Carbon nanotube (CNT) and carbon nanofibre (CNF) coating on CF reinforced polymer composites exhibit excellent properties that are essential in many high-performance applications including automotive

[86][87][86,87] and aerospace

[88][89][88,89]. High strength (>150 GPa), modulus (~1 TPa), thermal conductivity, electrical capacity and thermal stability are the common characteristics of this coating

[91]. Several research works have been done based on CNT coated CF reinforced polymer composites

[65][67][89][65,67,89]. Importantly, an optimal loading for CNT coating in the polymer composites is a key criterion to employ its outstanding mechanical characteristics in the composites. It has been studied that increasing CNT loading can primarily lead to an increase in tensile strength and tensile modulus, however, increasing CNT loading has an adverse effect on the tensile modulus and strength of the composite beyond a critical weight fraction

[92]. For example, the deterioration of tensile strength, failure strain and elastic modulus of polystyrene composites has been found beyond a critical CNT mass fraction

[93]. Nanotubes can cause agglomeration that decreases the interphase region and produces stress concentration sites of the composites, thereby leading to failure

[94]. This can cause a reduction in the load carrying capacity of the composite as well. Therefore, it is necessary to grow CNT directly on the CFs surface. The processing parameters such as the growth time, catalyst, and growth temperature play an important role in the extent of CNT coating and the fibre surface coverage. Agnihotri et al.

[95] have studied the effects of CNT coating on the CNT-coated CF/polyester composites’ properties. The researchers have found that the optimization of the multiscale composite properties can be achievable by changing the reactor duration for chemical vapor deposition (CVD). Dispersion, degradation of the CNTs and matrix viscosity are some challenging issues for CNT coating

[96]. In some cases, the dispersion techniques of CNTs coating in the polymer composites resulted in low CNT graphitization, poor nanotube alignment, CNT agglomeration, inadequacy to small weight percentage (wt%) accumulations, deficiency of morphology control, and reduced matrix infusion capability while using infusion techniques, such as resin transfer molding (RTM) and vacuum assisted resin transfer molding (VARTM). The role of CF as a substrate for CNT coating permits well dispersed and high-density CNTs for the incorporation in the composite. The link among the adjoining CFs, generating electrical and thermal percolation routes throughout the composite and improving the mechanical characteristics of CF-based composites can be possible by CNTs. The interfacial adhesion between the resin-dominated (i.e., volume or weight fraction of resin is much higher than the filler) processes and the CFs can also be improved by the CNTs. The effect of sonication time on the mechanical properties of CNTs reinforced multiscale composites. Compared with neat epoxy resin, the residual heat, rate of reaction and heat flow and conversion at the beginning stage of the cure course has been enhanced by involving non-woven CNFs in the composites. Sharma and Lakkad

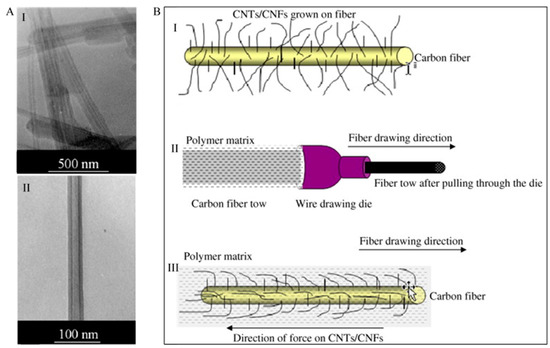

[91] investigated the CF before and after the growth of CNTs/CNFs. According to the TEM images (

Figure 1A), the centre of the CNT has a hollow core, which is very narrow. It is clear that the CNT covered the fibre surface uniformly and grew long enough with various diameter and length. As shown schematically in (

Figure 1B), the long CNTs may orient themselves with the direction of drawing of the fibre when it is being pulled out through the very small orifice of the wire drawing die. The CNTs/ CNFs grown on CF is shown in

Figure 1B(I) whereas the schematic diagram of polymer matrix dipped fibre and its pulling through the wire drawing die is portrayed in

Figure 1B(II). The CNTs/carbon nanofibre coated CF after pulling out through the die is shown in

Figure 1B(III), which displays an expected partial alignment of long CNTs/CNFs along the fibre axis, whereas the short CNTs/CNFs are still expected to remain unchanged. The cause of the alignment is due to the viscous force of the polymer matrix and also the frictional force due to the compactness of the opening of the die. Throughout the fibre pulling across the die, the exertion of the forces took place. The increase in the composites’ tensile strength is due to this partial alignment.