Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Seung-Jun Shin and Version 2 by Lily Guo.

Flexible manufacturing systems (FMSs) are manufacturing systems that can fabricate diverse product types simultaneously under programmed control at various workstations.

- flexible manufacturing systems

- job shop scheduling

1. Introduction

Flexible manufacturing systems (FMSs) are manufacturing systems that can fabricate diverse product types simultaneously under programmed control at various workstations [1]. FMSs consist of a group of workstations that are interconnected through automated material handling systems and storage systems, and controlled by a computer-integrated system [2]. Along with the advancement of not only manufacturing technology, but also information and communication technology (ICT), FMSs have evolved to handle more diverse product types with greater efficiency and effectiveness. A multimodal factory is a representative example of a modern FMS, which can fabricate and assemble various products demanded across heterogeneous industrial sectors in a single facility [3].

2. Methodology

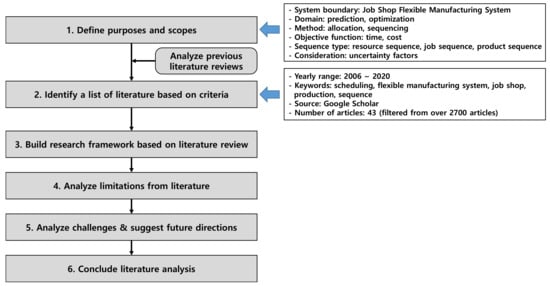

Figure 1 illustrates the research methodology; this methodology is revised from Rasheed and Wahid [4][16], and Akbar and Irohara [5][17], as they suggest reasonable and logical procedures for literature review and analysis. In the first step, the purpose and scope of the review are defined, as described in Section 2.2. Second, a list of literature within the target areas is identified. Here, we searched for the following keywords using Google Scholar: “scheduling”, “flexible manufacturing system”, “job shop”, “production”, and “sequence”. We obtained over 2700 articles from online journal sources. We then chose the literature filtered by only journals and international proceedings from the past 14 years (2006–2020). The determination of this duration stems from our judgment that the relevant technologies have recently been growing rapidly.

Figure 1.

Research methodology.

3. Review Summary

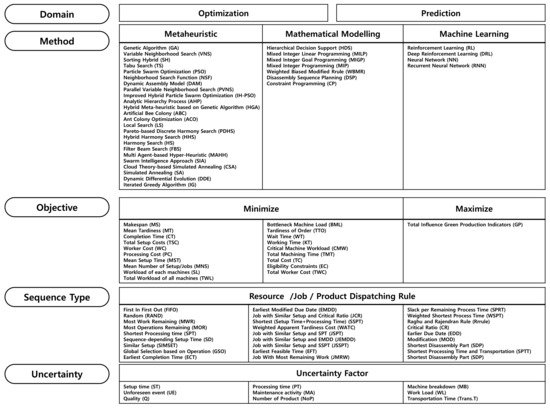

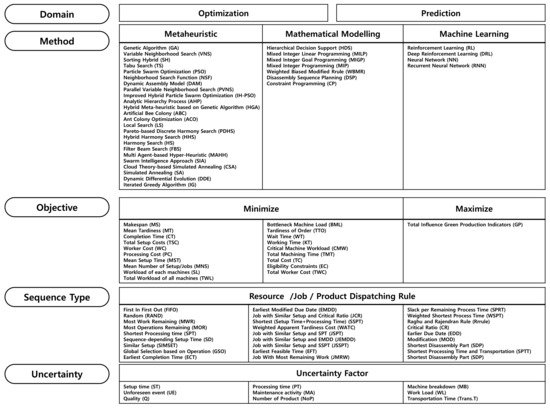

The research framework is illustrated in Figure 3; this framework comprises the layers of domain, method, objective, sequence type, and uncertainty. In Figure 3, we derive items from the individual articles reviewed. Table 3 summarizes the articles in terms of their domain, method, objective, sequence type, and uncertainty.

Figure 3.

Research framework.

4. Challenges

1. Lack of uncertainty: The availability of uncertainty largely affects the dynamics and flexibility in JS-FMSs, and it is hard to know and predict uncertainty in reality. In 11 of the articles analyzed, quality, unforeseen events, maintenance activity, number of products, machine breakdowns, machine workload, and dynamic transportation time were considered to be uncertainty factors. A total of 23 articles regarded dynamic processing time and SDST as indirect uncertainty factors, whereas 13 articles excluded the consideration of uncertainty factors. Incorporating uncertainty can increase the difficulty and complexity of problem identification; however, excluding uncertainty can lead to a large discrepancy between reality and the derived solutions;

2. Stationary dispatching rules: Choosing dispatching rules produces various resource and job allocations, and can lead to the derivation of completely different indicator values. The dispatching rule used for the initial sequence setup can change during production, owing to the availability of uncertainty. A total of 29 articles sustained a single and fixed dispatching rule over their proposed algorithms and solutions; meanwhile, 10 articles combined more than two rules, or adaptively chose one of them purely for machine and job allocations, and not for comparative purposes. It is challenging to obtain feasible solutions for dynamic changes in dispatching rules, especially when products demand diverse processing times and operation sequences;

3. Holistic-than atomic-level solutions: Scheduling problems can be defined from the viewpoint of the entire system or a part of the whole system. From a holistic perspective, algorithms and solutions predict or optimize aggregative indicators at the production (macro-) level, and then allow derivation of subordinate indicator values at the process (micro-) level, whereas the opposite is true from the atomic view. A total of 39 articles set the minimization of the makespan as the objective function. The makespan demands holistic-level algorithms because it associates the completion time of all jobs in all machines during production. Such algorithms have demonstrated their excellence in makespan prediction or optimization within a given system boundary; however, it is controversial whether they can work well when disruptions and uncertainty occur during production;

4. Optimization-then-prediction: Prediction-then-optimization is known as the standard stream in real-world analysis [6][76]. Thus, optimization models can be specified by setting the objective function and constraints on the predictive models that have been derived to figure out numerical relations between the control variables and the target indicators. A total of 12 articles used the strategy of optimization-then-prediction to predict their optimization results for the verification and validation purposes in the given scenarios.