Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 3 by Mohd Ashraf Zainol Abidin and Version 2 by Mohd Ashraf Zainol Abidin.

Agrivoltaic systems (AVS) offer a symbiotic strategy for co-location sustainable renewable energy and agricultural production. This is particularly important in densely populated developing and developed countries, where renewable energy development is becoming more important; however, profitable farmland must be preserved. As emphasized in the Food-Energy-Water (FEW) nexus, AVS advancements should not only focus on energy management, but also agronomic management (crop and water management).

- agrivoltaic system

- solar photovoltaics

- agronomic management

- crop production

- Food-Energy-Water nexus

- sustainable integration

1. Introduction

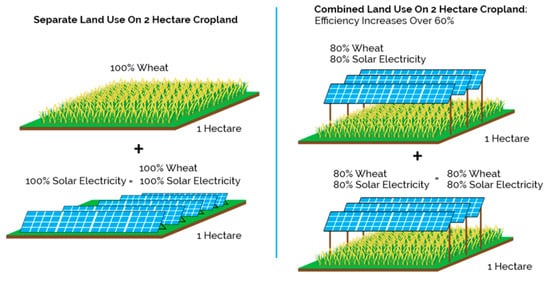

The concept of integrating solar PV with agricultural produce, known as agrivoltaic system (AVS), was originally proposed by [1] back in 1982; however, this concept was rarely discussed until the beginning of the new millennium. This agrivoltaism approach is derived from the intercropping method applied in the agricultural sector to increase the land equivalent ratio and total revenue [2][3][4][5][6]. AVS technology is gaining popularity due to its dependability in variable-scale applications. The development of commercial and research facilities around the world demonstrates the potential of this technology [5][7][8]. The concept of the system utilizes the generation of electrical energy and the production of agricultural products in the same area of production [6][9][10][11][12]. In other words, beneficial interaction, or symbiosis between these two productions in the same area, is created in this way [2][3][8][13][14][15][16]. Solar production could also offset global energy demand if less than 1% of cropland were converted to an AV system [17]. The integration of both productions in the same area may reduce the efficiency of either solar energy generation, agricultural production, or both productions; however, the total revenue may be increased [7][15][18][19][20][21] as illustrated in Figure 1. Additionally, crop production consumes less than 1% of the total energy generated by AVS [10].

Figure 1. Comparison of efficiency traditional farming versus AVS. (Source: [22]).

1.1. Motivation for the Development of Agrivoltaic System

There is a connection between sustainability and resilience, and COVID-19 has illustrated how rapidly life can change. The work of [23] demonstrates that the deployment of new infrastructure lowers land-use availability, and this element must be managed properly. Despite the profound upheaval and uncertainty produced by the Covid-19 epidemic in the energy industry, which has forced global energy consumption to decline by 5% by 2020, renewables continue to play a critical part in all of our circumstances, with solar taking center stage [24]. The rapid development of solar farms raises a new threat and friction in terms of land-use for electricity production whilst satisfying increasing food demand. The amount of land required to establish large-scale solar farms has become a source of concern [8][13][25][26][27].

Current studies also show that the environmental factors that may influence the efficiency of photovoltaic (PV) panels are sometimes ignored [12][17][28][29][30][31]; however, for AVS, these factors are very crucial [32][33]. For example, gravel underlay for solar PV sites may contribute to a heat island effect that increases the ambient temperature below the PV structure. This situation potentially reduces the efficiency and life span of the solar panel [3][10][11][34][35]. Simultaneously, agricultural lands are shrinking due to land reuse for new industry production, homes, and urban areas [8][10][36][37][38][39]. The summary report of World Agriculture: Towards 2015/2030, released by [40], has stated that the global demand for an agricultural product will keep on increasing every year. Developed countries will suffer from a high dependency on agricultural imports, and food insecurity in developing countries will persist without a significant increase in local production. These conflicts are compounded by the fact that the amount of arable land available per capita decreased by 48 percent between 1961 and 2016, owing to the global population increase [41]. Thus, it is believed that the solution of AVS technologies enables the possibility of resolving the competing interest between the two sectors’ requirements while meeting the demand [14][21][42][43][44].

1.2. Benefits of Agrivoltaic System

There are a variety of fascinating details about AVS technology derived from previous studies such as: (1) increase in total revenue [7][15][19][20][21][45][46]; (2) crops cultivated beneath the solar structure help reduce the ambient air temperature by creating a cooler microclimate [7][11][47][48][49]; hence, indirectly reducing the solar panel temperature up to 1–2 ℃ and increasing the solar PV efficiency [21][50]; (3) solar PV panels must be washed regularly to maintain their solar radiation efficiency. The water used to clean them can be reused to irrigate the agriculture beneath the solar panel, resulting in increased water efficiency [2][13][21][26][34][51]; (4) emissions due to CO2 are also uptaken by crops, while low CO2 is produced by solar energy compared to fossil fuel-based power generation [2][20][43]; (5) solar PV provides a good shading effect on some plants that do not like direct sunlight [30][39][52][53][54][55]; (6) providing new jobs [12][21][27][51][56]; (7) raising taxes [20] and (8) the expansion of cleaner and renewable energies are necessary to reduce the fossil fuel dependency and global warming [9][28][29][41][46][57][58][59]. Furthermore, efforts to reduce CO2 emissions and promote sustainable energy are always gaining international support [60]. Thus, these AVS initiatives are highly in line with Food-Energy-Water (FEW) nexus [9][13][14][34][61] and Sustainable Development Goals (SDGs) [28][32][56][62][63][64].

1.3. Land Equivalent Ratio

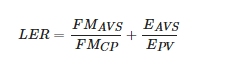

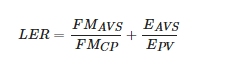

Land equivalent ratio (LER) is a method used for measuring the efficiency of land utilization for the simultaneous production of crops and electricity [11][18][53][55][65][66]. A similar technique is used in agroforestry systems, which integrate trees and food crops [4][41][66][67]. The LER can be extended to include the mixing of any two (or more) production systems in the same area. Numerous previous studies have also used this method to identify the possibility of integrating agriculture production with a solar farm. In general, LER is the ratio of the AVS installation’s area to the total of the areas required to meet the AVS installation’s agricultural and electric production [18]:

where FMAVS and FMCP denote fresh biomass in the AVS installation and on the CP control plot (agricultural mono-production), while EAVS and EPV denote the AVS installation’s and PV installation’s electric production, respectively. LER values greater than one indicate that combining agriculture and solar PV is more efficient than doing so separately [11][37][68]. To be noted, the efficiency of AVS technology is highly dependent on the solar PV architecture [4][6][21][28][51][53][69][70] and agronomic management [6][25][31][53][54][56]. Numerous methods are constantly being developed to improve the effectiveness of this technology. However, AVS applications are still in their early stages, therefore there is plenty of room for technological advancements and expanded application fields [14][34][61][62][71][72][73]. Thus, this paper is written to discuss the consideration of AVS architecture with design criteria for solar photovoltaic systems and agronomic managements to improve the AVS outputs.

where FMAVS and FMCP denote fresh biomass in the AVS installation and on the CP control plot (agricultural mono-production), while EAVS and EPV denote the AVS installation’s and PV installation’s electric production, respectively. LER values greater than one indicate that combining agriculture and solar PV is more efficient than doing so separately [11][37][68]. To be noted, the efficiency of AVS technology is highly dependent on the solar PV architecture [4][6][21][28][51][53][69][70] and agronomic management [6][25][31][53][54][56]. Numerous methods are constantly being developed to improve the effectiveness of this technology. However, AVS applications are still in their early stages, therefore there is plenty of room for technological advancements and expanded application fields [14][34][61][62][71][72][73]. Thus, this paper is written to discuss the consideration of AVS architecture with design criteria for solar photovoltaic systems and agronomic managements to improve the AVS outputs.

2. Solar Photovoltaic Architecture in Agrivoltaic System

2.1. Alteration and Modification of Solar Photovoltaic

A solar photovoltaic (PV) system is a power generation unit made up of an electrically integrated assembly of a PV array, inverter, and other components. PV panels (also called PV modules) are composed of several photovoltaic cells that convert sunlight energy to electricity. The solar PV modules are wired together in series to form PV strings, which are then linked together in parallel to form a PV array (MS IEC 61836:2010) [74]. The process is simple as it is a direct conversion of sunlight to electricity without any complicated mechanical movement or release of waste to the surrounding environment [52][75][76]. The solar PV cells can absorb up to 80% of the incident solar radiation received from the solar band, but only a small amount of this absorbed energy is transformed into electricity, with the rest increasing the temperature of the cells [77][78][79]. Next, grid-connected and stand-alone solar systems are the two types of solar energy systems. These two systems are intended to offer a direct current or alternating current source for use with the utility grid, an independent storage system, or other electrical/electronic equipment [80][81][82][83]. Even though much of the photovoltaic system demand can be matched with aggressive building-integrated PV (BIPV) and rooftop PV [84][85][86][87], both systems cannot provide all the energy necessary, especially for regions with high population densities compared to land-based solar farms [8][86]. A solar farm is designed to generate enough energy [37] to power thousands of homes and business [9][88]. They are much like the solar panels you place on your roof to power your specific requirements [28]. Most energy generated by solar farms is sold to the grid. However, to sell power to the grid first you need approval from your country’s power provider and authorities [32][89].

The AVS idea is mainly based on photovoltaic technology being adapted for agricultural use, considering space and wiring restrictions [30][38][78][90][91]. However, AVS is configured differently from typical ground-mounted photovoltaic systems (PV-GM), which are more prevalent because of their cheaper installation costs and higher panel density, which improve energy production [3][25][36][62]. The systems in traditional ground-mounted solar installations are immobile [2][36][81]. For this solar installation, the PV panels are around 1.6 feet (0.5 m) from the ground, and space between rows is kept to a minimum to avoid shade. Also, panel clusters do not have spacings since they abut [92]. Certain modifications of the solar PV structure to suit the agricultural production requirements are needed to allow optimum solar radiation to reach the ground under the solar PV structure. Among the modifications are: (1) elevation of solar PV structure [25][28][65][93][94]; (2) optimizing the distance between solar PV structure [15][25][68][86]; (3) configuring of the density of solar panels in one solar structure [4][6][49][85]; (4) optimization of the sloping angle of the solar panel [4][6][95][96]. Nevertheless, AVS developers should keep in mind that all modifications and alterations to solar photovoltaic structures would adhere to AVS approaches [97][98][99], geographical regions [19][65], crop selection [33][65][69], and agronomic management [18][19][33].

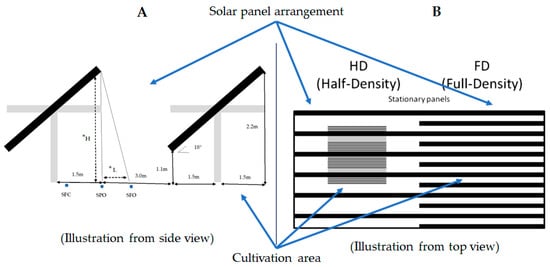

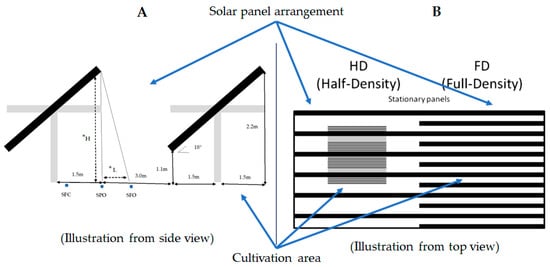

Several studies have been conducted at Montpellier Experimental Agrivoltaic Station since 2010 by [4][6][18][69] to determine the characteristics of the photovoltaic structure to be integrated into the AV system. Full-density (FD) and Half-density (HD) AV systems have been developed and tested in this facility for almost 10 years. FD structure is designed for optimal solar energy production, thus only allowing around 50% of solar radiation to the crop below the panel. While HD structure is designed to balance between electric generation and agriculture production, thus allowing up to 70% of solar radiation to reach the crop level. The percentage of light transmission was determined under the FD and HD experimental panels. To obtain the percentage of targeted solar radiation, the FD and HD structures were designed at 5.0 ft (1.6 m) and 10.0 ft (3.2 m) in the panel row spacing, respectively. Moreover, both panels were mounted 13.0 ft (4.0 m) above the ground and tilted at an angle of 25 degrees. The elevated PV panels make the spatial distribution of radiation increase because light can penetrate underneath the panels from the sides, thus creating conditions where crops are able to grow below the panels [53]. In another study conducted at UMass Crop Research Farm (Massachusetts), the AVS structure without concrete bases was constructed with a height of 7.5 ft (2.3 m) from the ground to allow nearly 70% of solar radiation to reach the crop below the panel. The study found that 4.0 ft (1.2 m) and 5.0 ft (1.5 m) distances are optimal for the AVS plots for biomass production [92]. These conclude that the modification of panel rows spacing, the height of mounted panels, configuration of the density of the solar panel, and the tilting angle are variable and dependent on the specific geographic location. In addition, the growing season also contributed to AVS adjustment [18][25][45].

In addition to the modification of the tilted monofacial PV structure, a vertical bifacial PV structure could be an alternative to AVS infrastructure [5][7][47][65]. According to [65], vertical bifacial PV provides several advantages, including less land coverage, less interference with agricultural machinery and rains, natural resilience to PV soiling, faster cleaning, and cost savings owing to a possible lower elevation. However, the combined PAR/energy yields for this type of arrangement may not always be superior [65]. Still, the trade-off between a higher capital expense and a low cost for frequent cleaning should be carefully considered when calculating the relative Levelized Cost of Energy (LCOE) [41][62][65].

Next, instead of modifying the PV structure and use of opaque photovoltaic (OPV) as modules, there is also a study conducted to determine the potential of using semi-transparent photovoltaic (STPV) modules in AV system [100][97][101]. The idea is to turn the agrivoltaic principle from just solar sharing to the selective use of various light wavelengths [102][101]. The solar sharing concept is a common concept in conventional AVS that uses OPV modules and creates a shade to the portion of farm fields, throwing a shadow on the underlying plants [102][103][104]. However, The STPV’s eclipsing frequency was 9.7 percent, and the cell shadow never completely covers the plants while the gap between the module and the crop is greater than 1 m [101]. Next, as illustrated in Figure 2, sinince the electrical energy generation capacity also varies depending on the light spectrum (illustration is available in full-text) [55][75][78][105], special attention should be paid to identify suitable types of crops that are able to carry out the photosynthesis process with the limitation of certain PAR wavelengths [28][47][69] to be integrated with SPTV modules in agrivoltaic system [102][101]. In addition, Table 21 summarizes some of the studies that have been conducted worldwide to improve AVS technology.

Table 21. Overview of Existing Agrivoltaic System Research Project.

| Location | Electricity Yield (kWha−1) | Capacity (kWp) | Solar Tracking | PV Specification | Cultivated Crops | Sub-Treatment | Highlights |

|---|---|---|---|---|---|---|---|

| Oregon State University, USA | unknown | 1435 | No | Polycrystalline, east-west oriented strips, 1.65 m wide and inclined southward with a tilt angle of 18°, 1.1 m above ground (at lowest point) and distance between panel is 6 m | semi-arid pasture | SFO, SPO, SFC | Extreme heterogeneity and spatial gradients in biomass production and soil moisture were observed as a result of the heterogeneous shade pattern of the PV array. |

| Po Valley, Northern Italy | 1,890,000 | 1461 | Yes (2-axis) | Polycrystalline panel, height 4.5 m above ground, spacing between rows of panels is added to decrease the density of panels, the fixed panels were set at 30 degrees whereas sun-tracking had differing angles throughout the day. | Maize (Zea maysL.) | Single density (panel area/land area ratio) of 0.135 and double density of 0.36 | Yield under AVS is slightly lower when water is non-limiting, it is higher in conditions of drought stress |

| Sardinia, Italy | E-W 1547 N-S 1330 (100% Mono-pitched roof), E-W 1562 N-S 1290 (60% Venlo-type), E-W 1553 N-S 1317 (50% Gable roof), E-W 1523 N-S 1292 (25% Gable roof) | 71 (100% Mono-pitched roof), 47 (60% Venlo-type), 35 (50% Gable roof), 20 (25% Gable roof) | No | Multicrystalline and Monocrystalline, PV greenhouse (mono-pitched, venlo-type, gable roof). East-west and north-south orientations. PV cover ratios ranging from 25% to 100% | Unknown |

53]. According to [80][112][108], a solar tracker system can be classified based on the techniques used to control the movement of the PV panels. The tracker system can be a passive, active [75][77], or chronological tracker system [80]. The operation, advantages, and disadvantages of each type of solar tracking system technology are summarized in Table 32 [80]. Even though an active solar tracker (also known as a dynamic solar tracker) is required, despite extra power consumption and not being very accurate under a cloudy day, the use of this type of solar tracking system contributed to the higher energy generation efficiency compared to a passive and chronological system [80][113]. For this reason, previous studies by [4][18][53][111] also used this type of solar tracking system. The active solar tracker uses sensors and motors [80][112] to control the rotational angle of the PV axis and allows them to follow the sun’s trajectory directly [4][75][111][113], or based on a tracking algorithm [27][49][53][75][114]. For AVS conditions, the integration of a solar tracker in the AVS is focused on creating an ingenious partnership between both parties to optimize the productions of electricity and agriculture [28][30][61][85][115]. A specific and improvised tracking algorithm can be developed to optimize light penetration beneath the solar structure to suit selected crops while balancing the energy production [47][53][111].

Table 32. Passive, Active, and Chronological Solar Tracking System.

| Technology | Descriptions | Advantages | Disadvantages | AVS Preference | ||

|---|---|---|---|---|---|---|

| Passive |

|

|

|

- | ||

| Active |

|

|

|

Single-axis: Sun-tracking system (ST) and Controlled-tracking system (CT) |

||

| Chronological |

| unknown |

|

|

|

- |

3. Agronomic Management for Agrivoltaic System

3.1. Crop Selection

The microclimate aspect under the solar PV structure should be taken into account in the selection of suitable crops to be cultivated in solar farms [5][46][116][101]. A setup by Refs. [42][117] in particular divided the area beneath the solar panel into three sub-treatments: (1) sky fully open area between panels (SFO); (2) Solar partially open between panels (SPO); (3) solar fully covered area under panels (SFC) as illustrated in Figure 32A. SFO zones are located between the edges of mounted photovoltaic panels and areas that have received full light [28]. No shade covers the SFO zone, according to the shadow length estimate [113], while SPO areas are situated in the penumbra and have been subjected to episodic shade [118]. SFC areas are located immediately under the photovoltaic panels and receive complete shade [73]. However, the division of the sub-treatments are subjective and subjected to the solar photovoltaic design [5][19][38][97]. For example, the AVS design at Montpellier Experimental Agrivoltaic Station by [4][6][18][69] (as described on page 9) is high in length, and is thus less suitable to be divided into SFO, SPO, and SFC. Previous researchers at that station classified the area beneath the solar panel as FD and HD. The average proportion of daily radiation emitted below the solar panel (FD and HD treatments) relative to the FS treatment varies with the growing season. In general, AVS is not recommended in crop rotation systems [41]. However, crop rotation could increase the production of agriculture in AVS farms [69], especially in regions that experience different seasons throughout the year [104]. Furthermore, when used in conjunction with permanent cultures—such as berries, bananas, or wine grapes—the cost of these types of applications is smaller, thus delivering increased efficiency through the optimization of techno-ecological synergies [41].

Next, the heat or thermal energy dissipated under the photovoltaic array is also a critical factor to consider in relation to the continuous development of the crops beneath [19][54][119][90]. In this case, the open field AVS is better than the closed greenhouse AVS [120], as its key characteristics are the mean daily reduction in light access for plants [28][38] without major changes in other microclimate parameters such as relative humidity, wind speed and direction, and soil moisture [26][121][113] at the level of the canopy [69][103]. If the AVS design were able to regulate adequate air circulation below the open structure, the air temperature, VPD [69], mean relative humidity, and wind speed [113] might be insignificantly different [122], or optimized [11], compared to the ambient surrounding; however, it depends on the structural design [21][54][62] and regions [10][116][96]. Enclosed structures, on the other hand, offer the advantage of being able to regulate the temperature inside the structure to meet the demands of the crop [97][116][101]. Furthermore, in a study conducted by [31], it was found that reduced light is not often harmful to crop quality, as improved Radiation Interception Efficiency (RIE) has been shown in the shade; however, a specific arrangement of the solar panel is needed to compromise between agriculture production and electricity generation in a way that can improve the production of both. However, solar management is not amenable to all types of crops, and there is a need for further research before an economically viable approachable system using PV technology can be designed [7][12][26][113][123].

There are several factors suggested by the author, based on reviews, to facilitate the crop selection for AVS: (1) the design of solar PV structure [8][54][62][63]; (2) the location of sub-treatments [6][69][113]; (3) the approaches of AVS [44][98]. For the first factor, types of design considered for solar PV structure have been described in Section 3. In case the introduction of agriculture production is on the existing solar farms or an unaltered solar panel structure, the approach used by [50] could be the sustainable solution to combine both productions. They suggested the planting of high-value herbal crops in solar farms with zero or minimal modification of the solar PV structure. The authenticity of growing herbal crops under solar photovoltaic arrays is justified by the sustainability and morphological aspect of the arrangement as a way of using unused land. For example, the maximum height of the Java Tea Plant (high-value herbal crops), which is less than three feet (from the ground) and grows in a regulated manner, is considered suitable and will not interfere with the PV panel electricity generation operation. The chosen plant is also classified as a shade-loving herb, and the temperature beneath the solar PV structure measured is within an acceptable range for ornamental herbal plants. The solar farm project’s maintenance requirements are met by field arrangements of herbal polybags and a manual irrigation solution [59].

For the location of sub-treatments which are SFO, SPO and SFC [42][113], or FD and HD [4][6][18][69], a wide range of crops can be selected to be planted based on their physiological and morphological traits [4][28][71]. Besides that, the selection of suitable crops for AVS should also be identified based on local climate and weather conditions [5][12][21][28]. In general, shade-loving plants are best suited for planting in less sunlit areas, while sun-loving plants are better suited to seeding in sunlight areas [64][98][94]. For the arid region, such spices may be successfully grown between two rows of solar PV, as these are short in nature, for example: Trigonella foenum-graecum Linn. (‘methi’), Plantago ovata Forsk. (‘isabgol’), Coriandrum sativum Linn. (coriander or ‘dhania’), etc [25]. The following vegetable crops may also be grown: Brassica oleracea var. botrytis (cauliflower), Brassica oleracea var. capitate (cabbage), Allium cepa Linn. (onion), Allium sativum (garlic), Capsicum annum Linn. (chilli), etc. [25]. The land area beneath photovoltaic panels can also be used to grow vegetable crops of the Cucurbitaceae family, such as Cucurbita pepo Linn. (‘kakri’), Lagenaria siceraria (‘lauki’), Citrullus fistulosus Stock (‘tinda’), etc. [25]. Cultivating crops in areas below the photovoltaic panel has the added benefit of reducing the heat load on the bottom surface of the photovoltaic panel by modifying the microclimate and thus assisting in generating the maximum amount of electricity [21][50]. Additionally, [59] also proposed that herbs could be planted in tropic areas using AVS applications with minor modification of the solar panel structures. Herbal plants such as Orthosiphon stamnieus is suitable in the tropical region [50], while Cassia angustifolia (senna), Aloe vera (‘gwarpatha’), and others may also be considered as potential crops if the PV structure is in rocky scrubs or degraded lands, depending on the region [25]. Next, some studies performed in various regions of the world indicate different kinds of crops, such as semi-arid pasture (Oregon, USA; [113]), Maize (Po Valley, Northern Italy; [53]), lettuce (short cycle crop), cucumbers (short cycle crop), durum wheat (long cycle crop) cultivated at Montpellier Experimental Agrivoltaic Station, France [6][31], and potato and wheat (Demeter-certified farm community Heggelbach, Germany; [41]). In addition, [5] stated that, in some regions, certain crops such as fruit trees (i.e., kiwi, apple, pear, cherry), berries (i.e., raspberries, blackberries), tomatoes, sweet peppers, coffee, and ginseng, are among the crops that are also able to cope with a reduction of more than 50% in the light source. Based on these findings, it is possible to conclude that the selection of suitable crops for integration into the AV system is subjective, depending on local weather and the architecture of the PV structure [8][28][33][85][116][124].

However, a suggestion from [98], as shown in the table below, to include the AVS approaches may be able to further facilitate the selection of suitable crops. The table illustrates how solar farms and crops can be combined according on the land-use type and AVS strategies. Next, several modifications of the solar PV structure and types of the crop cultivated will be recommended. For example, the suggestions for short crop planting area with agriculture centric approach are as follows: (1) plant mix of sun-loving and shade-tolerant crops, (2) raised solar PV structures, and (3) space solar PV structures. Other options are covered in Table 43.

| Energy Centric | Agriculture Centric | Integrated Agriculture-Energy Centric | |||||

|---|---|---|---|---|---|---|---|

| Grazing/un-used/scrub/desert land |

|

|

|

||||

| Agriculture (short crop) |

|

|

|

||||

| Agriculture (tall crop) |

|

|

| (1) Both the checkerboard pattern and the N-S orientation allowed to improve the uniformity of light distribution. (2) A valid design criterion to improve the agronomic sustainability of next-generation PV greenhouses |

|||

| Japan | unknown | Unknown | No | Installing semi-transparent PV module (STM) on the greenhouse roof | Unknown | unknown | (1) The conversion efficiency of the semi-transparent module (STM) was stable at around 0.2% and was not affected by the slope angle, because of the isotropic photoreception of the spherical microcells. (2) The eclipsing level of the STM was 9.7% and the cell shadow never covers the plants entirely when the distance between the module and the crop is greater than 1 m |

| Montpellier Experimental Agrivoltaic Station, France | Unknown | Unknown | No | Monocrystalline, panels were mounted 13 ft (4 m) above the ground, 14 degree aspect angle orientation of the panels towards East, tilted at an angle of 25 degrees, space every 1.64 m (distance between panel structure) | lettuces (short cycle crop), cucumbers (short cycle crop), and durum wheat (long cycle crop) | FD (50% light allowable) 1.6 m panel spacing, HD (70% light allowable) 3.2 m panel spacing | (1) The study found that although the FD plot had higher LER’s than the HD plot because of higher energy production, the HD plot significantly limited crop yield losses while also maintaining an LER over 1. (2) AV system should be designed to allow about 70% radiation to the crop to prevent significant restrictions in yields. (3) Different varieties of certain crops that can be chosen for AV systems due to their adaptability to shaded conditions. (4) Shading in the AV systems saved between 14–29% water depending on the level of shade (FD or HD). |

| Yes (single-axis) | Controlled-tracking (CT) system (Distance from the ground: 16.5 ft (5 m), Panel rotation: 50 degrees E and 50 degrees W), Sun-tracking (ST) system (Distance from the ground: 16.5 ft (5 m), Panel rotation: 50 degree E and 50 degrees W) | FD, HD, ST and CT | (1) ST AVS is the most effective design to optimise AV outputs (LER 1.5), while Fixed HD AVS and CT were the most efficient in producing biomass. | ||||

| Renewable Energy Research Office (RERO), Malaysia | unknown | 10 | No | Monocrystalline | Java Tea | FD | (1) Strong justifications of sustainable herbal plant growth, profitable margin with short returns of the initial investment is the backbone of this work. (2) It is observed that high humidity level due to water evaporation process with PV shading features provides a good attraction for pests which increases the risk of attack to crop. |

| Demeter-certified farm community Heggelbach, Germany | unknown | 194.4 | No | Duo bi-facial PV, clearance height: 5 m, overall height: 7.8 m, Unit width: 19 m | Potato, winter wheat | unknown | (1) The maximum sunlight reduction due to shading from the PV panels on any square foot of land under the dual-use system may be no more than 50%. (2) Beneficial price-performance ratio of 0.85 for potato production and a nonbeneficial price-performance ratio of 4.62 for winter wheat |

| Zhangjiakou, China | unknown | 1500–1700 | Yes (single-axis) | Oblique PV, East-west oriented and faces towards the south, PV height: 2.5 m from ground, tilt angle 39 degree | unknown | unknown | (1) By studying the tracking law of oblique single-axis AV system, it can be found that in the higher latitude, variations in rotation angle are approximately similar during every day of the growth period of plants. (2) Light adaption point (LAP) and required solar radiation time length of crops can be regarded as two indexes to select the right crop |

| India | unknown | 200–250 | No | Ground clearance: 0.5 m, structure width: 2.95 m, structure heigh: 1.94 m, row distance: 6 m | * | SFO, SPC | Suitable crops for AVS suggested here is applicable for arid western India and for other regions different crops need to be identified as per prevailing rainfall and weather conditions |

*Detail discussion in full-text

2.2. Solar Tracker for Agrivoltaic System

Solar monitoring is a technique for increasing the amount of energy obtained by keeping a solar collector, either PV or photothermal, in an optimal location perpendicular to the sun during daylight hours [7][100][80]. A solar tracker aims to ensure that the panels achieve the greatest amount of solar irradiation possible during the day [54][106][107][108]. Solar tracking began in 1962 when Finster launched the world’s first fully mechanical tracker. The following year, Saavedra demonstrated an electronic-controlled system for orienting an Eppleypyrheliometer [109]. Since then, the techniques of solar tracking were improved with the main purpose being to increase the total amount of irradiance to the maximum possible [35][75][110]. Despite that fixed solar PV configuration is preferable to be integrated with AV systems [1][6][54] because fixed solar PV intercepts less solar radiation compared to single-axis and dual-axis solar trackers, there is an effort towards the integration of solar trackers into AV systems [8][30][53][111][103].

Refs. [4][18] have developed an AV solar tracking system at Montpellier Experimental Agrivoltaic Station in their trials to increase the electricity generation without having detrimental effects on agricultural production. There are five plots set up in their experiments. The first plot is a fixed structure with full-density (FD) AVS and the second plot is a fixed plot with half-density (HD) and has the same specifications as the original AV systems developed by [6]. The two types of AV solar tracker system used in their studies are controlled-tracking (CT) system and sun-tracking (ST) system. Both systems were specifically designed by: (1) altering the density of the PV panel and height of the solar PV from the ground; (2) developing a specific solar tracking algorithm with the inclusion of the parameters for agricultural growth. The LER values obtained were more than one in all AV plots, indicating that the AV system is more efficient than the monosystem production. With LER values of 1.5 and above, the ST plot has proven to be the most successful method for optimizing AV outputs; the ST plot’s high LER value is mostly due to electricity generation. It is critical to highlight that the CT layout was the most efficient in terms of agricultural production. Furthermore, the LER values for either the CT or ST plots were greater than the LER values for the HD plot.

In another study by [53], at Po Valley (Northern Italy), a new platform was developed and introduced to conduct simulations aimed at optimizing agrivoltaic systems, which combine the output of electrical energy and arable crops. There are four configurations of AVS set up in this study: (1) dual-axis, sun-tracking system equipped with 5 secondary axes and 10 solar panels (ST1); (2) dual-axis, sun-tracking system equipped with 4 secondary axes and 32 solar panels (ST2); (3) still unit equipped with 5 secondary axes and 10 solar panels (F1); (4) still unit equipped with 4 secondary axes and 32 solar panels (F2). All the AV systems were constructed by raising the panels and fixed to a rotating axis before being coupled with Agrovoltaico software. A radiation model was integrated with the Agrovoltaico programme (based on the shading conditions determined from the AVS structure set-up). A crop model known as GECROS was used to input AVS’s modelled radiation and a 40-year temperature and environmental dataset from the site. Then, the software is used to measures radiation mitigation and its effect on simulated crop yields in aggregate. Based on the simulation, the highest electricity generation came from ST2, followed by F2, ST1, and F1. While, for biomass, even though F2 has the highest yield, the yield in all treatments ranges from 2202–2091 gm−3 only. Surprisingly, ST1 and ST2 have higher biomass yields compared to stand-alone agriculture production. Other summaries of studies that utilize solar trackers are mentioned in Table 21.

To the best of the understanding of the authors, there is a potential to integrate the solar tracking system into the agrivoltaic system [4][5][30][

3.2. Agronomic Practices

Solar energy is the most plentiful and readily available source of energy [25][28][47][122]. The use of AVS technologies in areas where a solar farm and agriculture coexist [51][125][99] could have synergistic effects that aid in the production of ecosystem services such as crop production [9][20][38], local climate regulation [34][96][126], water conservation [13][18][56], and renewable energy production [21][85][127]; and it also aligns with food-energy-water (FEW) nexus [34][63][126].

Thus, the integration should potentially influence the microclimate and soil moisture [21][51][116]; hence, it may provide suitable environmental conditions [18][34][43] and increase the water-use efficiency for agricultural production [3][120][102] while maintaining the renewable energy production [41][44]. As mentioned in 2.1, the photosynthesis process requires light, carbon dioxide, and water to produce glucose as the source of energy for plants. If the sources of light and carbon dioxide are not limited, an optimum amount of irrigation water is needed to enhance the photosynthesis rate. Thus, regions with insufficient water resources are most likely to benefit as solar management decreases potential evapotranspiration (PET) and water demand [26][51][113][126]. The reducing amount of irrigation water needed without compromising crop-water requirements can make a significant contribution to reducing agricultural production costs, making the industry more competitive and sustainable [18][21][65]. However, a systematic or proper irrigation schedule is a must in AVS sites [120][128] to minimize the environmental impacts caused by excess water and leaching of subsequent agrichemicals [129] that might affect the structure of solar PV. Water-use efficiency can be improved [3][8][120] by understanding the concept of evaporation, evapotranspiration (ET), and irrigation water requirements [130]. ET is the mechanism by which water originates from a wide range of sources such as soil compartment and/or layer of vegetation and is transferred to the atmosphere [131]. Also, ET involves evaporation from bodies of surface water, surface of land, sublimation of snow and ice, plant transpiration, and intercepted canopy water [120]. Besides that, the evaporation process that happens also significantly reduces the percentage of soil moisture content [19][41][126]. On the other hand, irrigation water requirements are defined as the quantity of water necessary for crop growth [130][132]. In addition, the loss of electrical output due to dust accumulation on the panel surface as a result of agricultural management, such as tillage and harvesting, is also a source of concern [5][7][10][21]. In regions with low precipitation or long stretches of dry weather (e.g., monsoon climates), periodic cleaning of the module surface should be considered to prevent decreasing electricity yields due to dust accumulation [85]. This could be done by combining irrigation systems and PV cleaning to reduce increased water use [51]; however, without a small water distributor under the panels, it may result in inconsistent watering of crops [119]. Hence, proper assessment of evapotranspiration [128], soil moisture content [129], and PV cleaning processes [10][119] are needed before designing the irrigation system for agricultural production in AVS.

Another aspect is that extreme heterogeneity and spatial gradients in biomass production [5] and soil moisture [45][120] were observed as a result of the heterogeneous shade pattern of the PV array [113]. In the studies conducted at Montpellier Experimental Agrivoltaic Station by [4][6][18][69], the shadow effect of the PV array can be seen from the agricultural yield, where the HD structure produces more yield than the FD structure. The results show that, with the improvement of PV panel arrangement, LER may potentially exceed 1 [38][85]. Next, a solar tracker controller developed by [53] found that maize grown under the AVS plots tended to have more stabilized and higher yields in drought stressors and rainfed conditions. Besides that, crop selection can also reduce the effect of the heterogeneous shade pattern of the PV array [11][25][28]. This can be seen in the experiment conducted by [61] using Java Plant Tea in Malaysia. The result obtained shows a good agreement between the selected crop and the PV panels above them that act as their artificial shading. To sum up, acts to reduce the extreme heterogeneity and spatial gradients in agricultural production are: (1) optimize PV array placement to create a spatially uniform shadow pattern [4][10][125]; (2) improve the solar tracker controller that considers the need for solar radiation for both productions (electricity and agriculture) [53][97][111]; (3) select a suitable crop to be planted with a minimal light source (due to shading effect of solar PV structure) [25][54][85]. Besides that, as suggested by [5][94], the PV structure can be raised to reduce the heterogeneity effect, while allowing the conventional agricultural machines to pass [4][28][38], and reducing the back pain [68] while doing agricultural work due to low PV structure [86]. The gap between the pillars also needs to be suitable for planting distances and working widths of the machinery to avoid the loss of utilizable land [5][41]. Careful planning is essential, since the space required for the machine to pass might restrict the amount of land available for solar panels [19][68]. Also, ram protection should be installed to avoid collisions between agricultural machines and the solar PV pillars [68].

Other than that, the agronomic practices for agricultural production at AVS, likely similar to standard and common agronomic practices [62][101], include the steps listed in Figure 43. More information on standard practices can be found in documents such as the ones written by [133], which specifically address cropping systems and agronomic management. However, precision agriculture methods such as site-specific crop management (SSCM), for which decisions on resource application and agronomic procedures are being improvised, can be developed to better meet crop requirements based on soil heterogeneity in the field [33].

Figure 43. Common Agronomic Practices.

References

- Goetzberger, A.; Zastrow, A. On the Coexistence of Solar-Energy Conversion and Plant Cultivation. Int. J. Sol. Energy 1982, 1, 55–69.

- Proctor, K.W.; Murthy, G.S.; Higgins, C.W. Agrivoltaics align with green new deal goals while supporting investment in the us’ rural economy. Sustainability 2021, 13, 137.

- Hernandez, R.R.; Armstrong, A.; Burney, J.; Ryan, G.; Moore-O’Leary, K.; Diédhiou, I.; Grodsky, S.M.; Saul-Gershenz, L.; Davis, R.; Macknick, J.; et al. Techno–ecological synergies of solar energy for global sustainability. Nat. Sustain. 2019, 2, 560–568.

- Valle, B.; Simonneau, T.; Sourd, F.; Pechier, P.; Hamard, P.; Frisson, T.; Ryckewaert, M.; Christophe, A. Increasing the total productivity of a land by combining mobile photovoltaic panels and food crops. Appl. Energy 2017, 206, 1495–1507.

- Weselek, A.; Ehmann, A.; Zikeli, S.; Lewandowski, I.; Schindele, S.; Högy, P. Agrophotovoltaic systems: Applications, challenges, and opportunities. A review. Agron. Sustain. Dev. 2019, 39, 1–20.

- Dupraz, C.; Marrou, H.; Talbot, G.; Dufour, L.; Nogier, A.; Ferard, Y. Combining solar photovoltaic panels and food crops for optimising land use: Towards new agrivoltaic schemes. Renew. Energy 2011, 36, 2725–2732.

- Sekiyama, T.; Nagashima, A. Solar sharing for both food and clean energy production: Performance of agrivoltaic systems for corn, a typical shade-intolerant crop. Environments 2019, 6, 65.

- Mavani, D.D.; Chauhan, P.M.; Joshi, V. Beauty of Agrivoltaic System regarding double utilization of same piece of land for Generation of Electricity & Food Production. Glob. Sci. J. 2019, 10, 118–148.

- Babatunde, O.M.; Denwigwe, I.H.; Adedoja, O.S.; Babatunde, D.E.; Gbadamosi, S.L. Harnessing renewable energy for sustainable agricultural applications. Int. J. Energy Econ. Policy 2019, 9, 308–315.

- Majumdar, D.; Pasqualetti, M.J. Dual use of agricultural land: Introducing ‘agrivoltaics’ in Phoenix Metropolitan Statistical Area, USA. Landsc. Urban Plan. 2018, 170, 150–168.

- Kostik, N.; Bobyl, A.; Rud, V.; Salamov, I. The potential of agrivoltaic systems in the conditions of southern regions of Russian Federation. IOP Conf. Ser. Earth Environ. Sci. 2020, 578, 012047.

- Winkler, B.; Lewandowski, I.; Voss, A.; Lemke, S. Transition towards renewable energy production? Potential in smallholder agricultural systems in West Bengal, India. Sustainability 2018, 10, 801.

- Al-Saidi, M.; Lahham, N. Solar energy farming as a development innovation for vulnerable water basins. Dev. Pract. 2019, 29, 619–634.

- Miao, R.; Khanna, M. Harnessing Advances in Agricultural Technologies to Optimize Resource Utilization in the Food-Energy-Water Nexus. Annu. Rev. Resour. Econ. Forthcom. 2019, 12, 65–85.

- Lytle, W.; Meyer, T.K.; Tanikella, N.G.; Burnham, L.; Engel, J.; Schelly, C.; Pearce, J.M. Conceptual Design and Rationale for a New Agrivoltaics Concept: Pasture-Raised Rabbits and Solar Farming. J. Clean. Prod. 2021, 282, 124476.

- Othman, N.F.; Mat Su, A.S.; Ya’Acob, M.E. Promising Potentials of Agrivoltaic Systems for the Development of Malaysia Green Economy. IOP Conf. Ser. Earth Environ. Sci. 2018, 146, 012002.

- Adeh, E.H.; Good, S.P.; Calaf, M.; Higgins, C.W. Solar PV Power Potential is Greatest Over Croplands. Sci. Rep. 2019, 9, 1–6.

- Elamri, Y.; Cheviron, B.; Lopez, J.M.; Dejean, C.; Belaud, G. Water budget and crop modelling for agrivoltaic systems: Application to irrigated lettuces. Agric. Water Manag. 2018, 208, 440–453.

- Cuppari, R.I.; Higgins, C.W.; Characklis, G.W. Agrivoltaics and weather risk: A diversification strategy for landowners. Appl. Energy 2021, 291, 116809.

- Li, C.; Wang, H.; Miao, H.; Ye, B. The economic and social performance of integrated photovoltaic and agricultural greenhouses systems: Case study in China. Appl. Energy 2017, 190, 204–212.

- Patel, B.; Gami, B.; Baria, V.; Patel, A.; Patel, P. Co-generation of solar electricity and agriculture produce by photovoltaic and photosynthesis-dual model by Abellon, India. J. Sol. Energy Eng. 2019, 141, 031014.

- Metsolar What is Agrivoltaics? How Can Solar Energy and Agriculture Work Together? Available online: https://metsolar.eu/blog/what-is-agrivoltaics-how-can-solar-energy-and-agriculture-work-together/ (accessed on 1 October 2020).

- D’Adamo, I.; Rosa, P. How do you see infrastructure? Green energy to provide economic growth after COVID-19. Sustainability 2020, 12, 4738.

- IEA. World Energy Outlook 2020. Available online: https://www.iea.org/reports/world-energy-outlook-2019 (accessed on 21 March 2021).

- Santra, P.; Pande, P.C.; Kumar, S.; Mishra, D.; Singh, R.K. Agri-voltaics or solar farming: The concept of integrating solar PV based electricity generation and crop production in a single land use system. Int. J. Renew. Energy Res. 2017, 7, 694–699.

- Al-Agele, H.A.; Proctor, K.; Murthy, G.; Higgins, C. A case study of tomato (Solanum lycopersicon var. legend) production and water productivity in agrivoltaic systems. Sustainability 2021, 13, 2850.

- Kim, B.; Kim, C.; Han, S.U.; Bae, J.H.; Jung, J. Is it a good time to develop commercial photovoltaic systems on farmland? An American-style option with crop price risk. Renew. Sustain. Energy Rev. 2020, 125, 109827.

- Chamara, R.; Beneragama, C. Agrivoltaic systems and its potential to optimize agricultural land use for energy production in Sri Lanka: A Review. J. Sol. Energy Res. 2020, 5, 417–431.

- Li, P.C.; Ma, H. Evaluating the environmental impacts of the water-energy-food nexus with a life-cycle approach. Resour. Conserv. Recycl. 2020, 157, 104789.

- Kussul, E.; Baydyk, T.; García, N.; Herrera, G.V.; Department, A.V.C.L. Combinations of Solar Concentrators with Agricultural Plants. J. Environ. Sci. Eng. B 2020, 9, 168–181.

- Marrou, H.; Wery, J.; Dufour, L.; Dupraz, C. Productivity and radiation use efficiency of lettuces grown in the partial shade of photovoltaic panels. Eur. J. Agron. 2013, 44, 54–66.

- Othman, N.F.; Mohammad, E.; Suhaizi, A.; Su, M.; Jaafar, J.N.; Hizam, H.; Shahidan, M.F.; Jamaluddin, A.H.; Chen, G.; Jalaludin, A. Modeling of Stochastic Temperature and Heat Stress Directly Underneath Agrivoltaic Conditions with Orthosiphon Stamineus Crop Cultivation. Agronomy 2020, 10, 1472.

- Kumar, S.; Saravaiya, S.N.; Pandey, A.K. Precision Farming and Protected Cultivation: Concepts and Applications, 1st ed.; CRC Press: Oxon, UK, 2021; ISBN 9781032052762.

- Barron-gafford, G.A.; Pavao-zuckerman, M.A.; Minor, R.L.; Sutter, L.F.; Barnett-moreno, I.; Blackett, D.T.; Thompson, M.; Dimond, K.; Gerlak, A.K.; Nabhan, G.P.; et al. Agrivoltaics provide mutual benefits across the food–energy–water nexus in drylands. Nat. Sustain. 2019, 2, 848–855.

- Skoplaki, E.; Palyvos, J.A. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624.

- Kumar, N.M.; Kanchikere, J.; Mallikarjun, P. Floatovoltaics: Towards improved energy efficiency, land and water management. Int. J. Civ. Eng. Technol. 2018, 9, 1089–1096.

- Guerin, T.F. Impacts and opportunities from large-scale solar photovoltaic (PV) electricity generation on agricultural production. Environ. Qual. Manag. 2019, 28, 7–14.

- Dos Santos, C.N.L. Agrivoltaic System: A Possible Synergy between Agriculture and Solar Energy; KTH Royal Institute of Technology: Stockholm, Sweden, 2020.

- Marucci, A.; Zambon, I.; Colantoni, A.; Monarca, D. A combination of agricultural and energy purposes: Evaluation of a prototype of photovoltaic greenhouse tunnel. Renew. Sustain. Energy Rev. 2018, 82, 1178–1186.

- FOA. World Agriculture: Towards 2015/2030 Summary Report; FAO: Rome, Italy, 2002.

- Schindele, S.; Trommsdorff, M.; Schlaak, A.; Obergfell, T.; Bopp, G.; Reise, C.; Braun, C.; Weselek, A.; Bauerle, A.; Högy, P.; et al. Implementation of agrophotovoltaics: Techno-economic analysis of the price-performance ratio and its policy implications. Appl. Energy 2020, 265, 114737.

- Andrew, A.C.; Higgins, C.W.; Smallman, M.A.; Graham, M.; Ates, S. Herbage Yield, Lamb Growth and Foraging Behavior in Agrivoltaic Production System. Front. Sustain. Food Syst. 2021, 5, 1–12.

- Leon, A.; Ishihara, K.N. Assessment of new functional units for agrivoltaic systems. J. Environ. Manage. 2018, 226, 493–498.

- Pascaris, A.S.; Schelly, C.; Pearce, J.M. A First Investigation of Agriculture Sector Perspectives on the Opportunities and Barriers for Agrivoltaics. Agronomy 2020, 10, 1885.

- Elamri, Y.; Cheviron, B.; Mange, A.; Dejean, C.; Liron, F.; Belaud, G. Rain concentration and sheltering effect of solar panels on cultivated plots. Hydrol. Earth Syst. Sci. 2018, 22, 1285–1298.

- Sani Ibrahim, M.; Kumari, R. Emerging Solar Energy Technologies for Sustainable Farming: A Review. J. Xi’an Univ. Archit. Technol. 2020, 12, 5328–5336.

- Imran, H.; Riaz, M.H.; Butt, N.Z. Optimization of Single-Axis Tracking of Photovoltaic Modules for Agrivoltaic Systems. Conf. Rec. IEEE Photovolt. Spec. Conf. 2020, 2020, 1353–1356.

- Hassanien, R.H.E.; Li, M.; Yin, F. The integration of semi-transparent photovoltaics on greenhouse roof for energy and plant production. Renew. Energy 2018, 121, 377–388.

- Kumpanalaisatit, M.; Setthapun, W.; Sintuya, H.; Jansri, S.N. Design and Test of Agri—Voltaic System. Turk. J. Comput. Math. Educ. 2021, 12, 2395–2404.

- Othman, N.F.; Ya’Acob, M.E.; Abdul-Rahim, A.S.; Hizam, H.; Farid, M.M.; Abd Aziz, S. Inculcating herbal plots as effective cooling mechanism in urban planning. Acta Hortic. 2017, 1152, 235–242.

- Ravi, S.; Macknick, J.; Lobell, D.; Field, C.; Ganesan, K.; Jain, R.; Elchinger, M.; Stoltenberg, B. Colocation opportunities for large solar infrastructures and agriculture in drylands. Appl. Energy 2016, 165, 383–392.

- Yano, A.; Onoe, M.; Nakata, J. Prototype semi-transparent photovoltaic modules for greenhouse roof applications. Biosyst. Eng. 2014, 122, 62–73.

- Amaducci, S.; Yin, X.; Colauzzi, M. Agrivoltaic systems to optimise land use for electric energy production. Appl. Energy 2018, 220, 545–561.

- Cossu, M.; Cossu, A.; Deligios, P.A.; Ledda, L.; Li, Z.; Fatnassi, H.; Poncet, C.; Yano, A. Assessment and comparison of the solar radiation distribution inside the main commercial photovoltaic greenhouse types in Europe. Renew. Sustain. Energy Rev. 2018, 94, 822–834.

- Allardyce, C.S.; Fankhauser, C.; Zakeeruddin, S.M.; Grätzel, M.; Dyson, P.J. The influence of greenhouse-integrated photovoltaics on crop production. Sol. Energy 2017, 155, 517–522.

- Chel, K. Renewable energy for sustainable agriculture. Agron. Sustain. Dev. 2011, 31, 91–118.

- Ott, E.M.; Kabus, C.A.; Baxter, B.D.; Hannon, B.; Celik, I. Environmental Analysis of Agrivoltaic Systems. In Reference Module in Earth Systems and Environmental Sciences; Elsevier: Amsterdam, The Netherlands, 2020; ISBN 9780128197271.

- Leon, A.; Ishihara, K.N. Influence of allocation methods on the LC-CO2 emission of an agrivoltaic system. Resour. Conserv. Recycl. 2018, 138, 110–117.

- Othman, N.F.; Ya’acob, M.E.; Abdul-Rahim, A.S.; Shahwahid Othman, M.; Radzi, M.A.M.; Hizam, H.; Wang, Y.D.; Ya’Acob, A.M.; Jaafar, H.Z.E. Embracing new agriculture commodity through integration of Java Tea as high Value Herbal crops in solar PV farms. J. Clean. Prod. 2015, 91, 71–77.

- Zhai, M.; Huang, G.; Liu, L.; Zheng, B.; Guan, Y. Inter-regional carbon flows embodied in electricity transmission: Network simulation for energy-carbon nexus. Renew. Sustain. Energy Rev. 2020, 118, 109511.

- Othman, N.F.; Yap, S.; Ya’Acob, M.E.; Hizam, H.; Su, A.S.M.; Iskandar, N. Performance evaluation for agrovoltaic DC generation in tropical climatic conditions. AIP Conf. Proc. 2019, 2129, 020006.

- Agostini, A.; Colauzzi, M.; Amaducci, S. Innovative agrivoltaic systems to produce sustainable energy: An economic and environmental assessment. Appl. Energy 2021, 281, 116102.

- Makavana, J.M.; Kalaiya, S.V.; Chauhan, P.M.; Dulawat, M.S. Advantage of Agrivoltaics Across the Food-Energy-Water Connection. ACTA Sci. Agric. 2020, 4, 15–17.

- Santiteerakul, S.; Sopadang, A.; Tippayawong, K.Y.; Tamvimol, K. The role of smart technology in sustainable agriculture: A case study of wangree plant factory. Sustainability 2020, 12, 4640.

- Riaz, M.H.; Younas, R.; Imran, H.; Alam, M.A.; Butt, N.Z. Module Technology for Agrivoltaics: Vertical Bifacial vs. Tilted Monofacial Farms. EEE J. Photovolt. 2021, 11, 469–477.

- Burgess, P.; Graves, A.; de Jalón, S.G.; Palma, J.; Dupraz, C.; van Noordwijk, M. Modelling Agroforestry Systems. In Agroforestry for Sustainable Agriculture; Burleigh Dodds Science Publishing: Cambridge, UK, 2019; pp. 209–238.

- Dupraz, C.; Talbot, G.; Marrou, H.; Wery, J.; Roux, S.; Liagre, F.; A., F.Y.N.; System, U.M.R.; Viala, P.; Cedex, M.; et al. To Mix or Not to Mix: Evidences for the Unexpected High Productivity of New Complex Agrivoltaic and Agroforestry Systems. In Proceedings of the 5th World Congress of Conservation Agriculture: Resilient Food Systems for a Changing World, Brisbane, Australia, 26–29 September 2011; pp. 5–7.

- Trommsdorff, M.; Kang, J.; Reise, C.; Schindele, S.; Bopp, G.; Ehmann, A.; Weselek, A.; Högy, P.; Obergfell, T. Combining food and energy production: Design of an agrivoltaic system applied in arable and vegetable farming in Germany. Renew. Sustain. Energy Rev. 2021, 140, 110694.

- Marrou, H.; Guilioni, L.; Dufour, L.; Dupraz, C.; Wery, J. Microclimate under agrivoltaic systems: Is crop growth rate affected in the partial shade of solar panels? Agric. For. Meteorol. 2013, 177, 117–132.

- Cossu, M.; Ledda, L.; Urracci, G.; Sirigu, A.; Cossu, A.; Murgia, L.; Pazzona, A.; Yano, A. An algorithm for the calculation of the light distribution in photovoltaic greenhouses. Sol. Energy 2017, 141, 38–48.

- Jumali, S.; Ya’acob, M.E.; Shamsudin, R.; Othman, N.F. Field assessment for photovoltaic array as herbal plots based on bioactive compounds analysis. In Proceedings of the 2016 IEEE Industrial Electronics and Applications Conference, Kota Kinabalu, Malaysia, 20–22 November 2016; pp. 88–91.

- Groesbeck, J.G.; Pearce, J.M. Coal with Carbon Capture and Sequestration is not as Land Use Efficient as Solar Photovoltaic Technology for Climate Neutral Electricity Production. Sci. Rep. 2018, 8, 1–17.

- Barbera, E.; Sforza, E.; Vecchiato, L.; Bertucco, A. Energy and economic analysis of microalgae cultivation in a photovoltaic-assisted greenhouse: Scenedesmus obliquus as a case study. Energy 2017, 140, 116–124.

- Department of Standard Malaysia. Solar Photovoltaic Energy Systems—Terms, Definition and Symbols; Department of Standard Malaysia: Cyberjaya, Malaysia, 2010.

- Seme, S.; Štumberger, B.; Hadžiselimović, M.; Sredenšek, K. Solar photovoltaic tracking systems for electricity generation: A review. Energies 2020, 13, 4224.

- Nakoul, Z.; Bibi-Triki, N.; Kherrous, A.; Bessenouci, M.Z.; Khelladi, S. Optimization of a solar photovoltaic applied to greenhouses. Phys. Procedia 2014, 55, 383–389.

- Chang, T.P. Output energy of a photovoltaic module mounted on a single-axis tracking system. Appl. Energy 2009, 86, 2071–2078.

- Husain, A.A.F.; Hasan, W.Z.W.; Shafie, S.; Hamidon, M.N.; Pandey, S.S. A review of transparent solar photovoltaic technologies. Renew. Sustain. Energy Rev. 2018, 94, 779–791.

- Shukla, A.; Kant, K.; Sharma, A.; Biwole, P.H. Cooling methodologies of photovoltaic module for enhancing electrical efficiency: A review. Sol. Energy Mater. Sol. Cells 2017, 160, 275–286.

- Amelia, A.R.; Irwan, Y.M.; Leow, W.Z.; Mat, M.H.; Rahim, M.S.A.; Esa, S.M. Technologies of solar tracking systems: A review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 767, 1–10.

- Yadav, A.K.; Chandel, S.S. Tilt angle optimization to maximize incident solar radiation: A review. Renew. Sustain. Energy Rev. 2013, 23, 503–513.

- Zaini, N.H.; Mohd Zainal, M.Z.A.; Radzi, M.A.M.; Izadi, M.; Azis, N.; Ahmad, N.I.; Nasir, M.S.M. Lightning surge analysis on a large scale grid-connected solar photovoltaic system. Energies 2017, 10, 2149.

- Wan Abdullah, W.S.; Osman, M.; Ab Kadir, M.Z.A.; Verayiah, R. The Potential and Status of Renewable Energy Development in Malaysia. Energies 2019, 12, 2437.

- Lim, J.R.; Shin, W.G.; Lee, C.G.; Lee, Y.G.; Ju, Y.C.; Ko, S.W.; Kim, J.D.; Kang, G.H.; Hwang, H. A Study of the Electrical Output and Reliability Characteristics of the Crystalline Photovoltaic Module According to the Front Materials. Energies 2021, 14, 163.

- Dinesh, H.; Pearce, J.M. The potential of agrivoltaic systems. Renew. Sustain. Energy Rev. 2016, 54, 299–308.

- Malu, P.R.; Sharma, U.S.; Pearce, J.M. Agrivoltaic potential on grape farms in India. Sustain. Energy Technol. Assess. 2017, 23, 104–110.

- Fadaeenejad, M.; Radzi, M.A.M.; Fadaeenejad, M.; Zarif, M.; Gandomi, Z. Optimization and comparison analysis for application of PV panels in three villages. Energy Sci. Eng. 2015, 3, 145–152.

- Loik, M.E.; Carter, S.A.; Alers, G.; Wade, C.E.; Shugar, D.; Corrado, C.; Jokerst, D.; Kitayama, C. Wavelength-Selective Solar Photovoltaic Systems: Powering Greenhouses for Plant Growth at the Food-Energy-Water Nexus. Earth Future 2017, 5, 1044–1053.

- REN21. Key Findings of The Renewables 2020 Global Status Report; REN21: Paris, France, 2020.

- Othman, N.F.; Jamian, S.; Su, A.S.M.; Ya’Acob, M.E. Tropical field assessment on pests for Misai Kucing cultivation under agrivoltaics farming system. AIP Conf. Proc. 2019, 2129.

- Osterthun, N.; Neugebohrn, N.; Gehrke, K.; Vehse, M.; Agert, C. Spectral engineering of ultrathin germanium solar cells for combined photovoltaic and photosynthesis. Opt. Express 2021, 29, 938.

- Oleskewicz, K. The Effect of Gap Spacing Between Solar Panel Clusters on Crop Biomass Yields, Nutrients and The Microenvironment in a Dual-Use Agrivoltaic System; University of Massachusetts Amherst: Amherst, MA, USA, 2020.

- Harinarayana, T.; Vasavi, K.S.V. Solar Energy Generation Using Agriculture Cultivated Lands. Smart Grid Renew. Energy 2014, 5, 31–42.

- Kadowaki, M.; Yano, A.; Ishizu, F.; Tanaka, T.; Noda, S. Effects of greenhouse photovoltaic array shading on Welsh onion growth. Biosyst. Eng. 2012, 111, 290–297.

- Chen, N.; Wu, P.; Gao, Y.; Ma, X. Review on Photovoltaic Agriculture Application and Its Potential on Grape Farms in Xinjiang, China. Adv. Sci. Eng. 2018, 10, 73–81.

- Dias, L.; Gouveia, J.P.; Lourenço, P.; Seixas, J. Interplay between the potential of photovoltaic systems and agricultural land use. Land Policy 2019, 81, 725–735.

- Moretti, S.; Marucci, A. A photovoltaic greenhouse with variable shading for the optimization of agricultural and energy production. Energies 2019, 12, 2589.

- Macknick, J.; Beatty, B.; Hill, G. Overview of Opportunities for Co-Location of Solar Energy Technologies and Vegetation; National Renewable Energy Lab.: Golden, CO, USA, 2013.

- Pascaris, A.S.; Schelly, C.; Burnham, L.; Pearce, J.M. Integrating solar energy with agriculture: Industry perspectives on the market, community, and socio-political dimensions of agrivoltaics. Energy Res. Soc. Sci. 2021, 75, 102023.

- Tang, Y.; Li, M.; Ma, X. Study on Photovoltaic Modules on Greenhouse Roof for Energy and Strawberry Production. In Proceedings of the E3S Web of Conferences (ICAEER 2019), Shanghai, China, 16–18 August 2019; Volume 118, p. 03049.

- Cossu, M.; Yano, A.; Li, Z.; Onoe, M.; Nakamura, H.; Matsumoto, T.; Nakata, J. Advances on the semi-transparent modules based on micro solar cells: First integration in a greenhouse system. Appl. Energy 2015, 162, 1042–1051.

- Thompson, E.P.; Bombelli, E.L.; Shubham, S.; Watson, H.; Everard, A.; D’Ardes, V.; Schievano, A.; Bocchi, S.; Zand, N.; Howe, C.J.; et al. Tinted Semi-Transparent Solar Panels Allow Concurrent Production of Crops and Electricity on the Same Cropland. Adv. Energy Mater. 2020, 10, 1–9.

- Weselek, A.; Bauerle, A.; Zikeli, S.; Lewandowski, I.; Högy, P. Effects on Crop Development, Yields and Chemical Composition of Celeriac (Apium graveolens L. var. rapaceum) Cultivated Underneath an Agrivoltaic System. Agronomy 2021, 11, 733.

- Zorz, J.; Richardson, W.D.L.; Laventure, A.; Haines, M.; Cieplechowicz, E.; Aslani, A.; Vadlamani, A.; Bergerson, J.; Welch, G.C.; Strous, M. Light manipulation using organic semiconducting materials for enhanced photosynthesis. Cell Reports Phys. Sci. 2021, 2, 100390.

- Daigle, Q.; Talebzadeh, N.; O’Brien, P.G.; Rauf, I.A. Spectral Splitting Luminescent Solar Concentrator Panels for Agrivoltaic Applications. Proc. 3rd Int. Conf. Energy Harvest. Storage Transf. 2019, 3, 132–133.

- Ayush Das, S.D. Simulation and Implementation of Single Axis Solar Tracker Ayush. Int. Res. J. Eng. Technol. 2020, 7, 756–761.

- Ozcelik, S.; Prakash, H.; Challoo, R. Two-axis solar tracker analysis and control for maximum power generation. Procedia Comput. Sci. 2011, 6, 457–462.

- Guo, L.; Han, J.; Otieno, A.W. Design and Simulation of a Sun Tracking Solar Power System. In Proceedings of the 120th ASEE Annual Conference and Exposition, Atlanta, GA, USA, 23–26 June 2013; p. 7854.

- Roth, P.; Georgiev, A.; Boudinov, H. Cheap two axis sun following device. Energy Convers. Manag. 2005, 46, 1179–1192.

- Hafez, A.Z.; Soliman, A.; El-Metwally, K.A.; Ismail, I.M. Tilt and azimuth angles in solar energy applications–A review. Renew. Sustain. Energy Rev. 2017, 77, 147–168.

- Wang, D.; Sun, Y. Optimizing Light Environment of the Oblique Single-axis Tracking Agrivoltaic System. IOP Conf. Ser. Earth Environ. Sci. 2018, 170, 042069.

- Kuttybay, N.; Saymbetov, A.; Mekhilef, S.; Nurgaliyev, M. Optimized Single-Axis Schedule Solar Tracker. Energies 2020, 13, 5226.

- Adeh, E.H.; Selker, J.S.; Higgins, C.W. Remarkable agrivoltaic influence on soil moisture, micrometeorology and water-use efficiency. PLoS ONE 2018, 13.

- Hubach, J.O. Solar Tracking Using a Parallel Manipulator Mechanism to Achieve Two—Axis Position Tracking; Rose-Hulman Institute of Technology: Terre Haute, IN, USA, 2019.

- Irie, N.; Kawahara, N.; Esteves, A.M. Sector-wide social impact scoping of agrivoltaic systems: A case study in Japan. Renew. Energy 2019, 139, 1463–1476.

- Marucci, A.; Cappuccini, A. Dynamic photovoltaic greenhouse: Energy balance in completely clear sky condition during the hot period. Energy 2016, 102, 302–312.

- Kentli, F.; Yilmaz, M. Mathematical modelling of two-axis photovoltaic system with improved efficiency. Elektron. Elektrotechnika 2015, 21, 40–43.

- Dufour, L.; Metay, A.; Talbot, G.; Dupraz, C. Assessing light competition for cereal production in temperate agroforestry systems using experimentation and crop modelling. J. Agron. Crop Sci. 2013, 199, 217–227.

- Yeongseo, Y.; Yekang, K. A Review of the Attributes of Successful Agriphotovoltaic Projects. In Proceedings of the APRU 2020 Sustainable Cities and Landscapes. PhD. Thesis, The University of Auckland, Auckland, Australia, 2020.

- Marrou, H.; Dufour, L.; Wery, J. How does a shelter of solar panels influence water flows in a soil-crop system? Eur. J. Agron. 2013, 50, 38–51.

- Pérez-Alonso, J.; Pérez-García, M.; Pasamontes-Romera, M.; Callejón-Ferre, A.J. Performance analysis and neural modelling of a greenhouse integrated photovoltaic system. Renew. Sustain. Energy Rev. 2012, 16, 4675–4685.

- Touil, S.; Richa, A.; Fizir, M.; Bingwa, B. Shading effect of photovoltaic panels on horticulture crops production: A mini review. Rev. Environ. Sci. Biotechnol. 2021, 20, 281–296.

- Saini, V.; Tiwari, S.; Tiwari, G.N. Environ economic analysis of various types of photovoltaic technologies integrated with greenhouse solar drying system. J. Clean. Prod. 2017, 156, 30–40.

- Sacchelli, S.; Garegnani, G.; Geri, F.; Grilli, G.; Paletto, A.; Zambelli, P.; Ciolli, M.; Vettorato, D. Trade-off between photovoltaic systems installation and agricultural practices on arable lands: An environmental and socio-economic impact analysis for Italy. Land Policy 2016, 56, 90–99.

- Perna, A.; Grubbs, E.K.; Agrawal, R.; Bermel, P. Design Considerations for Agrophotovoltaic Systems: Maintaining PV Area with Increased Crop Yield. In Proceedings of the IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; pp. 668–672.

- Higgins, C.W.; Najm, M.A. An Organizing Principle for the Water-Energy-Food Nexus. Sustainability 2020, 12, 8135.

- Nonhebel, S. Renewable energy and food supply: Will there be enough land? Renew. Sustain. Energy Rev. 2005, 9, 191–201.

- Aguilar, J.; Rogers, D.; Kisekka, I. Irrigation Scheduling Based on Soil Moisture Sensors and Evapotranspiration. Kans. Agric. Exp. Stn. Res. Rep. 2015, 1.

- Muñoz-Carpena, R.; Dukes, M.D. Automatic Irrigation Based on Soil Moisture for Vegetable Crops; AE354: Gainesville, FL, USA, 2005.

- Jensen, M.E.; Allen, R.G. Evaporation, Evapotranspiration and Irrigation Water Requirements, 2nd ed.; American Society of Civil Engineers: Reston, VA, USA, 2016; No.70; ISBN 9780784479209.

- Verstraeten, W.W.; Veroustraete, F.; Feyen, J. Assessment of evapotranspiration and soil moisture content across different scales of observation. Sensors 2008, 8, 70–117.

- Sharu, E.H.; Ab Razak, M.S. Hydraulic performance and modelling of pressurized drip irrigation system. Water 2020, 12, 2295.

- Moswetsi, G.; Fanadzo, M.; Ncube, B. Review Article Cropping Systems and Agronomic Management Practices in Smallholder Farms in South Africa: Constraints, Challenges and Opportunities. J. Agron. 2017, 16, 51–67.

More