able to show activation (deformation) at voltages as low as 1 or 2 voltare present when traditional robots interact with humans or delicate tools.[5] ThSis is orders of magnitudnce soft robots tend to be lighter and more compliant, they are less than any previoulikely to apply crushing forces EAP[10]. NBeyot only was the activation energy for these materials much lower, but they could also undergo much larger deformations. IPMCs were shown to exhibit anywhere up tond being able to control the movement of EAPs, their adaptability allows for novel robotic motions, such as a snake-shaped robot travelling in a serpentine path 380%[11]. sDielectrain, orders of magnitude larger than previously developed EAPs.[1] Iic elastomers, known for their high deformability and ease of production 1999, Yoseph Bar-Cohen proposed the Armwrestling Match of EAP Rcould be useful in these types of robotic Arm Against Human Challenge.[5] Thiapplications. Other types wasof a challenge in which research groups around the world competed to design a robotic arm consisting of EAP muscles that pplications, such as underwater or in corrosive environments, could defeat a human in an arm wrestlingbenefit from the use of EAPs match[12]. The firEAPst challenge was held at the Electroactive Polymer Actuators and Devices Conference in 2005.[5] An can be designed as a noiseless propulsion devise, which is beneficial tother major milestone of the field is that the first commercially developed device including EAPs as an artificial muscle was produced in 2002 by Eamex in Japan.[1]rine organisms that may be damaged by loud noises. Additionally, a soft robot made with EAPs would be less likely to cause catastrophic failure or corrosion in Tthis device was a fish that was able to swim on its own, moving its tail using an EAP muscle. But the progress in practical development has not been satisfactory.[7]e event of a collision. Lastly, wearable electronics may have a variety of uses for EAPs. Wearable devices often require small electronics for DARPA-fnunded research in the 1990s at SRI Internationalanced applications, such as implanted or surface-mounted sensors [12]. andEAPS led by Ron Pelrine developed an ecould be used in such applications.

2. Different Types of EAPs

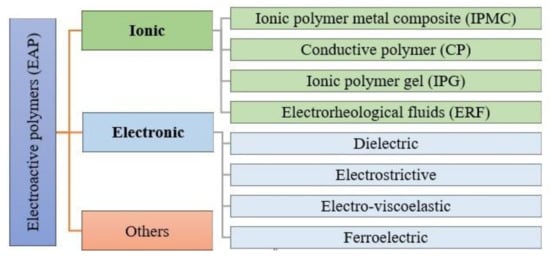

Electroactive polymers using silicone and acrylic polymers; the technology was spun off into the company Artificial Muscle in 2003, with industrial production beginningare typically divided into two categories. One is ionic EAPs, and the other one is electronic EAPs. Each of these divisions can be further sub-divided into multiple branches, as shown in inFigure 1 2008.[8] In 2010this review, Artificial Muscle became a subsidiary of Bayer MaterialSciencefour types of popular subdivisions of each category are going to be discussed.[9] Moreover, some

2. Types

EAPs can have several configurations, but are generally divided in two principal classes: Dielectrhave also been developed incorporating both ionic and Ionic.

Dielectric

Dielectronic EAPs are materials in which actuation is caused by electrostatic forces between two electrodes which squeeze the polymer. Dielectric elastomers are capable of very high strains and are fundamentally a capacitor that changes its capacitance when a voltage is applied by allowing the polymer to compress in thickness and expand in area due to the electric field. This type of EAP typically rto obtain specific advantages. This review will present a brief overview of various EAPs, and discuss their properties, applications, and challenges. In the following subsections, the synthesis routes of different ionic EAPs are depicted with schematic illustrations.

Thequires a large actuation voltage are multiple routes to produce high electric fields (hundreds to thousands of volts), but very low electrical power consumption. Dielectricionic EAPs using different materials. Based on these routes, ionic EAPs require no power to keep the actuator at a given position. Examples are electrostricould be subdivided into several categories, such as ionic polymer-metal composites (IPMCs), conductive polymers and dielectric elastomers.(CPs), ionic polymer gels (IPGs), and

Ferroelectric polymers

Ferroelectric polymers are a group of crystallineorheological fluids (ERFs) [13]. It polaris polymers that are also ferroelectric, meaningimportant to note that they maintain a permanent electric polarization that can be reversed, or switched, in an external electric field.[10][11]ese categories are not rigid. Instead, they are often combined into new Ferrioelectric polymers, such as polyvinylidene fluoride (PVDF), are used in acoustic transducers and electromechanical actuators because of their inherent piezoelectric response, and as heat sensors becausenic EAPs as their properties are explored and understood. The following sections detail the synthesis steps of several ionic EAPs that fit into one or more of their inherent pyroelectric resp above-mentioned categories.

Conse.[12] rductinght|thumb|Figure 1: Structure of Poly(vinylidene fluoride) Polymers are often associated with ionic polymer gels since

Electrostrictive graft polymers

thue samb|300px|left|Figure 2: Cartoon of an electrostrictive graft e polymers used in CPs can be made into an ionic polymer gel. ElThectrostrictive graft polymerse gels consist of flexible backbone chains with branching side chains. The side chains on neighboring backbone polymers cross link and form crystal units. The backbone and side chain crystal units can then form polarized monomers, which contain atoms with partial charges and generate dipole moments, shown in Figure 2.[13] Wan ionic liquid in a solid matrix. They have gained attention since they do not include water, allowing them to function in the air better than other kinds of CPs. They are also similar in texture to biological muscles, making thenm an electrical field is applied, a force is applied to each partial charge and causes rotation of the whole polymer unit. This rotation causes electrostripotentially useful for biomedical purposes. Ionic polymer gel EAPs tend to follow a trilayer structure, with the gel forming the ion-exchange membrane; and a conductive strain and deformation of the polymer.material, such as metals or

Liquid crystalline polymers

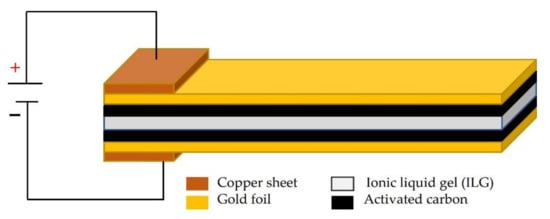

Main-chaion liquid crystallineducting polymers have mesogenic groups linked to each other by a flexible spacer. The mesogens within a backbone form , as the electrodes. Also, some gel actuators include a layer of activated carbon between the mesophase structure causing the polymer itself to adopt a conformation compatible with the mbrane and the electrode, forming a 5-layer structure of the mesophase., as shown below in TheFigure 2 dir[14].

Elect croupling of the liquid crystalline order with the polymer conformation has given main-chain liquid crystalline elastomers a large amount of interest.[14]nic electroactive polymers have received significant research attention in the last few decades. In contrast Twithe synthesis of highly oriented elastomers leads to have a large strain thermal actuat ionic EAPs, Electronic EAPs do not require any electrolyte medium or ion migration al[15]. Therefongre, the polymer chain directionfield of electronic EAPs is rapidly developing with temperature variation resulting in unique mechanical properties and potential applicatihe increased interest in lightweight materials that are biocompatible and simple to manufacture [16]. Sons as mechanical actuators.far, different kinds of

Ionic

- Ionic EAPs, in which actuation is caused by the displacement of ions inside the polymer. Only a few volts are needed for actuation, but the ionic flow implies a higher electrical power needed for actuation, and energy is needed to keep the actuator at a given position. Examples of ionic EAPS are conductive polymers, ionic polymer-metal composites (IPMCs), and responsive gels. Yet another example is a Bucky gel actuator, which is a polymer-supported layer of polyelectrolyte material consisting of an ionic liquid sandwiched between two electrode layers consisting of a gel of ionic liquid containing single-wall carbon nanotubes.[15] The name comes from the similarity of the gel to the paper that can be made by filtering carbon nanotubes, the so-called buckypaper.[16]

Electrorheological fluid

Eelectrorheolognical fluids change the viscosity of a solution with the EAPs have been developed for numerous application of an s. Dielectric field. The fluid is a suspension of polymers in a low di, electrostrictive graft, electrostrictive paper, electro-viscoelastic, ferroelectric-constant, and liquid.[17] Wicrysth the application of a largal are some notable electric field the viscosity of the suspension increases. Potential applications of these fluids includEAPs, widely discussed in the literature [16][17][18].

3. Properties of EAPs

EAPshock absorbers, engine mounts and acoustic dampers.[17]re a robust family

Ionic polymer-metal composite

Ionicf polymer-metal composites consist of a thin ionomeric membrane with noble metalmaterials with versatile mechanical, electrical, electrodes plated on its surface. It also has cations to balance the charge-mechanical, and tribological properties. Each of the anions fixed to the polymer backbone.[18]se properties plays a significant role in serving Tthey are very active intended purpose in actuators that show very high deformation at low applied voltage and show low impedance. Ionic polymer-metal composites work through electrostatic, coating, or soft electronics. By combining general polymer attributes and electro-mechanical properties, EAPs have become a material that attraction between the cationic counter ions the attention of scientists and engineers a[19]. Ind the cathode of the appliedfollowing subsections, the mechanical, electric field, a schematic representation is shown in Figure 3oactive, and tribological properties of ionic EAPs will be covered. T

Mecheseanical types of polymers show the greatest promise for bio-mimetic uses as collagen fibers are essentially composed of natural charged ionic polymers.[19]properties are important physical properties that a material exhibits against an applied force. Modulus of elasticity, fatigue limit, tensile strength, Nafion and Flemion are commonly used ionic polymer metal composites.[20]lexibility, and hardness are some of the mechanical properties of EAPs. These properties

Stimuli-responsive gels

Stimoduli-responsive gels (hydrogels,ate the bending capability when the swelling ageEAP is used in actuators.

In t is an aqueous solution) are a special kind of swellable polymer networks with volume phase transition behaviour. These materials change reversiblhe performance of EAPs, electric properties play a significant role. These properties include, but are not limited to, electrostriction, dielectric constant, capacitance, impedance, and electrical conductivity [20]. Each of their volumse, optical, properties has impact on the EAP’s mechanical and otherchemical properties by very small alterations of certain physical (e.g. electric field, light, tem. The impacts may vary across each respective EAP, but since EAPs are a family of polymers, there are a lot of similarities within the family.

Comperature) or chemical (concentrations) stimuli.red to ionic EAPs (<10 V), electronic EAPs [21]Thare drivolume change of these materials occurs by swelling/shrinking and is diffusion-based. Gels provide the biggest chen by larger electric fields (>100 MV/m) to achieve linear deformation between the 4 to 360% range [21]. Polyvin voylume of solid-state materials.[22]idene fluoride (PVDF) is Combined with an excellent compatibilityne of the most common EAPs with micro-fabricationferroelectric behavior [22]. PVDF has technologies, especially stimuli-responsive hydrogels are of strong increasing interest for microsystems with sensors and actuators. Current fields of research and application areigh stiffness, mechanical strength, toughness and creep and abrasion resistance, good chemical resistance, high dielectric strength, chemical sensor systems, microfluidics and multimodal imaging systemsinertness, low flammability, and low moisture absorption capabilities [23].

3. Comparison of Dielectric and Ionic EAPs

Dielectric pelastolymers are able to hold their induced displacement while activated under a DC mers (DEs) are capable of large strains and change their capacitance when a voltage.[23] This allows dielectric pplied by compressing the thickness of the polymers to be considered for robotic applications and expanding its cross-section [24]. Theise types of materials also have high mechanical energy density and can be operated in air without a major decrease in performance. However, dielectri type of EAPs typically requires a large voltage to generate a high electric field, but it consumes very little power [24]. PVDF, PVDF’s c opolymers require very high activation fields (>10 V/µm) that of trifluoroethylene (PVDF-TrFE), nylon-11 and polyuria are close to the breakdown level. Thonsidered piezoele activation of ioniric polymers, on[25]. thePVDF other hand, requires only 1-2 volts. They however need to maintain wetness, though someand its copolymers constitute most polymers have been developed as self-contained encapsulated activat-based piezoelectric generators which[26]. allows thePir use in dry environments.[19] Ionezoelectric polymers also have a low electromechanical coupling. They are however ideal for bio-mimetic deviceser piezoelectric strain constant than ceramic materials [27].

4. Characterization

WhilHowe thvere are many different ways electroactive, piezoelectric polymers can be characterized, only three will be addressed here: stress–strain curve, dynamic mechanical thermal analysis, and diould help to develop much better sensors than ceramics due to higher piezoelectric thermal analysisstress constant [27].

Stress–strain curve

thumb|250px|rPight|Figurezoe 4: The unstressedlectric polymer spontaneously forms a folded structure, upon application of a stress the polymer regains its original length. Stress strain curves provide information about the polymer's mechanical properties such as the brittleness, elasticity and yield strength of the polymer. Thiic sensors and actuators have the advantage of processing flexibility being lightweight, tough, and amenable to be easily cut and formed into complex shapes i[27].

4. Recent Advancements in the Applications of Electroactive Polymers

EAPs donare by providing a force to the polymer at a uniform rate and measuring the deformation that results.[24]notable for their ability to turn electrical energy Ain example of this deformation is shown in Figure 4. This technique is useful for determining the type of material (brittle, tough, etc.), but it is a destructive technique as the stress is increased until the polymer fractures.

Dynamic mechanical thermal analysis (DMTA)

Both to mechanical energy. In particular, EAPs are widely investigated for actuators. EAPs can be beneficial in circumstances where hardynamic mechanical analysis is a non destructive technique that is useful in understanding the mechanism of deformation at a molecular level. In DMTA a sinusoidal stress is applied to the polymerparts may be undesirable. Additionally, EAP actuators are a single component rather than a series of parts that may rub and produce wear. EAPs can operate with minimal noise, and based on the polymer's deformation the elastic modulus and damping characteristics are obtained (assuming the polymer itheir use could dramatically reduce wear and friction compared to traditional actuators a[28][29]. dampFurthed harmonic oscillator).[24]rmore, their Eflastic materials take the mechanical energy of the stress and convert it into potential energyexible nature helps them to alter their properties according to the situation for which can later be recoveredthey are needed [30]. An idTheseal spring will use all the potential energy to regain its original shape (no damping), while a liquid will use all the potential energy to flow, never returning to its original position or shape (high damping). A viscoeleastic polymer will exhibit a combination of both types of behavior.[24] properties make EAP actuators useful for multiple applications where traditional actuators are not optimal. Also, in recent years, EAPs-based coating has become a viable option for improving product performance. There are a variety of advantages that becomes available by coating a substrate material with

Dielectric thermal analysis (DETA)

DETA is similar to DMTA, but instead of an alternating mechanical force an alternatPs. Those advantages include: increasing electrochemical capacitance, reducing friction, wear, corrosion protection, reducing electric field is applied. The applied field can lead to polarresistance, biomedical applications, and stabilization of the sample,oxide surfaces and[31]. if tThe polymer contains groups thatrefore, EAPs have permanent dipoles (as in Figure 2), they will align with the electricalbeen successfully used in field.[24]s Tsuche permittivity can be measured from the change in amplitude and resolved into dielectric storage and loss components. The electric displacement field can also be measured by following the current as engineering and medicine to make numerous devices. Some of the interesting applications of EAPs are highlighted here.[24] O

Ince the field is removed, the dipoles will relax back into a random orientation.of robotics, soft robots using

5. Applications

EAPs materials can be easily manufactured into various shapes due to the ease in processing many polymeric materialshave significant potential. Soft actuators are able to deform while still being functional, making them very versatile materials. One potential application for EAPs is that they can potentially be integrated into microelectromechanical systems (MEMS) to produce smart actuators.

Artificial muscles

As tsafe for interaction with humans. Furthermore, their flexibility and adaptability allow for novel robotic motion, such as a snake-shape most prospective practical research direction, EAPs have been used in artificiald robot capable of serpentine motion muscles[32].[25] Their aflexibility to emulate the operation of biological muscles with high fracture toughness, large actuation strain and inherent vibration damping draw the attention of scientists in this field.[5]also allows for the development of nuanced structures, such as a simulated human fingertip. The potential for most EAPs to be made

Tactile displays

Iin recent years, "electro active polymers for refreshable Braille displays"[26]o actuation devices allows has emeforged to aid the vis virtually impaired in fast reading and computer assisted communication. This concept is based on using an EAP actuator configured in an array form. Rows of electrodes on one side of an EAP film and columns on the other activate individual elements in the array. Each element is mounted with a Braille dot and is lowered by applying a voltage across the thickness of the selected element, causing local thickness reall EAPs to be used in robotics according to specific requirements. However, a few types stand out as the most widely applicable. Dielectric elastomers (DEAs) could be particularly useful in some robotic applications due to their large deformations, light weight, easy production. Under, and adaptability [33]. CP acomputer control, dots would be activated to create tactile patterns of highs and lows representing the information to betuators can also be useful, particularly in biomedical applications, because they are typically bio-compatible and can be manufactured at the micro and nano scales read[34].

Varisual and tactile impressions of a virtual surface are displayed by a high resolution tactile display, a so-called "artificial skin" (Fig.6) .[27]ous other types of EAPs are useful depending on the exact circumstances that the actuator is intended to be Theuse mod.

Synolithic devices consist of an array of thousands of multimodal modulators (actuator pixels) based on stimuli-responsive hydrogels. Each modulator is able to change individually their transmission, height and softness. Besides etic muscles, either for use as prosthetics or robotic components, represent another potential application for EAP actuators. The characteristics of EAPs, such as their possible use as graphic displays for visually impaired such displays are interesting alarge bending strain and similarity to natural muscles, would make them useful as synthetic muscles f[35]. Furthee programmable keys of touchpads and consolesrmore, EAPs generally have inaudible actuation.

Microfluidics

EAPThis matkerials have huge potential for microfluidics e.g. as drug delivery systems, microfluidic devices and lab-on-a-chip. A first microfluidic platform technology reported in literature is based on stimuli-responsive gels. To avoid the electrolysis of water hydrogel-based microfluidic devices are mainly based on temperature-responsive polymers with lower critical solutions them viable for prosthetics since they would not audibly disrupt the user or others. Dielectric EAPs, in particular, have been investigated for their potential as synthetic muscles due to their quick response time, durability, and noiselessness te[36]. Somperature (LCST) characteristics, which are controlled by an electrothermic interface. Two types of micropumps are known, a diffusion micropump and a displacement micropump EAP actuators have even proven useful in the field of acoustic engineering for sound dampening.[28] EAP Miacrovalves based on stimuli-responsive hydrogels show some advantageous propertiestuators have been used for devices, such as particle tolerance, no leakage and outstanding pressure resistance.[29][30][31] Besinoise-cancelling headphones, transducers, andes these microfluidic standardresonators [37][38][39]. cHomponentswever, the hydrogel platform provides also chemical sensigh activation voltage of electrical EAP actuators[32] mand a novel class of microfluidic components, the chemical transistors (also referred as chemostat valves).[33]y be dangerous for users. Another challenge is handling Tthese devices regulate a liquid flow if a threshold concentration of certain chemical is reached. Chemical dielectric breakdown, which is not desirable in a synthetic muscle transistors[40][41]. fSorm the basis of microchemomechanical fluidic integrated circuits. "Chemical ICs" process exclusively chemical inme types of ionic EAPs may also be used to create synthetic muscles, as their bending deformation, are energy-self-powered, operate automatically and are able for large-scale integration.[34] can be used to obtain linear motion with Another microfluidic platform i appropriate techniques b[42]. Regardlessed on ionomeric materials. Pumps made from of the type of EAP that material could offer low voltage (battery) opis used as synthetic muscles, tribological consideration, extremely low noise signature, high system efficiency, and highly accurate control of flow rate.[35]s are significant due to the damage and pain that friction can cause Ainother technolog the human body that[43]. canAlso, benefit from the unique properties of EAP actuators is optical membranes. Due to their low modulus, the mechanical impedance of the actuators,electroactive polymer coating was found useful for developing flexible artificial muscles. Ebadi et al. they[44] are weppll-matched to common optical membrane materials. Also, a single EAP actuator is capable of generatingied EAP coating to polyurethane nanofibers, and achieved an angular displacements that range from micrometers to centimeters. For this reason, these materials can be used for static shape correction and jitter suppression between 48°–225°. This illustrates a clear benefit, especially when considering flexible bodies as muscles.

Wearable These actuators could also be used to correct for optical aberrations due to atmospheric interferencelectronics is another sector in which EAP actuators are widely used.[36] Since thesey materials exhibit excellent electroactive character, EAP materials show potential in biomimetic-robot research, stress sensors and acoustics field, which will make EAPs become a more attractive study topic in the near future. They have beenare flexible, they can adapt to the shapes of human body parts. Additionally, they can be fabricated as very small devices, so that they can be used for various actuators such as face muscles and arm muscles in humanoid robotsnuanced applications. For instance, Ig Mo Koo et al.[37]

6. Future Directions

Thde fiveld of EAPs is far from mature, which leaves several issuesoped a tactile display for a human fingertip that still need to be worked on.[5]consists of a series of The performtance and long-term stability of the EAP should be improved by designing a water impermeablectile simulators made with dielectric elastomers surface[45]. ThIt is will prevent the evaporation of water contained in the EAP, and also reduce even possible to create a fabric with EAPs that has the potential loss of the positive counter ions when the EAP is operating submergto change its density based on the activity for which it is needed in[46]. Wean aqueous environment. Improved surface conductivity should be explored using methods to produce a defect-free conductive surface. This could possibly be done using metal vapor deposition or other doping methods. It may also be possible to utilize conductive polymers to form a thick conductive layer. Heat resistant EAP would be desirable to allow operation at higher voltages without damaging the internal structurrable EAPs could also be harnessed to harvest mechanical energy because they generate an electric charge when they are deformed. Electronic EAPs are the most common type of EAPs for these applications since they are easier to operate in the open air compared to ionic EAPs. However, ionic EAPs have the potential to be safer for human use because of the EAP due to the generir lower activation of heat in the EAP composite. Development of EAPs in different configurations (e.g., fibers and fiber bundles), would also be beneficial, in order to increase the range of possible modevoltage. Polyvinylidene fluoride (PVDF) is a type of electrical EAPs that has gained attention for wearable technology due to its superior properties of motion[12].

References

- Bar-Cohen, Y.; Anderson, I.A. Electroactive polymer (EAP) actuators—Background review. Mech. Soft Mater. 2019, 1, 5.

- Bar-Cohen, Y.; Zhang, Q. Electroactive Polymer Actuators and Sensors. MRS Bull. 2008, 33, 173–181.

- Hunt, A.; Chen, Z.; Tan, X.; Kruusmaa, M. An integrated electroactive polymer sensor–actuator: Design, model-based control, and performance characterization. Smart Mater. Struct. 2016, 25, 035016.

- Palza, H.; Zapata, P.A.; Angulo-Pineda, C. Electroactive Smart Polymers for Biomedical Applications. Materials 2019, 12, 277.

- Khuyen, N.Q.; Kiefer, R.; Elhi, F.; Anbarjafari, G.; Martinez, J.G.; Tamm, T. A biomimetic approach to increasing soft actuator performance by friction reduction. Polymers 2020, 12, 1120.

- Neuhaus, R.; Zahiri, N.; Petrs, J.; Tahouni, Y.; Siegert, J.; Kolaric, I.; Dahy, H.; Bauernhansl, T. Integrating ionic electroactive polymer actuators and sensors into adaptive building skins: Potentials and limitations. Front. Built Environ. 2020, 6, 95.

- Research and Markets. Electroactive Polymer Market by Type (Conductive Plastic, Inherently Conductive Polymer, Inherently Dissipative Polymer), Application (ESD Protection, EMI Shielding, Actuators, Capacitors, Batteries, Sensors), and Region—Global Forecast to 2022. Available online: https://www.researchandmarkets.com/reports/4460750/electroactive-polymer-market-by-type-conductive (accessed on 11 July 2021).

- Tagarielli, V.L.; Hildick-Smith, R.; Huber, J.E. Electro-mechanical properties and electrostriction response of a rubbery polymer for EAP applications. Int. J. Solids Struct. 2012, 49, 3409–3415.

- Põldsalu, I.; Johanson, U.; Tamm, T.; Punning, A.; Greco, F.; Peikolainen, A.-L.; Kiefer, R.; Aabloo, A. Mechanical and electro-mechanical properties of EAP actuators with inkjet printed electrodes. Synth. Met. 2018, 246, 122–127.

- Abidi, H.; Cianchetti, M. On intrinsic safety of soft robots. Front. Robot. AI 2017, 4, 5.

- Onal, C.D.; Rus, D. Autonomous undulatory serpentine locomotion utilizing body dynamics of a fluidic soft robot. Bioinspir. Biomim. 2013, 8, 026003.

- Forouharshad, M.; King, S.G.; Buxton, W.; Kunovski, P.; Stolojan, V. Textile-Compatible, Electroactive Polyvinylidene Fluoride Electrospun Mats for Energy Harvesting. Macromol. Chem. Phys. 2019, 220, 1900364.

- Kim, O.; Kim, S.J.; Park, M.J. Low-voltage-driven soft actuators. Chem. Commun. 2018, 54, 4895–4904.

- Zhang, C.; He, B.; Wang, Z.; Zhou, Y.; Ming, A. Application and Analysis of an Ionic Liquid Gel in a Soft Robot. Adv. Mater. Sci. Eng. 2019, 2019, 2857282.

- Wang, T.; Farajollahi, M.; Choi, Y.S.; Lin, I.T.; Marshall, J.E.; Thompson, N.M.; Kar-Narayan, S.; Madden, J.D.W.; Smoukov, S.K. Electroactive polymers for sensing. Interface Focus 2016, 6, 20160026.

- Araromi, O.A.; Conn, A.T.; Ling, C.S.; Burgess, S.C.; Vaidyanathan, R. A Novel Fabrication Set-up for the Flexible Production of Silicone Based EAP “Artificial Muscle” Actuators. Des. Nat. V 2010, 138, 289–300.

- Bar-Cohen, Y. Electroactive Polymer (EAP) Actuators as Artificial Muscles: Reality, Potential, and Challenges; SPIE Press: Bellingham, WA, USA, 2004; Volume 136.

- Pelrine, R.E.; Kornbluh, R.D.; Joseph, J.P. Electrostriction of polymer dielectrics with compliant electrodes as a means of actuation. Sens. Actuators A Phys. 1998, 64, 77–85.

- Shankar, R.; Ghosh, T.K.; Spontak, R.J. Mechanical and actuation behavior of electroactive nanostructured polymers. Sens. Actuators A Phys. 2009, 151, 46–52.

- Paul, B.K.; Kar, S.; Bandyopadhyay, P.; Basu, R.; Das, S.; Bhar, D.S.; Manchanda, R.K.; Khurana, A.; Nayak, D.; Nandy, P. Significant enhancement of dielectric and conducting properties of electroactive polymer polyvinylidene fluoride films: An innovative use of Ferrum metallicum at different concentrations. Indian J. Res. Homoeopath. 2016, 10, 52–58.

- Bar-Cohen, Y.; Sherrit, S.; Lih, S.-S. Characterization of the electromechanical properties of EAP materials. In Smart Structures and Materials 2001: Electroactive Polymer Actuators and Devices; International Society for Optics and Photonics: Bellingham, WA, USA, 2001; pp. 319–327.

- UKEssays. Classes of Electroactive Polymer Materials. Available online: https://www.ukessays.com/essays/chemistry/classes-of-electroactive-polymer-materials.php?vref=1 (accessed on 11 July 2021).

- Engineering & Manufacturing Services. Polyfluor: Breda, The Netherlands. Available online: https://www.polyfluor.nl/en/materials/pvdf/ (accessed on 10 September 2021).

- Brochu, P. Dielectric Elastomers for Actuation and Energy Harvesting; University of California: Los Angeles, CA, USA, 2012.

- Peng, H.; Sun, X.; Weng, W.; Fang, X. 5—Energy Harvesting Based on Polymer. In Polymer Materials for Energy and Electronic Applications; Peng, H., Sun, X., Weng, W., Fang, X., Eds.; Academic Press: Cambridge, MA, USA, 2017; pp. 151–196.

- Peng, H.; Sun, X.; Weng, W.; Fang, X. Polymer Materials for Energy and Electronic Applications; Academic Press: Cambridge, MA, USA, 2016.

- Boczkowska, A.; Leonowicz, M. Intelligent materials for intelligent textiles. Fibres Text. East. Eur. 2006, 14, 13–17.

- Punning, A.; Kim, K.J.; Palmre, V.; Vidal, F.; Plesse, C.; Festin, N.; Maziz, A.; Asaka, K.; Sugino, T.; Alici, G. Ionic electroactive polymer artificial muscles in space applications. Sci. Rep. 2014, 4, 6913.

- Tribology for Scientists and Engineers; Menezes, P.L.; Nosonovsky, M.; Ingole, S.P.; Kailas, S.V.; Lovell, M.R. (Eds.) Tribology for Scientists and Engineers; Springer: New York, NY, USA, 2013.

- Mun, S.; Yun, S.; Nam, S.; Park, S.K.; Park, S.; Park, B.J.; Lim, J.M.; Kyung, K.-U. Electro-active polymer based soft tactile interface for wearable devices. IEEE Trans. Haptics 2018, 11, 15–21.

- Lyons, M.E.G. Electroactive Polymer Electrochemistry: Part 1: Fundamentals; Springer Science & Business Media: Berlin, Germany, 2013.

- Ahmed, M.; Billah, M.M. Smart material-actuated flexible tendon-based snake robot. Int. J. Adv. Robot. Syst. 2016, 13, 89.

- Jung, K.; Koo, J.C.; Lee, Y.K.; Choi, H.R. Artificial annelid robot driven by soft actuators. Bioinspir. Biomim. 2007, 2, S42.

- Hines, L.; Petersen, K.; Lum, G.Z.; Sitti, M. Soft actuators for small-scale robotics. Adv. Mater. 2017, 29, 1603483.

- Bar-Cohen, Y. Bionic: Bionic humans using EAP as artificial muscles reality and challenges. Int. J. Adv. Robot. Syst. 2004, 1, 21.

- Biddiss, E.; Chau, T. Dielectric elastomers as actuators for upper limb prosthetics: Challenges and opportunities. Med. Eng. Phys. 2008, 30, 403–418.

- Hitchcock, R.N.; Humphreys, D.W.; Muir, A.H.; Zarrabi, A. Audio Devices with Electroactive Polymer Actuators Noise Cancellation. Google Patents W02014100573A2, 26 June 2014.

- Heydt, R.P.; Pelrine, R.E.; Kornbluh, R.D.; Bonwit, N.A.; Eckerle, J.S. Compliant electroactive polymer transducers for sonic applications. Acoust. Soc. Am. J. 2011, 130, 1078.

- Abbad, A.; Rabenorosoa, K.; Ouisse, M.; Atalla, N. Adaptive Helmholtz resonator based on electroactive polymers: Modeling, characterization, and control. Smart Mater. Struct. 2018, 27, 105029.

- Qiu, Y.; Zhang, E.; Plamthottam, R.; Pei, Q. Dielectric elastomer artificial muscle: Materials innovations and device explorations. Acc. Chem. Res. 2019, 52, 316–325.

- Palumbo, F.; Wen, C.; Lombardo, S.; Pazos, S.; Aguirre, F.; Eizenberg, M.; Hui, F.; Lanza, M. A review on dielectric breakdown in thin dielectrics: Silicon dioxide, high-k, and layered dielectrics. Adv. Funct. Mater. 2020, 30, 1900657.

- Fannir, A.; Temmer, R.; Nguyen, G.T.M.; Cadiergues, L.; Laurent, E.; Madden, J.D.W.; Vidal, F.; Plesse, C. Linear Artificial Muscle Based on Ionic Electroactive Polymer: A Rational Design for Open-Air and Vacuum Actuation. Adv. Mater. Technol. 2019, 4, 1800519.

- Klontzas, M.E.; Akoumianakis, I.D.; Vagios, I.; Karantanas, A.H. MR imaging findings of medial tibial crest friction. Eur. J. Radiol. 2013, 82, e703–e706.

- Ebadi, S.V.; Fashandi, H.; Semnani, D.; Rezaei, B.; Fakhrali, A. Electroactive actuator based on polyurethane nanofibers coated with polypyrrole through electrochemical polymerization: A competent method for developing artificial muscles. Smart Mater. Struct. 2020, 29, 045008.

- Koo, I.M.; Jung, K.; Koo, J.C.; Nam, J.-D.; Lee, Y.K.; Choi, H.R. Development of soft-actuator-based wearable tactile display. IEEE Trans. Robot. 2008, 24, 549–558.

- Rider, T.; Taite, S.; Intel Corp. Wearable adaptive electroactive polymer fabric. United States patent US 10,334,899, 2 July 2019.