The roll bonding (RB) process involves the joining of two or more sheets of similar or dissimilar materials at various temperatures. The process requires rolling through a pair of rollers under adequate pressure resulting in the bonding of sheets. The process is categorized into three types, i.e., cold, hot, and warm roll bonding based on the ranges of the processing temperature which in turn is related to the recrystallization temperature.

- roll bonding

- solid-state joining

- mechanical properties

- joining mechanisms

1. Introduction

Nearly all engineering structures are an assemblage of several distinct components that require the application of a joining process. The selection of a certain joining technique plays a key part in determining the overall service life and functionality of an engineering structure in a particular environment. On the other hand, the key engineering elements in the selection of a joining process include materials to be joined, function, mode of loading and joint geometry and physical attributes, such as component topology, profile, accessibility, section thickness and tolerance. In addition, the desired functional requirements and ease of maintenance, which in turn depend on weld quality, i.e., microstructure and properties (mechanical, electrical, etc.), also dictate the choice of process selection. For instance, in light-metal transportation structures exposed to a range of different environments, joining processes such as riveting are preferred compared to fusion welding processes to avoid the detrimental effects of melting leading to degradation of mechanical properties. In a similar vein, there are many other applications, particularly those which involve the joining of dissimilar materials, where conventional fusion welding processes are rendered infeasible, and hence solid-state joining processes are attractive.

In solid-state joining processes, true metallurgical welds are obtained without melting—although some local and isolated pockets of melting may form—thus, bulk volume changes caused by solidification are avoided during the process [1]. In the last few decades, several solid-state joining and manufacturing processes have gained noticeable attention, owing to the inherent advantages of this technology. Several processes and variants, including friction stir welding [2], friction stir riveting [3], ultrasonic welding [4], roll bonding [5], etc., are considered to be quite mature and have been extensively used by industry for decades now. These processes can be used to induce desired changes at the microstructural level and to form bonds between metallic sheets of similar and dissimilar materials [6]. Solid-state methods therefore provide a wide range of joining solutions considering the functional requirements and component topology. Therefore, advancing solid-state joining processes remains an ongoing technical and scientific goal among the joining research community. As a result, these processes are constantly being looked at for further development, as is evident from the six-fold increase in research citations related to solid-state joining processes during the last decade.

In this context, two functional requirements that have attracted increasing attention in the last few years include: (1) the ability to join dissimilar metals that cannot be welded by conventional processes, such as joining stainless steel or steel to nickel, titanium, copper, and aluminum alloys, (2) the development of thick or ultra-thick layered composite materials with potential applications ranging from simple bi-metal strips for engine components to complex turbine blades as functional gradient structures. Different solid-state joining processes have been employed for the manufacturing such structures. The roll bonding process, among them, have shown significant potential and can be classified among the solid-state processes in which extensive mechanical deformation is produced in a metallic sheet with or without application of heat to change the microstructure or to create bonds between multiple metal sheets [7]. For example, cold roll bonding is a mature technology typically deployed to produce roll-clad plates to protect against corrosion or erosive wear encountered in various important industries. Some of the advantages of the RB process over conventional manufacturing and joining processes include simplicity and ease of operation, cost savings, desirable mechanical properties, and applicability to dissimilar materials. A detailed literature review indicates that a diversity of research is available on RB processes, including development and optimization process parameters, evolution of microstructure and mechanical properties for different materials and configurations. In addition, several review papers on different variants of the RB process are also available, providing comprehensive coverage of the research performed. However, to fully exploit any process, a thorough understanding of the relationship between processing parameters and the resultant performance indicators (i.e., mechanical, and electrical properties, behavior under hostile environment) is mandatory. Unfortunately, such a requirement has not been explicitly addressed in previous reviews. Moreover, no review paper is available that provides a comparative analysis of the different variants of the RB process. Such an analysis can help the designer to carefully select the process according to the requisite applications.

This review paper is, therefore, aims to serve as the missing link that can interconnect key aspects such as process parameters, microstructure, and defects, and their influence on the resultant properties. Moreover, a detailed discussion on the major variants of the RB processes (i.e., cold roll bonding, hot roll bonding, and accumulative roll bonding) is presented in this paper to provide a comparison of the different variants of the RB process. The paper covers different aspects of the RB process, including process mechanics, characterization, and evaluation (mechanical, electrical, and extreme environment), and modeling. An effort is made to discuss current applications and advantages, the limitations of the process, and developments in dissimilar material hot roll bonding technologies. For each aspect, research needs are identified and presented at the end of the respective section. The paper concludes by presenting some critical analyses, including joining mechanisms, engineering guidelines, and process–structure–property relationships. Finally, future research areas are identified based on modern manufacturing trends.

2. Characterization and Evaluation

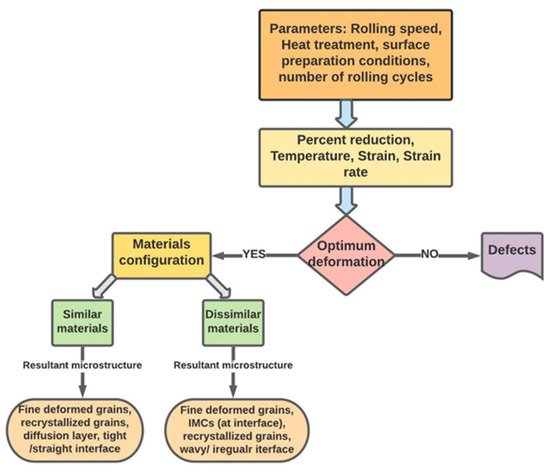

Figure 1 summarizes the overall microstructural evolution mechanism in RB processes. Although recrystallization is a common phenomenon in both configurations of the material, the recrystallization mechanism can be different for the two cases. Static recrystallization has been found to be more dominant in similar metal joints processed through CRB than dynamic recrystallization in dissimilar metals RB joints processed through HRB/ARB. Moreover, the morphology and extent of the diffusion layer and the nature/formation of intermetallic compounds (IMCs) are linked to the rolling temperatures, number of rolling cycles, and heat treatment (HT) conditions.

Different testing methods such as tensile, shear, multistep shear, and peeling tests are available for the quantitative evaluation of RB joints whereas several tests (impact, fatigue) for the qualitative evaluation for thick sheet joints are present as well. However, mechanical evaluation of thin sheet joints poses a challenge due to the involvement of different metal combinations. Moreover, for dissimilar metals joints, interfacial properties are critical, but no existing standard provides a guideline for their measurement. The development of such guidelines while taking aid from non-destructive measurements can be beneficial for improving the mechanical performance evaluation.

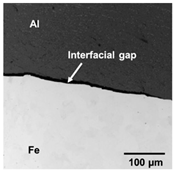

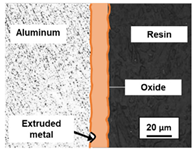

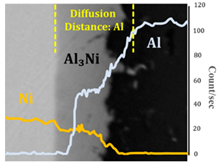

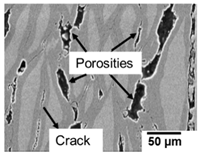

Brittle intermetallic formation at the interface mostly related to rolling bonded dissimilar materials joints can also be regarded as a defect, as it degrades the joint bonding strength. The intermetallic layer thickness, if not controlled, can severely affect the joint strength as observed in [8]. The thickness of the intermetallic layer can be controlled by carefully selecting the pre-, post-, and inter-rolling heating cycles/temperature. Porosities and cracks in the interfacial layer are also observed in the HRB joints where different IMCs are formed at the interface as a result of the dissociation of one IMC to others at prolonged annealing times/cycles [9]. Furthermore, porosities are pronounced due to the presence of simultaneous other mechanisms, such as the formation of Kirkendall voids because of the vacancies diffusion toward the interface, and the dissimilar contraction behavior of the IMCs during the cooling period results in voids and cracks between some layers. It can be inferred that the defects in the RB joints are more inherited from the process-control than the process dynamics. The defects in the preceding paragraphs are critical to joint performance in terms of peel resistance, fatigue resistance, and enhanced tensile strength. Table 1 provides a summary of the defects with their related cause in terms of process parameters. Careful selection of process parameters and their subsequent optimization is therefore critical for obtaining a sound joint.

| Nature of Defect | Key Process Parameters | Defect Morphology | Reported by |

|---|---|---|---|

| Interfacial gaps | Rolling speed Sheet thickness |

|

Wang et al. [10] |

| Presence of oxide layer | Surface treatment |  |

* Le et al. [11] |

| Brittle Intermetallics | High rolling temperatures and/or high post or inter-rolling cycles HT temperatures |  |

** Azimi et al. [12] |

| Porosity and cracks | Prolonged heat treatment cycles |  |

Mozafferi et al. [8] |

The electrical properties of the roll-bonded joints are found to be influenced by many factors including the formation of the intermetallic layer which in turn is highly dependent on the process parameters, for instance, rolling speed and temperature. Moreover, electrical properties depend on the type of process itself, for example, layer threshold reduction in the ARB process can significantly improve the electrical conductivity as compared to conventional roll bonding processes.

3. Modeling and Simulation

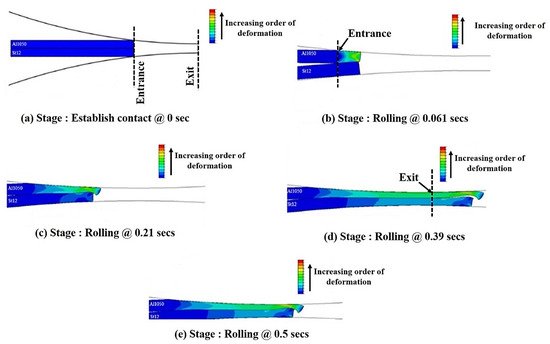

Different theoretical models have been suggested to elucidate various aspects of the roll bonding process. Most roll bonding models have focused on controlling the process parameters, while some models have developed the relationship between microstructure evolution and bond strength. The researchers in [13] suggested the following equation for evaluating joint strength. (1) ƞ = σ B σ 0= R f ( 2− R f ) where “ σ B ” denotes the bond strength, “ σ 0” is the strength of the base metal, “ ƞ ” is bond strength efficiency, and “ R f ” is the final reduction after rolling pass. In this model, the bonded area is proportional to R f . Wright et al. [14] presented the theoretical model for bond efficiency regarding threshold deformation and is defined below: (2) ƞ = H ( 1− ( 1− R f ) 2 ( 1− R t ) 2) where “ H ” is the empirical hardening factor, “ ƞ ” is bond strength efficiency, and “ R t ” is the threshold reduction deformation. Hosseini and Kokabi [15] developed a model that can estimate bond efficiency based on the peel test results of Al 5754 alloy. Das and Nafari [16] used density function formulation to present an analytical model that highlights the significance of electronic interaction in the roll bonding of two metals. Researchers used dislocation density evolution [17] to develop a model that can predict deviation in yield strength and average grain size in ARB passes. Al-AA1100 alloy was processed and tested to validate the results of the model. Researchers [18] analyzed different parameters of the ARB process using a dynamic explicit finite element model. Through modeling, the researchers were able to predict stresses and strains along with the deformation during the rolling process. The model was found to be in good conformity with the empirical results. Several models [19][20][21] have been constituted to predict the force and torque in joining two to three layers through roll bonding. These models primarily focused on the cladding of metals. In one such study, the slab method of analysis was used to define the deformation mechanism [21]. The model considered two regions in the rolling zone. The first area consisted of unbounded metals where merely the soft metal yielded while in region two, yielding took place in both materials. Other studies [22][23][24] developed numerical models to predict the process parameters. Researchers developed analytical models [25][26] for the roll bonding of multi-layered bi-metals. The model was based on anisotropy and strain hardening effects in addition to providing information about suitable processing conditions. Recently, researchers have studied the effects of total strip deformation, its initial thickness, the yield stress ratio, and the thickness ratio of the layers on the bonding strength in Steel/Al cold roll bonded joints and found a proportional effect of these parameters on the bond strength [27]. Plastic deformation as a function of rolling time from the computational analysis is presented in Figure 2.

Although several models are available for predicting the roll bonding process, theoretical models have their limitations in predicting the joint strength, especially where dissimilar metals are joined. Numerical models provide better accuracy than theoretical models but are difficult to use owing to the unavailability of comprehensive data set for different materials and expensive computation efforts.

Material flow and severe plastic deformation are key features of RB processes that render traditional mesh-based numerical simulations ineffective. High-fidelity full-scale numerical models involving fluid dynamics-based Eulerian method or particle-based meshless method may be used to capture the complex metallurgical changes during the joining process.

4. Process Merits and Applications

Roll bonding can be used for a wide variety of materials and has been found to work well for joining dissimilar materials [28]. RB process is easy to automate owing to its simplicity and appears as a promising technique for joining foils [29][30]. The ARB process, a variant of roll bonding, can be used to produce ultrafine grains. However, some limitations need to be overcome in order to use the process more efficiently. Surface preparation, which is an important consideration for manufacturing sound joints in roll bonding, is nontrivial to achieve. The limited availability of data regarding the relation of mechanical properties to interfacial bonding has also hindered the use of this process. The bonding mechanism in the hot roll bonding of dissimilar materials requires more extensive research, as the temperature effects during the process have not been fully established. Moreover, the availability of data on the service performance characteristics for roll bonded joints is very limited, making it difficult to compare the roll bonding process with other solid-state processes.

Different RB processes have been used extensively for various applications in the past few decades. The ARB process is used for making/joining metallic composite materials in different shapes such as the plate, strip, foil, tube, rod, and wire. These metallic composite materials lend advantages such as low cost and use in multiple applications, including thermal, structural, electrical, and magnetic applications. The joints produced through hot and cold roll bonding are used in different industries. Table 2 indicates some of the different material combinations and their applications.

| Material Combination | Applications |

|---|---|

| Cu/Al | Heat exchangers, electrical components |

| Cu/Al/steel | Cookware |

| Ti/stainless steel/Ni | The bipolar electrode in the fuel cell |

| Nb/Stainless steel | Fuel cell bipolar plate |

| Cu/Ag | Electrical components and appliances |

| Al/steel/Al | Automotive exhaust systems |

The HRB process has recently found wide application in numerous industries owing to its ability to produce a large area of bimetals through elevated temperature. Particularly, with regard to the joining of dissimilar metals, the HRB process lends advantages such as improved mechanical strength, cost saving, and corrosion and heat resistance [31]. Furthermore, the HRB process exhibits a better adaptability with respect to joining multilayer thick sheets compared to other solid-state processes, such as explosive welding and weld overlay cladding. Carbon steel substrate and stainless steel cladded HRB joints are widely used in different industries, including as pressure vessels, nuclear power equipment, desalination equipment, heat exchangers, armor, bridge engineering, automobile, etc. [32][33][34]. In a similar vein, Ti, which is one of the most sought-out metals due to its superior strength and corrosion properties, but for which the difficulty of its processing results in high costs, can be utilized in the form of Ti-Steel composite plates through the HRB process. Ti-Steel multilayer clad plates have gained wide application in the aerospace and construction industries, as well as in nuclear power equipment and heat exchangers [35].

References

- Cai, W.; Daehn, G.; Vivek, A.; Li, J.; Khan, H.; Mishra, R.S.; Komarasamy, M. A state-of-the-art review on solid-state metal joining. ASME J. Manuf. Sci. Eng. 2019, 141, 031012.

- Wang, K.; Khan, H.A.; Li, Z.; Lyu, S.; Li, J. Micro friction stir welding of multilayer aluminum alloy sheets. J. Mater. Process. Technol. 2018, 260, 137–145.

- Khan, H.; Li, J.; Shao, C. Analyses of friction stir riveting processes: A review. ASME J. Manuf. Sci. Eng. 2017, 139, 090801.

- Wang, K.; Li, Y.; Banu, M.; Li, J.; Guo, W.; Khan, H. Effect of interfacial preheating on welded joints during ultrasonic composite welding. J. Mater. Process. Technol. 2017, 246, 116–122.

- Göken, M.; Höppel, H.W. Tailoring Nanostructured, Graded, and Particle-Reinforced Al Laminates by Accumulative Roll Bonding. Adv. Mater. 2011, 23, 2663–2668.

- Khan, H.A.; Wang, K.; Li, J. Interfacial bonding mechanism and mechanical properties of micro friction stir blind riveting for multiple Cu/Al ultra-thin layers. Mater. Charact. 2018, 141, 32–40.

- Mansouri, H.; Eghbali, B.; Afrand, M. Producing multi-layer composite of stainless steel/aluminum/copper by accumulative roll bonding (ARB) process. J. Manuf. Process. 2019, 46, 298–303.

- Azimi, M.; Toroghinejad, M.R.; Shamanian, M.; Kestens, L.A. The effect of strain on the formation of an intermetallic layer in an Al-Ni laminated composite. Metals 2017, 7, 445.

- Mozaffari, A.; Hosseini, M.; Manesh, H.D. Al/Ni metal intermetallic composite produced by accumulative roll bonding and reaction annealing. J. Alloys Compd. 2011, 509, 9938–9945.

- Lauvdal, S. Experimental Studies of Cold Roll Bonded Aluminum Alloys. Master’s Thesis, Institutt for Materialteknologi, Trondheim, Norway, 11 August 2011.

- Wang, C.; Jiang, Y.; Xie, J.; Zhou, D.; Zhang, X. Interface formation and bonding mechanism of embedded aluminum-steel composite sheet during cold roll bonding. Mater. Sci. Eng. A. 2017, 708, 50–59.

- Le, H.R.; Sutcliffe, M.P.; Wang, P.Z.; Burstein, G.T. Surface oxide fracture in cold aluminum rolling. Acta Mater. 2004, 52, 911–920.

- Vaidyanath, L.R.; Nicholas, M.G.; Milner, D.R. Significance of Surface Preparation in Cold Pressure Welding. Br. Weld. J. 1959, 7, 1–6.

- Wright, P.K.; Snow, D.A.; Tay, C.K. Interfacial conditions and bond strength in cold pressure welding by rolling. Met. Technol. 1978, 5, 24–31.

- Hosseini, H.R.M.; Kokabi, A.H. Cold Roll Bonding of 5754-Aluminium Strips. Mater. Sci. Eng. A 2002, 335, 186–190.

- Das, M.P.; Nafari, N. Adhesive Forces at Bimetallic Interfaces. Solid State Commun. 1986, 63, 367–370.

- Yu, H.; Lu, C.; Tieu, A.K.; Godbole, A.; Su, L.; Sun, Y.; Liu, M.; Tang, D.; Kong, C. Fabrication of Ultra-Thin Nanostructured Bimetallic Foils by Accumulative Roll Bonding and Asymmetric Rolling. Sci. Rep. UK 2013, 3, 2373.

- Fratini, L.; Merklein, M.; Boehm, W.; Campanella, D. Modeling Aspects in Accumulative Roll Bonding Process by Explicit Finite Element Analysis. Key Eng. Mater. 2013, 549, 452–459.

- Yong, J.; Dashu, P.; Dong, L.; Luoxing, L. Analysis of Clad Sheet Bonding by Cold Rolling. J. Mater. Proc. Technol. 2000, 105, 32–37.

- Pan, S.C.; Huang, M.N.; Tzou, G.Y.; Syu, S.W. Analysis of Asymmetrical Cold and Hot Bond Rolling of Unbounded Clad Sheet under Constant Shear Friction. J. Mater. Process. Technol. 2006, 177, 114–120.

- Hwang, Y.M.; Tzou, G.Y. An Analytical Approach to Asymmetrical Cold and Hot Rolling of Clad Sheet using the Slab Method. J. Mater. Process. Technol. 1996, 62, 249–259.

- Chaudhari, G.P.; Acoff, V. Cold Roll Bonding of Multi-Layered Bi-Metal Laminate Composites. Compos. Sci. Technol. 2009, 69, 1667–1675.

- Herrmann, J.; Suttner, S.; Merklein, M. Experimental investigation and numerical modeling of the bond shear strength of multi-layered 6000 series aluminum alloys. Procedia Eng. 2017, 183, 283–290.

- Lee, S.; Lee, D.N. Slab Analysis of Roll Bonding of Silver Clad Phosphor Bronze Sheets. Mater. Sci. Technol. 1990, 7, 1042–1050.

- Tzou, G.Y. Theoretical Study on the Cold Sandwich Sheet Rolling Considering Coulomb Friction. J. Mater. Proc. Technol. 2001, 114, 41–50.

- Tzou, G.Y.; Tieu, A.K.; Huang, M.N.; Lin, C.Y.; Wu, E.Y. Analytical Approach to the Cold and Hot Bond Rolling of Sandwich Sheet with outer Hard and Inner Soft Layers. J. Mater. Proc. Technol. 2002, 125, 664–669.

- Rezaii, A.; Shafiei, E.; Ostovan, F.; Daneshmanesh, H. Experimental & theoretical investigation of roll bonding process of multilayer strips by finite element method. J. Manuf. Process 2020, 54, 54–69.

- Borts, B.V.; Korotkova, I.M.; Lopata, O.O.; Sytin, V.I.; Tkachenko, V.I.; Vorobyov, I.O. Production of Dissimilar Metals Materials by the Method of Solid-State Joining. Open J. Met. 2014, 4, 40–47.

- Karakozov, E.S.; Vasil’ev, V.N.; Paraev, S.A. Cold Welding Aluminum and Copper Foil. Part 1. Plastic Deformation Process. Weld. Int. 1991, 5, 300–303.

- Barlow, C.Y.; Nielsen, P.; Hansen, N. Multilayer Roll Bonded Aluminum Foil: Processing, Microstructure, and Flow Stress. Acta Mater. 2004, 52, 3967–3972.

- Movahedi, M.; Madaah-Hosseini, H.R.; Kokabi, A.H. The Influence of Roll Bonding Parameters on the Bond Strength of Al-3003/Zn Soldering Sheets. Mater. Sci. Eng. A 2000, 487, 417–423.

- Peng, X.K.; Wuhrer, R.; Heness, G. Rolling Strain Effects on the Interlaminar Properties of Roll Bonded Copper/Aluminum Metal Laminates. J. Mater. Sci. 2000, 35, 4357–4363.

- Peng, X.K.; Wuhrer, R.; Heness, G. On the Interface Development and Fracture Behavior of Roll Bonded Copper/Aluminum Metal Laminates. J. Mater. Sci. 1999, 34, 2029–2038.

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel Ultra-High Straining Process for Bulk Materials—Development of the Accumulative Roll-Bonding (ARB) Process. Acta Mater. 1999, 47, 579–583.

- Saito, Y.; Tsuji, N.; Utsunomiya, H.; Sakai, T.; Hong, R.G. Ultra-Fine-Grained Bulk Aluminum Produced by Accumulative Roll-Bonding (ARB) Process. Scr. Mater. 1998, 39, 1221–1227.