Liquid metal (LM) materials, including pure gallium (Ga) LM, eutectic alloys and their composites with organic polymers and inorganic nanoparticles, are cutting-edge functional materials owing to their outstanding electrical conductivity, thermal conductivity, extraordinary mechanical compliance, deformability and excellent biocompatibility. The unique properties of LM-based materials at room temperatures can overcome the drawbacks of the conventional electronic devices, particularly high thermal, electrical conductivities and their fluidic property, which would open tremendous opportunities for the fundamental research and practical applications of stretchable and wearable electronic devices. Therefore, research interest has been increasingly devoted to the fabrication methodologies of LM nanoparticles and their functional composites.

- liquid metal

- gallium-based materials

- wearable electronics

- energy storage and harvesting devices

- bio-applications

1. Introduction

Liquid metals (LMs) are metals that can stay as a liquid near room temperature because of their low melting points, such as mercury (Hg, −38.8 °C), francium (Fr, 27 °C), cesium (Cs, 28.5 °C), rubidium (Rb, 39.3 °C) and gallium (Ga, 29.8 °C) [1]. Despite their excellent electrical, thermal properties and the unique fluidic state, most of LMs are of limited utility due to their unfriendly physicochemical nature. For example, Hg is highly toxic and easily evaporable, Fr is radioactive and Cs and Rb are instable in air. As a consequence, Ga emerges as the best choice in the LM catalog owing to its low toxicity and high chemical stability. Furthermore, a self-limited, native, thin oxide layer can be formed on the surface of Ga, which can be used as a shell for the formation of geometrically defined shapes of Ga-based nanoparticles with controllable size and properties or a nucleation site for further polymerization reaction. In order to widen the application range, Ga based eutectic alloys such as the commercially available eutectic gallium–indium–tin alloy (Galinstan or EGaInSn, 68.5 wt% Ga, 21.5 wt% In and 10.0 wt% Sn) and gallium–indium alloy (EGaIn, 78.6 wt% Ga and 21.4 wt% In) have been developed and upon varying their composition the resulting melting point can be adjusted below room temperature. In particular, Galinstan has been used, for example, as a coolant [2][3][4][2,3,4], a soft electronic material [5][6][5,6] and a lubricant [7][8][7,8]. EGaIn has been widely used in many areas, such as non-destructive contact in large-area junctions [9][10][11][9,10,11], nanomedicine carriers in drug delivery systems [12][13][12,13] and soft robotics [14][15][16][14,15,16]. To further enrich their functionalities, LM composites have been synthesized to build new material systems in which LMs/alloys are suspended as nanodroplets within a soft polymer matrix or mixed with other inorganic nanoparticles. We limit this review to the metals that are stable as liquids at or near the room temperature, while we exclude Hg, Fr, Cs and Rb due to the above-mentioned reasons. Therefore, the focus of LM in this review is on Ga and their alloys. We briefly summarize the latest development in the synthetic approaches for Ga based materials including Ga particles, alloys and their composites with polymers or rigid inorganic particles and their applications in such as soft electronics, energy storage and harvesting systems and bio-applications.

2. Synthesis of LM Based Materials

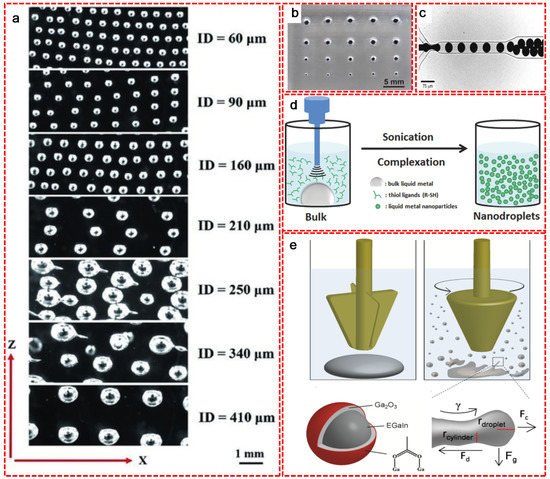

Over the past decades, LM droplets/particles have been produced by many fabrication methods (e.g., 3D printing, microfluidic approach, ultrasonication and molding) to control the droplet size and distribution. Figure 1 summaries the commonly used fabrication methods of LM droplets/particles.

The particle size and distribution are vital for certain applications such as biomedicines. Particles formed by ultrasonication, thermal decomposition, physical vapor deposition and atomic Ga beam have a smaller size ranging from 10 to 100 nm, while other methods such as (e.g., 3D printing, template-assisted molding) normally generate micron-scale particles. Post-treatment (e.g., filtering) is helpful to obtain Ga particles with controlled homogeneous distribution, which is of great importance for the improvement of performance and safety on those sensitive applications with particle size.

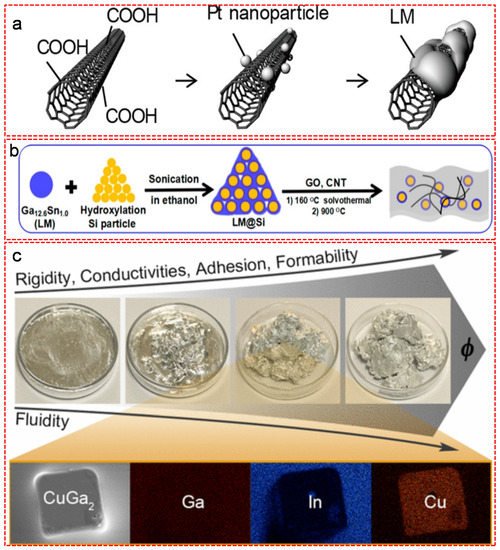

In order to enrich the functionalities of LM, doping with trace amount of inorganic nanoparticles such as carbon allotropies, ceramics and traditional rigid metals has been proven an effective strategy. Many methods have been applied to the incorporation of various nanoparticles into LM, thus forming LM-inorganic nanoparticle composites. The obstacle of forming LM-inorganic particle composites is the existence of the native oxide layer at the interface, which acts as a barrier to prevent inorganic particles from merging into LM. Prior to the formation of composition, the interfacial oxide layer must be removed. Zuraiqi et al. [22][36] and Daeneke et al. [23][37] demonstrated that acid-facilitated suspension, electrochemical amalgamation and mechanical mixing are the most commonly used strategies to effectively forming LM-inorganic nanoparticle composites or alloys. The acid-facilitated method use acid to remove the surface oxides of LM and metal particles, leading to the amalgamation of LM droplets with metal particles. The electrochemical amalgamation method is based on applying a substantial reductive potential to the metal particle pre-coated LM, which eliminates the oxides between the interface and thus promotes the amalgamation of metal particles into LM. The mechanical mixing method relies on destroying the interfacial oxides in the inert environment, thus ensures complete insertion of the inorganic particles into bulk LM. Ma et al. for the first time proposed the concept of the “nano LM fluid” and established an engineering route to design thermally conductive coolant by adding superior thermally conductive nanoparticles into the LM fluid [24][38]. The authors found that the particle size and shape, volume fraction and particle type played important roles in the enhancement of the thermal conductivity of LM-inorganic nanoparticle composites. Among those fillers, carbon nanotubes (CNTs) showed the best performance in the aspect of heat transfer. Following this track, Park et al. prepared a 3D printable soft electronic device with CNT/LM composite by homogeneously dispersing platinum (Pt) modified CNTs nanoparticles in a liquid metal matrix ( Figure 25 a) [25][39]. The CNTs were firstly functionalized with carboxylic groups, and then decorated with Pt nanoparticles as an interfacial material for binding CNTs and LM. Due to its high affinity to both CNTs and LM, the Pt nanoparticles was of great significance to avoid the separation and subsequent aggregation of CNTs and LM, leading to a uniformly dispersed CNT/LM composite. The resulting composite showed ultra-high mechanical strength in stretchable electronic devices. Wu et al. fabricated a Si/LM composite in corporation with CNTs and graphene oxide (GO) as a high-performance anode with self-healing function for lithium ion batteries ( Figure 25 b) [26][40]. The Si nanoparticles were firstly homogeneously mixed with LM by sonication in ethanol and milling to form a Si/LM composite, in which LM acted as a self-healing liquid buffer to restore the cracks caused by the volume expansion and contraction during lithiation and delithiation of Si. The addition of CNTs and GO worked as conductive network and skeleton to improve the conductivity of anode and prevent the Si/LM composite from traveling and aggregating. Besides carbon materials, rigid metal particles have also been incorporated with LM to alter their electrical, thermal, mechanical and magnetic properties. For instance, doping with different portions of Cu particles was confirmed as an efficient strategy to manipulate the physical properties of LM ( Figure 25 c) [27][41]. The resulting LM-Cu composite exhibited appealing semi-liquid/semi-solid mechanical behaviors such as excellent adhesion, tunable formability and self-healing ability, and with increasing the portion of Cu, remarkable enhancements in electrical conductivity (6 × 10 6 S·m −1 , ∼80% increase) and thermal conductivity (50 W·m −1 ·K −1 , ∼100% increase) were recorded.

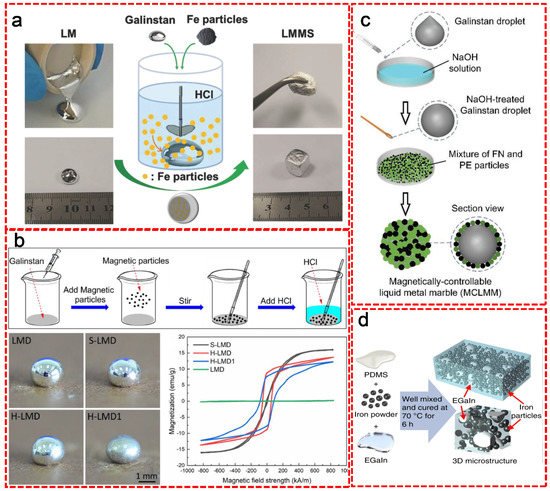

Moreover, particles bearing magnetic properties such as Fe, Ni and Co have been successfully added for preparing magnetically responsive LM composites [28][29][30][31][42,43,44,45]. Ren et al. reported a simple method for synthesizing LM-based magnetoactive slurries (LMMSs) by adding magnetic iron particles into a Ga-based LM matrix ( Figure 36 a) [32][46]. The native oxide layer of the Galinstan was removed in advance with diluted HCl solution, followed by mixing commercially pure Fe particles into Galinstan. Upon the addition of Fe particles, the liquid-state Galinstan was transferred into a readily patternable slurry-like material with a clear increase of viscosity. The successfully synthesized LMMSs exhibited a rapid response on mechanical properties, viscosity and stiffness when applying a magnetic field. He et al. showed a facial method of fabricating liquid metal composites with magnetic properties by simply adding different types of magnetic particles into Galinstan droplets ( Figure 36 b) [33][47]. After the mixture was welled dispersed by stirring, HCl solution was added to remove the oxide layer on the surface of the LM. Based on the type of magnetic particles, the resulting magnetic LM droplets (MLMDs) were classified into soft (with Fe) and hard (with NdFeB) MLMDs. The soft MLMDs can be easily manipulated under magnetic field due to the favorable deformability and flexibility, while the hard ones had much higher surface tension and mechanical robustness, as well as better electrical conductivity and strength. Chen et al. demonstrated the concept and fabrication procedure of magnetically controllable LM marble (MCLMM) ( Figure 36 c) [34][48]. A droplet of Galinstan was initially formed by squeezing raw LM alloy with a syringe in a petri dish, followed by a quick treatment using 30% NaOH solution to remove the oxide layer. As a result, a thin film of Ga-based gallate [Ga(OH) 4] − anti-oxidation layer was formed on the shell of LM droplet. After mixing with ferronickel (FN) and polyethylene (PE) microparticles, the sticky [Ga(OH) 4] − layer strongly bound to those particles, leading to the formation of MCLMM. The as-prepared MCLMM showed excellent magnetic controllability, good elasticity, favorable mechanical robustness and great stability in the ambient environment, which showed a bright potential in the field of robotic locomotion and manipulation, electronic circuits. With the help of PDMS matrix, Yun et al. fabricated a LM-filled magnetorheological elastomer comprising a hybrid of fillers of LM microdroplets and metallic magnetic microparticles by mixing iron powder with EGaIn and subsequent curing in the presence of PDMS at 70 °C for 6 h ( Figure 36 d) [35][49]. The resulting composite exhibited unconventional positive piezoconductive effect. In contrast to most elastic composites whose electrical conductivity decreased under tensile strain, the conductivity of the as-prepared composite was at a minimum level in the relaxed state and dramatically rose under strains. This exceptional phenomenon showed desirable potential for stretchable conductors. Moreover, the conductivity of the composite was highly responsive to the magnetic field. Upon applying an external magnetic field, the resistivity of the composite clearly decreased due to the reduced spacing of Fe particles arisen from the magnetic field induced particle alignment and the increased strain caused by the sample deformation.

3. Applications

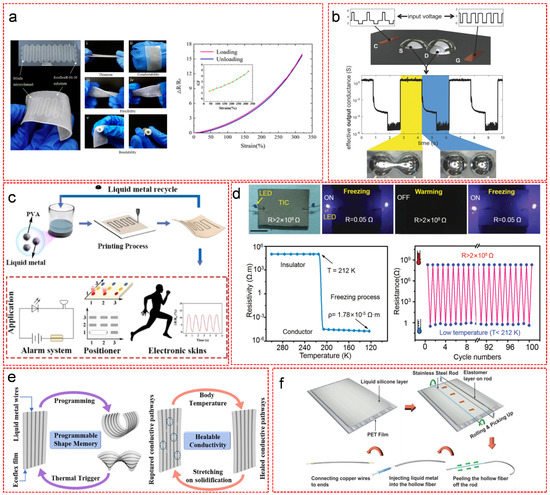

The most astonishing property of Ga-based materials is their high metallic conductivity under large strain. Dickey demonstrated that LMs are the only materials with high stretchability and conductivity compared to other representative stretchable conductors such as deterministic gold thin film, conductivity composites or ionogel [36][83]. By applying the afore-mentioned methods, LMs and their composites are readily utilized as inks to be printed or patterned for soft interconnects, sensors, transistors, stimuli-responsive electrical switches and self-healing conductors. However, precisely patterning Ga-based materials remains challenging due to the poor line edge roughness caused by the sticky nature of the instantaneously formed oxide layer on the surface of Ga especially when applying the methods such as imprinting, micro-contacting printing or stencil-assisted deposition [37][84]. Joshipura et al. suggested that injecting Ga into microchannels may be a good choice to achieve precise Ga pattern [37][84]. Oxygen-free encapsulation with other materials can avoid the instantaneous oxidation of Ga, which may also solve this problem. Chen et al. reported a microfluidic flexible strain sensor based on injecting LM into elastomeric microchannel matrix ( Figure 48 a) [38][85]. The microfluidic strain sensor showed many advantages including thinness, comfortability, flexibility and bendability. It managed to resist a maximum strain up to 320% with fast response, high sensitivity of strain change with a maximum gauge factor (GF = 4.91) at the 320% strain load, ( Figure 48 a) [38][85]. Recently, Liu et al. fabricated a printable conductor using EGaIn with high conductivity (2.06 × 10 6 S m −1 ), extreme high stretchability (>1000%), negligible strain-induced resistance change, good cyclic stability (consistent performance over 1500 cycles) and excellent interfacial contact with rigid surfaces [39][86]. More importantly, the compatibility of EGaIn conductor with scalable manufacturing methods may suggest an inspiration of direct conversion of the printed circuit board (PCB) assemblies into stretchable circuit board assemblies (SCBAs) [39][86]. LM based materials have also been widely used in stretchable field effect transistors [40][41][42][87,88,89]. Wissman et al. reported a field-programmable transistor with LM as the source and drain electrodes ( Figure 48 b) [43][90]. Similar to the conventional field-effect transistors, the switch between on/off states of the LM transistor was under voltage control. Applying a voltage over the gate-source threshold voltage can trigger the coalescence of the LM source and drain electrodes or a voltage across the gate and counter electrodes can cause capillary bridge separation due to the geometrically constrained droplet deformation during electrochemical oxidation. The periodic input voltage generated periodic signal of effective output conductance. Xu et al. developed a poly(vinyl alcohol)/LM composite (PVA-LM) with high surface tension and excellent surface wettability on diverse substrates as a printable and recyclable ink for building alarm systems, object locators and electronic skins ( Figure 48 c) [44][91]. The alarm system was fabricated by connecting an external power supply, a light-emitting diode and a buzzer with PVA-LM printed circuit, which would be triggered upon pressing, rolling or sweeping the circuit. The PVA-LM printed circuit was also well functional in a 3 × 3 array positioner. Objects falling at corresponding areas would turn on the positioning lights. Soft electric skins could also be prepared using the PVA-LM ink to monitor the motions of the different parts of human body. Once sensing external stimuli, such as pressure, bending and stretching, the cross-sectional area decreased and the movement of electrons was blocked, resulting in an increase of electrical resistance that was proportional to the intensity of the stimuli. Besides the mechanical and electrical stimuli, magnetic field was also utilized as a powerful tool to trigger the on/off switch of a magnetic LM based circuit [45][46][92,93]. Joen et al. reported a magnetic-field-driven electrical switch based on the manipulation of magnetic LM slug in microfluidic channels [47][94]. The magnetic LM slug was prepared by coating HCl-treated LM with Fe particles. By dragging the magnetic LM slug within the microfluidic channels with a magnet, the LED lights were sequentially switched on. Thermal treatment is an effective way to manipulate LM for electrical switching [48][49][95,96]. Wang et al. prepared a highly stretchable LM-polymer composite, which showed electrical switching behavior of reversible transition between insulating and conducting upon thermal treatment ( Figure 48 d) [49][96]. The as-prepared LED connected to the LM-polymer composite based circuits was initially off with a high electrical resistance (R > 2 × 10 8 Ω), because the stretchable silicone polymer prevented LM droplets from merging to create a conductive path at the room temperature. Upon freezing the LM-polymer composite by liquid nitrogen, the LED light was turned on with a low resistance (R = 0.05 Ω), because the silicone shell became extremely thin and rigid, allowing the rigid liquid metal droplets to expand and escape from the rigid polymer matrix and then connect with each other to form a conductive path. After warming up the LM-polymer composite, the polymer matrix became elastic and stretchable again and the LM droplets shrank to liquid state. The polymer matrix worked as enclosures to isolate the LM droplets, leading to a breakdown of the conductive path. It was worth mentioning that the temperature to trigger the electrical transition was about 212 K, at which point the resistivity value suddenly changed by more than nine orders of magnitude. Recently, Bhuyan et al. synthesized an elastomeric material with metallic conductivity and shape memory properties by injecting Ga into soft silicone microchannels ( Figure 48 e) [50][97]. On one hand, as a phase-change material, the rigidity of Ga helped the polymer to hold its programmed shape and store elastic energy in the external silicone matrix at the room temperature. On the other hand, the fluidic nature of gallium exhibited a rapid recovery (3−38 s) of the original polymer shape and the conductivity of Ga wires at high temperatures (35−65 °C). Sin et al. fabricated an ultrastretchable thermo- and mechanochromic fiber with healable metallic conductivity ( Figure 48 f) [51][98]. A stainless rod was covered with a composite of PDMS and thermochromic pigment by rolling-coating process. After thermal curing at 100 °C for 2 h, the solidified fiber was peeled off from the rod. Injecting EGaIn alloy into the hollow fiber and connecting Cu wire to the ends fulfilled the fabrication process. The fiber displayed the serial color change for the corresponding thermochromic pigments through precisely controlling the temperatures in the range 25 to 38 °C. Furthermore, the electrical conductivity of fractured fiber was successfully restored upon the introduction of body heat. Interestingly, Markvicka et al. fabricated an autonomously electrically self-healing LM-elastomer composite [52][99]. When the circuit was damaged, the LM droplets autonomously merged with neighbors to rapidly create new conductive paths and reconfigured around the damage in order to recover electrical signals with no interruption.

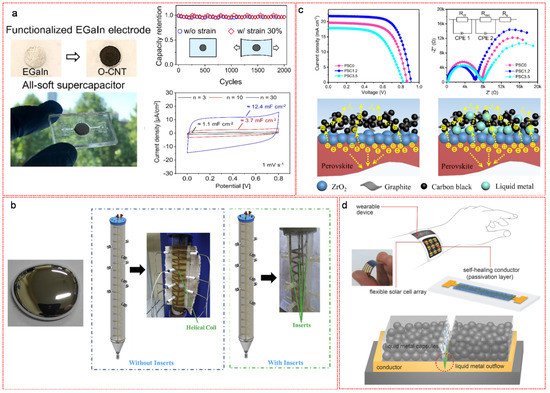

LM based materials have been widely used in energy storage systems (e.g., LM batteries [53][54][100,101] and capacitors [55][102]) and energy harvesting devices (e.g., wearable electric generators [56][57][58][103,104,105] and solar power systems [59][60][106,107]) due to their intrinsic fluidity, high thermal and electrical conductivities, nonflammability and non-toxic characteristics. More importantly, the self-healing ability of LM based materials can restrain the formation of Li dendrite growth caused by uneven nucleation and the crack of lithium ion batteries (LIBs) electrode caused by volume expansion/contraction during lithiation and delithiation reactions. Furthermore, LM can rapidly dissipate heat in photovoltaic cells to avoid fatal damage and dramatically enhance the heat generation efficiency and transfer efficiency of solar power generation and storage systems. Owing to their high boiling point and low melting point, LM based energy storage and harvesting systems can operate stably and safely at high temperatures, and maintain good interfacial properties at low temperatures. Li et al. demonstrated the advantages of using LM based electrode for batteries, compared to conventional solid metal and metal/alloy composite electrodes [61][108]. No Li dendrites were formed on LM electrode during the electrochemical process. In addition, LM can flow to eliminate the grain boundaries of electrodes during cycling in order to prolong the cycling life of batteries. Moreover, the interfacial contact between LM electrode and electrolyte was much better than the conventional solid electrode. In the earlier stage, Ga was directly used as a LIB anode for the purpose of improving the capacity and durability of electrode materials [62][109]. Compared to the conventional graphite anode, the theoretical columbic capacity of Ga (769 mAh·g −1 ) was doubled owing to the transition from Ga to Li 2Ga during charging process. The Ga anode exhibited an excellent self-healing function during the charging and discharging process [62][109]. Upon lithiation, the Ga LM electrode crystallized to become a solid-state Li 2Ga and during delithiation, cracks were formed and subsequently repaired based on the transformation of the solid-form Li 2Ga back into a liquid-state Ga. However, a gradual decrease of capacity with cycling occurred, probably due to the instability of the solid electrolyte interface. Introducing other elements was proven a promising strategy to enhance the stability of the Ga anode. Wu et al. prepared a LM-based self-healing anode for LIBs with Ga-Sn alloy as the active material and reduced graphene oxide (rGO)/CNT as the skeleton [63][110]. Introducing Sn decrease the melting point of Ga so that the Ga-Sn alloy was endowed with self-healing function at room temperatures and the higher specific capacity (993 mAh·g −1 ) of Sn dramatically improved the capacity of the Ga (769 mAh·g −1 ) anode. The rGO /CNT skeleton separated the Ga-Sn particles from each other, avoiding the aggregation and detachment from the current collector during cycling. The resulting Ga-Sn electrode showed a high capacity (775 mAh·g −1 ) and superior cycling performance (nearly no capacity loss within 4000 cycles). As for LM capacitors, Kim et al. reported an all-soft LM supercapacitor with an ultra-high capacitance reaching 12.4 mF·cm −2 and 95% capacitance retention after 2000 charging and discharging cycles under 30% strain ( Figure 59 a) [64][111]. The LM electrode was fabricated by patterning EGaIn alloy with a PDMS stamp followed by coating EGaIn surface with functionalized CNT, which enhanced the interfacial adhesion in between in order to avoid the delamination of the soft electrode during the strain induced deformation. The LM based materials have also played an important role in the fabrication of energy harvesters including solar energy harvesting devices (e.g., the solar thermal power generation system and solar photovoltaic cell) and soft wearable power generators (e.g., thermoelectric, triboelectric, piezoelectric generators). In a solar thermal power generation system, the essential parts are heat adsorption, transfer and storage. Therefore, the heat transfer medium is of crucial importance, as it determines the heat transfer efficiency from the heat collector to the generator. The conventional heat transfer mediums (e.g., heat transfer oil or molten salt) can only stably function below 600 °C, which is much lower than the working temperature of a typical solar thermal power generation system, leading to the decomposition of the heat transfer mediums. In contrast, LM can operate under high heat flux at high temperatures, due to its high boiling point, high thermal conductivity, nonflammability and non-toxic characteristics. Salyan et al. reported a novel heat transfer enhancement technique for solar thermal energy system with Ga acting as thermal energy carrier ( Figure 59 b) [65][112]. The novel system consist of a vertical cylindrical shell, a helical coil and Ga metalinserts. The experimental results indicated that the addition of Ga significantly enhanced the thermal performance of the system. In a photovoltaic cell, LM based materials can also act as an interface material to tune the interfacial properties between solid electrodes [66][67][113,114]. Zhang et al. demonstrated the interface engineering between ZrO 2 perovskite and carbon electrodes using Galinstan as a modifier to fabricate a compact-layer-free, fully printable solar cell ( Figure 59 c) [66][113]. Introducing a small amount of LM (1.2% by weight) remarkably increased the converted current density of the solar cell and significantly enhanced the interfacial contact properties by decreasing the carrier transfer resistance at the interface between ZrO 2 and carbon electrodes. More importantly, it improved the hole extraction via increasing the hole transport channel and reducing the possibility of carrier accumulation and recombination due to the high conductivity and density of LM particles. In addition, there is an increasing demand of electrical repairing of solar cells, as they are often working in extreme conditions. LM based materials are promising for prolonging the durability of devices to build sustainable and flexible solar cells with self-healing function. Chu et al. presented an efficient method for the fabrication of flexible perovskite solar cell applying Ga 0.61 In 0.25 Sn 0.13 Zn 0.01 LM-polymer composite as the self-healing reactant to restore the function of solar cell when damage occurred ( Figure 59 d) [68][115]. The LM-polymer composite was synthesized by encapsulating Ga LM alloy with in situ generated urea-formaldehyde, which subsequently was uniformly deposited as a passivation layer onto the interconnects of the as-built wearable solar cell. Once the electrical circuit was damaged, the LM capsules rapidly ruptured and flew to the disconnected sites, leading to an immediate recovery of electrical pathways. The experimental results indicated a rapid recovery of photovoltaic function with a power conversion efficiency retention of 99%.

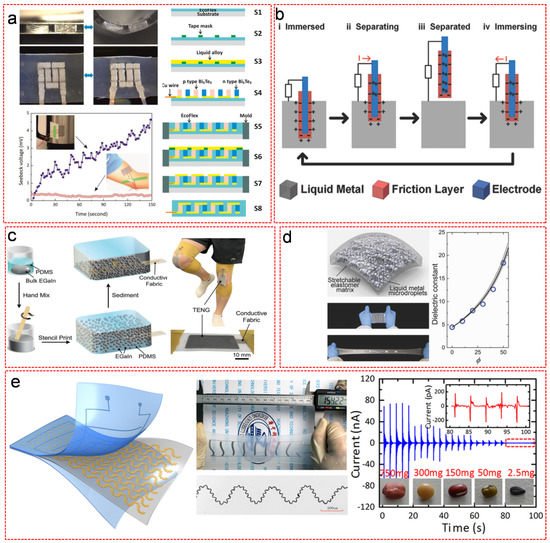

Wearable energy harvesters that attain energy from human body have been of increasing importance for more complex and diverse tasks, which, based on the energy conversion mechanisms, can be classified into wearable thermoelectric generators (TEGs), triboelectric nanogenerators (TENGs), dielectric elastomer (DEGs) and piezoelectric generators (PEGs). For a better service, such devices have to possess merits such as reliability, durability, scalability, high power density and comfortability. For this reason, soft and stretchable electrode materials with excellent thermal, electrical conductivities, power conversion efficiency and biocompatibility are needed. As one of the most promising candidates, LM based materials have gained a lot of attentions owing to their unique properties. In typical wearable TEGs, thermal energy collected from human body heat was directly converted to electrical energy via the Seebeck effect in which current flow can be induced through the p- and n-type semiconductors by the temperature gradients between the skin of human body and the atmosphere. Many groups have reported the recent advances of using patterned LM [69][70][71][116,117,118], or LMEE [72][73][74][119,120,121] for wearable TEGs. Joeng el al. fabricated high-performance soft and stretchable TEGs using conventional rigid Bi 2Te 3 pellets metallized with Ga based LM alloy as the interconnect ( Figure 610 a) [72][119]. The device was built by means of a tailored layer-by-layer fabrication process. Initially, a thin film of 100 µm EcoFlex elastomer prepolymer was uniformly coated on a plastic substrate. After the EcoFlex elastomer prepolymer was semi-cured at 75 °C, a tap mask was placed on top for patterning Ga based LM alloy as the bottom interconnects. Following the removal of the mask, n- and p-type Bi 2Te 3 semiconductors were alternatively deposited on the top of the patterned LM alloy. An additional layer of LM alloy was sprayed on the semiconductors in order to improve their wettability. Afterwards, copper wires were connected to the LM interconnects, followed by filling the gaps of the patterns with the EcoFlex prepolymer in the help of a slide glass mold. After curing the elastomer at 75 °C, another LM layer was patterned as the top interconnects using a tap mask. Subsequently, the mask was removed, followed by sealing the device with a top layer of cured EcoFlex prepolymer. The device was completed after removing the plastic support substrate. The resulting stretchable TEGs exhibited an excellent room-temperature output power density of 40.6 μW/cm 2. Upon introducing Ga LM alloy as the interconnects to the rigid pellets, the soft TEGs were still properly functional after being mechanically stretched and released more than 1000 times. Surprisingly, Malakooti et al. found that LMEE remained liquid state and maintained mechanical compliant and thermoelectric function at ultra-low temperatures, below −80 °C, which is much lower than the minimum working temperature of common fluidic LM systems [73][120]. To achieve this, carefully controlling the LM droplet size (to less than 3 µm in diameter) and appropriately selecting the polymer matrix were mandatary to strongly suppress their freezing temperature (down to −84.1 °C from −5.9 °C) and melting point (down to −25.6 °C from +17.8 °C) and thus maintained the mechanical compliant of the resulting LMEE based wearable TEG at the extreme low temperatures [73][120].

PEG that directly converts mechanical deformations (e.g., pressure, vibration, body motions) into electric energy is the prominent electromechanical energy harvester, owing to its high electromechanical coupling factor and piezoelectric coefficient compared to electrostatic, electromagnetic and triboelectric transductions. Furthermore, the piezoelectric effect is solely dependent on the intrinsic polarization of the material without the requirement of external stimuli such as a voltage source, magnetic field or contact with another material [79][80][131,132]. In addition, PEGs are durable, reliable, more sensitive to minor strains, and exhibit ∼3–5-fold higher density power output and higher voltage output compared to other energy harvesting devices [81][82][133,134]. Traditional piezoelectric materials are normally solid ceramics due to their high electromechanical coupling coefficient [83][84][85][135,136,137]. However, the stiffness and mechanical incompatibility hinder the rigid ceramic particles from direct incorporation into wearable PEGs. As with the aforementioned TEG, TENG and DEG devices, LM based materials have made a predominant contribution for the fabrication of flexible PEG to upgrade its stretchability, deformation detection limit and fatigue life. Huang et al. patterned EGaIn via electrohydrodynamic printing as microfluidic electrodes to acquire the accumulated charges from the strain-induced polarization of piezoelectric dipoles of self-similar serpentine-structured micro/nanofibers of PVDF in a hyper-stretchable self-powered PEG ( Figure 610 e) [78][138]. The as-prepared device displayed high stretchability (up to 320%), low detection limit (0.2 mg) and excellent stability under reciprocating deformation tests (1400 times at stretching 150%).

4. Conclusions and Perspectives

In this review, we summarize the recent advances of the synthesis of Ga based materials and their wide-range applications including soft electronics, energy storage and harvesting devices and biomedical materials. Low-melting-point LM materials possess a series of unique properties such as fluidity, self-healing ability, outstanding thermal and electrical conductivities and biocompatibility. So far, many methods have been developed to fabricate LM droplets and further control their size for the use towards different purposes. Due to its fluidic nature, LM materials can be readily manufactured as conductive ink to be printed on a wide range of substrates and easily patterned by diverse ways for the production of soft electronics. It has also played an important role in the development of self-healing electronic devices and batteries to maintain their performance due to mechanical damage or electrode failure during cycling. In addition, due to its high biocompatibility, LM have also been used for bio-applications. For example, the deformation induced phase transition of LM can promote rapid and efficient drug release in human body. Furthermore, their effective radiopacity and high thermal conductivity grant LM materials as contrast agent or photothermal electrode for medical angiogram or removal of tumor. In order to facilitate the functionalities of LM, composition strategy by integrating with polymers and/or inorganic nanoparticles have been proven an effective way to endow LM with more merits [86][156]. In contrast to those rigid metals, LM can easily fuse with other materials by mixing in ambient conditions to generate new heterostructures with controlled properties, such as enhanced thermal, magnetic and mechanical properties. The diverse LM functional materials dramatically widen the application range. For instance, LMEEs have been widely used in the fabrication of ultra-stretchable, printable electronic devices including wearable energy generators, solar cells and healthy monitors. LM-inorganic nanocomposites have shown great potential for heat absorption and transfer, robotic locomotion and manipulation. Highly stretchable Ga-polymer fiber has shown a bright future to complement or even replace the conventional Cu wire in many fields such as wearable electronics, soft robotics.

Another problem is its high-temperature material compatibility. As an excellent cooling agent, Ga based materials have been popularly used for rapid dissipation of heat from systems in order to protect them from burning. However, at high temperatures, Ga-based materials themselves tend to corrode and embrittle other metal substrates (e.g., stainless steel, Al, Cu), causing possible failure of electronic devices, solar cells or heat storage systems. Although surface modification of LM nanodroplets can lead to stable anti-corrosion effect towards metals, it dramatically reduces its electrical conductivity. Therefore, more efforts have to be devoted to fundamental research about Ga corrosion mechanism and protection methods to explore practical coating strategy for effective metal protection without the degradation of electrical properties.

Although the electrical conductivity of Ga is sufficient for building electronic devices, it is still one magnitude lower than Cu. Therefore, further improving the conductivity of Ga based materials is of critical importance to enhance the performance of Ga based devices [87][159].

In spite of those aspects to improve, the fruitful progresses of Ga based materials in recent years have showed a bright future of this new-generation functional materials. We strongly believe that with many unique properties Ga based LM materials will boost in all sorts of emerging research fields and industrial applications to facilitate people’s daily lives, innovate medical treatment, alleviate energy crisis and promote robotic artificial intelligence.