Utilising pyrolysis as a waste tyre processing technology has various economic and social advantages, along with the fact that it is an effective conversion method. Despite extensive research and a notable likelihood of success, this technology has not yet seen implementation in industrial and commercial settings. In this review, over 100 recent publications are reviewed and summarised to give attention to the current state of global tyre waste management, pyrolysis technology, and plastic waste conversion into liquid fuel. The study also investigated the suitability of pyrolysis oil for use in diesel engines and provided the results on diesel engine performance and emission characteristics. Most studies show that discarded tyres can yield 40–60% liquid oil with a calorific value of more than 40 MJ/kg, indicating that they are appropriate for direct use as boiler and furnace fuel. It has a low cetane index, as well as high viscosity, density, and aromatic content. According to diesel engine performance and emission studies, the power output and combustion efficiency of tyre pyrolysis oil are equivalent to diesel fuel, but engine emissions (NOX, CO, CO, SOX, and HC) are significantly greater in most circumstances. These findings indicate that tyre pyrolysis oil is not suitable for direct use in commercial automobile engines, but it can be utilised as a fuel additive or combined with other fuels.

- waste tyre

- waste management

- pyrolysis

- automobile engine

1. Introduction

2. Waste Tyre Management Practice

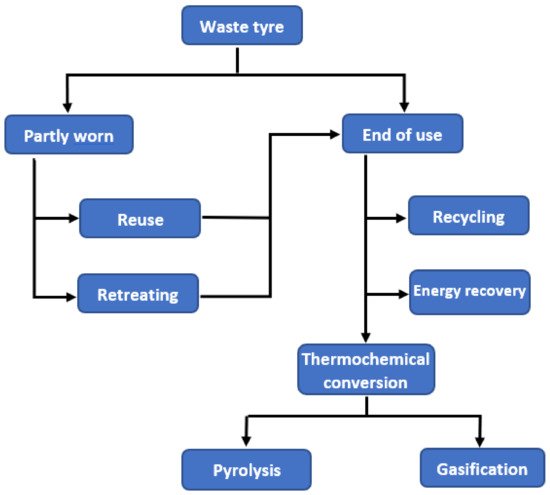

3. Waste Tyre to Fuel Using Thermochemical Conversion

4. Waste Tyre to Oil, Carbon, and Steel

The recycling of waste tyres into useful products is of interest for both environmental and economic reasons. Many researchers have been working to solve the aforementioned issues and convert waste tyres into valuable products such as oil, carbon, and steel [69,92,93][50][51][52]. Waste-tyre oil could be used for heating by industry, refined further for use in diesel engines, or used directly as blended fuel in some stationary diesel engines. Carbon has a plethora of industrial uses, from toothpaste to electrodes and pharmaceutical goods, as well as being about 35% cleaner than coal and burning hotter, while steel can be sold as scrap metal or returned to tyre manufacturers for reuse.5. Diesel Engine Performance and Exhaust Emission Using Tyre Oil

6. Discussion and Synthesis

-

Conduct in-depth energy and economic studies of integrated waste tyre pyrolysis plants over their entire life cycle.

-

Recognise the trade-offs between the scale of the waste tyre pyrolysis plant and feedstock, as well as the costs of transportation to a centralised upgrading facility.

-

Development of the technology to overcome the limitations of the tyre pyrolysis reactor and process and improve the reliability.

-

Identify TPO criteria and quality standards for manufacturers and end-user.

-

Improve quality and consistency of TPO through the development of more effective technologies.

-

Develop catalyst for TPO upgrading in order to meet vehicle fuel-quality standards.

-

Develop deoxygenated catalysts to extract oxygen-containing compounds for pyrolysis processes for oil property improvement.

-

Advocacy to develop relevant policy, regulation, and financial incentives for the tyre recyclers, refineries and start-ups who take up the challenges of recycling used tyres to oil.

References

- Uyumaz, A.; Aydoğan, B.; Solmaz, H.; Yılmaz, E.; Yeşim Hopa, D.; Aksoy Bahtli, T.; Solmaz, Ö.; Aksoy, F. Production of waste tyre oil and experimental investigation on combustion, engine performance and exhaust emissions. J. Energy Inst. 2019, 92, 1406–1418.

- Murugan, S.; Ramaswamy, M.C.; Nagarajan, G. A comparative study on the performance, emission and combustion studies of a DI diesel engine using distilled tyre pyrolysis oil–diesel blends. Fuel 2008, 87, 2111–2121.

- Saidur, R.; Jahirul, M.I.; Moutushi, T.Z.; Imtiaz, H.; Masjuki, H.H. Effect of partial substitution of diesel fuel by natural gas on performance parameters of a four-cylinder diesel engine. Proc. Inst. Mech. Eng. Part. A J. Power Energy 2007, 221, 1–10.

- Jahirul, M.I.; Koh, W.; Brown, R.J.; Senadeera, W.; Hara, I.; Moghaddam, L. Biodiesel Production from Non-Edible Beauty Leaf (Calophyllum inophyllum) Oil: Process Optimization Using Response Surface Methodology (RSM). Energies 2014, 7, 5317–5331.

- Rahman, M.M.; Pourkhesalian, A.M.; Jahirul, M.I.; Stevanovic, S.; Pham, P.X.; Wang, H.; Masri, A.R.; Brown, R.J.; Ristovski, Z.D. Particle emissions from biodiesels with different physical properties and chemical composition. Fuel 2014, 134, 201–208.

- Jahirul, M.I.; Brown, R.J.; Senadeera, W.; Ashwath, N.; Rasul, M.G.; Rahman, M.M.; Hossain, F.M.; Moghaddam, L.; Islam, M.A.; O’Hara, I.M. Physio-chemical assessment of beauty leaf (Calophyllum inophyllum) as second-generation biodiesel feedstock. Energy Rep. 2015, 1, 204–215.

- Haseeb, A.S.M.A.; Fazal, M.A.; Jahirul, M.I.; Masjuki, H.H. Compatibility of automotive materials in biodiesel: A review. Fuel 2011, 90, 922–931.

- Jahirul, M.I.; Brown, R.J.; Senadeera, W.; O’Hara, I.M.; Ristovski, Z.D. The Use of Artificial Neural Networks for Identifying Sustainable Biodiesel Feedstocks. Energies 2013, 6, 3764–3806.

- Guan, C.; Cheung, C.S.; Li, X.; Huang, Z. Effects of oxygenated fuels on the particle-phase compounds emitted from a diesel engine. Atmos. Pollut. Res. 2017, 8, 209–220.

- Alptekin, E. Emission, injection and combustion characteristics of biodiesel and oxygenated fuel blends in a common rail diesel engine. Energy 2017, 119, 44–52.

- Feng, Z.; Zhan, C.; Tang, C.; Yang, K.; Huang, Z. Experimental investigation on spray and atomization characteristics of diesel/gasoline/ethanol blends in high pressure common rail injection system. Energy 2016, 112, 549–561.

- Valentino, G.; Corcione, F.E.; Iannuzzi, S.E.; Serra, S. Experimental study on performance and emissions of a high speed diesel engine fuelled with n-butanol diesel blends under premixed low temperature combustion. Fuel 2012, 92, 295–307.

- Wang, W.-C.; Bai, C.-J.; Lin, C.-T.; Prakash, S. Alternative fuel produced from thermal pyrolysis of waste tires and its use in a DI diesel engine. Appl. Therm. Eng. 2016, 93, 330–338.

- Mokhtar, N.M.; Omar, R.; Idris, A. Microwave Pyrolysis for Conversion of Materials to Energy: A Brief Review. Energy Sources Part A Recovery Util. Environ. Eff. 2012, 34, 2104–2122.

- Damodharan, D.; Rajesh Kumar, B.; Gopal, K.; de Poures, M.V.; Sethuramasamyraja, B. Utilization of waste plastic oil in diesel engines: A review. Rev. Environ. Sci. BioTechnol. 2019, 18, 681–697.

- İlkılıç, C.; Aydın, H. Fuel production from waste vehicle tires by catalytic pyrolysis and its application in a diesel engine. Fuel Process. Technol. 2011, 92, 1129–1135.

- Aydın, H.; İlkılıç, C. Optimization of fuel production from waste vehicle tires by pyrolysis and resembling to diesel fuel by various desulfurization methods. Fuel 2012, 102, 605–612.

- Martínez, J.D.; Puy, N.; Murillo, R.; García, T.; Navarro, M.V.; Mastral, A.M. Waste tyre pyrolysis—A review. Renew. Sustain. Energy Rev. 2013, 23, 179–213.

- Williams, P.T. Pyrolysis of waste tyres: A review. Waste Manag. 2013, 33, 1714–1728.

- ETRMA. European Tyre and Rubber Industry Statistics. European Tyre and Rubber Manufacturing Association. Available online: (accessed on 20 December 2014).

- Martínez, J.D.; Rodríguez-Fernández, J.; Sánchez-Valdepeñas, J.; Murillo, R.; García, T. Performance and emissions of an automotive diesel engine using a tire pyrolysis liquid blend. Fuel 2014, 115, 490–499.

- Sienkiewicz, M.; Kucinska-Lipka, J.; Janik, H.; Balas, A. Progress in used tyres management in the European Union: A review. Waste Manag. 2012, 32, 1742–1751.

- Parthasarathy, P.; Choi, H.S.; Park, H.C.; Hwang, J.G.; Yoo, H.S.; Lee, B.-K.; Upadhyay, M. Influence of process conditions on product yield of waste tyre pyrolysis—A review. Korean J. Chem. Eng. 2016, 33, 2268–2286.

- Verma, P.; Zare, A.; Jafari, M.; Bodisco, T.A.; Rainey, T.; Ristovski, Z.D.; Brown, R.J. Diesel engine performance and emissions with fuels derived from waste tyres. Sci. Rep. 2018, 8, 2457.

- Mastral, A.M.; Murillo, R.; Callén, M.S.; García, T. Application of coal conversion technology to tire processing. Fuel Process. Technol. 1999, 60, 231–242.

- Mastral, A.M.; Murillo, R.; Callén, M.S.; García, T.; Snape, C.E. Influence of Process Variables on Oils from Tire Pyrolysis and Hydropyrolysis in a Swept Fixed Bed Reactor. Energy Fuels 2000, 14, 739–744.

- Gent, A.N. Chapter 1—Rubber Elasticity: Basic Concepts and Behavior. In The Science and Technology of Rubber, 4th ed.; Mark, J.E., Erman, B., Roland, C.M., Eds.; Academic Press: Boston, MA, USA, 2013; pp. 1–26.

- Kyari, M.; Cunliffe, A.; Williams, P.T. Characterization of Oils, Gases, and Char in Relation to the Pyrolysis of Different Brands of Scrap Automotive Tires. Energy Fuels 2005, 19, 1165–1173.

- Leung, D.Y.C.; Wang, C.L. Kinetic study of scrap tyre pyrolysis and combustion. J. Anal. Appl. Pyrolysis 1998, 45, 153–169.

- Lorber, K.E.; Sarc, R.; Aldrian, A. Design and quality assurance for solid recovered fuel. Waste Manag. Res. 2012, 30, 370–380.

- Sarc, R.; Lorber, K.E. Production, quality and quality assurance of Refuse Derived Fuels (RDFs). Waste Manag. 2013, 33, 1825–1834.

- Sarc, R.; Lorber, K.E.; Pomberger, R.; Rogetzer, M.; Sipple, E.M. Design, quality, and quality assurance of solid recovered fuels for the substitution of fossil feedstock in the cement industry. Waste Manag. Res. 2014, 32, 565–585.

- Dai, X.; Yin, X.; Wu, C.; Zhang, W.; Chen, Y. Pyrolysis of waste tires in a circulating fluidized-bed reactor. Energy 2001, 26, 385–399.

- Banar, M.; Akyıldız, V.; Özkan, A.; Çokaygil, Z.; Onay, Ö. Characterization of pyrolytic oil obtained from pyrolysis of TDF (Tire Derived Fuel). Energy Convers. Manag. 2012, 62, 22–30.

- Jahirul, M.I.; Rasul, M.G.; Chowdhury, A.A.; Ashwath, N. Biofuels Production through Biomass Pyrolysis—A Technological Review. Energies 2012, 5, 4952–5001.

- Rasul, M.G.; Jahirul, M.I. Recent Developments in Biomass Pyrolysis for Bio-Fuel Production: Its Potential for Commercial Applications; Centre for Plant and Water Science, Faculty of Sciences, Engineering and Health, Central Queensland University: Norman Gardens, Australia, 2012; pp. 256–265.

- Donatelli, A.; Iovane, P.; Molino, A. High energy syngas production by waste tyres steam gasification in a rotary kiln pilot plant. Experimental and numerical investigations. Fuel 2010, 89, 2721–2728.

- Janajreh, I.; Raza, S.S. Numerical simulation of waste tyres gasification. Waste Manag. Res. 2015, 33, 460–468.

- Zhang, L.; Zhou, B.; Duan, P.; Wang, F.; Xu, Y. Hydrothermal conversion of scrap tire to liquid fuel. Chem. Eng. J. 2016, 285, 157–163.

- Uddin, M.N.; Techato, K.; Taweekun, J.; Rahman, M.M.; Rasul, M.G.; Mahlia, T.M.I.; Ashrafur, S.M. An Overview of Recent Developments in Biomass Pyrolysis Technologies. Energies 2018, 11, 3115.

- Ward, J.; Rasul, M.G.; Bhuiya, M.M.K. Energy Recovery from Biomass by Fast Pyrolysis. Procedia Eng. 2014, 90, 669–674.

- Tudu, K.; Murugan, S.; Patel, S.K. Effect of diethyl ether in a DI diesel engine run on a tyre derived fuel-diesel blend. J. Energy Inst. 2016, 89, 525–535.

- Vihar, R.; Seljak, T.; Rodman Oprešnik, S.; Katrašnik, T. Combustion characteristics of tire pyrolysis oil in turbo charged compression ignition engine. Fuel 2015, 150, 226–235.

- Sharma, A.; Murugan, S. Potential for using a tyre pyrolysis oil-biodiesel blend in a diesel engine at different compression ratios. Energy Convers. Manag. 2015, 93, 289–297.

- Zebala, J.; Ciepka, P.; Reza, A.; Janczur, R. Influence of rubber compound and tread pattern of retreaded tyres on vehicle active safety. Forensic Sci. Int. 2007, 167, 173–180.

- Zhang, L.; Xu, C.; Champagne, P. Overview of recent advances in thermo-chemical conversion of biomass. Energy Convers. Manag. 2010, 51, 969–982.

- Bridgewater, A.V. Thermal Conversion of Biomass and Waste; Bio-Energy Research Group Aston University: Birmingham, UK, 2001.

- Bridgewater, A.V.; Peacocke, G.V.C. Fast pyrolysis processes for biomass. Renew. Sustain. Energy Rev. 2000, 4, 1–73.

- Srirangan, K.; Akawi, L.; Moo-Young, M.; Chou, C.P. Towards sustainable production of clean energy carriers from biomass resources. Appl. Energ. 2012, 100, 172–186.

- Williams, P.T.; Brindle, A.J. Catalytic pyrolysis of tyres: Influence of catalyst temperature. Fuel 2002, 81, 2425–2434.

- Kaminsky, W.; Mennerich, C.; Zhang, Z. Feedstock recycling of synthetic and natural rubber by pyrolysis in a fluidized bed. J. Anal. Appl. Pyrolysis 2009, 85, 334–337.

- Pantea, D.; Darmstadt, H.; Kaliaguine, S.; Roy, C. Heat-treatment of carbon blacks obtained by pyrolysis of used tires. Effect on the surface chemistry, porosity and electrical conductivity. J. Anal. Appl. Pyrolysis 2003, 67, 55–76.

- Murugan, S.; Ramaswamy, M.C.; Nagarajan, G. The use of tyre pyrolysis oil in diesel engines. Waste Manag. 2008, 28, 2743–2749.

- Quek, A.; Balasubramanian, R. Liquefaction of waste tires by pyrolysis for oil and chemicals—A review. J. Anal. Appl. Pyrolysis 2013, 101, 1–16.

- Doğan, O.; Çelik, M.B.; Özdalyan, B. The effect of tire derived fuel/diesel fuel blends utilization on diesel engine performance and emissions. Fuel 2012, 95, 340–346.

- Aylón, E.; Murillo, R.; Fernández-Colino, A.; Aranda, A.; García, T.; Callén, M.S.; Mastral, A.M. Emissions from the combustion of gas-phase products at tyre pyrolysis. J. Anal. Appl. Pyrolysis 2007, 79, 210–214.

- Žvar Baškovič, U.; Vihar, R.; Seljak, T.; Katrašnik, T. Feasibility analysis of 100% tire pyrolysis oil in a common rail Diesel engine. Energy 2017, 137, 980–990.

- Hossain, F.M.; Nabi, M.N.; Rainey, T.J.; Bodisco, T.; Bayley, T.; Randall, D.; Ristovski, Z.; Brown, R.J. Novel biofuels derived from waste tyres and their effects on reducing oxides of nitrogen and particulate matter emissions. J. Clean. Prod. 2020, 242, 118463.