1. Introduction

The first robotics and automated systems for construction were developed in the 1960s. However, since then, the technological progress in the construction industry has been very slow. Meanwhile, many other industrial sectors increased productivity and simultaneously increased efficiency. Therefore, the application of robotics and automated systems to the construction industry has the potential to reduce costs, improving both productivity and quality

[1].

On the other hand, conventional construction techniques have reached maximum technological performance. Consequently, in the scientific and technical world, the current objective aims to revolutionise the construction sectors’ techniques through the support of the digital fabrication

[2,3][2][3].

Digital fabrication is a production process that begins with digital drawings. It can be intended as an application of new technologies to embody the shapes and maximise the performance of materials, rather than imposing them in the production

[4].

Among the digital fabrication techniques, extrusion-based 3D concrete printing (3DCP) is one of the most promising technologies for the renovation of the construction sector

[5]. Indeed, different 3DCP applications for building construction have been developed in the last few years to modernise the construction sector

[6]. Different studies have demonstrated that, compared with conventional construction processes, 3D printing can reduce costs, reduce the use of energy and waste material, eliminate dangerous jobs, and minimise the chance of errors, all while increasing sustainability and architectural freedom

[6].

Since technology, performance, and freedom in printable forms are closely related to the study of materials, many types of extrudable cementitious materials have been developed in the last few years. The material used for concrete 3D printing must have specific properties including extrudability, viscosity, and workability

[7,8,9][7][8][9]. Moreover, binding time and early robustness are essential to building a layer on another without losing the designed shape. At the same time, high structuration rates could lead to so-called cold joints and weak interfaces between layers. To provide some examples, in the material research field, high performance fibre reinforced with fine-aggregate concrete has been applied in Concrete Printing technology

[6], and Ultra-High-Performance Concrete has been developed for large-scale 3DCP technology

[10]. In addition, other studies have investigated Sorel cement in D-Shape technology

[11]. Findings identified that geopolymer-based material

[12] and granular material mixed with pulverized metal oxide (MgO) reacted with magnesium chloride (MgCl

2) to produce an artificial double magnesium–carbonate sand stone

[13].

Operatively, many 3D printed constructions made with different concrete mixtures and shapes can be found in the available literature

[11,14,15,16][11][14][15][16]. Despite the fact that 3D printing of concrete buildings is growing fast, and whole 3D printed houses are now widespread in the world, there is still limited application and experimentation of 3D printing for concrete components prefabrication. However, prefabrication through 3D printing has enormous potential, especially in a long-term vision where the combination with robotic construction processes can lead to a fully automated and sustainable building process. Indeed, recent researchers have demonstrated the interest of the construction sector in the combination between digital concrete and prefabrication. For example, Meibodi et al. applied the Smart Dynamic Casting (SDC) to prefabricate and optimise load-bearing concrete structures, and to create the Smart Slab by using a large 3D printed formwork

[17]. Another example of precast digital concrete is the Eggshell fabrication process

[18]. Moreover, one of the few applications of 3D printing directly used for precast components in regard to the project “Office of the Future” of Killa Design, where office boxes are realised by using a large size prefabrication (8.9 × 1.9 × 2.1 m)

[19]. The 3DCP was also applied to slab prototypes in both the lightweight concrete ceiling designed at TU Graz

[20] and the prefabricated concrete slabs built at ETH Zürich

[21,22][21][22]. Another possible advantage of 3DCP is the concrete optimisation through efficient shapes, placing material only where functionally required. This controlled environment of concrete can be maximised by prefabrication, which can allow for the calibration of machines and the achievement of geometric complexity using 3DCP. In this regard, Anton et al. developed a 3DCP setup for the automated prefabrication of bespoke columns

[23].

On the other hand, the previous experiences of 3D printing for prefabrication focused on special components or uncommon constructions. Indeed, the limitations of previous studies concern the design of the precast component, which are not realised for the needs and performances of common buildings. In addition, the large size of the previous experiences compromises the easy assembly in situ (e.g., operation’s speed execution, specific machines for handling, and workers safety). Consequently, the combination between 3D printing and prefabrication for the building construction sector is still open with multiple aspects to explore.

In this study, we propose the design and prototyping of a new prefabricated system for innovative building envelopes made with 3D printing. The new design and conception aim to fully exploit the potential of 3D printing for prefabricated components, including the dry assembly, speed of implementation, reusability, recyclability, modularity, versatility, adaptability, and sustainability. In particular, the envelope system is composed of precast elements that can be printed on-site and assembled entirely dry to maximise the reversibility. Moreover, they can be easily dismantled, reused, or recycled. The dry assembly allows for more simplicity of commissioning and speed of assembly. The elements have modular dimensions and high levels of mobility, but the 3D printing technology makes it possible to simply change the dimensions of the blocks, specifically the height and width, and to adapt the proportions to every situation. The versatility of use does not only concern the solving of geometric problems, but also the possibility of applying the system to different types of indoor environments. Therefore, we tried to achieve an innovative aesthetic impact that is close to the traditional masonry in appearance, but that also emphasises the characteristics of the innovative technology. Another important aspect regards the structural and energy performance included in the proposed prototype. In order to ensure good performances, an innovative magnesium potassium phosphate cement (MKPC) has been specifically designed (and tested in previous research

[24]) to improve the performance of the proposed prefabricated system.

To sum up, the novelties of the proposed prefabricated system are threefold:

-

The combination between 3D printing and prefabrication for the building construction sector is explored in depth by designing a new “printable” prefabricated system.

-

The proposed multi-objective design combines, for the first time, different important aspects in a precast 3D printed component, including the following functions: thermal insulation, structural reinforcement, and housing of the technological plant.

-

A sustainable magnesium potassium phosphate cement (MKPC) is developed for the proposed 3D printed prefabricated system in order to avoid shell collapses during the printing process and to ensure good structural and energy performances.

2. Project Design: The Innovative Building Envelope Designed for 3D Printing

2.1. Concept: The Multi Objective Design

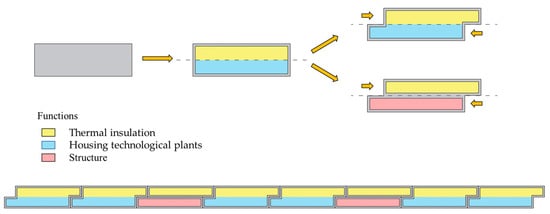

An innovative 3D printed building envelope construction was designed. To this aim, different modular elements have been conceived (Figure 1) to perform different functions, like thermal insulation, structural reinforcement, and building services integration. The elements can be printed industrially or on site, and can be assembled with a spigot and socket joint.

Figure 1. Innovative building envelope designed for 3D printing.

The concept is based on functional segmentation, as shown in Figure 2. Starting from a block of rectangular shape, a translational movement along the symmetry axis creates a half lap joint. This configuration prevents the discontinuity of thermal insulation, thus reducing the risk of thermal bridges. In addition, an insulating material panel can be inserted on one side of every single block.

Figure 2. Zones with different functions in a storage element.

In this process, two types of basic elements are designed: (i) one with thermal insulation and an air cavity for building services integration (standard blocks), and (ii) one with thermal and structural functions (structural blocks). These are obtained by including an internal partition to separate the structural reinforcement zone and to create a suitable formwork (Figure 2).

2.2. Precast Elements: Dry Assembly, Modularity and Adaptability

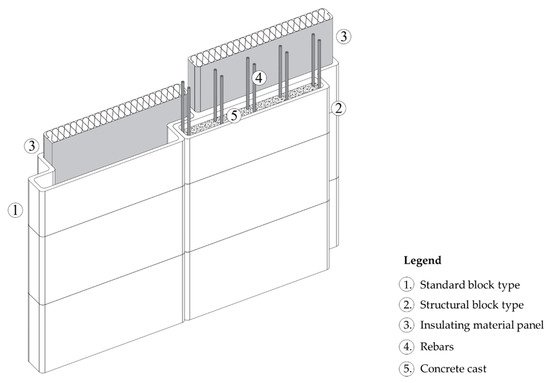

The two types of basic elements have the same shape and size to ensure a modularity of both structural and non-structural components (Figure 3). The visible side is 120 cm in length (the total length is 140 cm) and 60 cm in height. The total depth of the panel is 40 cm.

Figure 3. The two types of basic elements.

The thermal insulation panel can simply be placed inside the block after the 3D printing process is completed. Therefore, the blocks are ready to be assembled when they are moved to the construction site.

The structural blocks have two parts that are physically separated. At the time of building, one side has the panel already included, and the other side is empty. The elements are installed on the reinforcement and used for casting the concrete as formwork.

To fix the edge of the wall, the block happens to resemble a T-shape. This way, the special edge block ensures the continuity of the insulation with the perpendicular element.

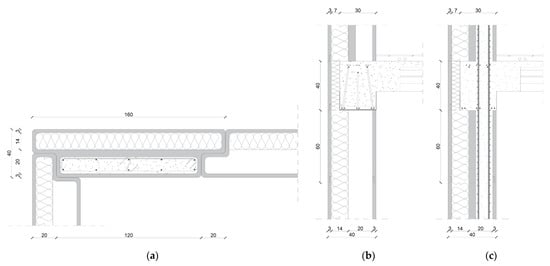

Figure 4 shows a technical representation of the blocks. The adoption of a special edge block con be noticed in Figure 4a, while Figure 4b shows the details of the connection between the block and a common reinforced concrete floor slab.

Figure 4. Building envelope section detail: (a) horizontal section of the envelope system at the edge; (b) vertical section of the beam-wall; (c) vertical section at the beam-column node.

The proposed sizes are modular, although the 3D printing technology allows for a simple modification of the height of each block in order to reduce or increase the number of layers, or to customise the construction.

2.3. Material: Printability and Sustainability

As the concrete rheological requirements influence the input parameters of 3D printing, specific studies were performed. According to previous studies

[8], the printing test of suitable materials should search for the following properties: (i) layer thickness

h0, (ii) maximum height

H, (iii) layer width, and (iv) radius curvature. Moreover, according to Bos et al.

[8]:

| Thermal Insulance ((m | 2 | ⋅K)/W) |

Thermal Transmittance (W/(m |

-

Yield stress in the bottom layer must be greater than g·ρ·H/√3 where ρ is the material density.

-

Initial shear elastic modulus must be higher than g∙h0/εtol where εtol is the tolerable deformation of the layer.

-

Young elastic modulus must be higher than 3·g∙H3/22.

In the proposed research, we identified a printable material (studied in detail in a previous study

[24]) that can be suitable to guarantee good performances for the designed component. We proposed an innovative MKPC cementitious material that could reach the appropriate characteristics of plasticity, fluidity, workability, and setting time needed for 3D printing

[25,26][25][26]. Two different compositions of the MKPC were obtained; one with common sand aggregates, and an alternative with recycled expanded glass that can be more performant in terms of thermal transmittance and sustainability

[24].

Table 1 shows the two mix compositions of the MKPC, while

Table 2 shows their mechanical properties.

Table 1. Mix composition.

| Compositions |

MgO |

KDP |

| Compositions |

Density |

Flow | FA |

Borax |

SF |

Flexural Strength [MPa] |

Compressive Strength [MPa] | Water |

Aggregates |

| 2 | ·K)) |

90 min |

7 days |

90 min |

7 days |

|---|

| 1st with sand |

5% |

6% |

8% |

52% |

2% |

19% |

8% |

| 2nd with glass |

| 1st with sand |

1350 kg/m | 3 |

46% |

1.23 ± 0.06 |

1.71 ± 0.09 |

3.14 ± 0.16 |

| 5% |

5% |

8% |

51% |

2% |

21% |

8% |

Table 2. MKPC mechanical properties.

| 5.73 ± 0.29 |

| 2nd with glass |

950 kg/m | 3 |

23% |

0.94 ± 0.05 |

1.63 ± 0.08 |

1.99 ± 0.10 |

4.80 ± 0.24 |

2.4. Structural and Energy Performances

This section presents some preliminary investigations regarding the structural and energy performance of the proposed precast blocks. In particular, beyond the traditional structural performances necessary for the construction operation, a 3D printed block needs to have good characteristics to ensure a correct printability. The resistance of the lower layers must be able to quickly support the weight of subsequent layers during the extrusion process. Assuming a layer width of 3 cm, the section area of the printed elements is 0.1 m2 and the volume is 0.06 m3. The supposed specific weight using MKPC cement with sand is 1350 kg/m3, while the supposed specific weight using MKPC cement with expanded glass as aggregates is 950 kg/m3. Consequently, the weight of a single block would be 81 kg or 57 kg, respectively.

According to the structural tests previously performed

[24] (

Table 2), the compressive strength (at 90 min curing) can vary between 3.14 MPa and 1.99 MPa depending on the used admixture of MKPC. This compressive strength is wide enough to enable printing without losing the designed shape. In addition, the compressive strength after 90 min allows for direct assembly of the block on site, ensuring the support of other blocks for fast printing and implementation.

The energy performance of the vertical closing system depends on the stratigraphy. The insulating material panel can be of variable thickness up to 14 cm, and can have variable insulating performance depending on the indoor requirements and the climatic conditions on site. We can value the global performances, assuming the use of a conventional insulation material like rock wool.

Table 3 and

Table 4 show the values of thermal transmittance of the two types of blocks (the first with an empty air cavity, and the second with the air cavity filled with reinforced concrete). The values of thermal transmittances are compliant with the energy codes of most central and southern European countries

[27,28,29][27][28][29].

Table 3. Thermal transmittance of the standard block type.

| |

Stratigraphy |

Thickness (m) |

Thermal Conductivity (W/(m·K)) |

Thermal Insulance ((m | 2 | ⋅K)/W) |

Thermal Transmittance (W/(m | 2 | ·K)) |

|

MKPC |

| | 0.03 |

|

MKPC |

0.030.70 |

0.04 |

|

| 0.70 |

0.04 |

|

Rock wool |

0.14 |

0.04 |

3.68 |

|

| Rock wool |

0.14 |

0.04 |

3.68 |

|

Air |

0.20 |

|

|

|

| MKPC |

0.06 |

0.7 |

0.04 |

|

MKPC |

0.03 |

0.70 |

0.04 |

|

| |

Envelope |

|

|

3.91 |

0.26 |

Table 4. Thermal transmittance of the structural block type.

| |

Stratigraphy |

Thickness (m) |

Thermal Conductivity (W/(m·K)) |

| Concrete |

| 0.14 |

1.80 |

0.08 |

|

| MKPC |

0.03 |

0.70 |

0.04 |

|

| |

Envelope |

|

|

4.07 |

0.25 |

2.5. On Site Assembly and Fast Implementation

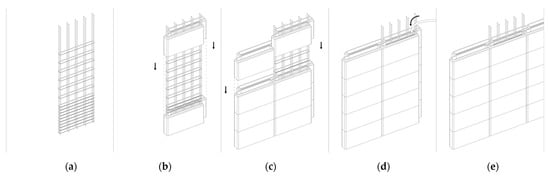

The proposed blocks are designed to guarantee an easy on-site assembly and a good speed of implementation. In particular, the construction of a reinforced concrete building by using the 3D printable blocks takes place floor by floor, and the construction of every wall can be described in five steps (Figure 5):

Figure 5. Building of the envelope system: (a) placing of reinforcing bars; (b) stacking of the elements on rebars; (c) placing of standard blocks on the element below; (d) casting of the pillars in the formwork part of the block; (e) completion of the wall.

-

The reinforcing bars are placed in the position where the structural blocks are to be assembled (Figure 5a);

-

The structural blocks are stacked on rebars (Figure 5b) and then the walls are completed by placing the standard block;

-

The blocks are fitted together by rotating the single element to the correct position and then placing it on the element below (Figure 5c). In this step, blocks at the corner should be placed first to facilitate assembly;

-

The concrete is cast in the formwork part of the structural block (Figure 5d);

-

After the setting time, the wall is complete (Figure 5d), and the next step concerns the realization of a beam over the wall.

The block system can be combined with a horizontal mixed steel–concrete structure. In correspondence with the slab, a space must be left to apply the thermal bridge correction by using an insulating panel. Then, the realisation of the next floor can be continued.

The developed system is designed to be visually close to a classic brick wall, even if the used material is cement. On the other hand, the proposed block uses a new concept, a new production technology, and an innovative construction technique. In this way, it is possible to take the first steps towards social acceptance of this technology for residential construction.

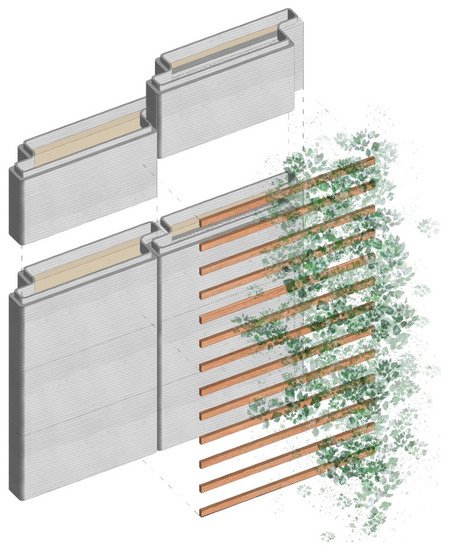

Concerning the finishing, the proposed system does not require coatings, which minimises manual operations, simplifies assembly on site, and increases the degree of automatization (excluding the possibility of human error). To this aim, it is possible to leave visible the shape of the wall and the layer texture given by the use of the production method. This solution is certainly easier and more sustainable, but the construction sector is not entirely ready for an aesthetic impact so different from the common practice. Consequently, classic plastering or plasterboard panelling can be proposed for residential buildings or to meet specific aesthetic needs of some users. Unlike classic plastering, the proposed blocks are compatible with green walls (Figure 6) thanks to the proposed MKPC, which is specifically developed with low permeability and corrosive resistance against chemicals. This flexibility can meet the necessities of different stakeholders and varying intended uses.

Figure 6. Example of combined system with green walls for functional and aesthetic purposes.