Product/service system (PSS) family design is a kind of designing a group of PSSs in order to provide the PSSs efficiently to a defined set of multiple customer segments, and was conceptualized with analogy to product family design. PSS is widely considered as a promising design object with the potential to enhance environmental sustainability of industrial solutions. PSS family design is potentially powerful to PSS customization and thereby expected to contribute to the competitiveness of PSS providers.

This entry introduces a concept termed product/service system (PSS) family design, which was proposed by an article in 2020. PSS is widely considered as a promising design object with the potential to enhance environmental sustainability of industrial solutions. PSS family design is a kind of designing a group of PSSs in order to provide the PSSs efficiently to multiple customer segments with different needs/wants, and was conceptualized with analogy to product family design. PSS family design is potentially powerful to PSS customization and thereby expected to contribute to the competitiveness of PSS providers.

- Product/Service System Design

- conceptual PSS design

- environmental sustainability

- resource-efficiency

- family design

- customization

1. Introduction

1. Background

A product/service system (PSS) can be defined as a mixture of tangible products and intangible services that are designed and combined so that they jointly are capable of fulfilling customer needs

[1]

. PSSs have been heralded as one of the most effective instruments for moving society towards a resource-efficient, circular economy

[2]

, and researched in several domains such as engineering design and environmental sustainability

. Customization targeting different segments is widely seen in industry, and even a question of its environmental consequences has been asked

[6]

. However, increasing variety does not always lead to enhanced performance: increased variety leads to increased complexity and then may end up with decreased competitiveness. To avoid this situation, it is effective to holistically customize a whole group of various offerings: family design

[7][8] is a major means to this end aiming to answer the question on the customization degree.

is a major means to this end aiming to answer the question on the customization degree.

2. Definition

PSS family design is a kind of designing a group of PSSs in order to provide the PSSs efficiently to a defined set of multiple customer segments.

3. Introduction

PSS family design was proposed by an article

[9]

in 2020 with its origin being product family design, which is a powerful means to product customization. Customization has been researched for products, services and PSSs; see a review

[10]

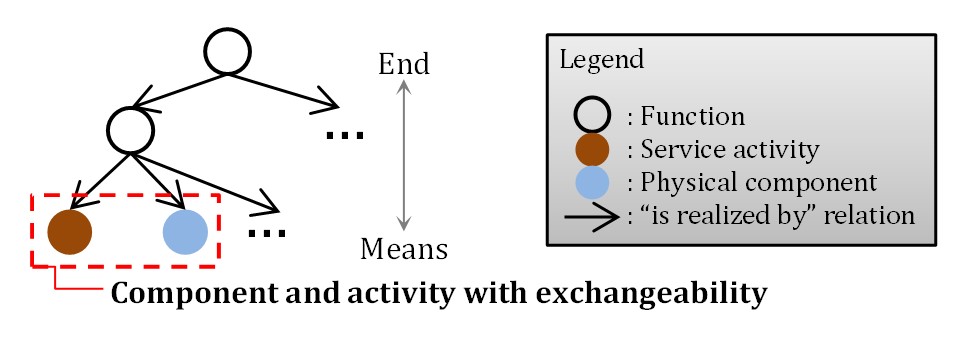

. A breakthrough was made by introducing PSS into family design and thereby taking an advantage of the features of PSS design such as exchangeability

[11] (see Fig. 1). It is at present expected that PSS providers strategically apply PSS family design to their PSSs for enhanced efficiency and competitiveness.

. It is at present expected that PSS providers strategically apply PSS family design to their PSSs for enhanced efficiency and competitiveness.

4. Data, Model and Impact

Figure 1. A schematic presentation of exchangeability between a product and a service

2. Data, Model and Impact

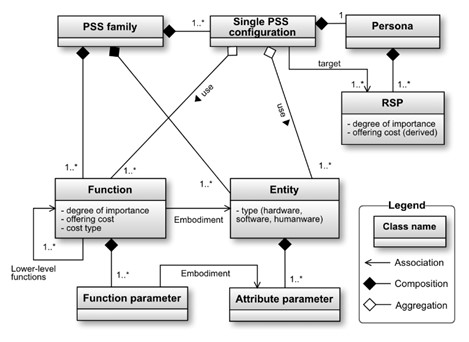

A model for PSSs is in principle applicable to further develop a model for a PSS family. A process of designing also needs to be defined for specific PSS family design. PSS family design is expected to involve high complexity, and hence computer support is powerful. In the article

A model for PSSs is in principle applicable to further develop a model for a PSS family. A process of designing also needs to be defined for specific PSS family design. PSS family design is expected to involve high complexity, and hence computer support is powerful. In the article

[9]

, a PSS model

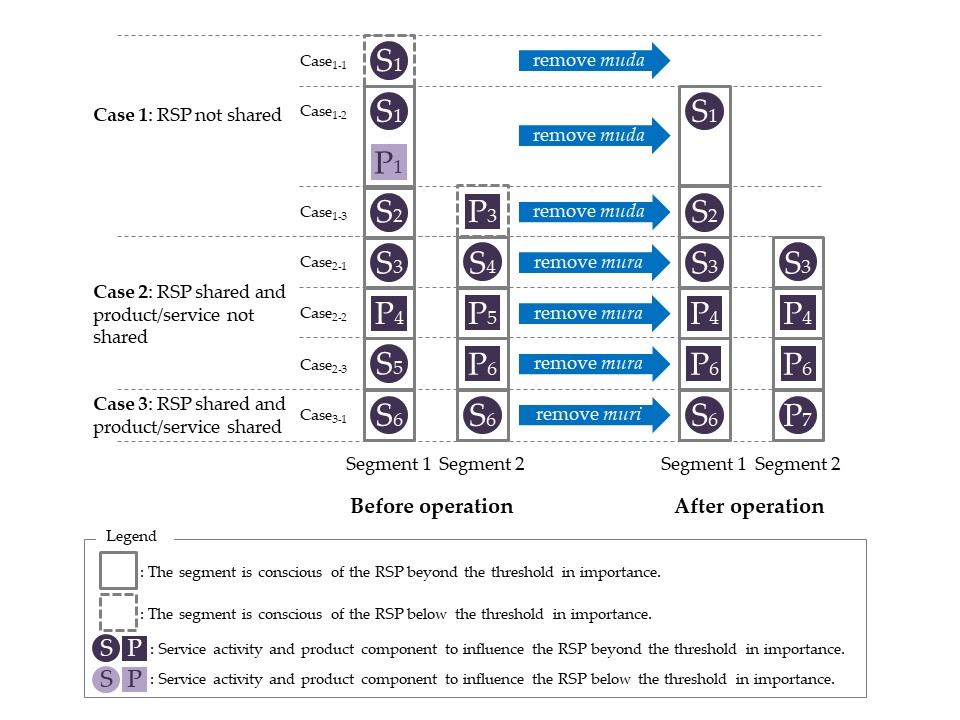

[12][13] was extended (see Fig. 2), a design process based on lean principles (especially, removing

was extended, a design process based on lean principles (especially, removing

muda

,

mura

and

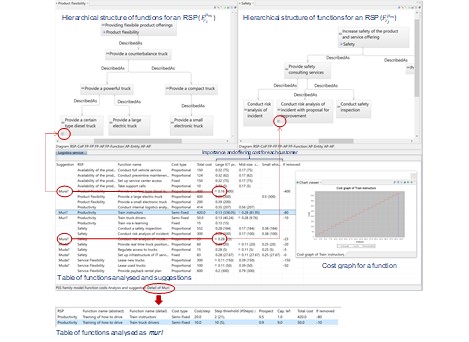

muri) was adopted (see Fig. 3), and computer software named Service Explorer

) was adopted, and computer software named Service Explorer

[14] was built upon (see Fig. 4). PSS design as such is challenging but can be used as a competitive advantage

was built upon. PSS design as such is challenging but can be used as a competitive advantage

[15]. PSS family design will strengthen PSS design and thus have a major impact on industry, especially if used in an early stage of design or research and development.

Figure 2. A model for a product/service system (PSS) family [9]

Figure 3. A PSS family design based on lean principles [9]

Figure 4. An extended version of Service Explorer [9]

. PSS family design will strengthen PSS design and thus have a major impact on industry, especially if used in an early stage of design or research and development.

References

- Tischner, U.; Verkuijl, M.; Tukker, A. First Draft PSS Review; Econcept: Cologne, Germany, 2002.

- Arnold Tukker; Product services for a resource-efficient and circular economy – a review. Journal of Cleaner Production 2015, 97, 76-91, 10.1016/j.jclepro.2013.11.049.

- Gokula Vijayumar Annamalai Vasantha; Rajkumar Roy; Alan Lelah; Daniel Brissaud; A review of product–service systems design methodologies. Journal of Engineering Design 2012, 23, 635-659, 10.1080/09544828.2011.639712.

- Tomohiko Sakao; Abhijna Neramballi; A Product/Service System Design Schema: Application to Big Data Analytics. Sustainability 2020, 12, 3484, 10.3390/su12083484.

- Sergio A. Brambila-Macias; Tomohiko Sakao; Christian Kowalkowski; Bridging the gap between engineering design and marketing: insights for research and practice in product/service system design. Design Science 2018, 4, e7, 10.1017/dsj.2018.3.

- Tomohiko Sakao; Mario Fargnoli; Customization in Ecodesign. Journal of Industrial Ecology 2010, 14, 529-532, 10.1111/j.1530-9290.2010.00264.x.

- Jianxin (Roger) Jiao; Timothy W. Simpson; Zahed Siddique; Product family design and platform-based product development: a state-of-the-art review. Journal of Intelligent Manufacturing 2007, 18, 5-29, 10.1007/s10845-007-0003-2.

- Flavio S. Fogliatto; Giovani J.C. Da Silveira; Denis Borenstein; The mass customization decade: An updated review of the literature. International Journal of Production Economics 2012, 138, 14-25, 10.1016/j.ijpe.2012.03.002.

- Tomohiko Sakao; Tatsunori Hara; Ryo Fukushima; Using Product/Service-System Family Design for Efficient Customization with Lean Principles: Model, Method, and Tool. Sustainability 2020, 12, 5779, 10.3390/su12145779.

- Tatsunori Hara; Tomohiko Sakao; Ryo Fukushima; Customization of product, service, and product/service system: what and how to design. Mechanical Engineering Reviews 2019, 6, 18-00184, 10.1299/mer.18-00184.

- Tomohiko Sakao; Mattias Lindahl; A method to improve integrated product service offerings based on life cycle costing. CIRP Annals 2015, 64, 33-36, 10.1016/j.cirp.2015.04.052.

- Tatsunori Hara; Tamio Arai; Yoshiki Shimomura; A CAD system for service innovation: integrated representation of function, service activity, and product behaviour. Journal of Engineering Design 2009, 20, 367-388, 10.1080/09544820903151715.

- Tomohiko Sakao; Yoshiki Shimomura; Erik Sundin; Mica Comstock; Modeling design objects in CAD system for Service/Product Engineering. Computer-Aided Design 2009, 41, 197-213, 10.1016/j.cad.2008.06.006.

- T. Arai; Y. Shimomura; Proposal of Service CAD System - A Tool for Service Engineering -. CIRP Annals 2004, 53, 397-400, 10.1016/s0007-8506(07)60725-2.

- Johannes Matschewsky; Marianna Lena Kambanou; Tomohiko Sakao; Designing and providing integrated product-service systems – challenges, opportunities and solutions resulting from prescriptive approaches in two industrial companies. International Journal of Production Research 2017, 56, 2150-2168, 10.1080/00207543.2017.1332792.