In the last three decades, the development of new kinds of textiles, so-called smart and interactive textiles, has continued unabated. Smart textile materials and their applications are set to drastically boom as the demand for these textiles have been increasing with the emergence of new fibers, new fabrics, and innovative processing technologies. Moreover, people are eagerly demanding washable, flexible, lightweight, and robust e-textiles. These features depend on the properties of the starting material, the post-treatment, and the integration techniques. In this work, a comprehensive review has been conducted on the integration techniques of conductive materials in and onto a textile structure. The review showed that an e-textile can be developed by applying a conductive component on the surface of a textile substrate via plating, printing, coating, and other surface techniques, or by producing a textile substrate from metals and inherently conductive polymers via the creation of fibers and construction of yarns and fabrics with these. In addition, conductive filament fibers or yarns can be also integrated into conventional textile substrates during the fabrication like braiding, weaving, and knitting or as a post-fabrication of the textile fabric via embroidering. Additionally, layer-by-layer 3D printing of the entire smart textile components is possible, and the concept of 4D could play a significant role in advancing the status of smart textiles to a new level.

- e-textile

- integration technique

- conductive material

- smart textile

1. Introduction

Clothing has been one of the three basic human needs since the beginning of our species. In the primitive age, textile was used for clothing purposes and progressively extended to household and domestic applications. The textile was also used for technical applications such as sailcloth, tent, protective garments, ropes, etc., which leveraged the textile properties to create a technical performance advantage.

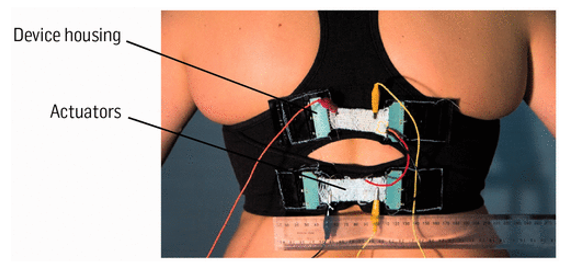

Smart textiles are materials and structures that sense and react to environmental conditions or stimuli, such as those from mechanical, thermal, chemical, electrical, magnetic, or other sources [1]. Textiles are materials that can react on themselves, unlike ordinary clothes. The expressions of “smart” and “intelligent” textiles or “wearable electronic” textiles, are commonly used interchangeably. The term “smart textile” may refer to either a “smart textile material” or a “smart textile system”. The definition is determined only by the context. Smart (intelligent) textile materials are functional textile materials actively interacting with their environment, i.e., responding or adapting to changes in the environment and smart (intelligent) textile systems are textile system exhibiting an intended and exploitable response as a reaction either to changes in its surroundings/environment or to an external signal/input [2]. For instance, Steele et al. developed a bionic bra (Figure 1) using electro-material sensors and artificial muscle technology to detect the increase in breast motion and then respond with increased breast support to improve active living [3].

Figure 1. Bionic bra [3].

Smart textiles integrate a high level of intelligence and can be classified into three subgroups: passive, active, and very smart or intelligent smart textiles [4]. They can be made by incorporating electronic materials, conductive polymers, encapsulated phase change materials, shape memory polymers and materials, and other electronic sensors and communication equipment. As Dadi 2010 studied, these materials interact according to their designed feature with the stimuli in their environment [5]. As an example of a very active smart textile, the first generation of wearable motherboards—which haves sensors integrated inside garments that can detect injury and health information of the wearer and transmit such information remotely to a hospital—has already been developed [6].

1.1. Building Blocks of Smart Textile Systems

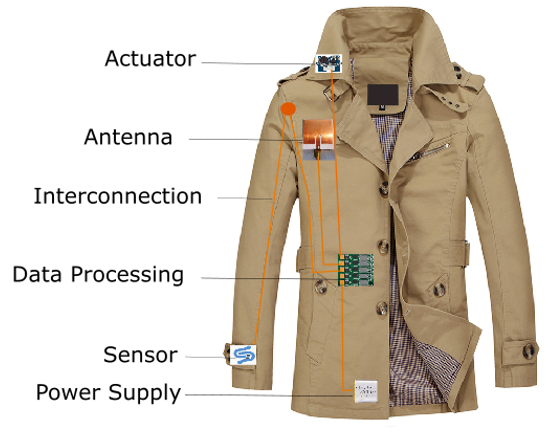

Smart textiles with sensing and actuating capabilities for the desired use have been produced as a single- purpose textile. However, the entire smart textile system could have specific function building blocks such as sensor, actuator, interconnection, a controlling unit, communication device, and power supply. The schematic representation of a smart textile system is shown in Figure 2.

Figure 2. Building blocks of the smart textile system.

Sensor: A sensor is an electronic component that detects or measures a physical property and tracks and records, indicates, or otherwise responds to it. Typical textile-integrated sensor types include textile electrodes for strain [7][8][9][10][11], electrocardiography [12][13][14][15][16], electromyography [17][18][19], electroencephalography [20][21][22], humidity [23][24][25][26], temperature [27][28], pressure [28][29][30], light [31][32], and molecule detection [33][34].

Actuator: An actuator is a building component that can influence its environment. A Ttypical use is to move or control other parts, but also light or sound generating parts are actuators. Common examples of textile actuators introduced are, organic light-emitting diodes [35][36][37], phase changing materials [5][38][39], temperature regulating textiles [40][41][42], and sound- generating textile [43][44][45].

Interconnection: The interconnection is the part that links two or more functional components to one another. A lot of conductive textiles have been introduced for interconnection purposes [4][46][47].

Control Unit: The control unit is an electric board that directs the operation of the processor and is responsible for interpreting the signals from the sensor, ordering the actuator to react, and commanding the communication device to transmit necessary messages. Specific examples of control units that can be integrated into the teextile systems are Arduino [14][48][49], OpenBCI board [50], etc.

Communication Device: This is a unit integrated to transmit and receive electronic data and/or information from and to another system, respectively. A microstrip textile patch antenna [51][52][53][54] is a typical example.

Power Supply: The entire smart textile system must get the power to perform its task; the component included to provide power to the system is the power supply unit. For smart textiles, lithium polymer (LiPo) batteries are commonly used due to their size convenience. However, recently introduced textile-based energy harvesting devices [48][55][56][57] and storage capacitors [58][59][60][61] could replace these for some applications.

2. Conductive Materials for Textiles

Electrical conductive textiles are used in many applications of smart textile materials. However conventional textile materials are usually insulating materials, where they cannot be used directly for smart textile applications that require electrical conductivity. It is possible to obtain electrically conductive textiles by integrating metallic wires, conductive polymers, or other conductive compounds into the textile structure at different stages, such as fiber construction, yarn spinning, or fabric creation stages. To impart conductivity, non-textile metallic filament wires made from silver, stainless steel, nickel, aluminum, and copper can be inserted into the textile structure. Metals provide high conductivity which is very important for some smart textile applications but increases the weight of the material and affects their flexibility. Moreover, some metals are prone to corrosion. Apart from using metal wires, metal-based conductive textiles can also be produced by coating metal ink on the surface of textile materials, but these have limitations in wash stability. This leads to the search for alternative conductive compounds to produce reliable conductive textiles with better flexibility. Up to now, the conductive materials for textile materials can be categorized as conductive inks, carbon-based conductive polymers, intrinsically conductive polymers, and conductive polymer composites.

2.1. Conductive Inks

The success of inkjet printing for printed electronics has been attributed to the emergence of functional printable inks with different nanoscale sizes and structures. Based on their constituents, conductive inks can be categorized into three-dimensional nanostructured materials as nanoparticles, nanowires, nanotubes or they may exhibit plate-like shapes. The printable ink has a wide range of choices such as conductive, semi-conductive, and dielectric inks. The conductive inks can be prepared from conductive metal nano-particles and micro-particles. The semi-conductive inks can be prepared from metal-oxides, organic polymers, and inorganic semiconductors. The dielectric inks are organic polymers in solvents, organic polymer thermosets or ceramic-filled organic polymers. Therefore, the functional conductive inks can be developed from metals, metal oxides, conductive polymers, organometallic inks, graphene, carbon nanotubes, and a mixture of the different inks. Some examples of the conductive inks employed for the development of conductive textile are reactive silver [62], graphene ink [63], and carbon nanotube [64], etc. For instance, Liang et al. used a silver nanoparticle-based conductive ink that was configured with poly(styrene-block-ethylene-ran-butylene-block styrene) to develop a skin-inspired ultra-sensitive pressure sensor [65].

2.2. Carbon-Based Conductive Materials

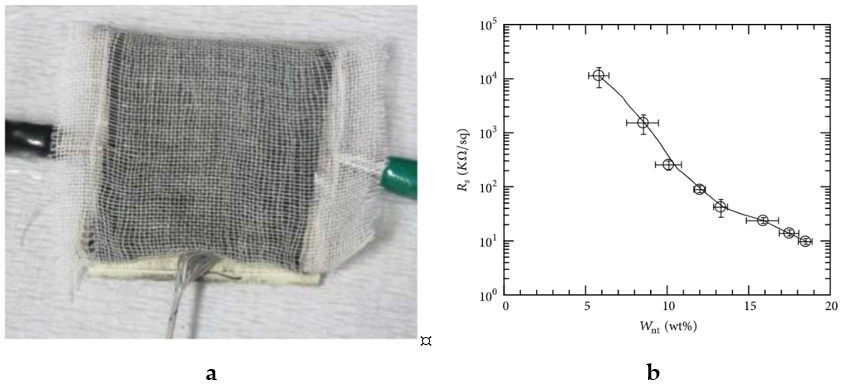

As the need for conductive textiles gains importance, carbon-based materials such as graphene [66], carbon nanotube (CNT) [67], carbon black [68], graphene oxide [69], and reduced graphene oxides [70] have been investigated to develop electrically conductive textiles. These carbon materials are preferable for producing conductive textiles as most of them are relatively inexpensive, and they are corrosion-resistant and flexible [71]. In [72] graphene-based polyester conductive fabric was developed and used for bio-potential monitoring applications. Rahman and Mieno have also developed an electro-conductive cotton textile by multiple dip-coating of the cotton fabric in a multi-walled carbon nanotubes solution. The surface resistance of the coated fabric decreased as the amount of carbon loading increased, which depends on the number of dippings [73]. The carbon-based conductive fabric is shown in Figure 3. Therefore, these materials can be used to produce a conductive textile with different ranges of conductance, up to more than 0.20 S/m depending on the load content. Other integration techniques like plating, transfer printing, inkjet printing, solution, and electrospinning of carbon-based conductive materials could also provide a textile material with better conductivity and bulk property. For instance, Zhu et al. single-walled carbon nanotubes to fabricate machine-washable conductive textiles via dip-coating and spray coating [74]. The developed conductive textiles exhibit a high electrical conductivity of up to 7.4 × 102 S/m.

Figure 3. (a) Multi-walled carbon nanotube/cotton textile covered with one layer of cotton sheet; (b) the effect loading of multi-walled carbon nanotube in the cotton textile on sheet resistance [73].

2.3. Intrinsically Conductive Polymers

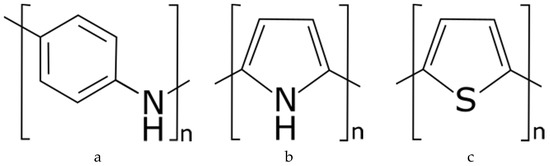

At present, intrinsically conductive polymers are widely used in the development of electro-conductive textiles. Traditional organic polymers are electrical insulators or semiconductors, so the discovery of conductive polymers in the 1970s [75], opened a new opportunity to produce electro-conductive textiles. Conductive polymers are polymers that contain a conjugated molecular structure that is having alternative single and double bonds between carbon atoms. They can combine the electrical property of metals or semiconductors with the benefit of conventional polymers such as price, structural diversity, flexibility, and durability [76], which makes them an ideal choice for textile-based electrodes. Among the conductive polymers, polypyrrole (PPy), polyaniline (PANI), and polythiophene derivative poly(3,4-ethylene dioxythiophene):poly(styrene sulfonate) (PEDOT:PSS) are the most successful in the production of conductive textile [77]. The conductivity of the polymers can be enhanced by adding organic solvents called dopants, for instance, the conductivity of PEDOT:PSS can be enhanced from one to three orders of magnitude by adding polar organic solvents like ethylene glycol, dimethyl sulfoxide, glycerol [78][79][80][81]. Therefore, these conductive polymers can be used to develop all building blocks of the smart textile system as a wide range of electrical properties could be achieved by playing with the polymer add-on, and the extent of dopant. The chemical structure of some conductive polymers is shown in Figure 4.

Figure 4. The most successful conductive polymers: (a) polyanniline; (b) polypyrrole; (c) polythieophene.

2.4. Conductive Polymer Composites

Metal-based conductive textiles have the highest conductivity but are often not flexible enough. While the existing conductive polymers show a promising conductivity, their mechanical properties need improvements. This has led to conductive polymeric composites with improved electrical conductivity and mechanical stability. Electrically conductive polymer composites are polymers consisting of single or hybrid conductive fillers such as carbonaceous, metallic, and conducting polymeric particles dispersed in a polymer matrix. They can be produced based on a single polymer or a multi-phase blend depending upon the electrical and mechanical properties required. Conductive polymer composites have been growing steadily and are being exploited for academic and industrial applications. [82][83][84][85]. As a result, a lot of conductive polymer composites have been introduced and used in developing conductive textiles. For instance, PEDOT:PSS-polydimethylsiloxane [84], PPy-silver nanocomposites [86], PANI-copper [87], graphene-PPy [88], PEDPT:PSS–CNT-Gr [89] have been reported as conductive polymer composites.

References

- Tseghai, G.; Malengier, B.; Fante, K.A.; Van Langenhove, L. The Status of Textile-Based Dry EEG Electrodes. Autex Res. J. 2020, Ahead of Print, doi:10.2478/aut-2019-0071.

- CENTEXBEL VKC. Smart Textiles. 2019. Available online: https://www.centexbel.be/en/lexicon/smart-textiles (accessed on 12 February, 2019).

- Steele, J.R.; A Gho, S.; E Campbell, T.; Richards, C.J.; Beirne, S.; Spinks, G.M.; Wallace, G.G. The Bionic Bra: Using electromaterials to sense and modify breast support to enhance active living. Rehabil. Assist. Technol. Eng. 2018, 5, 205566831877590, doi:10.1177/2055668318775905.

- Stoppa, M.; Chiolerio, A. Wearable Electronics and Smart Textiles: A Critical Review. Sensors 2014, 14, 11957–11992, doi:10.3390/s140711957.

- Dadi, H.H. Literature over View of Smart Textiles; Boras University: Boras, Sweden, 2010.

- Tao, X. Smart Fibres, Fabrics and Clothing, 1st ed.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Washington, DC, USA, 2001.

- Seyedin, S.; Razal, J.M.; Innis, P.C.; Jeiranikhameneh, A.; Beirne, S.; Wallace, G.G. Knitted Strain Sensor Textiles of Highly Conductive All-Polymeric Fibers. ACS Appl. Mater. Interfaces 2015, 7, 21150–21158, doi:10.1021/acsami.5b04892.

- Lee, C.; Jug, L.; Meng, E.; Lee, C.; Jug, L.; Meng, E. High strain biocompatible polydimethylsiloxane-based conductive graphene and multiwalled carbon nanotube nanocomposite strain sensors. Phys. Lett. 2013, 102, 183511, doi:10.1063/1.4804580.

- Seyedin, M.Z.; Razal, J.M.; Innis, P.C.; Wallace, G.G. Strain-responsive polyurethane/PEDOT:PSS elastomeric composite fibers with high electrical conductivity. Funct. Mater.2014, 24, 2957–2966, doi:10.1002/adfm.201303905.

- Zahid, M.; Papadopoulou, E.L.; Athanassiou, A.; Bayer, I.S. Strain-responsive mercerized conductive cotton fabrics based on PEDOT:PSS/grapheme. Des. 2017, 135, 213–222, doi:10.1016/j.matdes.2017.09.026.

- el Zein, A.; Hupp, C.; Cochrane, C. Development of a Flexible Strain Sensor Based on PEDOT :PSS for Thin Film Structures. Sensors 2017, 17, 1337, doi:10.3390/s17061337.

- Pani, D.; Dess, A.; Saenz-cogollo, J.F.; Barabino, G.; Fraboni, B.; Bonfiglio, A. Fully Textile, PEDOT:PSS Based Electrodes for Wearable ECG Monitoring Systems. IEEE Trans. Biomed. Eng. 2016, 63, 540–549, doi:10.1109/tbme.2015.2465936.

- Lee, E.; Cho, G. PU nanoweb-based textile electrode treated with single-walled carbon nanotube/silver nanowire and its application to ECG monitoring. Smart Mater. Struct. 2019, 28, 045004, doi:10.1088/1361-665x/ab06e0.

- Ankhili, A.; Tao, X.; Koncar, V.; Coulon, D.; Tarlet, J. Ambulatory Evaluation of ECG Signals Obtained Using Washable Textile-Based Electrodes Made with. Sensors 2019, 19, 416, doi:10.3390/s19020416.

- Achilli, A.; Bonfiglio, A.; Pani, D. Design and characterization of screen-printed textile electrodes for ECG monitoring. EEE Sens. J. 2018, 8, 4097–4107, doi:10.1109/jsen.2018.2819202.

- An, X.; Stylios, G.K. A hybrid textile electrode for electrocardiogram (ECG) measurement and motion tracking. Materials 2018, 11, 1887, doi:10.3390/ma11101887.

- Paul, G.M.; Cao, F.; Torah, R.; Yang, K.; Beeby, S.; Tudor, J. A smart textile based facial EMG and EOG computer interface. IEEE Sens. J. 2013, 14, 393–400, doi:10.1109/jsen.2013.2283424.

- Lee, S.; Kim, M.O.; Kang, T.; Park, J.; Choi, Y. Knit Band Sensor for Myoelectric Control of Surface EMG-Based Prosthetic Hand. IEEE Sens. J. 2018, 18, 8578–8586, doi:10.1109/jsen.2018.2865623.

- Niijima, A.; Isezaki, T.; Aoki, R.; Watanabe, T. hitoeCap: Wearable EMG Sensor for Monitoring Masticatory Muscles with PEDOT-PSS Textile Electrodes. In Proceedings of the 2017 ACM International Symposium on Wearable Computers, Maui, HI, USA, 11–15 September 2017; 215–220.

- Golparvar, A.J.; Yapici, M.K. Electrooculography by Wearable Graphene Textiles. IEEE Sens. J. 2018, 18, 8971–8978, doi:10.1109/jsen.2018.2868879.

- Lin, C.-T.; Liao, L.-D.; Liu, Y.-H.; Wang, I.-J.; Lin, B.-S.; Chang, J.-Y. Novel Dry Polymer Foam Electrodes for Long-Term EEG Measurement. IEEE Trans. Biomed. Eng. 2011, 58, 1200–1207, doi:10.1109/tbme.2010.2102353.

- Sahi, A.; Rai, P.; Oh, S.; Ramasamy, M.; Harbaugh, R.E.; Varadan, V.K. Neural activity based biofeedback therapy for Autism spectrum disorder through wearable wireless textile EEG monitoring system. Biosens. Info-Tech Sens. Syst. 2014, 9060, 90600D, doi:10.1117/12.2045530.

- Pang, Y.; Jian, J.; Tu, T.; Yang, Z.; Ling, J.; Li, Y.; Wang, X.; Qiao, Y.; Tian, H.; Yang, Y.; et al. Wearable humidity sensor based on porous graphene network for respiration monitoring. Bioelectron. 2018, 116, 123–129, doi:10.1016/j.bios.2018.05.038.

- Weremczuk, J.; Tarapata, G.; Jachowicz, R. Humidity Sensor Printed on Textile with Use of Ink-Jet Technology. Procedia Eng. 2012, 47, 1366–1369, doi:10.1016/j.proeng.2012.09.410.

- Abbasi, M.A.B.; Vryonides, P.; Nikolaou, S. Humidity sensor devices using PEDOT:PSS. In Proceedings of the 2015 IEEE International Symposium on Antennas and Propagation & USNC/URSI National Radio Science Meeting, Vancouver, BC, Canada, 19–25 July 2015; pp. 1366–1367.

- Kang, T.-G.; Park, J.-K.; Yun, G.-H.; Choi, H.H.; Lee, H.-J.; Yook, J.-G. A real-time humidity sensor based on a microwave oscillator with conducting polymer PEDOT:PSS film. Actuators B Chem. 2019, 282, 145–151, doi:10.1016/j.snb.2018.09.080.

- Maslik, J.; Andersson, H.; Forsberg, V.; Engholm, M.; Zhang, R.; Olin, H. PEDOT:PSS temperature sensor ink-jet printed on paper substrate. Instrum. 2018, 13, C12010, doi:10.1088/1748-0221/13/12/c12010.

- Zhang, F.; Zang, Y.; Huang, D.; Di, C.-A.; Zhu, D. Flexible and self-powered temperature–pressure dual-parameter sensors using microstructure-frame-supported organic thermoelectric materials. Commun. 2015, 6, 8356, doi:10.1038/ncomms9356.

- Lei, K.F.; Lee, K.-F.; Lee, M.-Y. Development of a flexible PDMS capacitive pressure sensor for plantar pressure measurement. Eng. 2012, 99, 1–5, doi:10.1016/j.mee.2012.06.005.

- Tseghai, G.B.; Malengier, B.; Nigusse, A.B.; Langenhove, L.V. Development and evaluation of resistive pressure sensors from electro-conductive textile fabric. In Proceeding of the Second International Forum on Textiles for Graduate Students (IFTGS) 2018, Tianjin, China, 30 September 2018; p. 9.

- Macharia, D.K.; Ahmed, S.; Zhu, B.; Liu, Z.; Wang, Z.; Mwasiagi, J.I.; Chen, Z.; Zhu, M. UV/NIR-Light-Triggered Rapid and Reversible Color Switching for Rewritable Smart Fabrics. ACS Appl. Mater. Interfaces 2019, 11, 13370–13379, doi:10.1021/acsami.8b22443.

- Cesarini, M.; Vasile, F.; Natali, D. Inkjet printed hybrid light sensors based on titanium dioxide and Inkjet printed hybrid light sensors based on titanium dioxide and PEDOT:PSS. Sci. Technol. 2019, 34, 024005.

- Pasha, A.; Khasim, S.; Ahmed, F.; Dhananjaya, K.N. Fabrication of gas sensor device using poly (3, 4-ethylenedioxythiophene)-poly (styrenesulfonate)-doped reduced graphene oxide organic thin films for detection of ammonia gas at room temperature. Polym. J. 2019, 28, 183–192, doi:10.1007/s13726-019-00689-4.

- Kinkeldei, T.; Zysset, C.; Münzenrieder, N.; Tröster, G. An electronic nose on flexible substrates integrated into a smart textile. Actuators B Chem. 2012, 174, 81–86, doi:10.1016/j.snb.2012.08.023.

- Mu, W.; Lin, T.; Hu, Y.; Sun, Y.; Du, Z.; Jin, J.; Zhang, D.; Cui, Z. Double layer printed high performance OLED based on PEDOT:PSS/Ir(bt)2acac:CDBP. AIP Adv. 2018, 8, 115112, doi:10.1063/1.5053133.

- Shin, D.; Lee, J.; Kim, G.; Park, J. Improved Intrapixel Thickness Uniformity of Slot-Coated PEDOT:PSS Films for OLEDs via Dilution and Predrying Treatments. IEEE Trans. Electron Devices 2018, 65, 4506–4512, doi:10.1109/TED.2018.2866693.

- Zheng, Y.; Yu, J.-L.; Wang, C.; Yang, F.; Wei, B.; Zhang, J.; Zeng, C.-H.; Yang, Y. Highly efficient red fluorescent organic light-emitting diodes by sorbitol-doped PEDOT:PSS. Phys. D Appl. Phys. 2018, 51, 225302, doi:10.1088/1361-6463/aabf7c.

- Tao, X. Handbook of Smart Textiles, 1st ed.; Springer Science+Business Media: Singapore, 2014.

- Koncar, V. Smart Textiles and Their Applications; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2016.

- van Langenhove, L. Advances in Smart Medical Textiles: Treatments and Health Monitoring; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2016.

- Dai, L. Intelligent Macromolecules for Smart Devices: From Materials Synthesis to Device Applications; Springer: London, UK, 2004.

- Kirstein, T. Multidisciplinary Know-How for Smart-Textiles Developers, 1st ed; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2013.

- Park, S.; Ahn, S.; Kim, J.; Jeong, J.; Park, T.H.; Yoon, H.; Hur, J.; Park, J.-J. Textile Speaker Using Polyvinylidene Fluoride/ZnO Nanopillar on Au Textile for Enhancing the Sound Pressure Level. Adv. Mater. 2018, 10, 1788–1792, doi:10.1166/sam.2018.3378.

- Grant, E.; Luthy, K.; Muth, J.; Mattos, L.S.; Braly, J.; Seyam, A.-F.M.; Ghosh, T.; Dhawan, A.; Natarajan, K. Developing portable acoustic arrays on a large‐scale e‐textile substrate. J. Cloth. Sci. Technol. 2004, 16, 73–83, doi:10.1108/09556220410520379.

- Luthy, K.A.; Mattos, L.S.; Braly, J.C.; Grant, E.; Muth, J.F.; Dhawan, A.; Natarajan, K.; Ghosh, T.; Seyam, A. Initial Development of a Portable Acoustic Array on a Large-Scale E-Textile Substrate. MRS Proc. 2002, 736, D3.7, doi:10.1557/PROC-736-D3.7.

- Briedis, U.; Valisevskis, A.; Grecka, M. Development of a Smart Garment Prototype with Enuresis Alarm Using an Embroidery-machine-based Technique for the Integration of Electronic Components. Procedia Comput. Sci. 2017, 104, 369–374, doi:10.1016/j.procs.2017.01.147.

- Komolafe, A.O.; Torah, R.N.; Yang, K.; Tudor, J.; Beeby, S.P. Durability of screen printed electrical interconnections on woven textiles. In Proceedings of the 2015 IEEE 65th Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 26–29 May 2015; pp. 1142–1147, doi:10.1109/ECTC.2015.7159738.

- He, T.; Shi, Q.; Wang, H.; Wen, F.; Chen, T. Nano Energy Beyond energy harvesting-multi-functional triboelectric nanosensors on a textile. Nano Energy 2019, 57, 338–352, doi:10.1016/j.nanoen.2018.12.032.

- Lund, A.; Darabi, S.; Hultmark, S.; Ryan, J.D.; Andersson, B.; Ström, A.; Müller, C. Roll-to-Roll Dyed Conducting Silk Yarns: A Versatile Material for E-Textile Devices. Mater. Technol. 2018, 3, 1–6, doi:10.1002/admt.201800251.

- Ultracortex ‘Mark IV’ EEG Headset. 2019. Available online: https://openbci.com/ (accessed on 05 May, 2019).

- Hertleer, C.; Rogier, H.; Member, S.; Vallozzi, L.; van Langenhove, L. A Textile Antenna for Off-Body Communication Integrated Into Protective Clothing for Firefighters. IEEE Trans. Propag. 2009, 57, 919–925.

- Kannadhasan, S.; Shagar, A.C. Design and Analysis of U-Shaped Microstrip Patch Antenna. In Proceedings of the 3rd International Conference on Advances in Electrical, Electronics, Information, Communication and Bio-Informatics (AEEICB17) Design, Chennai, India, 27–28 February 2017; pp. 3–6.

- Roshni, S.B.; Jayakrishnan, M.P.; Mohanan, P.; Surendran, K.P. Design and fabrication of an E-shaped wearable textile antenna on PVB-coated hydrophobic polyester fabric. Smart Mater. Struct. 2017, 26, 105011, doi:10.1088/1361-665x/aa7c40.

- Chen, S.J.; Fumeaux, C.; Chivers, B.; Shepherd, R. A 5.8-GHz Flexible Microstrip-Fed Slot Antenna Realized in PEDOT:PSS Conductive Polymer. In Proceedings of the 2016 IEEE International Symposium on Antennas and Propagation (APSURSI), Fajardo, Puerto Rico, 26 June–1 July 2016; Volume 2015, pp. 1317–1318, doi:10.1109/APS.2016.7696366.

- Jin, S.; Sun, T.; Fan, Y.; Wang, L.; Zhu, M.; Yang, J.; Jiang, W. Synthesis of freestanding PEDOT:PSS/PVA@Ag NPs nanofiber film for high-performance flexible thermoelectric generator. Polymer 2019, 167, 102–108, doi:10.1016/j.polymer.2019.01.065.

- Liu, J.; Li, Y.; Arumugam, S.; Tudor, J.; Beeby, S. Screen Printed Dye-Sensitized Solar Cells (DSSCs) on Woven Polyester Cotton Fabric for Wearable Energy Harvesting Applications. Today Proc. 2018, 5, 13753–13758, doi:10.1016/j.matpr.2018.02.015.

- Ryu, J.; Kim, J.; Oh, J.; Lim, S.; Sim, J.Y.; Jeon, J.S.; No, K.; Park, S.; Hong, S. Nano Energy Intrinsically stretchable multi-functional fiber with energy harvesting and strain sensing capability. Nano Energy 2019, 55, 348–353, doi:10.1016/j.nanoen.2018.10.071.

- Giuri, A.; Colella, S.; Listorti, A.; Rizzo, A.; Mele, C.; Esposito, C. GO/glucose/PEDOT:PSS ternary nanocomposites for fl exible supercapacitors. Part B 2018, 148, 149–155, doi:10.1016/j.compositesb.2018.04.053.

- Yin, C.; Zhou, H.; Li, J. Facile one-step hydrothermal synthesis of PEDOT:PSS/MnO2 nanorod hybrids for high-rate supercapacitor electrode materials. Ionics 2018, 25, 685–695, doi:10.1007/s11581-018-2680-6.

- Fong, K.D.; Smoukov, S.K.; Wang, T. Multidimensional performance optimization of conducting polymer-based supercapacitor electrodes. Energy Fuels 2017, 1, 1857–1874, doi:10.1039/C7SE00339K.

- Nuramdhani, I.; Malengier, B.; Deferme, W.; de Mey, G.; van Langenhove, L. Charge-Discharge Characteristics of Textile Energy Storage Devices Having Different PEDOT:PSS Ratios and Conductive Yarns Configuration. Polymers 2019, 11, 345, doi:10.3390/polym11020345.

- Shahariar, H.; Kim, I.; Soewardiman, H.; Jur, J.S. Inkjet Printing of Reactive Silver Ink on Textiles. ACS Appl. Mater. Interfaces 2019, 11, 6208–6216, doi:10.1021/acsami.8b18231.

- Lam, C.L.; Saleh, S.M.; Yudin, M.B.M.; Harun, F.K.C.; Sriprachuabwong, C.; Tuantranont, A.; Wicaksono, D.H. Graphene Ink-Coated Cotton Fabric-Based Flexible Electrode for Electrocardiography. In Proceedings of the 2017 5th International Conference on Instrumentation, Communications, Information Technology, and Biomedical Engineering (ICICI-BME), Bandung, Indonesia, 6–7 November 2017; pp. 73–75, doi:10.1109/ICICI-BME.2017.8537771.

- Thangakameshwaran, N.; Santhoskumar, A.U. Cotton Fabric Dipped in Carbon Nano Tube Ink for Smart Textile Applications. Int. J. Polym. Mater. Polym. Biomater. 2014, 63, 557–562, doi:10.1080/00914037.2013.854227.

- Liang, F.-C.; Ku, H.-J.; Cho, C.-J.; Chen, W.-C.; Lee, W.-Y.; Chen, W.-C.; Rwei, S.-P.; Borsali, R.; Kuo, C.-C. An intrinsically stretchable and ultrasensitive nanofiber-based resistive pressure sensor for wearable electronics. J. Mater. Chem. C 2020, 8, 5361–5369, doi:10.1039/D0TC00593B.

- Hu, X.; Tian, M.; Qu, L.; Zhu, S.; Han, G. Multifunctional cotton fabrics with graphene/polyurethane coatings with far-infrared emission, electrical conductivity, and ultraviolet-blocking properties. Carbon 2015, 95, 625–633, doi:10.1016/j.carbon.2015.08.099.

- Shim, B.S.; Chen, W.; Doty, C.; Xu, C.; Kotov, N.A. Smart Electronic Yarns and Wearable Fabrics for Human Biomonitoring made by Carbon Nanotube Coating with Polyelectrolytes. Nano Lett. 2008, 8, 4151–4157.

- Islam, R.; Khair, N.; Ahmed, D.M.; Shahariar, H. Fabrication of low cost and scalable carbon-based conductive ink for E-textile applications. Mater. Today Commun. 2019, 19, 32–38, doi:10.1016/j.mtcomm.2018.12.009.

- Fugetsu, B.; Sano, E.; Yu, H.; Mori, K.; Tanaka, T. Graphene oxide as dyestuffs for the creation of electrically conductive fabrics. Carbon 2010, 48, 3340–3345, doi:10.1016/j.carbon.2010.05.016.

- Zulan, L.; Zhi, L.; Lan, C.; Sihao, C.; Dayang, W.; Fangyin, D. Reduced Graphene Oxide Coated Silk Fabrics with Conductive Property for Wearable Electronic Textiles Application. Adv. Electron. Mater. 2019, 5, 1800648, doi:10.1002/aelm.201800648.

- Gamage, S.J.P.; Yang, K.; Braveenth, R.; Raagulan, K.; Kim, H.S.; Kim, J.S.; Yang, C.-M.; Jung, M.J.; Chai, K.Y. MWCNT Coated Free-Standing Carbon Fiber Fabric for Enhanced Performance in EMI Shielding with a Higher Absolute EMI SE. Materials 2017, 10, 1350, doi:10.3390/ma10121350.

- Lou, C.; Li, R.; Li, Z.; Liang, T.; Wei, Z.; Run, M.; Yan, X.; Liu, X. Flexible Graphene Electrodes for Prolonged Dynamic ECG Monitoring. Sensors 2016, 16, 1833, doi:10.3390/s16111833.

- Rahman, M.J.; Mieno, T. Conductive Cotton Textile from Safely Functionalized Carbon Nanotubes. J. Nanomater. 2015, 2015, 1–10, doi:10.1155/2015/978484.

- Zhu, S.; Wang, M.; Qiang, Z.; Song, J.; Wang, Y.; Fan, Y.; You, Z.; Liao, Y.; Zhu, M.; Ye, C. Multi-functional and Highly Conductive Textiles with Ultra-high Durability through ‘Green’ Fabrication Process. Chem. Eng. J. 2020, 406, 127140, doi:10.1016/j.cej.2020.127140.

- Chatterjee, K.; Tabor, J.; Ghosh, T.K. Electrically Conductive Coatings for Fiber-Based E-Textiles. Fibers 2019, 7, 51, doi:10.3390/fib7060051.

- Prakash, S.; Chakrabarty, T.; Singh, A.K.; Shahi, V.K. Polymer thin films embedded with metal nanoparticles for electrochemical biosensors applications. Biosens. Bioelectron. 2013, 41, 43–53, doi:10.1016/j.bios.2012.09.031.

- Maity, S.; Chatterjee, A. Polypyrrole Based Electro-Conductive Cotton Yarn. J. Text. Sci. Eng. 2014, 4, 171, doi:10.4172/2165-8064.1000171.

- Achilli, A.; Pani, D.; Bonfiglio, A. Characterization of Screen-Printed Textile Electrodes Based on Conductive Polymer for ECG Acquisition. Presented at the 2017 Computing in Cardiology Conference, Rennes, France, 24–27 September 2017, doi:10.22489/CinC.2017.129-422.

- Sankar, K.N.A.; Mohanta, K. Preparation of Highly Conductive Yarns by an Optimized Impregnation Process. J. Electron. Mater. 2017, 47, 1970–1978, doi:10.1007/s11664-017-5998-3.

- Castrillón, R.; Pérez, J.J.; Andrade-Caicedo, H. Electrical performance of PEDOT:PSS-based textile electrodes for wearable ECG monitoring: A comparative study. Biomed. Eng. Online 2018, 17, 38, doi:10.1186/s12938-018-0469-5.

- Kellomäki, T.; Virkki, J.; Merilampi, S.; Ukkonen, L. Towards Washable Wearable Antennas: A Comparison of Coating Materials for Screen-Printed Textile-Based UHF RFID Tags. Int. J. Antennas Propag. 2012, 2012, 1–11, doi:10.1155/2012/476570.

- Pang, H.; Xu, L.; Yan, D.-X.; Li, Z.-M. Conductive polymer composites with segregated structures. Prog. Polym. Sci. 2014, 39, 1908–1933, doi:10.1016/j.progpolymsci.2014.07.007.

- Maity, S.; Chatterjee, A. Textile/Polypyrrole Composites for Sensory Applications. J. Compos. 2015, 2015, 1–6, doi:10.1155/2015/120516.

- Tseghai, G.B.; Malengier, B.; Fante, K.A.; Nigusse, A.B.; van Langenhove, L. Development of a Flex and Stretchy Conductive Cotton Fabric Via Flat Screen Printing of PEDOT:PSS/PDMS Conductive Polymer Composite. Sensors 2020, 20, 1742, doi:10.3390/s20061742.

- Feller, J.F.; Grohens, Y. Electrical response of Poly(styrene)/carbon black conductive polymer composites (CPC) to methanol, toluene, chloroform and styrene vapors as a function of filler nature and matrix tacticity. Synth. Met. 2005, 154, 193–196, doi:10.1016/j.synthmet.2005.07.050.

- Ghadim, M.F.; Imani, A.; Farzi, G. Synthesis of PPy–silver nanocomposites via in situ oxidative polymerization. J. Nanostruct. Chem. 2014, 4, 1–5, doi:10.1007/s40097-014-0101-6.

- Liu, A.; Bac, L.H.; Kim, J.-S.; Kim, B.-K.; Kim, J.-C. Synthesis and Characterization of Conducting Polyaniline-Copper Composites. J. Nanosci. Nanotechnol. 2013, 13, 7728–7733, doi:10.1166/jnn.2013.7831.

- Loryuenyong, V.; Khadthiphong, A.; Phinkratok, J.; Watwittayakul, J.; Supawattanakul, W.; Buasri, A. The fabrication of graphene-polypyrrole composite for application with dye-sensitized solar cells. Mater. Today Proc. 2019, 17, 1675–1681, doi:10.1016/j.matpr.2019.06.198.

- Liu, Y.-X.; Liu, H.-H.; Wang, J.-P.; Zhang, X.-X. Thermoelectric behavior of PEDOT:PSS/CNT/graphene composites. J. Polym. Eng. 2018, 38, 381–389, doi:10.1515/polyeng-2017-0179.