Fiber-based thermoelectric materials and devices have the characteristics of light-weight, stability, and flexibility, which can be used in wearable electronics, attracting the wide attention of researchers.

- thermoelectric

- fiber

- wearable

1. Introduction

In recent decades there has been a significant focus upon the combination of sensitive materials and flexible substrates with wearable electronics to realize functions such as sensing, health management, and environmental monitoring [1][2][3][4][5][1,2,3,4,5]. Owing to the increasing demand for power supply and people’s requirements for wearing comfort, flexible energy-harvesting devices with weight-light and self-powering have attracted increasing attention. Flexible generators that capture and convert ambient energy (solar, mechanical, thermal energy, etc.,) into electric energy are suitable candidates to achieve this goal because their flexibility and mechanical stability enable them to maintain their power generation function during deformation when they fit the human skin [6][7][8][9][6,7,8,9]. Among the above energy sources, thermal energy is a form of energy that can easily be reached and utilized. Life is maintained by the metabolism, resulting in a continuous heat dispersion from the human body with an energy density of 20 mW cm −2 [10]. Therefore, the human body is a sustainable heat resource for thermoelectric power generation.

Thermoelectric (TE) materials can directly realize the conversion between heat energy and electric energy base on the Seebeck effect and Peltier effect. Due to the exclusive advantages of solid-state conversion, long service life, and no moving parts, thermoelectric plays a vital role in solar energy collection, waste heat harvesting, and temperature management [11][12][13][14][15][11,12,13,14,15]. Thermoelectric technology also has excellent prospects for application in wearable electronics. However, the rigid architecture of conventional thermoelectric devices is not skin-conformal and comfortable for the real aim or wrist wearing [16]. Consequently, enormous efforts have been thrown into improving the flexibility of thermoelectric devices [17][18][19][20][21][17,18,19,20,21]. One strategy is to use flexible electrodes to replace the rigid electrode with a ceramic plate [20][22][20,22]. Another route is to make thermoelectric materials into thin films to increase their flexibility [18][23][24][25][26][18,23,24,25,26]. These devices have a certain degree of flexibility, but there are also many unsolved technique challenges. For example, flexible thermoelectric devices assembled with thermoelectric bulks have limited flexibility, restricting their ability to contact irregular surfaces. Thin-film flexible thermoelectric devices generally can be stretchable and bendable in one direction. Furthermore, since these devices lack air permeability, long-term wearing will make users feel uncomfortable.

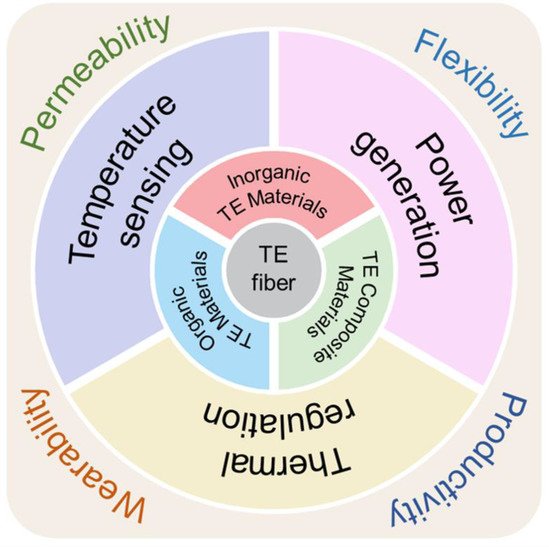

Fiber-based sensors and thermoelectric devices have gained wide attention in recent years due to their excellent mechanical properties and good wearing experience [27][28][29][27,28,29]. Figure 1 shows the current application scenarios and advantages of fiber-based thermoelectric materials and devices. It is very promising in wearable applications due to its excellent light-weight, flexibility, ductility, and in-plane shear properties. Compared with bulk-based flexible devices and thin-film flexible devices, fiber-based flexible devices have natural flexibility and good conformability in all directions. Consequently, fiber thermoelectric materials can act as functional components of thermoelectric devices and act as flexible substrates to improve the flexibility of devices.

2. Fabrication Methods for TE Fiber

Fabrication method, such as coatings, micro-nano fabrication techniques, fiber extrusion, thermal co-drawing, yarn formation, and fabric formation, are common methods for fabricating wearable electronic devices [30][31][32][33][34][35][35,36,37,38,39,40]. These methods can effectively transfer three-dimensional or two-dimensional functional materials into one-dimensional fibers, which dramatically improves the flexibility of available materials and expands the application of functional materials in the field of wearable electronics. Thermoelectric fibers are mainly prepared by thermal co-drawing, electrospinning, wet spinning, coating, and other methods ( Figure 2 ).

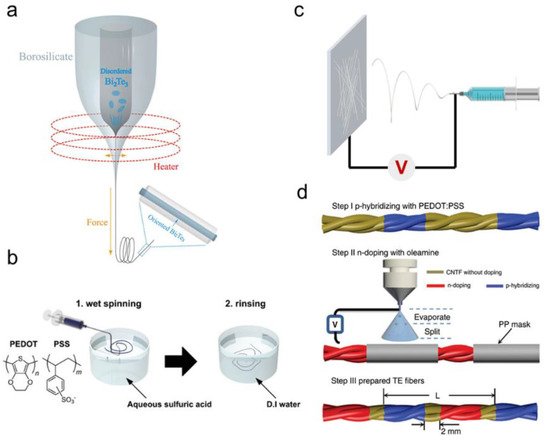

Thermal co-drawing is a method for preparing inorganic fibers and has been widely used to produce fibers with uniform longitudinal direction [36][39][40][41,44,45]. The inorganic core material is wrapped in a glassy material to prepare a preform, which is placed in a heater to make it soft. Then the blank is pulled at a suitable speed to form a viscous flow, which can finally be elongated into fibers with micron-scale diameters. Yang et al. prepared a Sn-Se alloy core borosilicate glass-clad fiber with a core diameter of 94 µm by thermal co-drawing [41][46]. The TE fiber core was composed of SnSe polycrystalline grains and had a high Seebeck coefficient of −151 µV K −1 at 300 K. They used the same method to fabricate bismuth selenide fibers with a diameter of 50 μm [42][47]. Because low-dimensional materials can improve thermoelectric performance [43][48], the Seebeck coefficient of the Bi 2Se 3 fiber can be up to −150 µV K −1 , much higher than that of bulk Bi 2Se 3. Zhang et al. prepared single-crystalline SnSe fibers by thermal co-drawing and recrystallization process by using a CO 2 laser [44][49]. The experimental results showed that the single-crystal SnSe fiber had good thermoelectric properties, and the ZT value can reach 2 at 862 K.

Wet spinning is another standard method for preparing polymer fibers. The conductive polymer and solvent are mixed to obtain a spinnable stock solution. Then the spinning stock solution is ejected at an appropriate speed through a spinneret immersed in a coagulation bath to precipitate and solidify the fibers. Jang et al. used a ball mill to mix poly (3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT: PSS) spheres, carbon nanotubes, and deionized water into spinning stock solution and then extruded it into the coagulation bath of methanol at a flow rate of 4 mL/min to prepare carbon nanotubes (CNT)/PEDOT: PSS composite fiber [45][52] . After post-treatment, the thermoelectric properties of CNT/PEDOT: PSS composite fibers were optimized, and the power factors of P-type and N-type were 83.2 ± 6.4 and 113 ± 25 µW m −1 K −2 , respectively. Jang et al. also investigated the effect of single-walled carbon nanotubes (SWCNT) content and dispersion on the properties of thermoelectric fibers by using insulating polymer poly(vinylidene fluoride) (PVDF) as the polymer matrix for wet spinning [46][53]. The results showed that the electrical conductivity of the optimized SWCNT/PVDF composite fiber was as high as 1950 ± 483 S cm −1 , and the P-type and N-type power factors of the optimized SWCNT/PVDF composite fiber were the highest among all the reported data.

Fabrics, yarns, and threads can be converted into wearable, biologically compatible thermoelectric devices upon being coated with films of thermoelectric materials. Coatings can be prepared on traditional textile materials by a variety of methods, including dip coating, vapor deposition, electrochemical deposition, in situ solution polymerization, and inkjet printing [47][54]. These techniques can be extended to the textile industry on a large scale with cost advantages. Jiang et al. used the dip-coating method to soak ordinary cotton fabric in PEDOT: PSS solution containing 5 vol. % dimethyl sulfoxide and then repeated the above process after taking it out and drying to absorb different amounts of PEDOT: PSS on the surface of cotton fabric, which had a relatively high conductivity of 18.8 S cm −1 [48][55]. Snyder et al. prepared P-N alternate thermoelectric fibers on carbon nanotube fibers using a coating technique [38][43].

3. Thermoelectric Fiber Materials

The choice of appropriate materials is of most importance for the design and construction of fiber-based thermoelectric devices, which require the materials to have the features of high thermoelectric figure-of-merit, excellent mechanical properties, eco-friendliness, and low cost. The following section presents the latest progress in fiber-based inorganic thermoelectric materials, organic thermoelectric materials, and composite thermoelectric materials.

Since discovering the thermoelectric effect, inorganic thermoelectric materials have been widely investigated [49][50][51][52][64,65,66,67]. Although many inorganic materials have a high ZT at high temperatures, the working temperature of wearable thermoelectric devices is around 310 K, limiting the application of inorganic thermoelectric materials in the field of wearable electronics. Bi 2Te 3 is a classic room-temperature thermoelectric material, which has the characteristics of good room temperature stability, high electrical conductivity, and low thermal conductivity, and has been rapidly developed in recent years [53][54][55][68,69,70]. In 2001, Stacy et al. prepared dense and continuous Bi 2Te 3 wires with a diameter of 40 nm in a porous alumina template by the electrodeposition method [56][71]. The deposited wire had a high texture in the (110) direction. Subsequently, Kaviany et al. studied phonon and electron transport in Bi 2Te 3 using a multi-scale approach, demonstrating the potential of low-dimensional Bi 2Te 3 materials for wearable thermoelectric devices [57][72].

The organic conductive polymers such as polyaniline (PANI), polypyrrole (PPy), polythiophenes (PTs), PEDOT: PSS, and polyacetylene (PA) have inherent flexibility and good adhesion to the skin, so they can make better use of the temperature difference between the human body and the environment [58][59][60][78,79,80]. In contrast to traditional inorganic materials, organic conductive polymers have the characteristics of low thermal conductivity, light-weight, softness, low toxicity, and convenient production. It is believed that organic TE materials are better for next-generation wearable thermoelectric devices. PEDOT: PSS is considered to be one of the most promising conductive polymers for wearable thermoelectric devices. In recent years, the thermoelectric properties of PEDOT:PSS fibers have been extensively studied, and some remarkable progress has been made [61][62][81,82]. Xu et al. explored the influence of different solvents on the properties of PEDOT: PSS fiber, showing a significant impact on the gelation process of PEDOT:PSS [63][57]. While the post-treatment with organic solvents of ethylene glycol and dimethyl sulphoxide significantly increased the electrical conductivity up to two times. Weisenberger et al. developed a continuous wet-spinning process to prepare PEDOT: PSS fibers with high electrical conductivity, excellent mechanical properties, and moderate thermoelectric properties [64][83]. They found that stretching the fiber induced a preferred orientation of the polymer chains along the fiber axial direction, resulting in superior electrical, thermal, and mechanical properties. The conductivity was saturated at about 2000 S cm −1 at room temperature with increasing tensile strength, while the Seebeck coefficient was almost constant with stretch. Although organic thermoelectric materials have many benefits, their low Seebeck coefficient and low conductivity limit their large-scale application in the wearable field. Moreover, due to the relatively complex system of organic thermoelectric materials and lack of systematic investigation, new strategies are needed to design organic thermoelectric materials and fibers.

Thermoelectric organic/inorganic composite material usually has a balance between the flexibility of organic materials and the high thermoelectric ZT of inorganic materials, and hence is widely used for TE fibers [65][66][67][84,85,86]. Segalman et al. have fabricated a PEDOT: PSS/ Te-nanowire composite fibers, which has an optimized power factor of 100 µW m −1 K −2 , which was nearly five orders of magnitude higher than that of pure PEDOT:PSS [68][87]. Wu et al. used a coating method to prepare p-type and n-type Ag 2Te nanocrystals on the surface of nylon fibers to form a flexible composite thermoelectric material [69][88]. At the temperature difference of 20 °C, a thermoelectric generator prepared with such fiber can generate about 0.8 nW of power. Carbon-based thermoelectric composite fiber was another promising choice. Zhu et al. prepared high-performance thermoelectric composites using carbon fiber as filler and poly (3-alkylthiophene) (P3AT) as matrix [70][60]. The carbon fiber provided a good conductive path in the composites, and the optimized composites had of electrical conductivity of 380 S m −1 and Seebeck coefficient of 136 μVk −1 . Through various optimization methods to improve the chemical incompatibility between organic materials and inorganic materials, the thermoelectric properties of composite materials have been greatly improved.

4. Fiber-Based Thermoelectric Devices and Applications

Thermoelectric fibers can adapt to complex deformation through stretching or twisting, which can be woven or knitted into functional textiles with higher dimensional structures in various configurations and integrated into a large-area array. Thermoelectric fabrics have good flexibility, good stretchability, and air permeability, and some are even washable, which can significantly expand the application of thermoelectric fabrics in wearable electronics. This section will go through the research progress of fiber-based wearable thermoelectric devices, including temperature sensors, thermoelectric generators, and temperature controllers.

Temperature is one of the most important physical quantities for the human body to perceive the environment, as well as an essential health indicator that responds to physiological activity. Since the COVID-19 pandemic, body temperature measurement has become an essential part of keeping the public safe, usually using thermometers and thermal imaging. It is helpful to realize intelligent healthcare by using wearable electronic devices to monitor the temperature data of the environment or human body in real-time. TE fibers are highly flexible and can be woven or knitted into a variety of functional textiles, such as masks and clothing, making them a feasible material for the development of health information collection and tracking devices. The thermocouple is a temperature sensor based on the Seebeck effect for temperature measurement. The thermocouple involves connecting two different metals or semiconductors with a voltage meter to form a closed-circuit loop. When the temperature of the two junctions is different, an electromotive force is generated in the loop. With the advantages of small size, fast response speed, low cost, and wide working range, a flexible thermocouple is an ideal component for the scenario of the Internet of Things in the future. Due to the inherent flexibility and two-dimensional network structure, TE fiber-derived thermocouple sensors possess better mechanical flexibility and conformability to be well attached to complex surfaces for accurate temperature measurements.

Temperature regulation is essential to improve the thermal comfort of the human body for the application of smart fabrics. The heat exchange methods between human skin and the environment mainly include conduction, radiation, evaporation, and convection. By influencing these heat exchange modes, people have developed various smart fabrics for temperature regulation, including electrothermal conversion, phase change heat storage, radiant cooling, and so on [71][72][73][74][75][76][94,95,96,97,98,99]. These fabrics exhibit excellent temperature regulation capabilities in specific environments. However, most of them only have a one-way adjustment function, which cannot maintain the thermal comfort of the human body in a complex environment. Thermoelectric materials can actively control the temperature, which is suitable for personalized temperature control. Integrating thermoelectric equipment into clothing systems for personalized temperature regulation is a promising solution to energy waste and climate change. When the human body is in a high-temperature environment, the cold side of the thermoelectric device is attached to the skin surface for cooling, so that the human body can feel the cold. When the human body is in a low-temperature environment, the hot side of the thermoelectric device is attached to the skin surface for heating, so that the human body can feel the warmth. This is an active form of temperature regulation that can be used to heat or cool objects. By adjusting the size and direction of the current, thermoelectric devices can keep the body feel comfortable in complex temperature environments. Although thermoelectric fabrics have great potential in regulating human body temperature, the current thermoelectric temperature regulation devices are mostly made of bulk materials and flexible substrates because of the poor thermoelectric properties of fiber-based thermoelectric materials.